Interface paint with high hydrophobicity, heat conductivity and adhesion

A technology with high thermal conductivity and high adhesion, applied in the direction of coating, etc., can solve the problems of poor film surface hardness, low hydrophobicity, poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

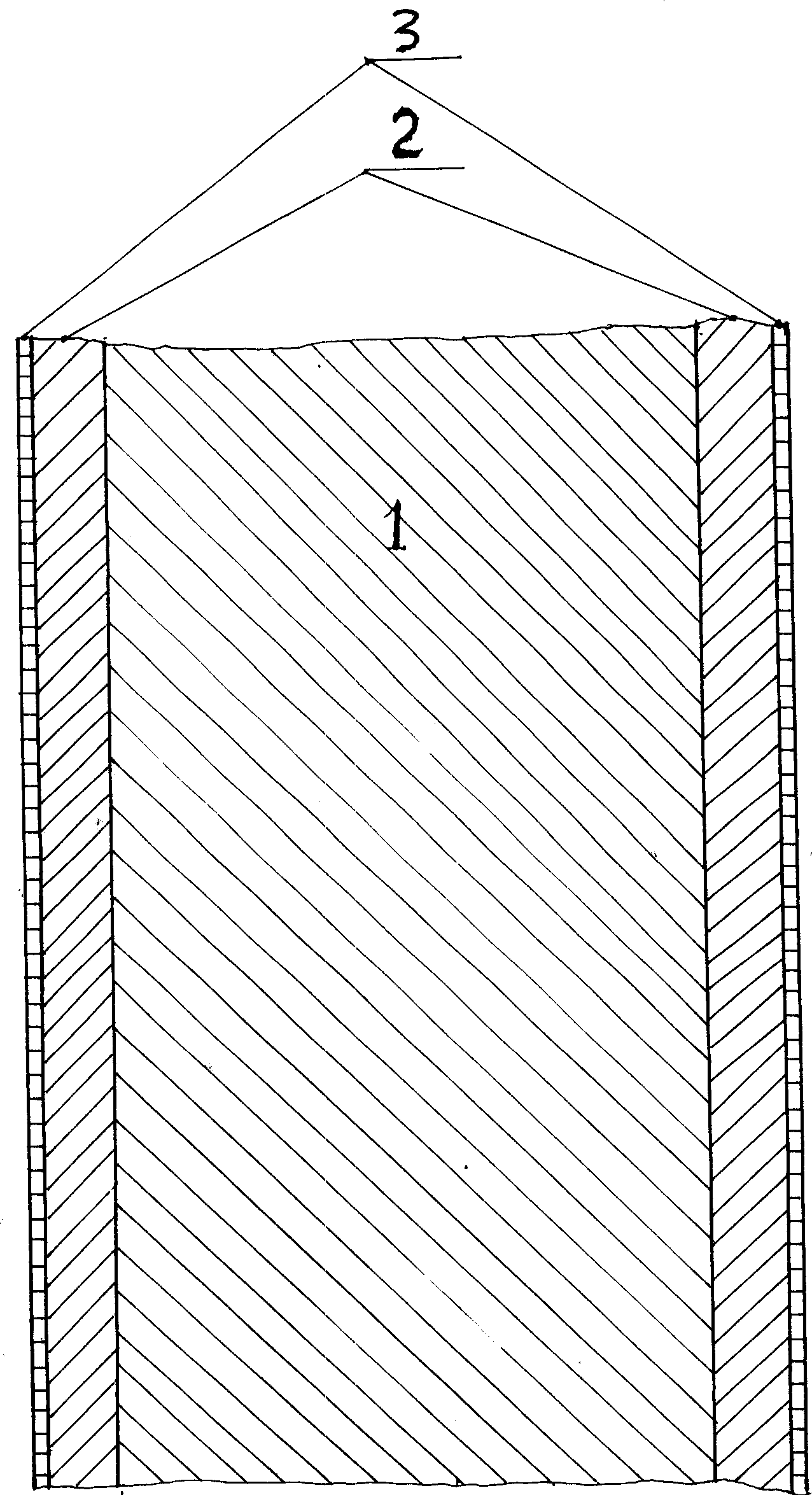

Image

Examples

Embodiment 1

[0035] In Example 4 of patent ZL 001 10559.0, WGS-0310 is applied to the evaporator of Jetta automobile air conditioner. The performance test data of the single evaporator shows that the air side capacity is improved with WGS-0310 coating film compared with no coating film up 3.4%. In the present invention, polyester-modified dimethylsiloxane (BYK-310) is added to WGS-0310, and the amount added is the film-forming base material in WGS-0310 (5% by volume), The coating solution with additive BYK-310 was applied to the evaporator of the Zhengzhou Nissan automobile air conditioner. On the same test bench, the test data of the performance test of the evaporator monomer showed that the air with this coating film was better than that without the coating film. Lateral capacity increased by 9.02% > 3.4%. There may be other factors, but the addition of BYK-310 to the improved three-dimensional interface coating has a positive effect.

Embodiment 2

[0037] The purpose of this example is to experimentally verify the dispersion stability of the coating solution prepared by silicone oil-treated fumed silica (R202, initial average particle size 12 nm, white amorphous powder).

[0038] The film-forming base material is W33-15, and its volume is V W Represent; dispersion medium (1) trichloroethane, its volume is V Cl Express, dispersion medium (2) methyl ethyl ketone, its volume is V b Indicates; the solid particle is R202, and its volume is V S Expressed; the auxiliary agent is YGO-1401, and its volume is V v express. The volume ratio of each component of this composition is:

[0039] V W :V v :V Cl :V b :V S =1:0.1:1.5:1.5:5.5

[0040] After the above mixture was prepared, it was dispersed in an ultrasonic homogenizer for 1 hour. The viscosity of the coating liquid is 13.6 seconds for Tu-4 cups. Dip the glass slide [25.4×76.2mm (1″×3″), 1mm thick] into the coating solution, stay for 20 seconds, take it o...

Embodiment 3

[0043] Film-forming base material W33-15, its volume is V W Expressed; the dispersion medium is trichloroethane, and its volume is V Cl Indicates; solid particle (1) R202, its volume is V S Express, solid particle (2) ordinary pigment carbon black, its volume is V C Represent; auxiliary agent (1) YGO-1401, its volume is V v Indicates that the auxiliary agent (2) BYK-310, its volume is V 310 (3) Silicone oil 201-1000 for active group adsorption on carbon black is dimethyl silicone oil with a viscosity of 1000mm 2 / s (medical sanitary grade, produced by Shanghai Resin Factory), its volume is V 201 express.

[0044] The volume ratio of each component of this composition is:

[0045] V W :V v :V 201 :V 310 :V Cl :V C :V S =1:0.1:0.01:0.05:3:2:3.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com