Accurate part positioning method based on binocular microscopy stereo vision

A stereo vision, precise positioning technology, applied in image data processing, instruments, calculations, etc., can solve the problems of small area of the part to be tested, non-contact, small target area to be measured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

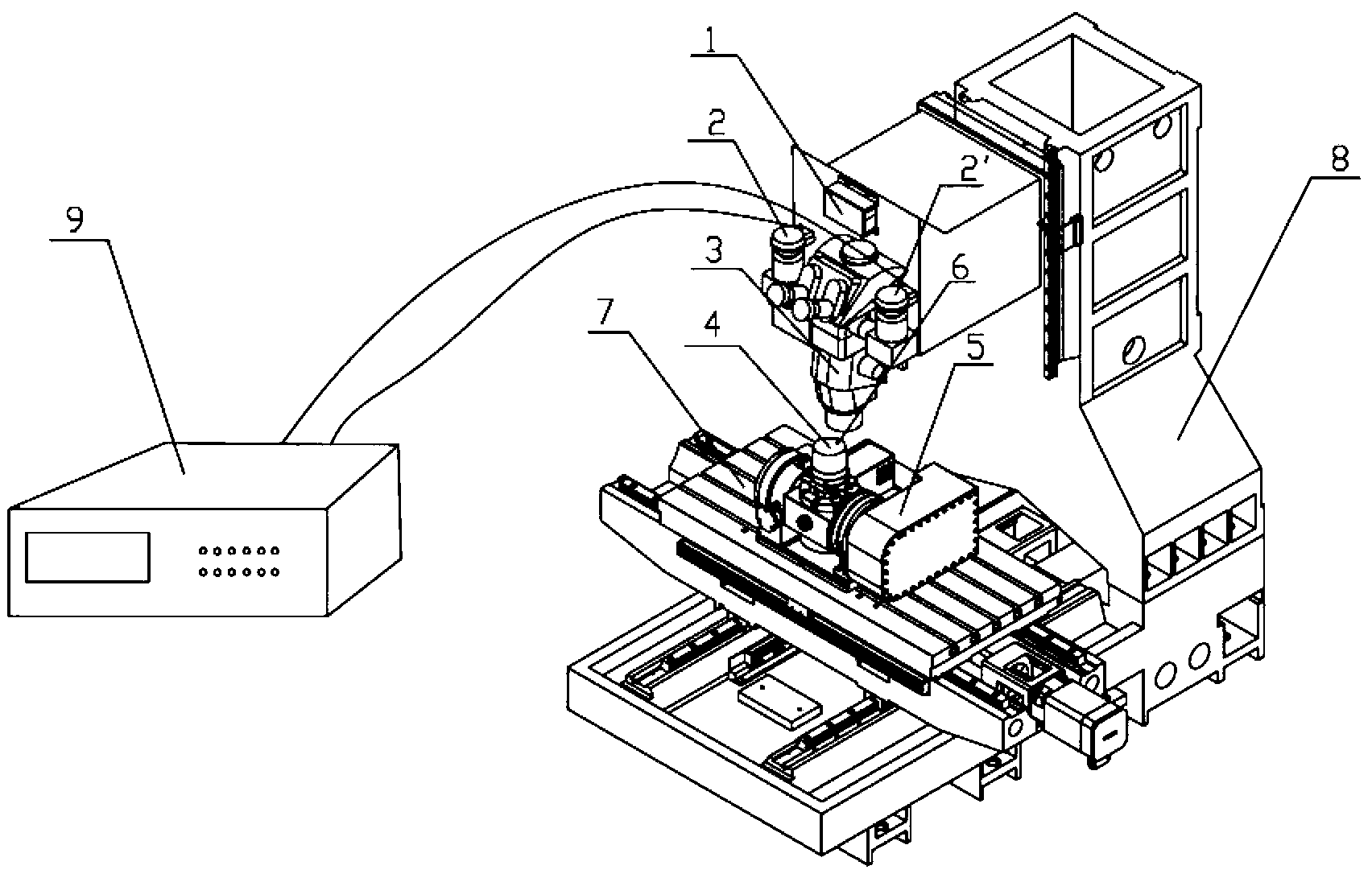

[0064] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings. Attached figure 1 It is a device model diagram of precise parts positioning based on binocular microscopic stereo vision. The device collects the position information of the area to be measured in the workpiece to be measured through the left and right CCD cameras 2, 2', and finds the three-dimensional space coordinates of the point to be measured through the relationship between the established image coordinate system and the world coordinate system. Realize precise positioning. The installation method of the device is as follows: the machine bed 8 is placed on the ground; the precision numerical control displacement platform 7 is installed with the machine bed through the guide rail, which can meet the high-precision translation and angle rotation requirements of the checkerboard calibration plate in the calibration experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com