High-precision non-contact measurement method and device for three-dimensional profile of optical freeform curved surface

A three-dimensional shape, high-precision technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of improving detection accuracy and resolution, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

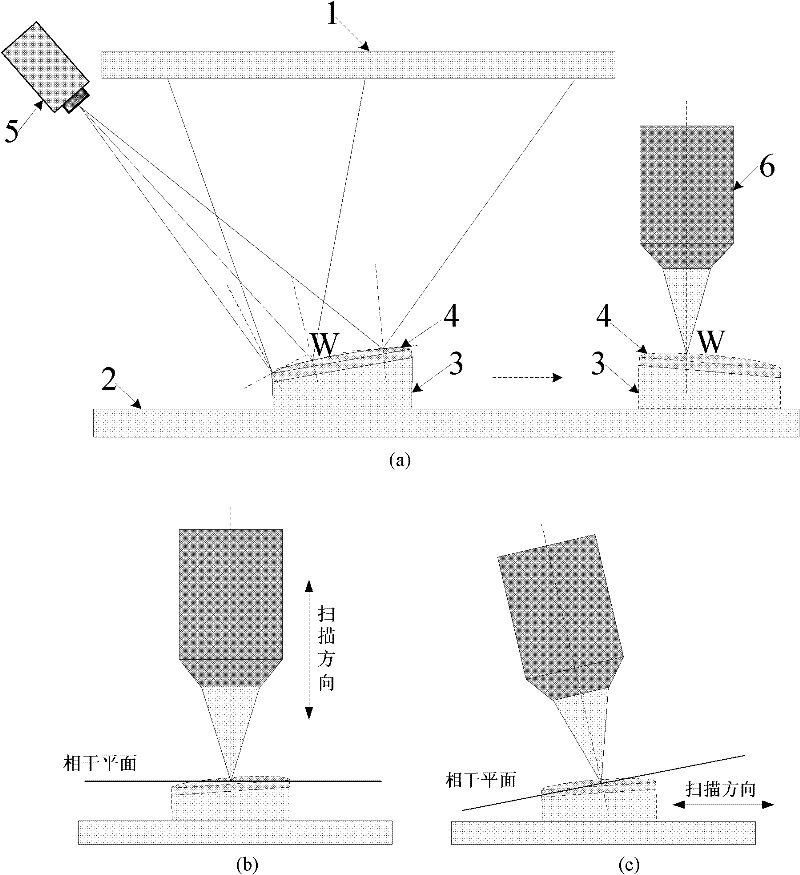

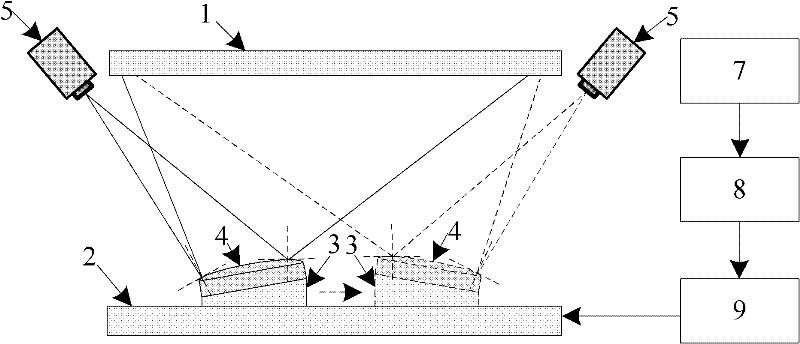

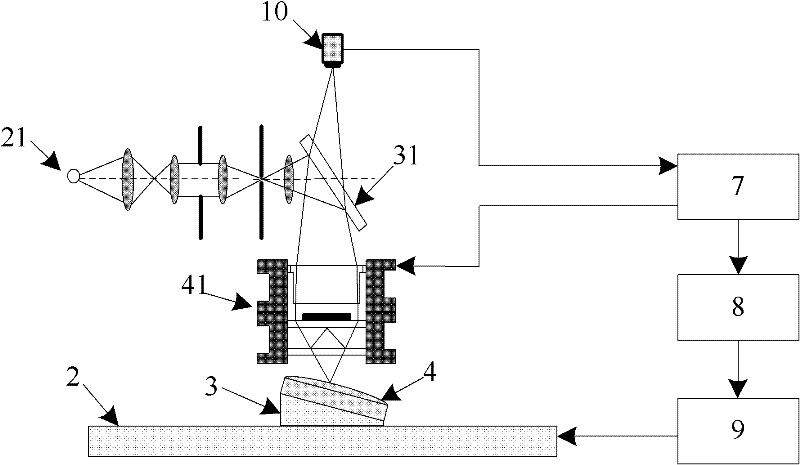

[0027] A high-precision non-contact measurement method for the three-dimensional shape of optical free-form surfaces based on multi-sensor fusion technology: a grating projection visual detection unit and a white light scanning interferometry unit are constructed within the framework of the same high-precision positioning motion control system, and the grating projection device is used to measure the measured Sinusoidal grating fringes are projected on the surface of the measured object, and the image acquisition device obtains the deformed fringe pattern modulated by the surface of the measured object, and sends it to the computer for subsequent processing to restore the three-dimensional shape of the surface of the measured object. According to the three-dimensional topography data of the surface of the measured object measured by the grating projection visual detection unit, the automatic recognition of the part pose is performed, the white light scanning interferometry path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com