Wire rod husking sander

A technology of sanding machine and disc unit, which is applied in the direction of abrasive belt grinder, grinding/polishing equipment, grinding machine, etc., can solve the problems of low production efficiency, environmental pollution, material corrosion, etc., achieve high processing accuracy and automation, and improve Mechanical and physical properties, effect of improving surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

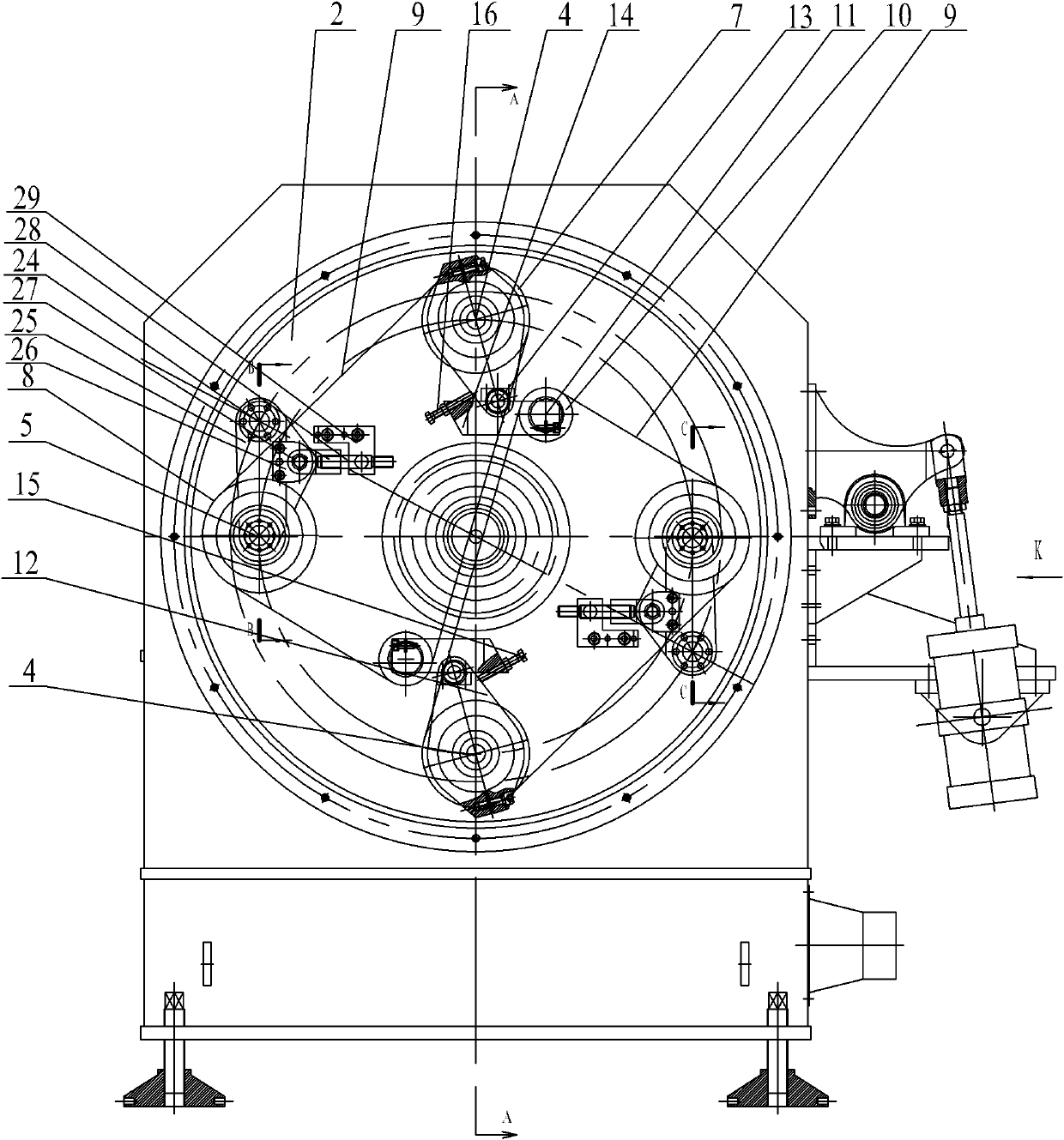

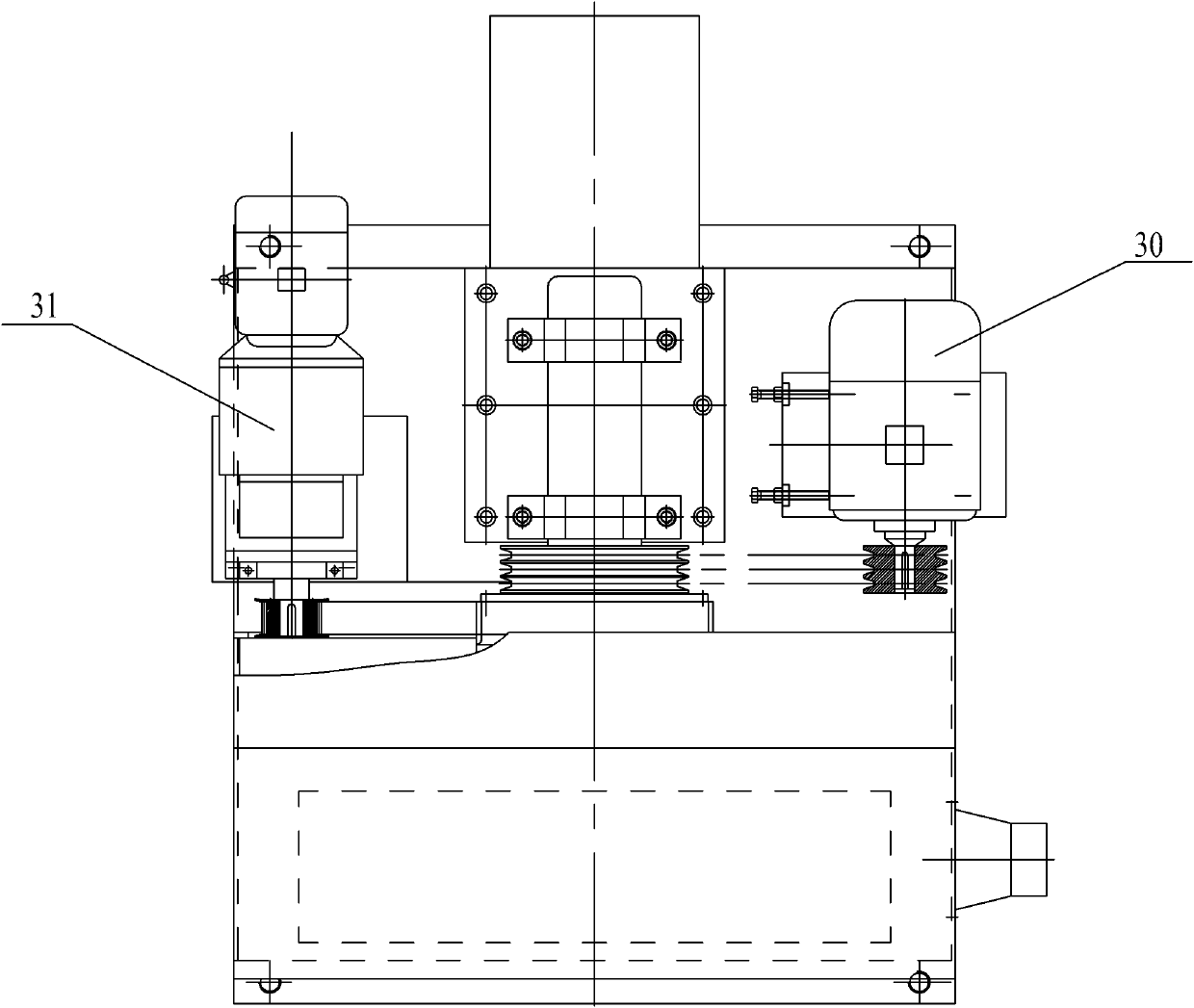

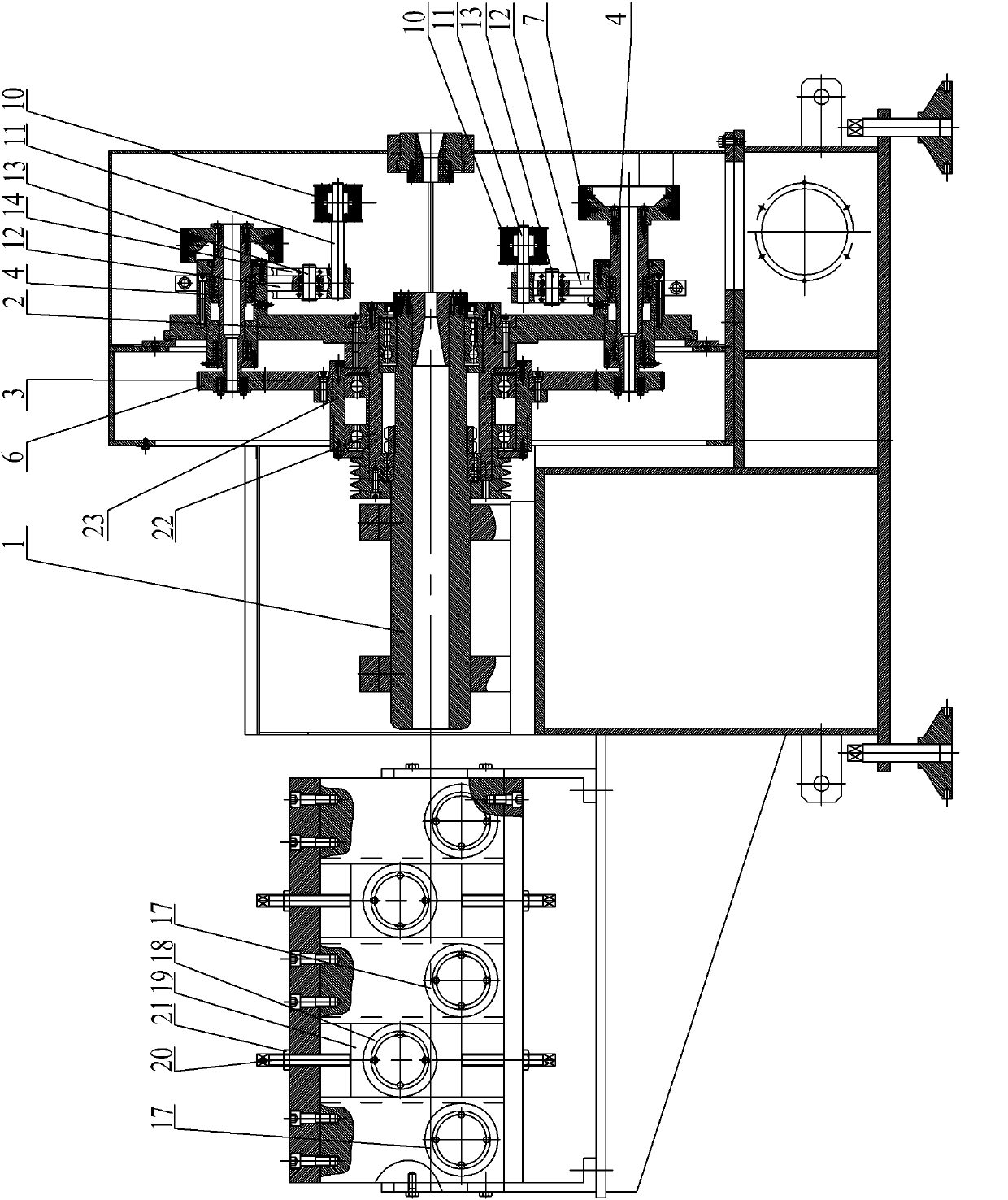

[0019] As shown in the figure: the disk element peeling sander includes a main shaft 1 fixed on the frame, and a through hole is opened in the axial direction of the main shaft 1, and a main turntable 2 and a driving gear 3 are installed on the main shaft 1 to rotate. Several driving shafts 4 are mounted on the main turntable 2, and each driving shaft 4 is equipped with a passive pulley mounting shaft 5, and a driving gear 6 and a driving pulley 7 are fixedly installed on the driving shaft 4. The driving gear 6 and the driving The gear 3 meshes; a passive pulley 8 is installed rotating on the passive pulley installation shaft 5, and a grinding belt 9 is provided on the driving pulley 7 and the passive pulley 8, and each set of driving pulley 7 and passive pulley 8 is equipped with There is a tensioning pulley 10, the tensioning pulley 10 has a tensioning shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com