Lignin wastewater recycling technology

A technology of lignin and waste water, which is applied in the direction of waste water treatment, descaling and water softening, water/sewage treatment, etc. in the processing process. achieve a high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

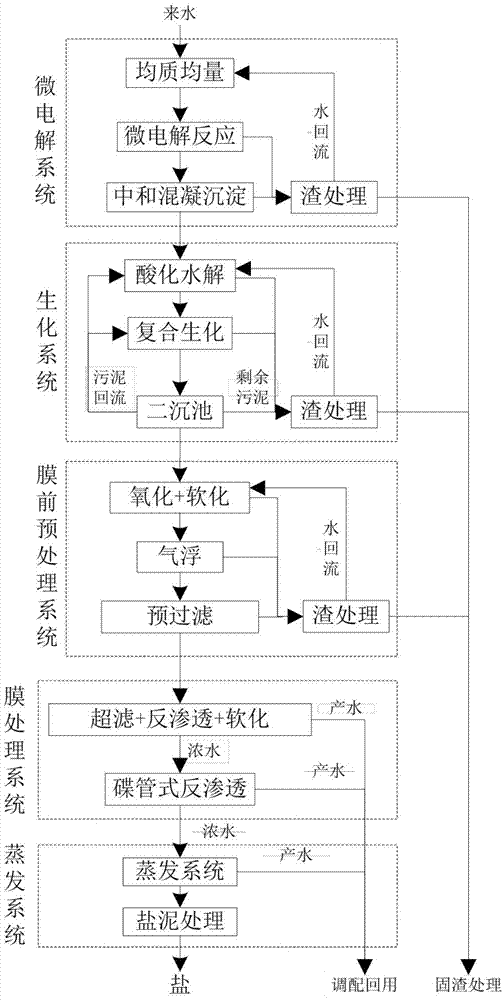

[0025] Wastewater from a paper mill needs to be reused as process water. The process flow chart is as follows figure 1. The volume of wastewater is 2000t / d, the water quality is BOD53254mg / L, CODCr is 13017mg / L, TDS is 2337mg / L, and lignin substance is 783mg / L. The effluent water quality after passing through the micro-electrolysis system is BOD53817mg / L, CODCr is 8237mg / L, and TDS is 2569mg / L. The B / C ratio of wastewater is increased from 0.25 to 0.47, that is, the biochemical properties of wastewater are converted from difficult biochemical treatment to good biodegradability, which is conducive to the efficient removal of COD by subsequent biochemical systems. After the effluent from the micro-electrolysis system passes through the biochemical system, the effluent quality is CODCr290mg / L, TDS is 2483mg / L, hardness is 635mg / L, SS is 188mg / L, and the removal rate of COD by the biochemical system reaches 96%. Due to the high COD, hardness, and SS of the effluent of the bioche...

Embodiment 2

[0027] Papermaking wastewater is reused as circulating cooling water, the process flow chart is as follows figure 1 . The volume of wastewater is 240t / d, the water quality is BOD5735.6mg / L, CODCr is 4327mg / L, TDS is 1275mg / L, and lignin is 180mg / L. The effluent water quality after passing through the micro-electrolysis system is BOD5971mg / L, CODCr is 2942mg / L, and TDS is 1338mg / L. The B / C ratio of wastewater is increased from 0.17 to 0.33, that is, the biochemical properties of wastewater are converted from unsuitable for biochemical treatment to biochemical treatment. After the micro-electrolysis system effluent passes through the biochemical system, the effluent water quality is CODCr86mg / L, TDS is 1174mg / L, hardness is 301mg / L, and SS is 175mg / L. Due to the high SS of the effluent of the biochemical system, the pre-membrane pretreatment system is set to air flotation and filter cloth filter. After the pre-membrane pretreatment system, the effluent water quality is CODCr57...

Embodiment 3

[0029] Pulping wastewater is reused as circulating cooling water, the process flow chart is as follows figure 1 . The volume of wastewater is 800t / d, the water quality is BOD52102mg / L, CODCr is 8083mg / L, TDS is 4589mg / L, and lignin is 672mg / L. The effluent water quality after passing through the micro-electrolysis system is BOD52036mg / L, CODCr is 5358mg / L, and TDS is 4634mg / L. The B / C ratio of wastewater is increased from 0.26 to 0.38, that is, the biochemical properties of wastewater are converted from difficult biochemical treatment to biochemical treatment. The effluent water quality of the micro-electrolysis system after passing through the biochemical system is CODCr157mg / L, TDS is 4418mg / L, hardness is 774mg / L, and SS is 235mg / L. Because the effluent hardness and SS of the biochemical system are high, the pre-membrane pretreatment system is set to softening, air flotation, and media filter. After the pre-membrane pretreatment system, the effluent quality is CODCr68mg / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com