Heat-sheet membrane sealing machine and membrane sealing process of dialyser

A film sealing machine and dialyzer technology, which is applied in the field of hot film sealing machine and film sealing technology, can solve the problems of continuous mass production, large heat loss of silk thread, easy breakage, etc., achieve stable product quality, improve production efficiency, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

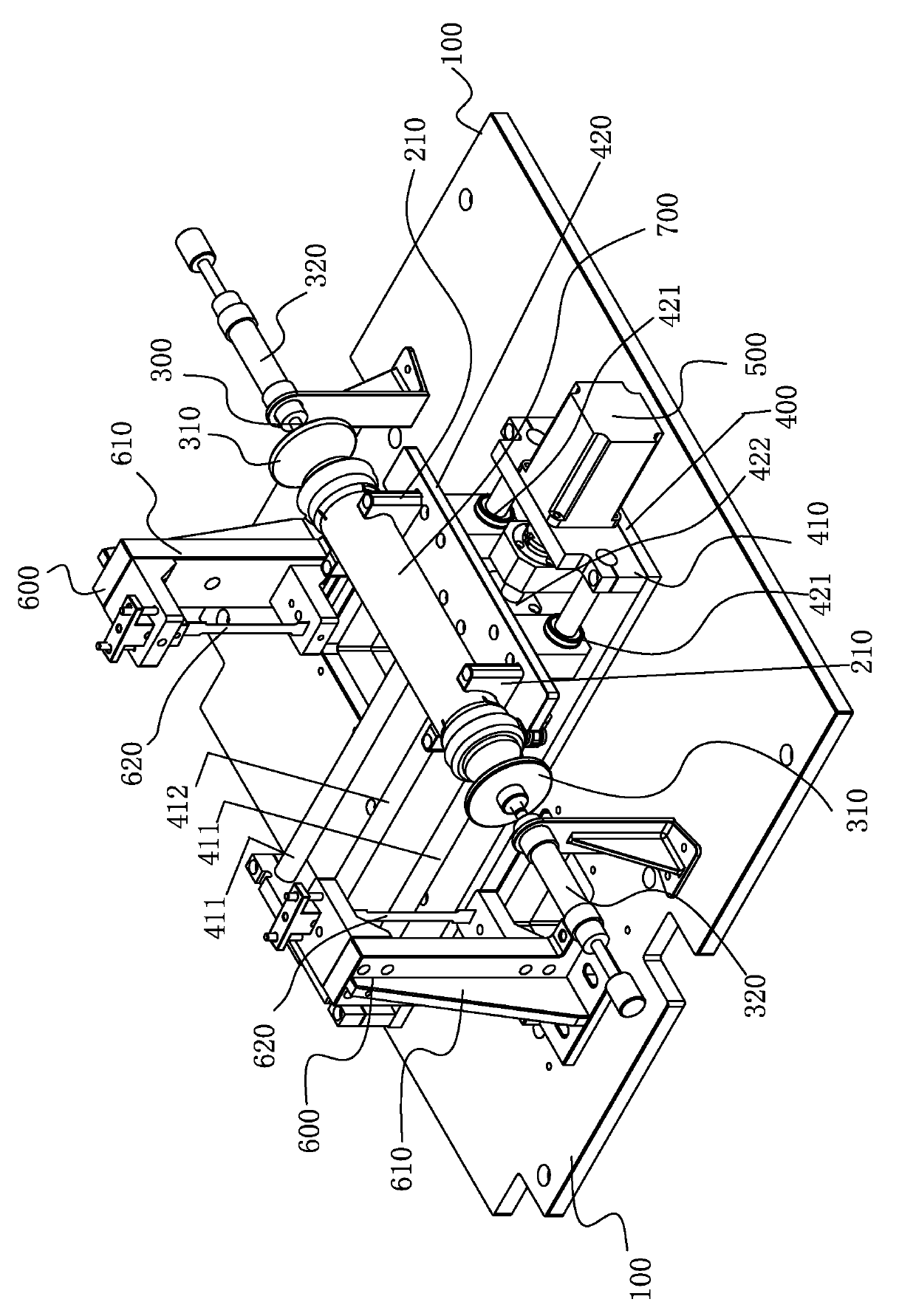

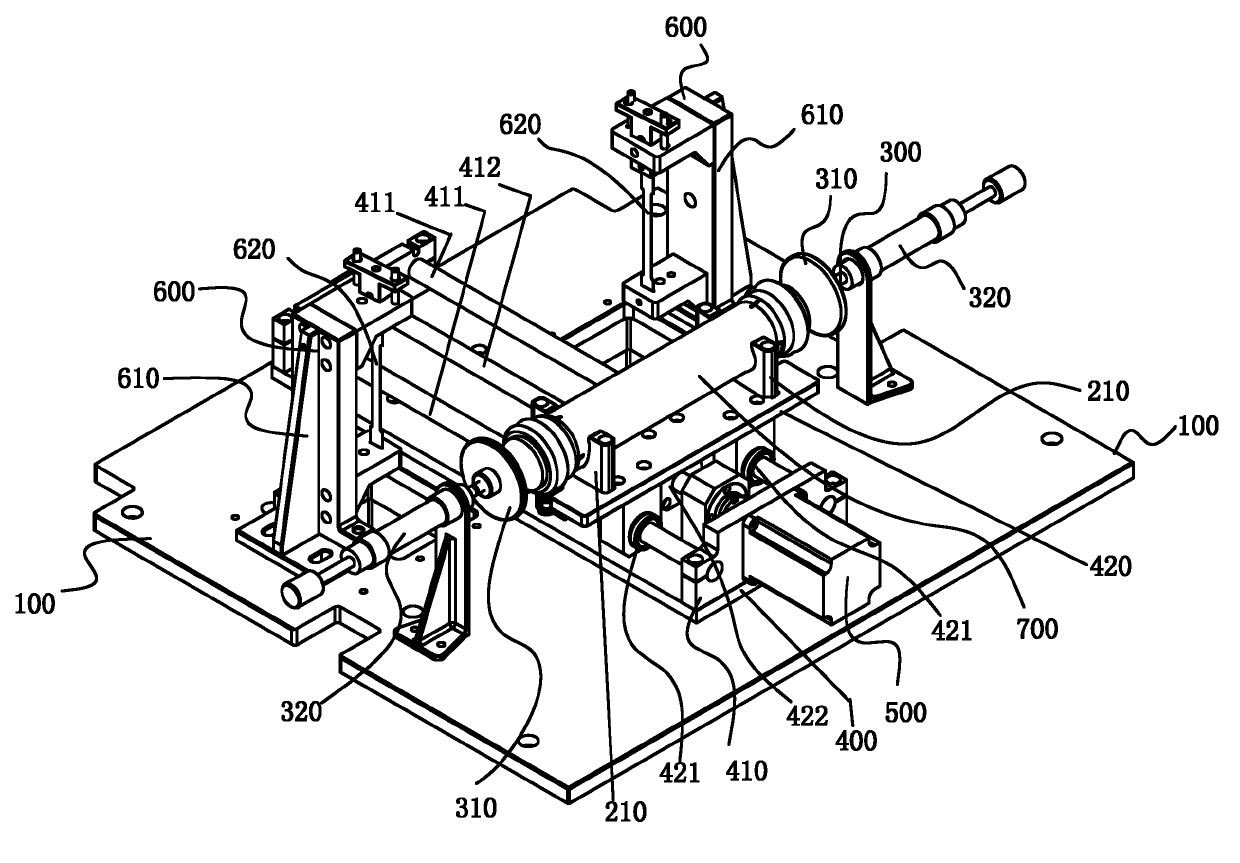

[0047] A hot sheet sealing machine, such as figure 1 As shown, a frame body 100, a clamping device, a calibration device 300, a moving device 400, a driving device 500 for driving the moving device 400 to and fro, a heat sealing device 600 and a control device are provided.

[0048] The clamping device, the alignment device 300 , the driving device 500 , the moving device 400 , the heat sealing device 600 and the control device are fixed on the frame body 100 .

[0049] The clamping device is fixed on the moving device 400, the moving device 400 is connected with the driving device 500, and the calibration device 300 is arranged on both sides of the clamping device; the calibration device 300, the driving device 500 and the heat sealing device 600 are respectively connected with the control device.

[0050] The clamping device is used to fix the dialyzer 700. After the dialyzer 700 is fixed on the clamping device, it needs to be adjusted so that the length of the inner fiber m...

Embodiment 2

[0064] A film sealing process of a dialyzer is carried out by using the hot plate film sealing machine in Example 1, comprising the following steps.

[0065] Step A. Put the dialyzer 700 on the holding device.

[0066] The clamping device is provided with a U-shaped bracket 210, and the step A is specifically to place the dialyzer 700 on the U-shaped bracket 210 of the clamping device.

[0067] Step B, the alignment device 300 adjusts the end of the dialyzer 700 .

[0068] The calibration device 300 is provided with a calibration board 310 and a calibration cylinder 320, the calibration board 310 is fixedly connected with the calibration cylinder 320, and the step B is specifically that the calibration cylinder 320 of the calibration device 300 drives the calibration board 310 from the two The ends approach and clamp the fiber membranes at both ends of the dialyzer 700 , and then the cylinder 320 drives the calibration plate 310 away from the end of the dialyzer 700 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com