Curved surface forming and processing device

A processing equipment and curved surface forming technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problem of low yield rate of curved screens, affecting the popularization of mobile terminals with curved screens, and the high price of mobile terminals no second question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

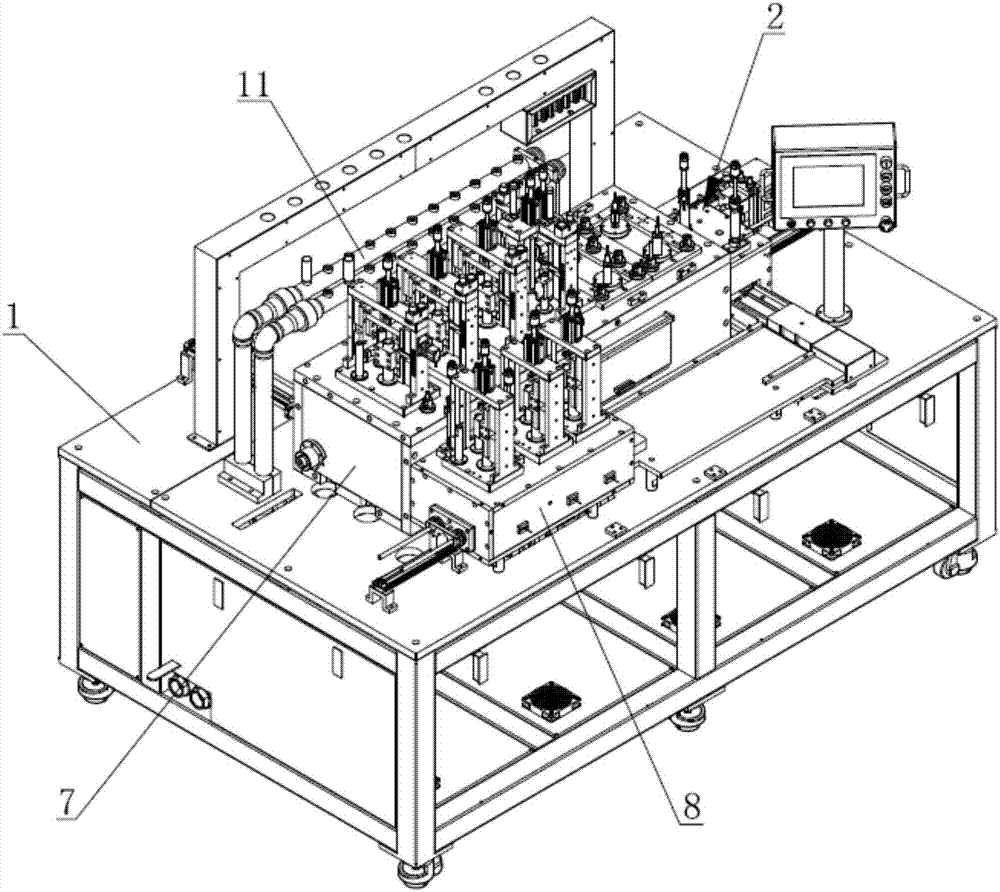

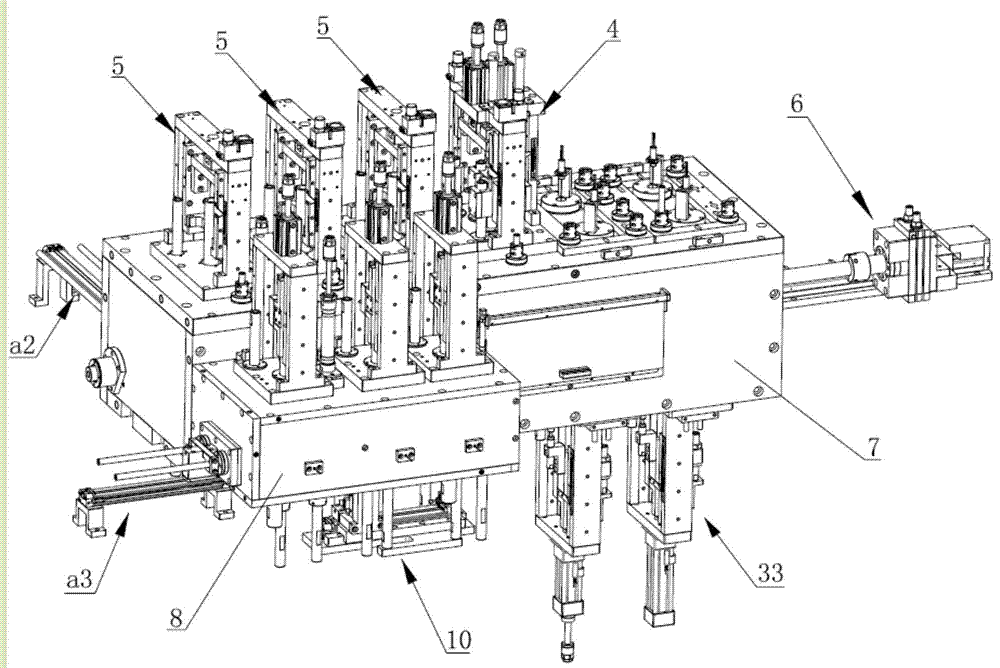

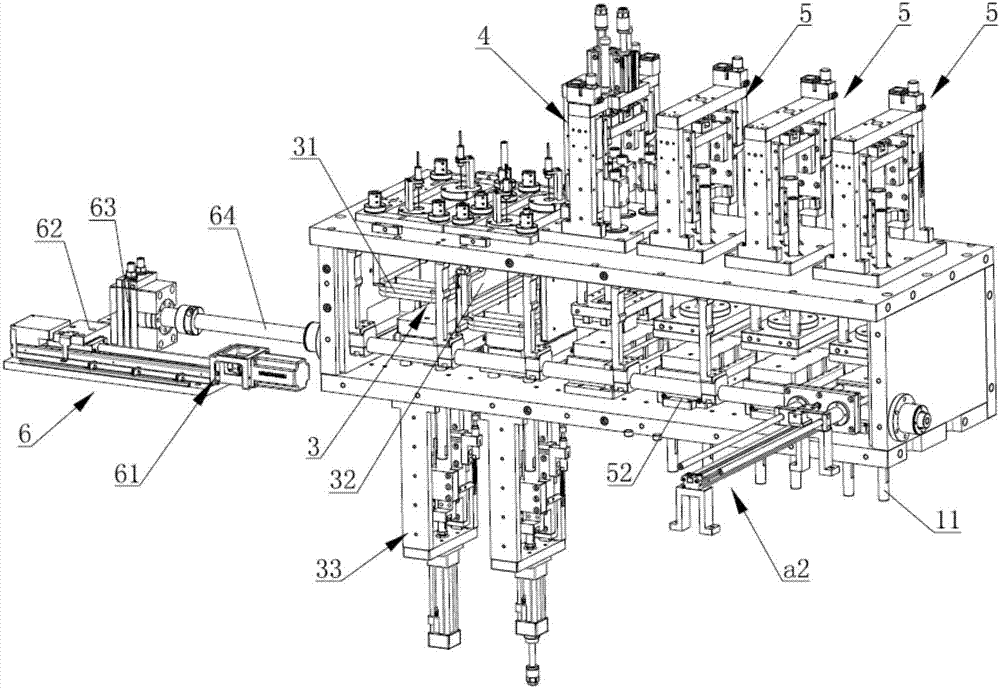

[0029] Such as Figure 1-7 As shown, a curved surface forming processing equipment includes a workbench 1. The workbench 1 is equipped with a processing box and a vacuum feeding device 2. The vacuum feeding device 2 is connected with the processing box. The processing box is sequentially installed with a heating device 3. , a hot-pressing device 4 and a cooling and shaping device 5, the heating device 3 includes two sets of heating coils 31 arranged in dislocation, the hot-pressing device 4 includes a pressing assembly 41, and the pressing assembly 41 includes a first press for pressing the middle part of the forming mold. A closing mechanism 411 and a second pressing mechanism 412 used to compress the surroundings of the forming mold. The cooling and shaping device 5 includes a shaping upper part 51 and a cooling table 52 set corresponding to the shaping upper part 51. The material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com