Hydraulic floating centering and clamping transmission device

A transmission device, hydraulic clamping technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of difficulty in completing order tasks on time, rising manufacturing costs, labor recruitment and management difficulties, etc. Convenience and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawings and examples.

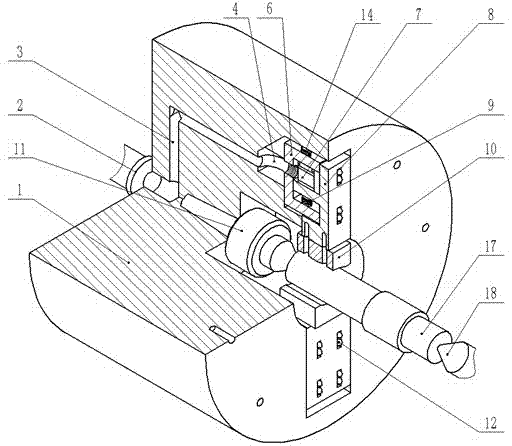

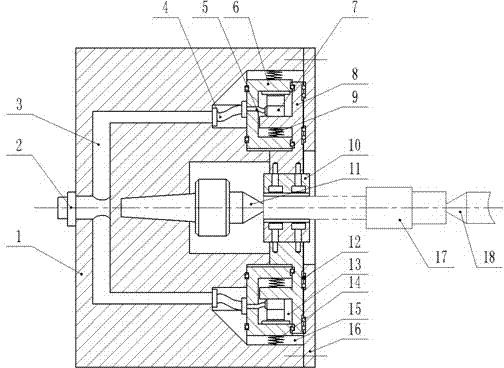

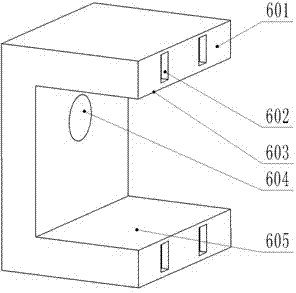

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a chuck body 1, a rotary joint 2, two semicircular chucks 10, a center 11, an end cover 16 and two hydraulic clamping devices with the same structure. The center hole of the cylindrical chuck body 1 is equipped with a tip 11, the tail end of the tip 11 is fixed in the tapered hole of the chuck body 1, and the center hole of the chuck body 1 with the tip of the tip facing outward is equipped with a symmetrically arranged semicircle. Chuck, the chuck body 1 outside the two semicircular chucks 10 is symmetrically opened with rectangular holes, and the two rectangular holes are respectively equipped with hydraulic clamping devices with the same structure and opposite installation directions, and the two hydraulic clamping devices They are fixedly connected with their respective semicirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com