Rotary buffering valve

A technology of rotary buffer and buffer valve, which is used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of inconvenient installation and use, short service life, not concise and compact enough, etc. Easy to leak oil, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

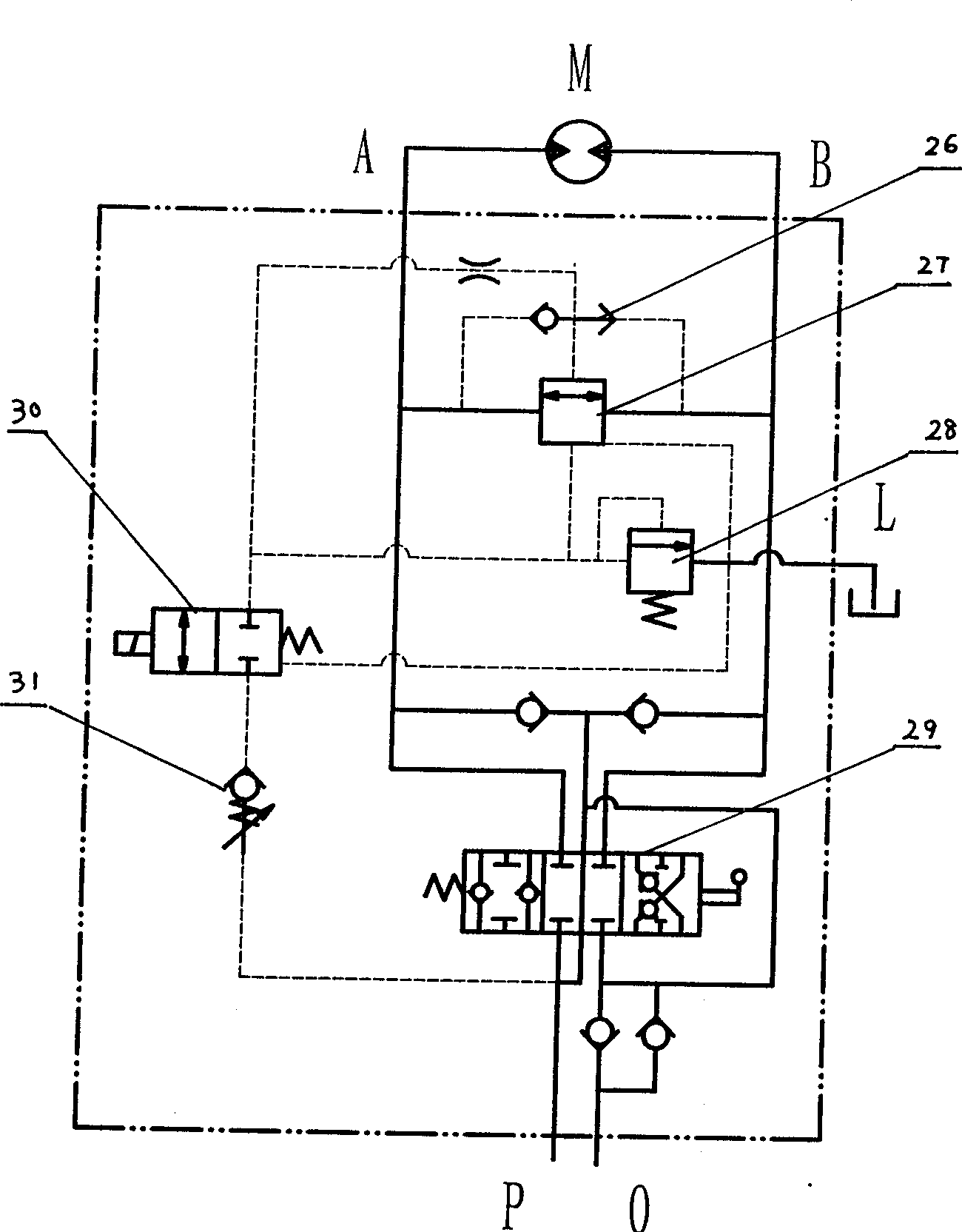

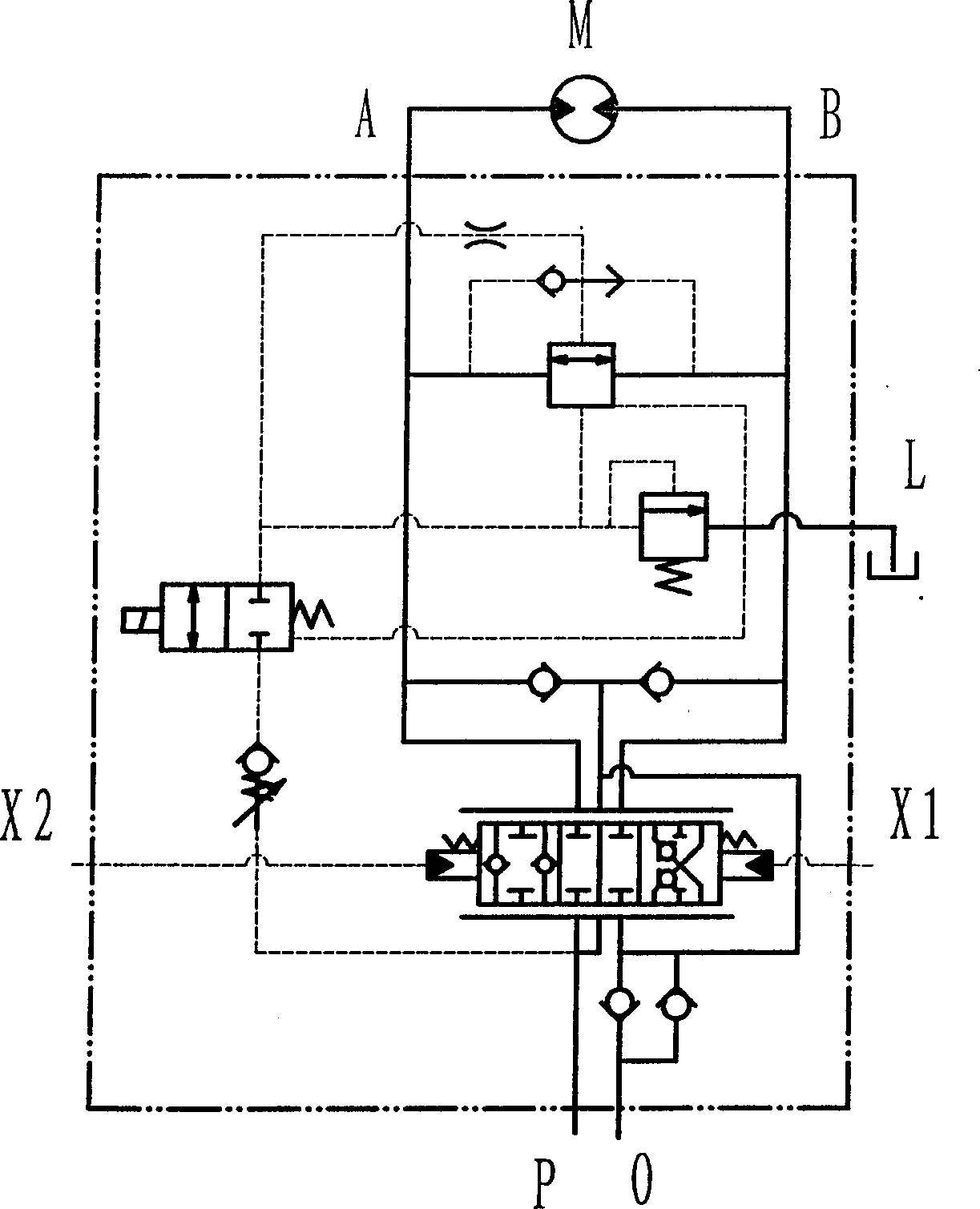

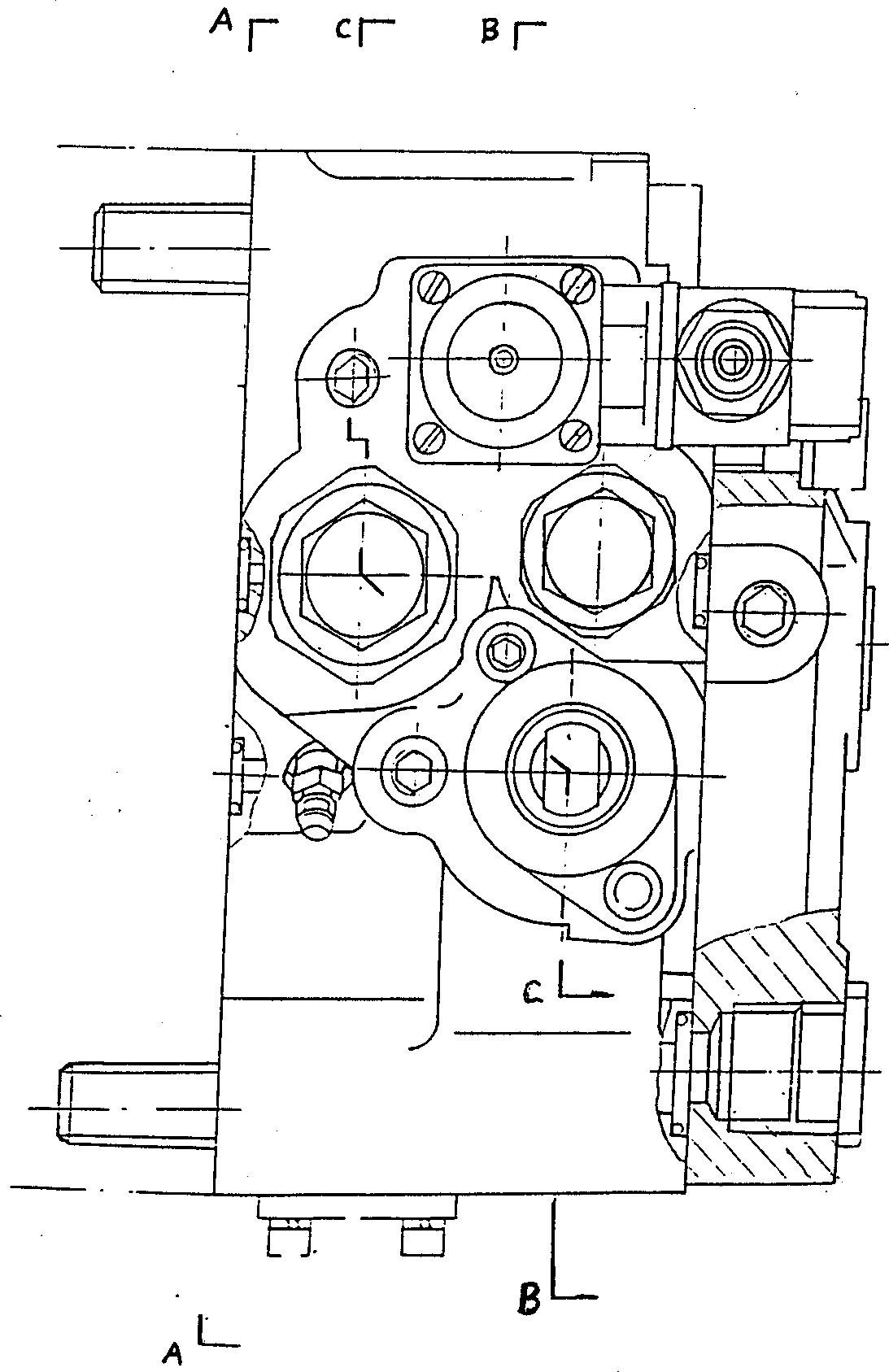

[0021] As shown in the figure, the main components of this type of rotary buffer valve are main valve body 1, damping 2, oil passage 3, solenoid valve core oil inlet 4, damping 5, buffer spool spring 6, pilot spool 7, pilot Spool spring 8, inner runner 9, selector valve steel ball 10, buffer spool 11, inner runner 12, solenoid spool spring 13, solenoid spool 14, adjustable back pressure spool 15, adjustable back pressure valve Core spring 16, electromagnet 17, built-in one-way spool spring 18, built-in one-way valve steel ball 19, oil return and replenishment one-way spool 20, oil return back pressure spool spring 21, oil return back pressure spool 22 , Inner flow channel 23, reversing valve stem 24, oil supply check valve core 25, selection valve 26, buffer valve 27, pilot valve 28, control valve 29, solenoid valve 30, adjustable back pressure v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com