Crystal silicon solar battery with multi-hole silicon layer structure

A technology of solar cells and porous silicon layers, applied in the field of solar cells, to achieve the effects of reducing consumption, improving photoelectric conversion efficiency, long life value and diffusion length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

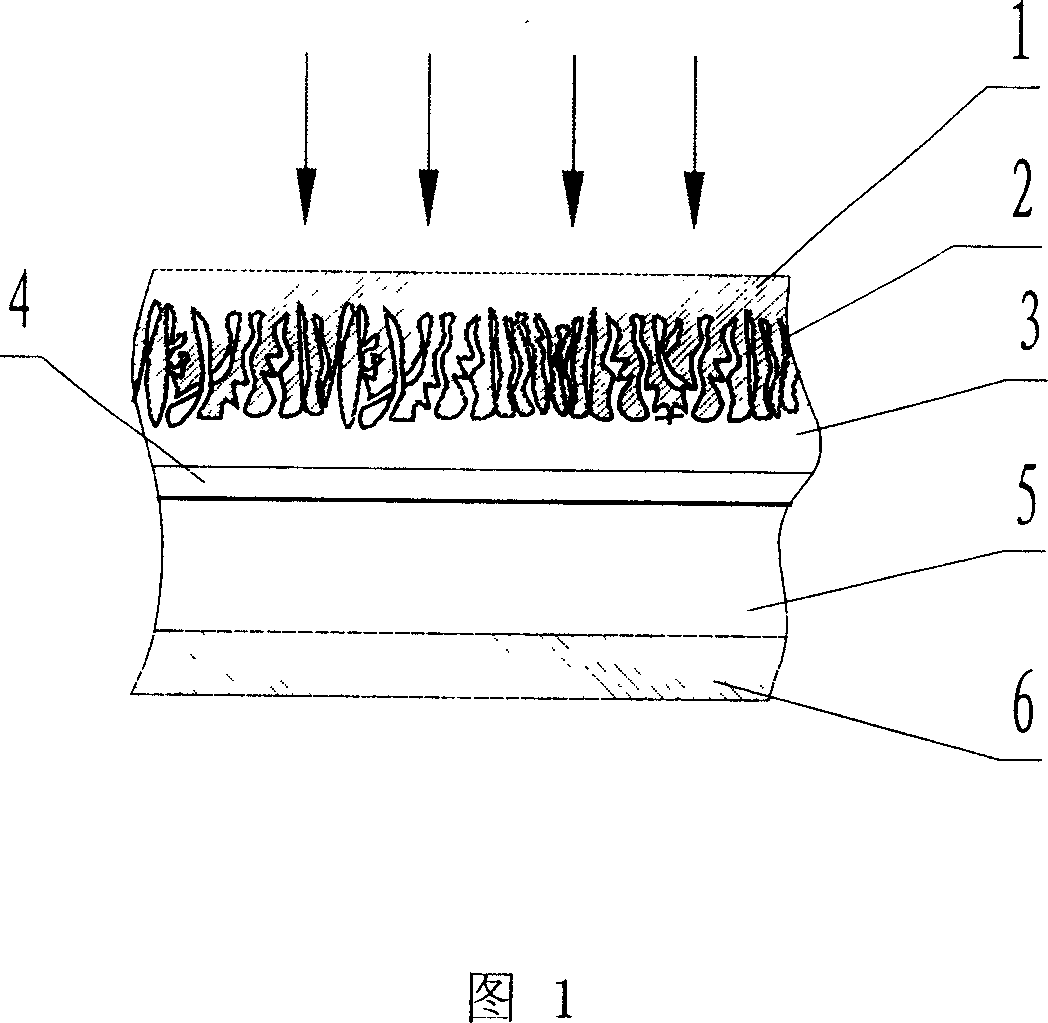

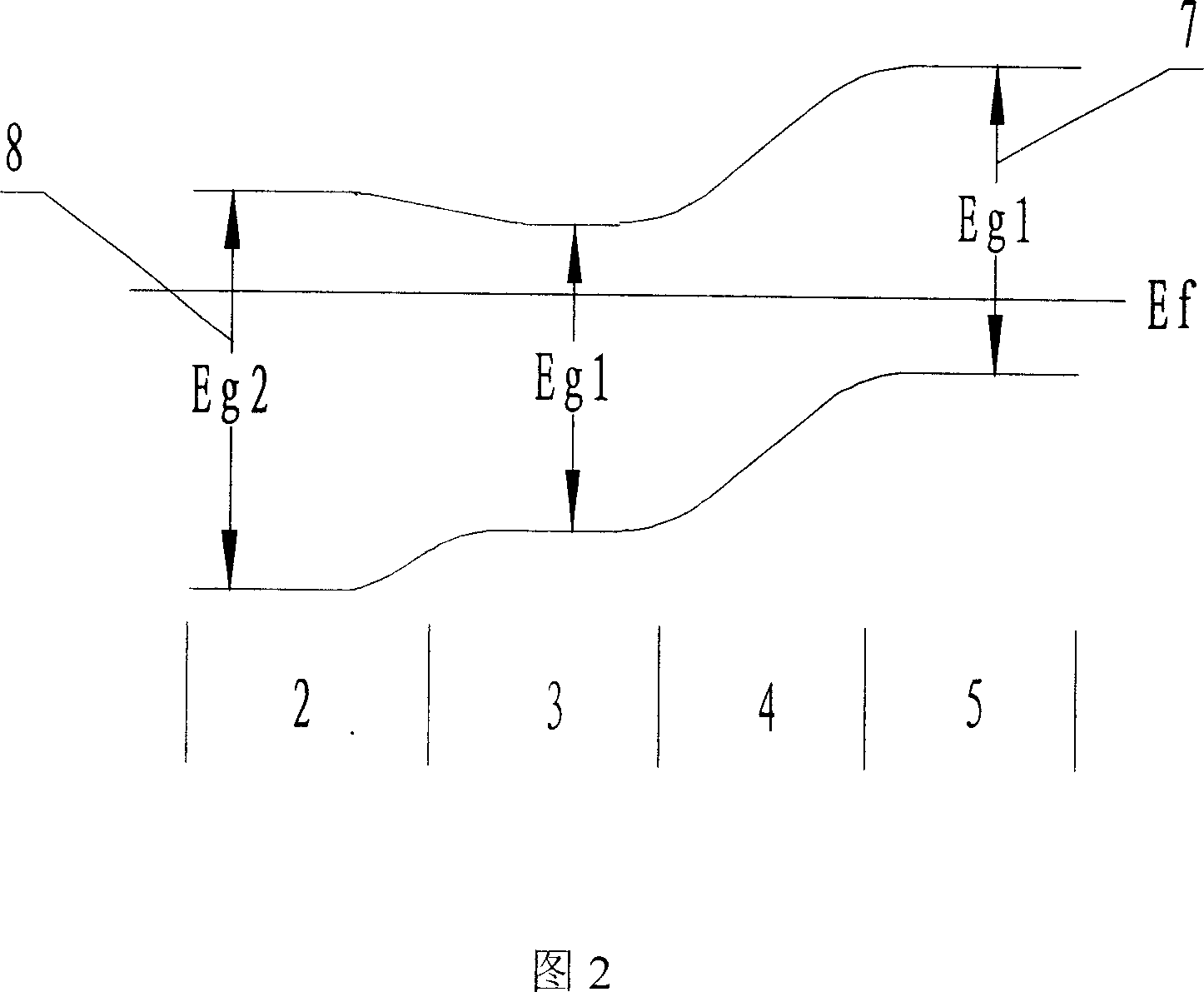

[0013] In order to illustrate the implementability of the present invention, in conjunction with accompanying drawing 1, enumerate an implementable scheme:

[0014] a. Using a P-type silicon substrate 5, according to the prior art, prepare a typical N silicon substrate by diffusing pentavalent elements on the side receiving light + P junction 4 (if an N-type silicon substrate is used, 3-valent elements must be diffused to prepare P + N junction. In addition to silicon wafers, N can be made on other suitable silicon substrate materials, such as silicon substrates obtained by epitaxy and silicon substrates obtained by chemical deposition. + P junction or P + N) to obtain an N-type silicon layer 3 .

[0015] b. On the non-light-receiving surface of the battery, prepare a thin layer with the same conductivity type as the semiconductor silicon on this surface with higher conductivity to form a back reflection field, and prepare the back electrode 6 on this basis.

[0016] c. Di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com