Damping vibration absorber with magnetism-isolating covers, magnetic liquid and application of first-order buoyancy principle

A magnetic liquid, magnetic isolation cover technology, applied in the direction of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of difficult magnetic liquid flow, fragile permanent magnets, and can not be applied, and reduce the phenomenon of magnetic leakage , The effect of vibration reduction is good, and the effect of avoiding difficult flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described with accompanying drawing as specific embodiment:

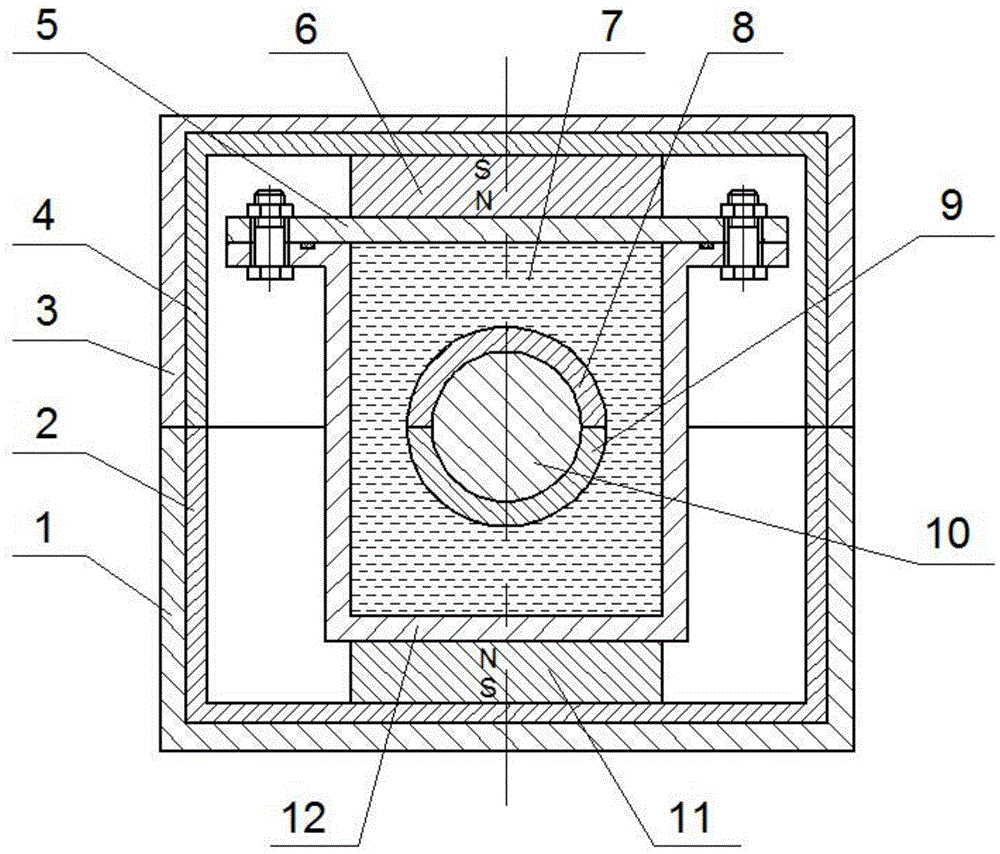

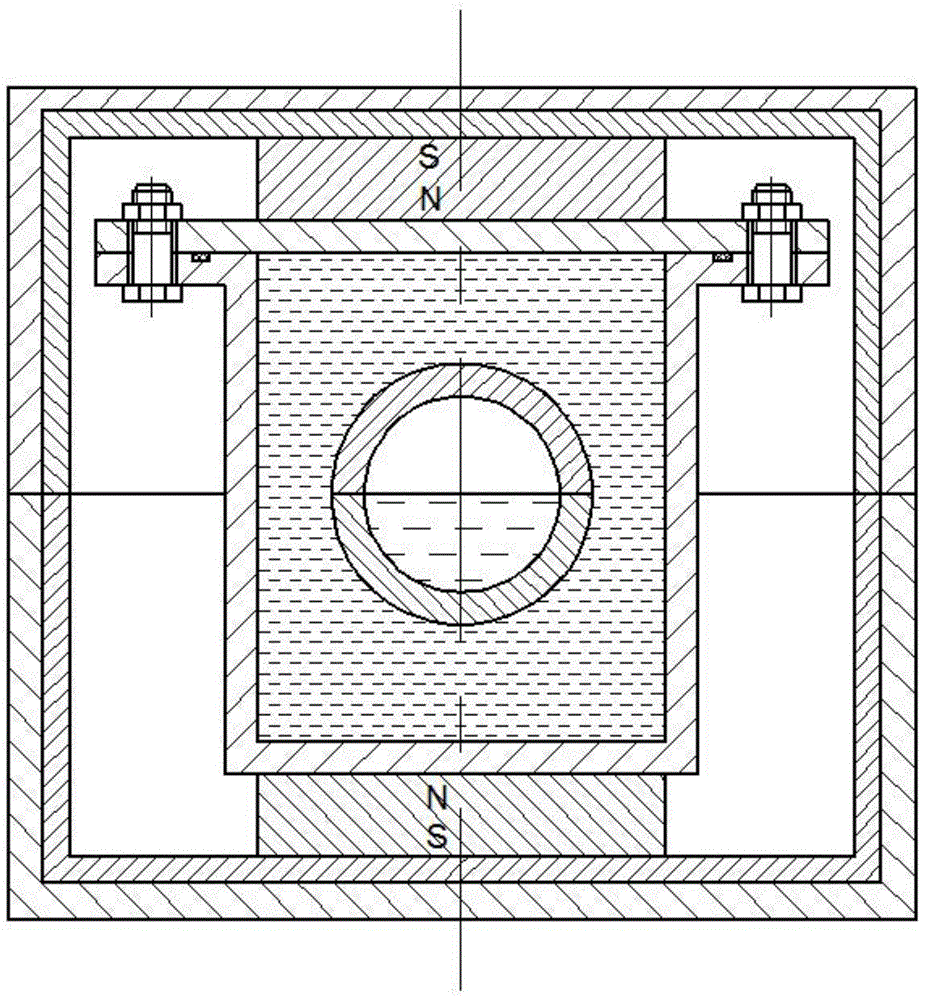

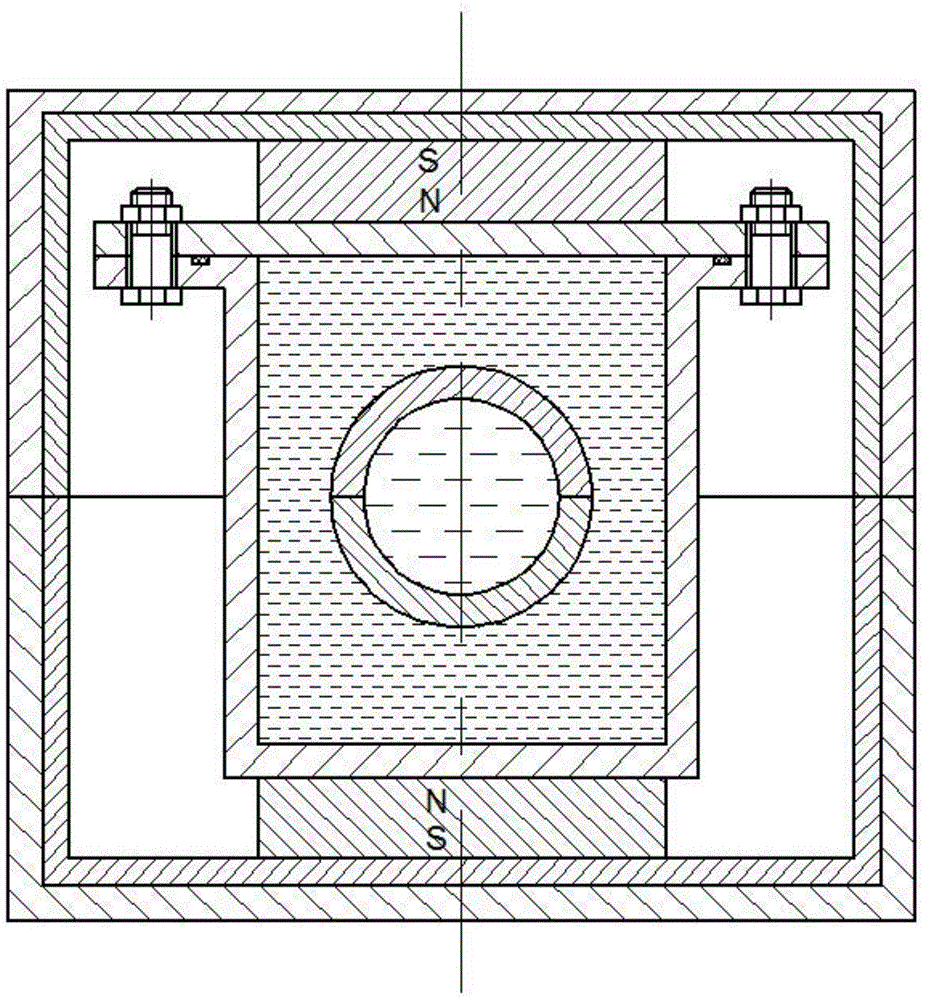

[0025] First-order buoyancy principle magnetic liquid damping shock absorber with magnetic isolation cover, such as figure 1 , the vibration damping device includes: a lower magnetic isolation outer sleeve 1, a lower magnetic inner sleeve 2, an upper magnetic isolation outer sleeve 3, an upper magnetic inner sleeve 4, an end cover 5, a first permanent magnet 6, a magnetic liquid 7, an upper spherical shell 8. Lower spherical shell 9, counterweight 10, second permanent magnet 11, housing 12.

[0026] Connections between the parts making up the device:

[0027] When the counterweight 10 is a solid material, the counterweight 10 is put into the lower spherical shell 9 first, and then the lower spherical shell 9 is fixedly connected with the upper spherical shell 8 to form a mass block, and the connection method can be welding or bonding.

[0028] The counterweight 10 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com