Film bulk acoustic resonator and method of forming the same

A thin-film bulk acoustic wave and resonator technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve It is not easy to control the resonance frequency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

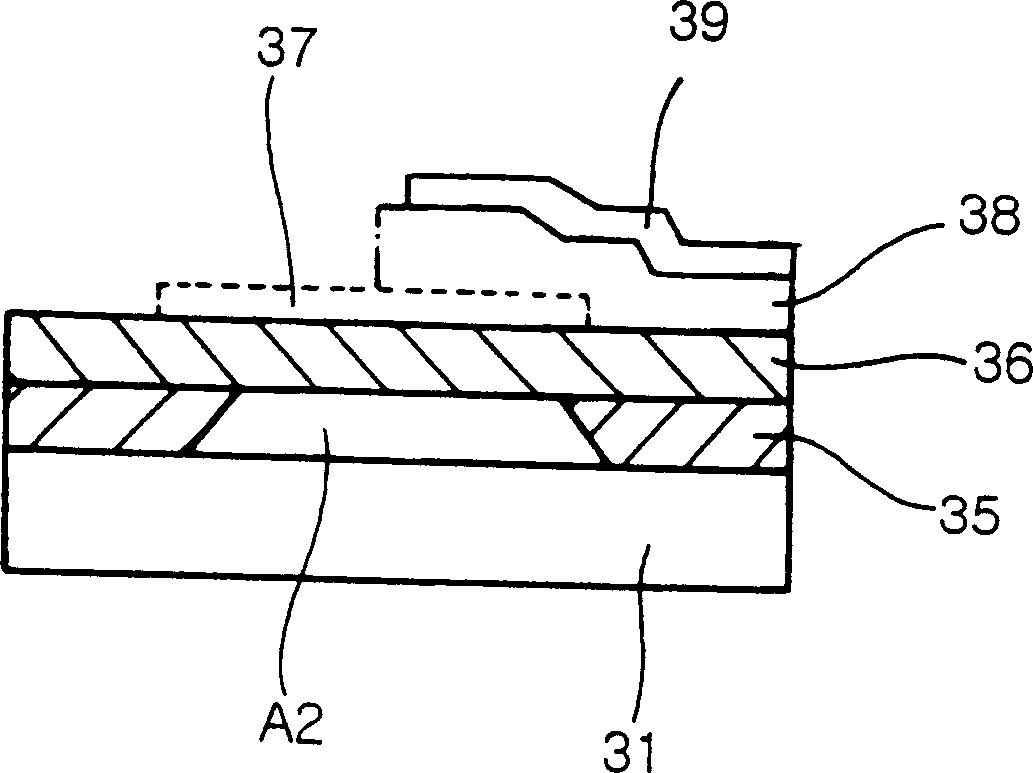

[0042] Reference will now be made in more detail to embodiments of the invention, examples of which are described in conjunction with the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention through the figures.

[0043] Figure 4A and 4B are a cross-sectional view and a plan view, respectively, of an FBAR according to an embodiment of the present invention. refer to Figure 4A , the FBAR comprises a substrate 51, an insulating layer 52 formed on the substrate 51, a film supporting layer 55 formed on the insulating layer 52 so as to have an air gap A3, a film layer 56 formed on the film supporting layer 55, a film layer 56 formed on the film A first electrode 57 on layer 56 , a piezoelectric layer 58 formed on first electrode 57 , and a second electrode 59 formed on piezoelectric layer 58 .

[0044] According to this embodiment of the present invention, since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com