Planar carbon commutator

A commutator and planar carbon technology, applied in the field of commutators, can solve the problems of cumbersome manufacturing process, complex structure of carbon commutator segments, high cost consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

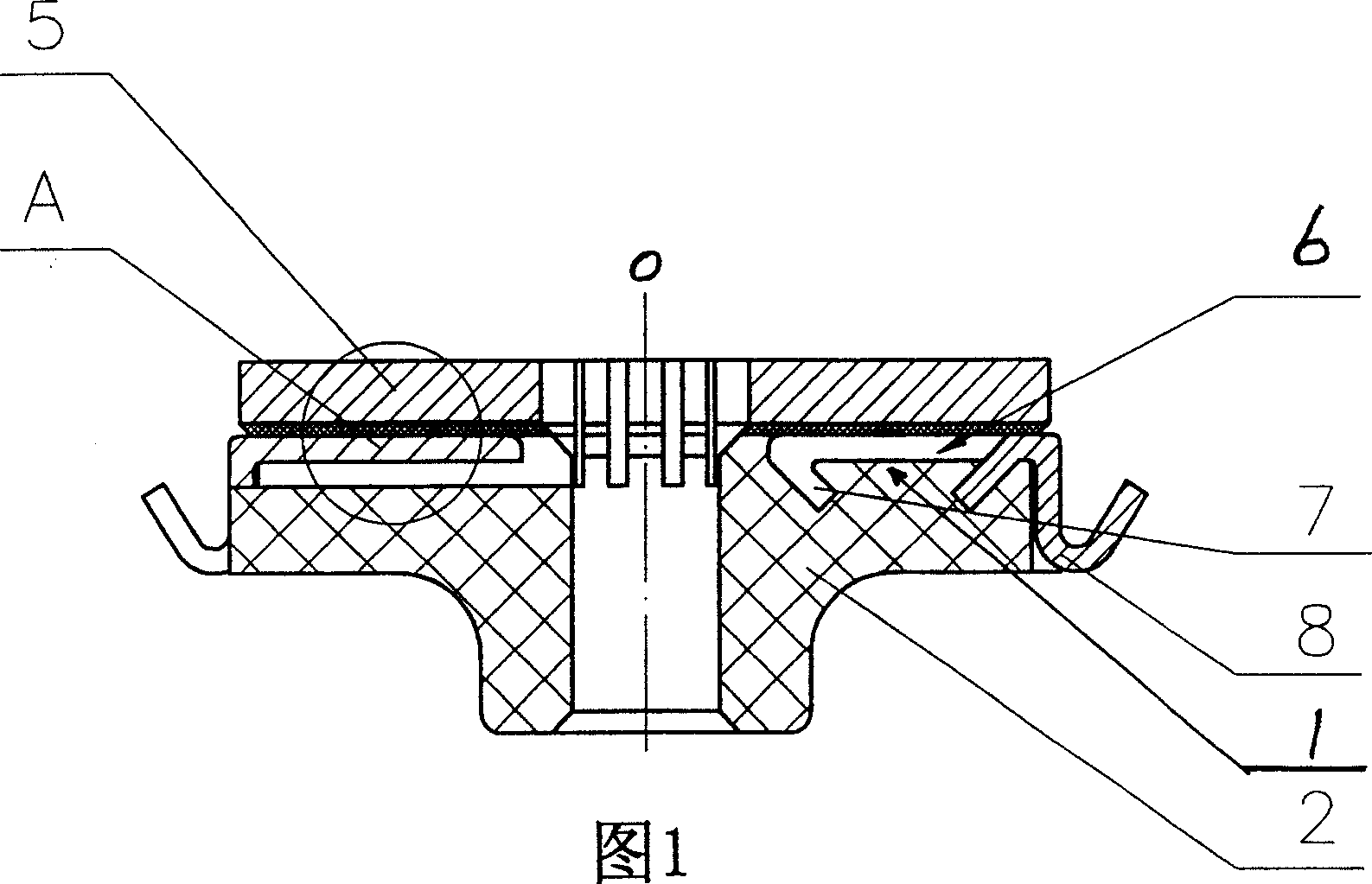

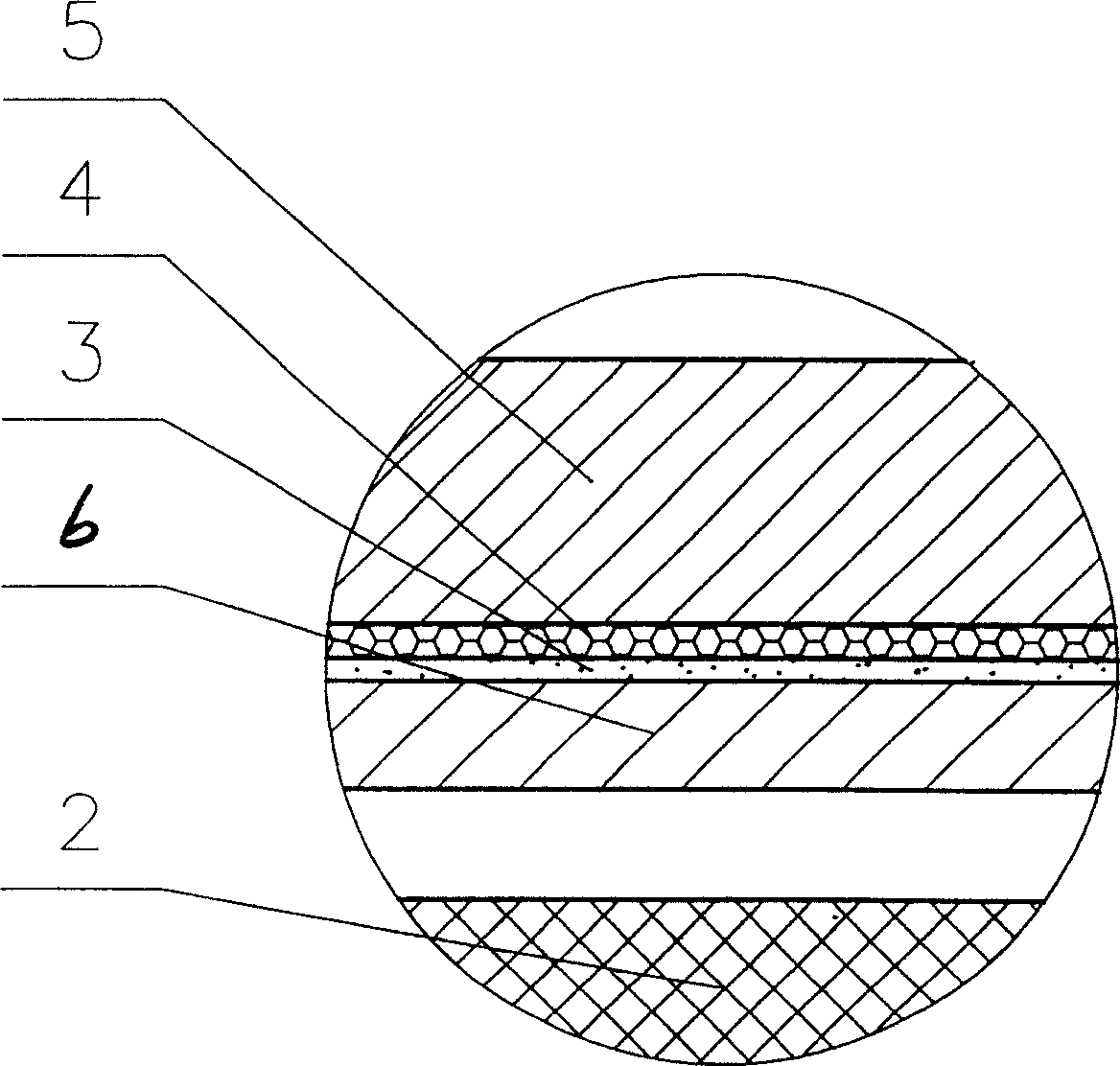

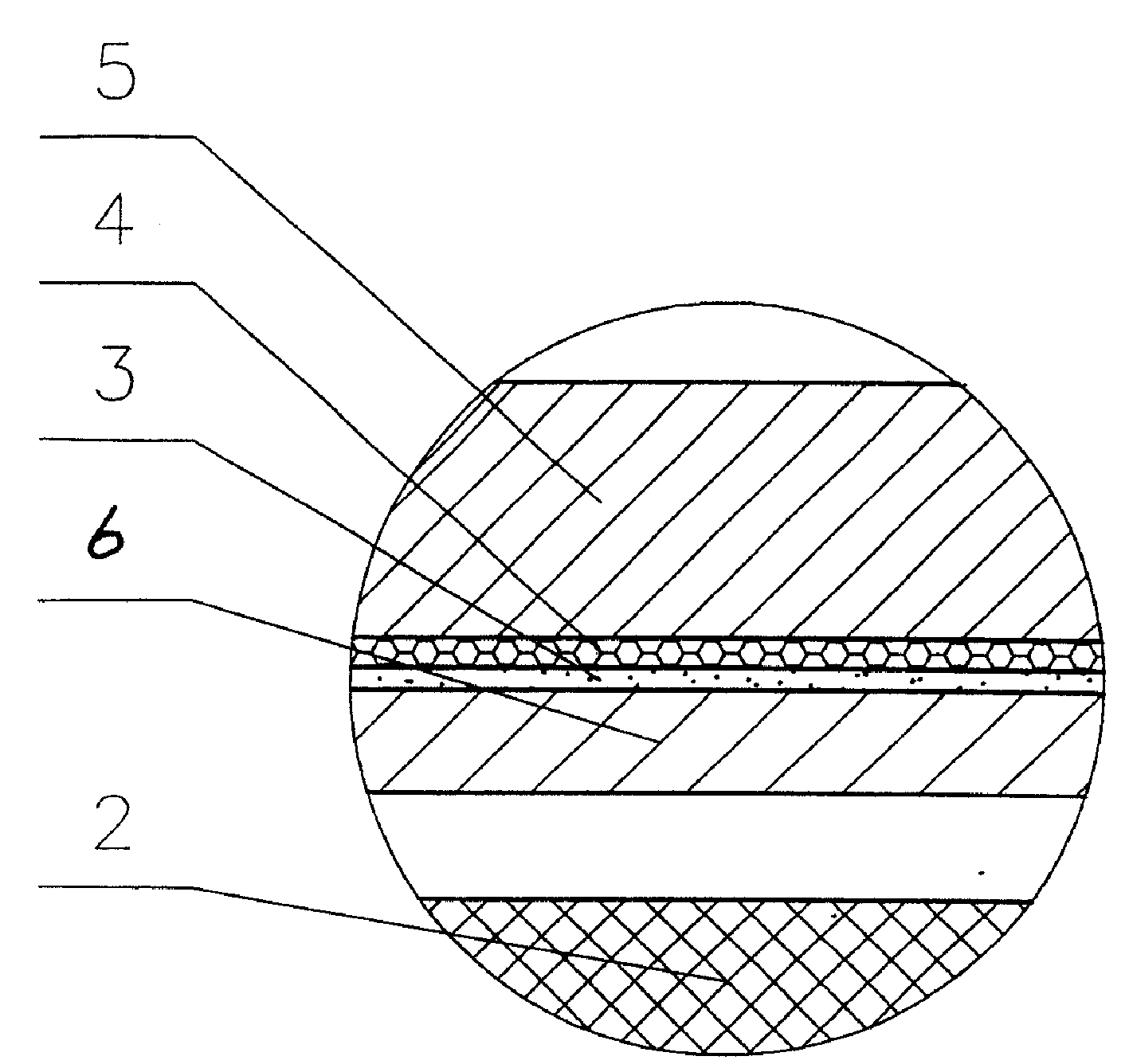

[0010] Referring to Figure 1, figure 2 It can be seen that the planar carbon commutator of the present invention includes a commutator segment 1, a molding compound 2, and a carbon block 5, and the body 6 of the commutator segment 1 is perpendicular to the rotation axis (O axis) of the commutator. The segment 1 is arranged in the molding compound 2 and exposes the outer surface of the body 6 of the commutator segment, and the outer surface of the body 6 of the commutator segment is plated with a silver-copper alloy layer 3 (its function is to increase the thickness of the body of the commutator segment). outer surface roughness), the silver-copper alloy layer 3 is coated with a mixed strong adhesive layer 4, and the carbon block 5 is arranged on the mixed strong adhesive layer 4. Wherein, the commutator segment 1 is made of a silver-copper alloy material, the silver-copper alloy layer 3 is formed of a silver-copper alloy that is the same as or similar to the material of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com