Slightly-arched seam crossing type bridge continuous seam structure

A bridge and seam-spanning technology, which is applied in the field of continuous seam structure of micro-bow-span bridges, can solve problems such as lack of consideration, lack of support for rubber plates, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

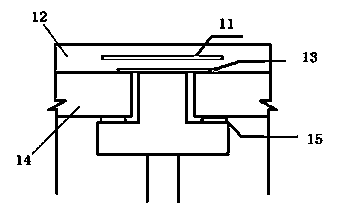

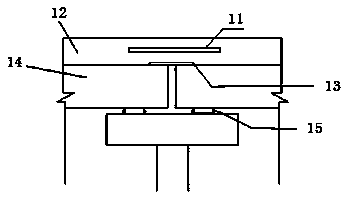

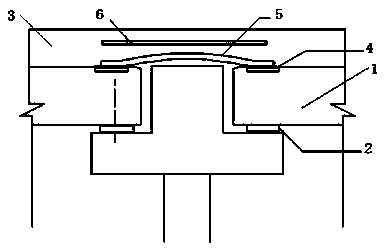

[0005] It includes beam 1, support 2 and pavement layer 3, and is characterized in that a pre-embedded steel plate 4 is arranged on the upper surface of the beams on both sides, and the center line of the pre-embedded steel plate and the center line of the lower support are located on the same vertical plane. There is a micro-arch cross-line steel plate 5, the two contact surfaces of the micro-arch cross-line steel plate are welded to the pre-embedded steel plates of the two side beams, the middle of the micro-arch cross-line steel plate is slightly arched, and the two ends of the reinforcing rib 6 in the pavement adopt gradual densification set up. It is characterized in that: the width of the pre-embedded steel plate is 300mm, the thickness of the pre-embedded steel plate is 10mm, the width of the two contact surfaces of the micro-bow cross-line steel plate is 150mm, its thickness is 10mm, and the highest bow height is less than 15mm. There are 8-10mm threaded steel bars wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com