Vibration equipment and concrete pouring vibration method for tall special-shaped column

An equipment and column technology, applied in the field of bridge construction, can solve the problems of infeasibility, high construction cost, impact on structural performance, etc., and achieve the effects of avoiding leakage and over-vibration problems, uniform color quality, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

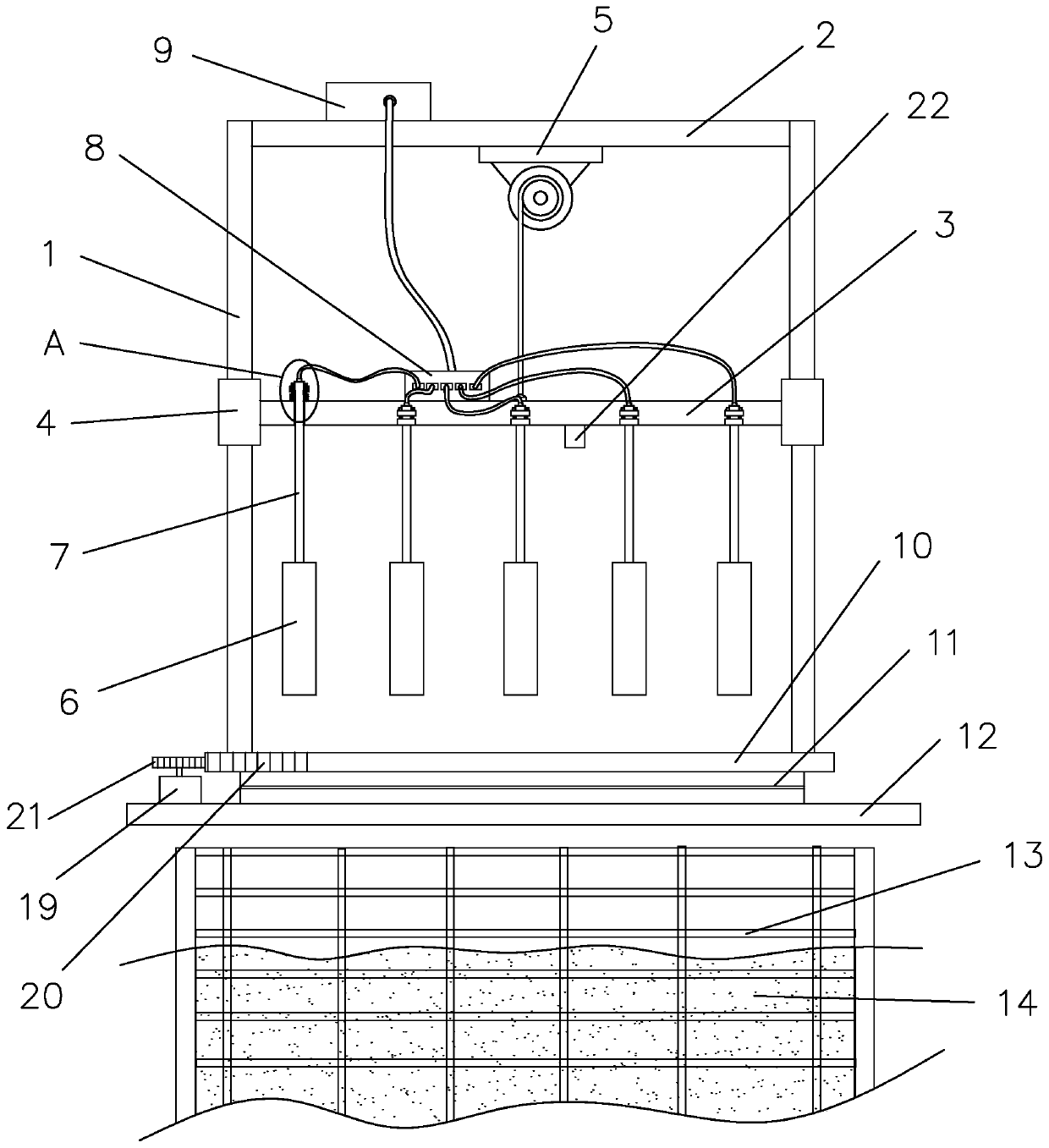

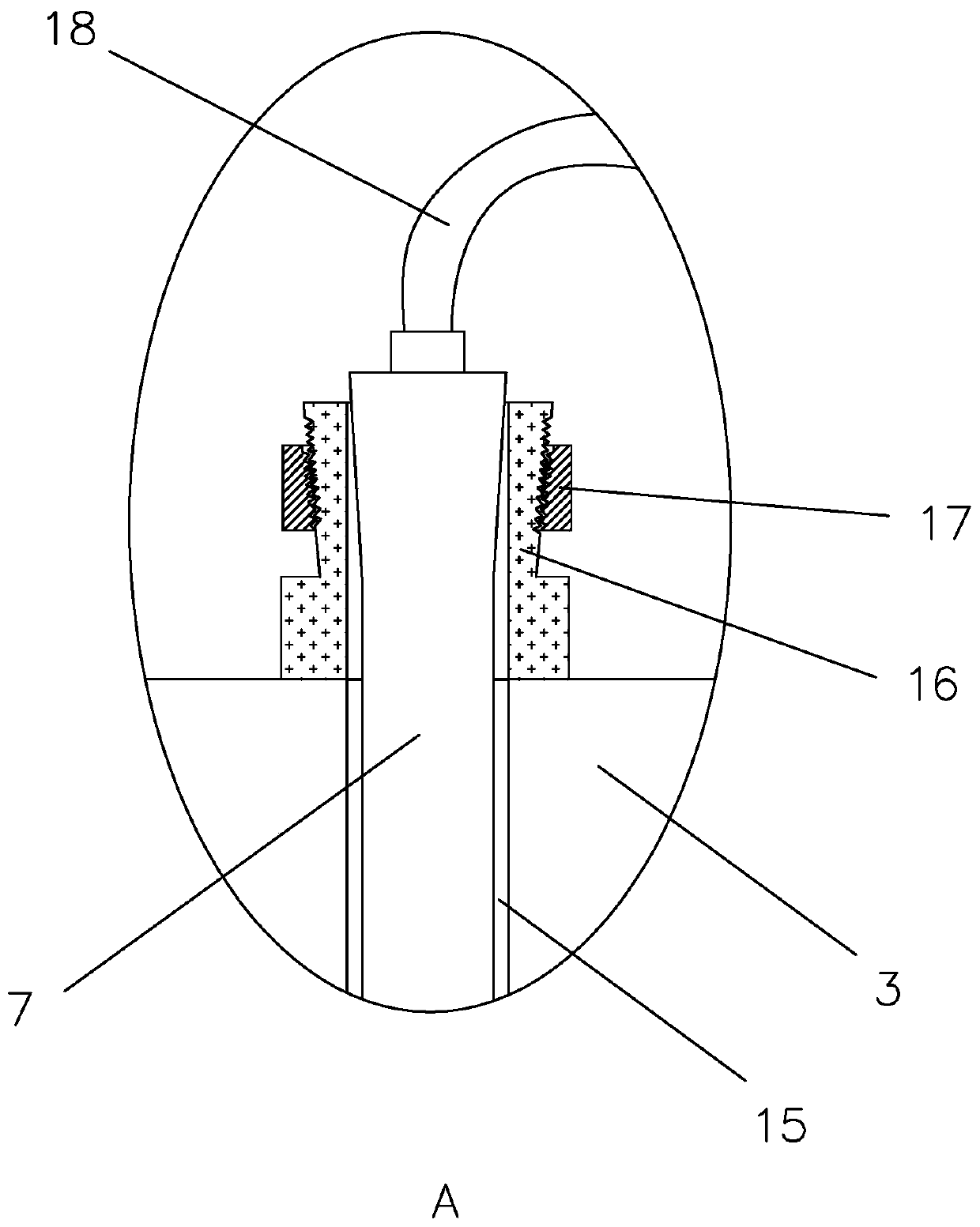

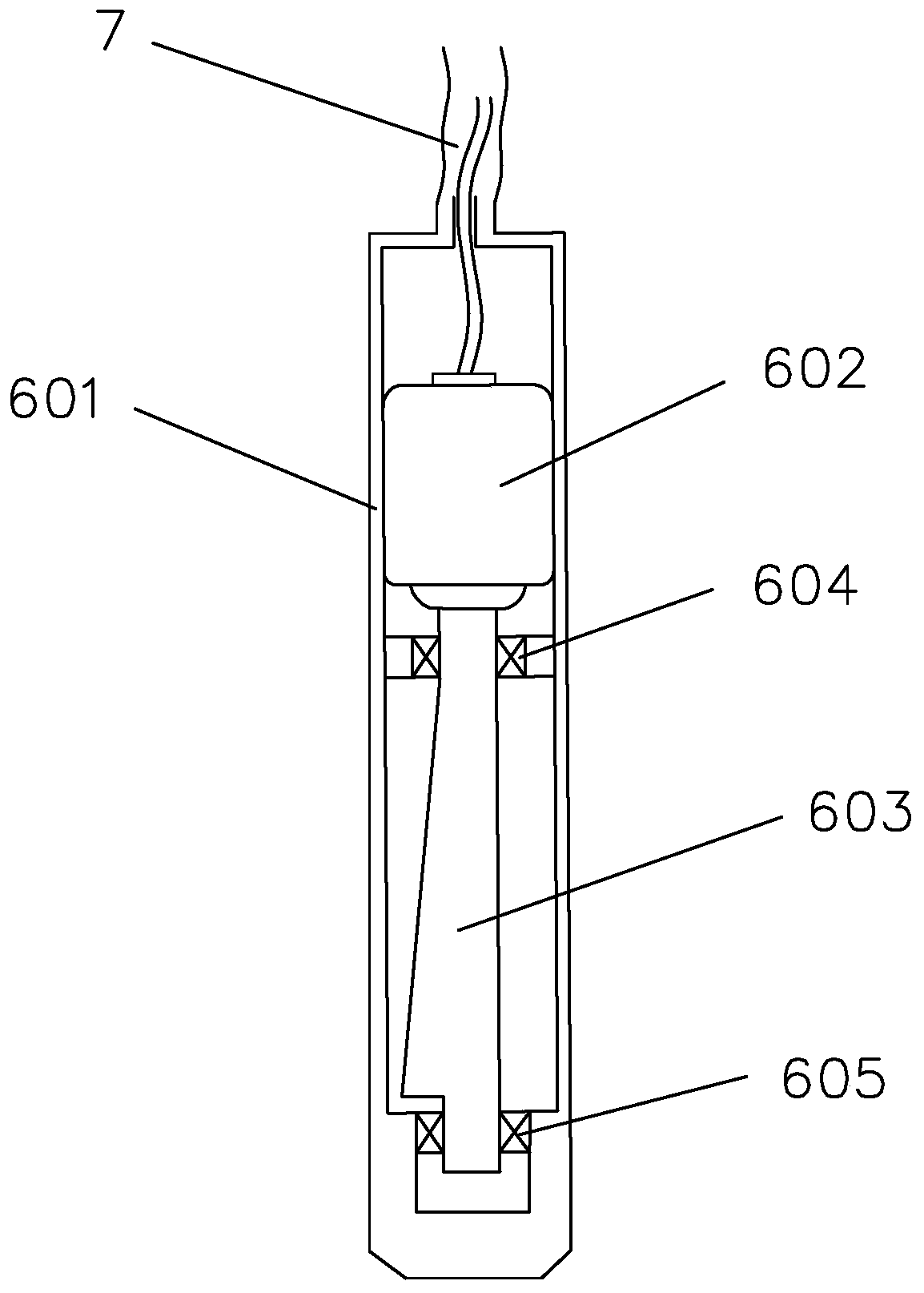

[0036] refer to figure 1 , a vibrating device, including a support frame, a driving mechanism and a vibrating system, the support frame includes at least a pair of vertically arranged support rods 1, the upper ends of each support rod 1 are connected and fixed by connecting beams 2, and the inner side of the support frame A suspension 3 is provided, and the edge of the suspension 3 is provided with a sleeve 4 slidingly sleeved on the support rod 1, so that the suspension 3 can move up and down, and the connecting beam 2 is installed and fixed for pulling the suspension 3 up and down. The lifting motor 5 of the lifting motor, the lifting motor 5 traction rope is connected and fixed with the suspension 3, and the vibrating system includes a plurality of vibrating rods 6, a main controller 9 for controlling the vibrating rods 6, and a plurality of vibrating rods 6 The tap 8 connected to the main controller 9, the vibrating rod 6 is suspended below the suspension 3, the upper end ...

Embodiment 2

[0043] Since the shape and area of the cross-section of the concrete with special-shaped columns at different heights are different, this vibrating method adopts the method of vibrating while injecting concrete into the reinforced grid frame, and needs to follow the As the concrete rises, the height of the vibrating rod is increased, so the vibrating method is designed as follows.

[0044] refer to Figure 6 , a method for vibrating tall and large special-shaped column concrete pouring, comprising the following steps:

[0045] S1. According to the height and shape of the column concrete, mark the height along its height direction;

[0046] S1. Use a crane to lift the vibrating equipment and erect it on the top of the reinforced grid, and determine the number and position of the vibrating rods installed on the suspension according to the cross-sectional area and shape of the vibrating area at the current height of the column ( That is, which installation holes should instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com