Underfilled magnetic liquid shock absorber adopting first-order buoyancy principle

A magnetic liquid and shock absorber technology, which is applied in the direction of magnetic spring, spring/shock absorber, spring, etc., can solve the problems that the mass block is difficult to suspend, the mass block is difficult to move, and cannot be applied, so as to increase the magnetic field gradient, Accelerates the consumption of vibration energy and is conducive to the effect of suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with accompanying drawing as specific embodiment:

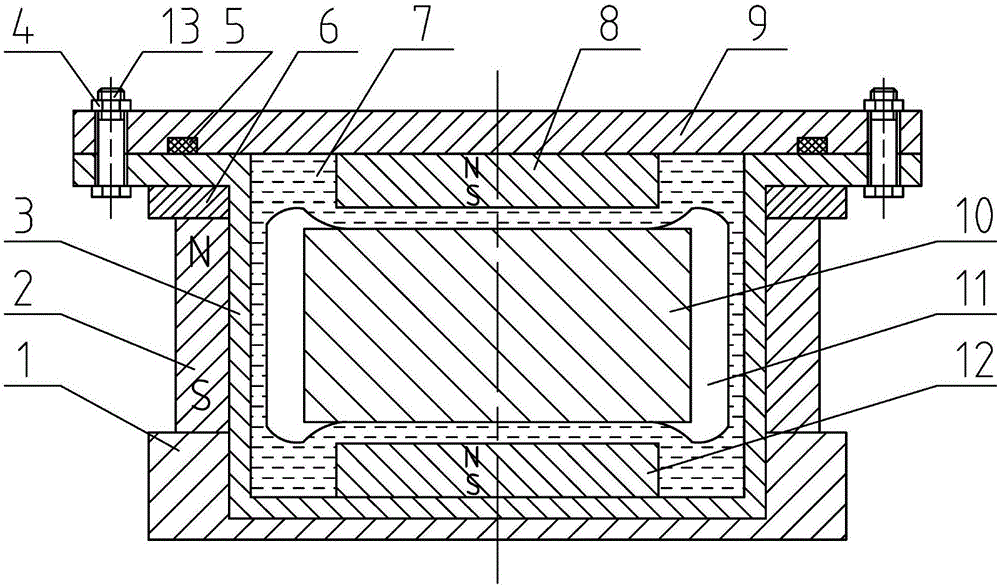

[0028] A non-filled magnetic liquid first-order buoyancy principle shock absorber, such as figure 1 , the damping device includes: a base 1, an annular permanent magnet 2, a housing 3, a nut 4, a sealing ring 5, a gasket 6, a magnetic liquid 7, a first circular permanent magnet 8, an end cover 9, a mass block 10, an empty Cavity 11, second circular permanent magnet 12, bolt 13. Connections between the parts making up the device:

[0029] The second circular permanent magnet 12 and the housing 3 are fixedly connected to the inner end surface of the bottom of the housing 3, and the connection method can be welding, bonding or threaded connection; insert the gasket 6 from the bottom of the housing 3 into the outer side of the housing 3 Next, insert the ring-shaped permanent magnet 2 from the bottom of the shell 3, and contact the gasket 6, and connect the base 1 with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com