Operation mechanism of self-propelled multifunctional border stone slip form machine

A working mechanism and curb stone technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of increased project cost, high slump requirements, and easy deformation of structures, so as to improve the tensile strength and enhance the compaction effect. , The effect of relative rotation and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

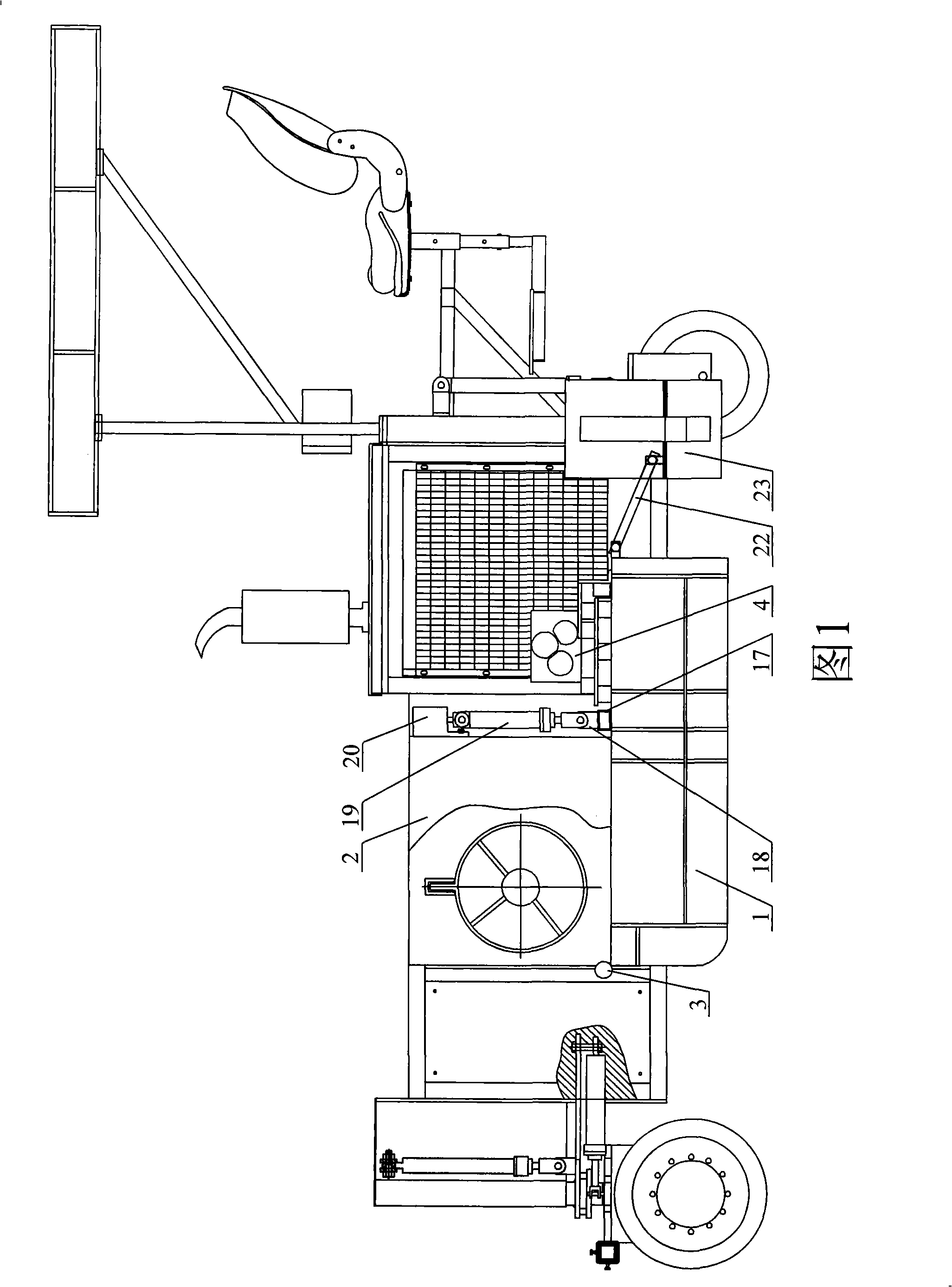

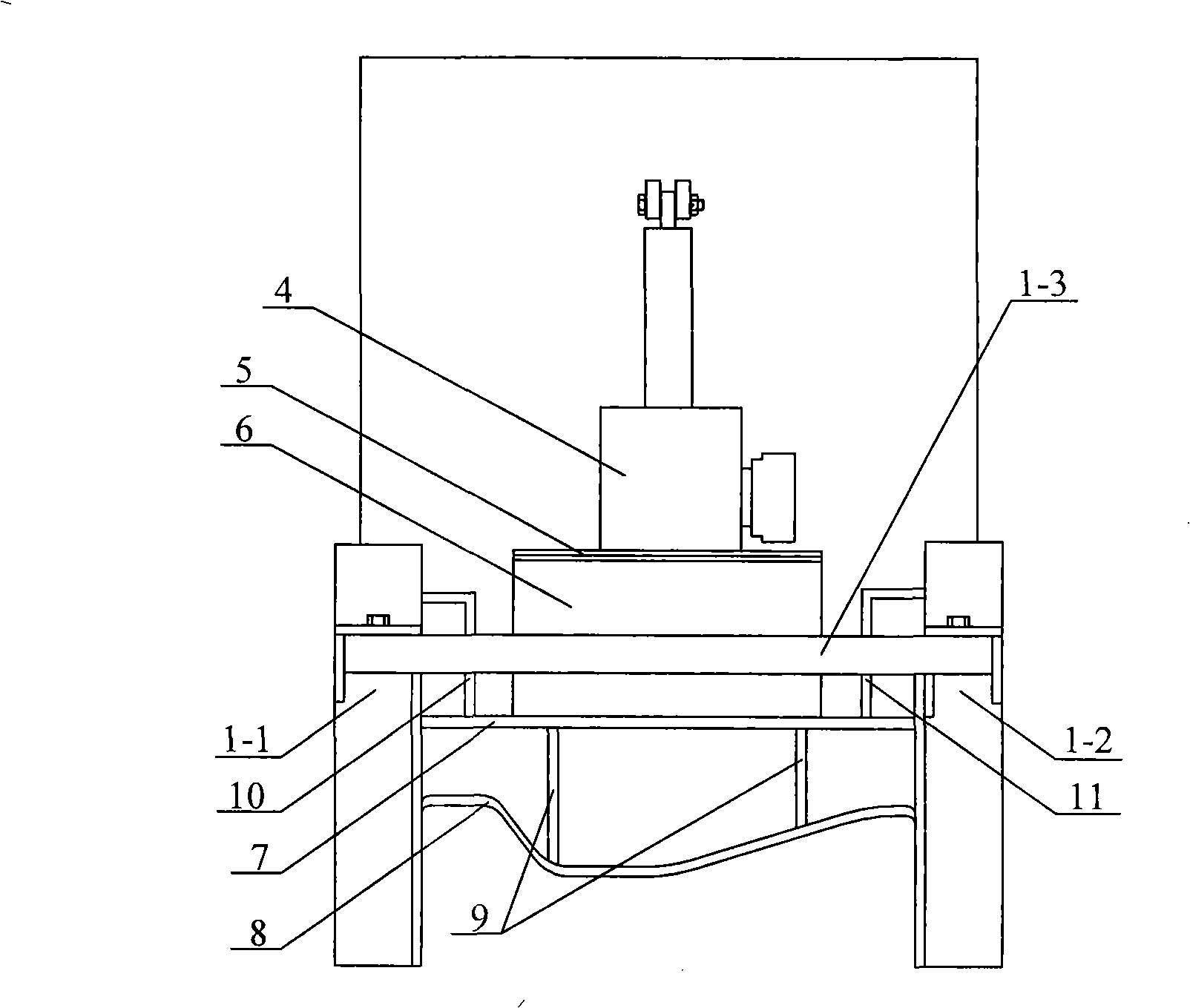

[0032] As shown in FIG. 1 , the forming mold 1 is arranged below the mold hopper 2 and hinged to the mold hopper 2 through a pivot device 3 . The pivot device 3 connects the front plate 1 - 3 of the forming mold 1 and the front side of the mold hopper 2 .

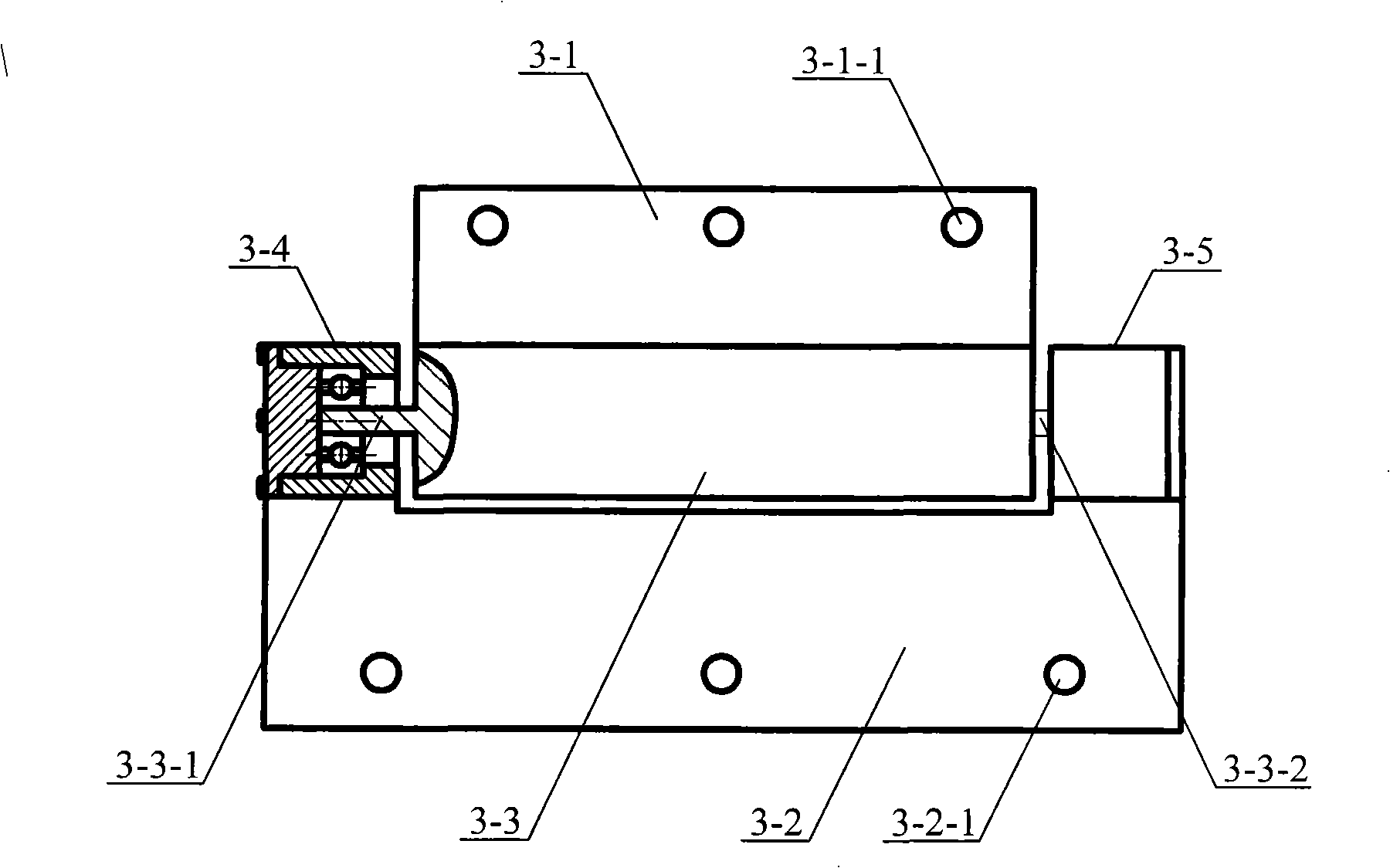

[0033] Such as figure 2As shown, the pivot device 3 includes an upper connecting plate 3-1, a lower connecting plate 3-2, a cylindrical shaft 3-3, a first bearing mechanism 3-4 and a second bearing mechanism 3-5. The lower side of the upper connecting plate 3-1 is welded to the outer surface of the cylindrical shaft 3-3 along the length direction of the cylindrical shaft 3-3. The first bearing mechanism 3-4 and the second bearing mechanism 3-5 are welded on the upper side of the lower connecting plate 3-2. A first connecting shaft 3-3-1 is arranged at one end of the cylindrical shaft 3-3, and a second connecting shaft 3-3-2 is arranged at the other end. The above-mentioned cylindrical shaft 3-3 is arranged between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com