Rotor mechanical pumping foam proportional mixing device

A proportional mixing device and mechanical pump technology, which is applied to mechanical equipment, rotary piston type/oscillating piston type pump parts, pump elements, etc., can solve the problems of large volume, achieve small volume, reduce installation space, and cleanliness less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

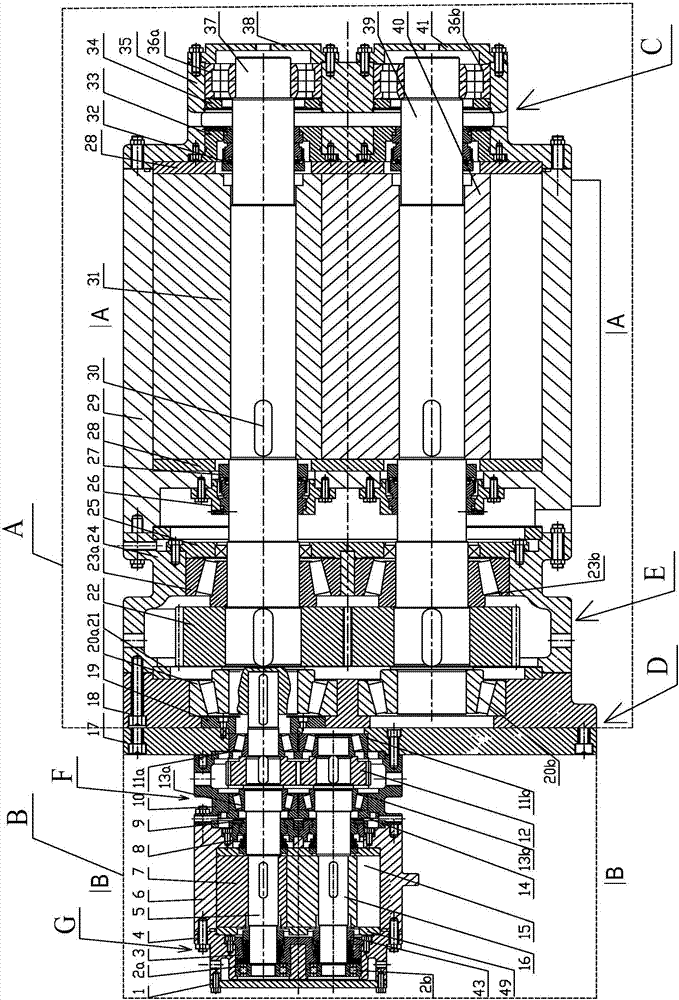

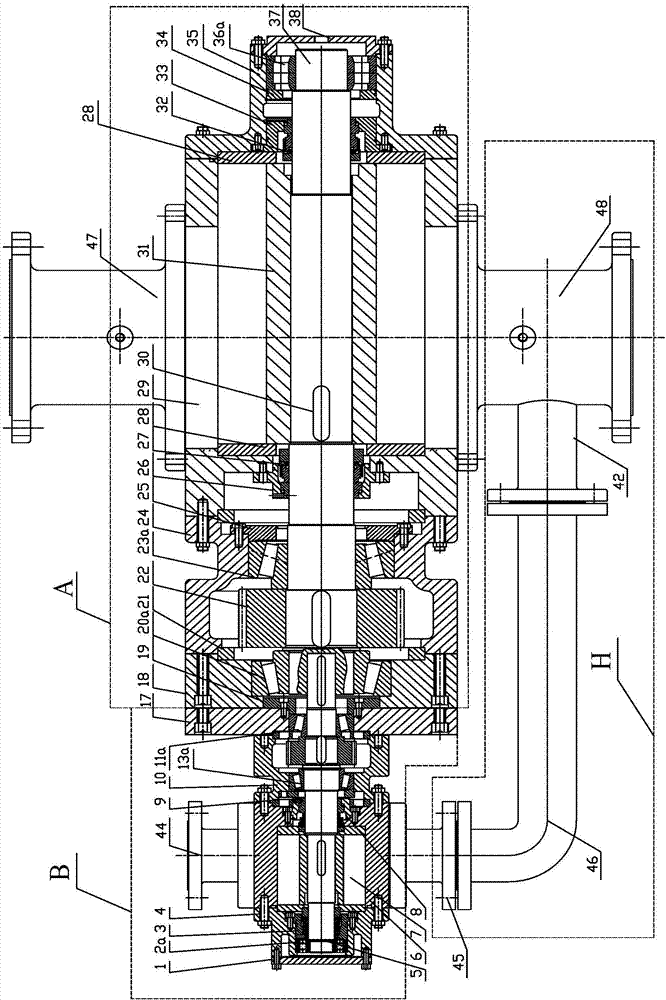

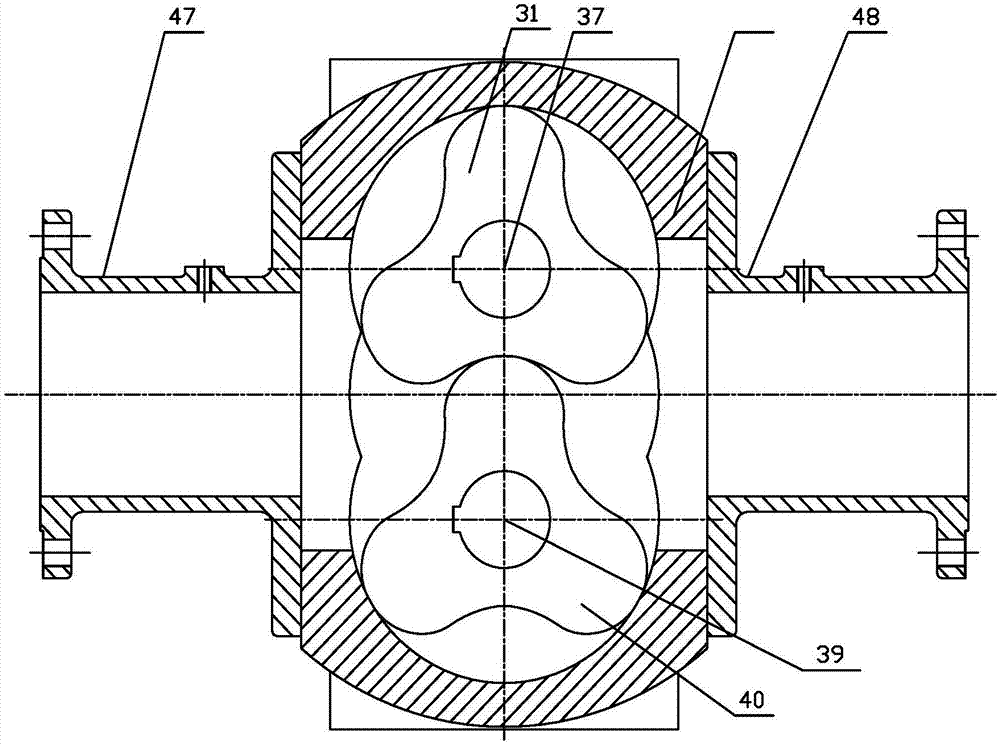

[0069] A rotor mechanical pump-in foam proportional mixing device of the present invention will be described in detail below in conjunction with examples and accompanying drawings.

[0070] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of rotor mechanical pumping type foam proportional mixing device of the present invention includes: a hydraulically driven rotor type water turbine A powered by fire-fighting water, through an intermediate bearing mechanism D and the hydraulically driven rotor type water turbine A. The drive output shaft is connected to the foam rotor pump B used to pressurize the normal-pressure foam and discharge it, and is connected to the water outlet of the hydraulically driven rotor turbine A and the liquid outlet of the foam rotor pump B respectively, and is used to output the fire-fighting mixture. The mixed liquid export mechanism H, wherein, the hydraulically driven rotor type water turbine A and the foam rotor pump B are both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com