Patents

Literature

43 results about "Screw turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The screw turbine is a water turbine which uses the principle of the Archimedean screw to convert the potential energy of water on an upstream level into work. It may be compared to the water wheel. The turbine consists of a rotor in the shape of an Archimedean screw which rotates in a semicircular trough. Water flows into the turbine and its weight presses down onto the blades of the turbine, which in turn forces the turbine to turn. Water flows freely off the end of the turbine into the river. The upper end of the screw is connected to a generator through a gearbox.

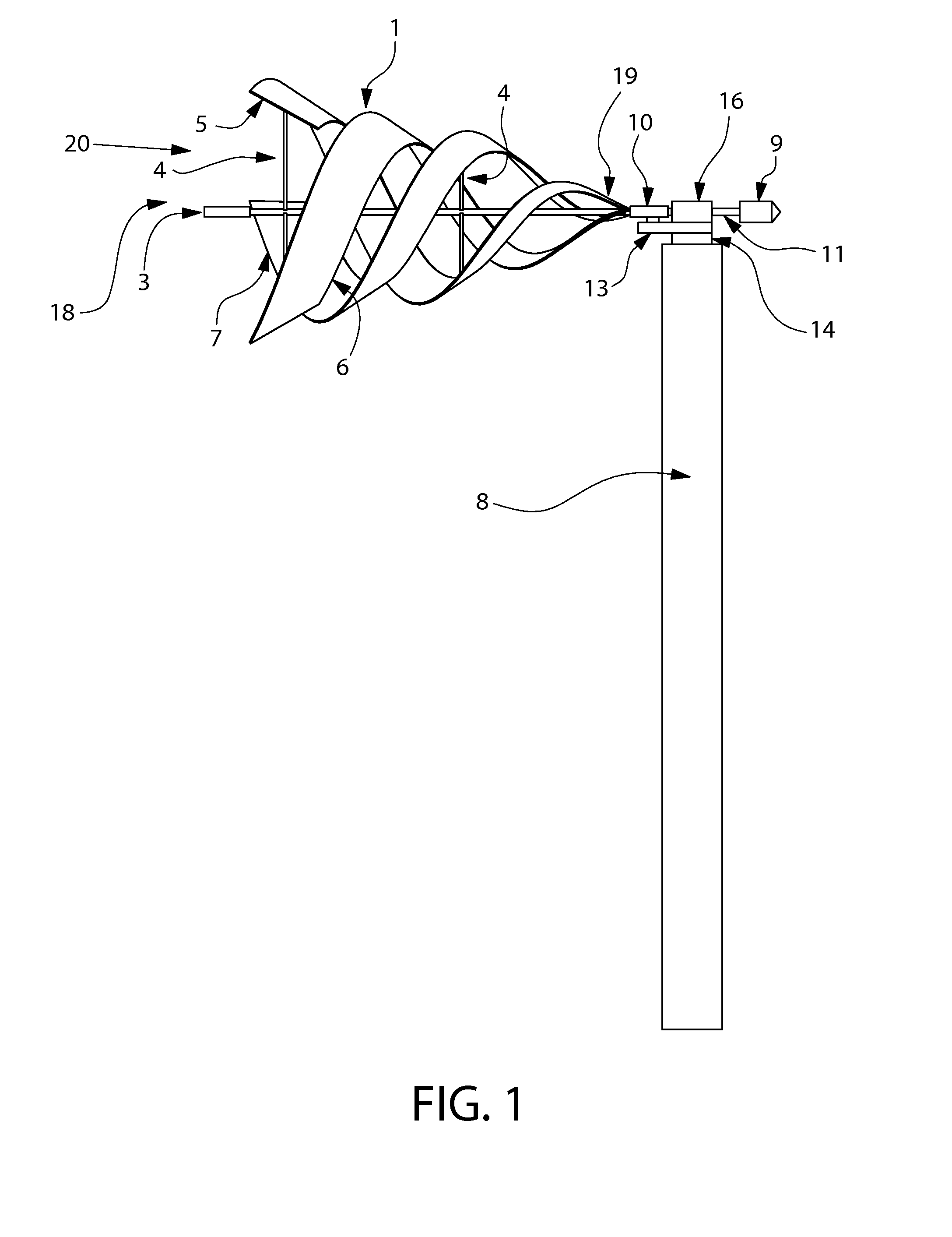

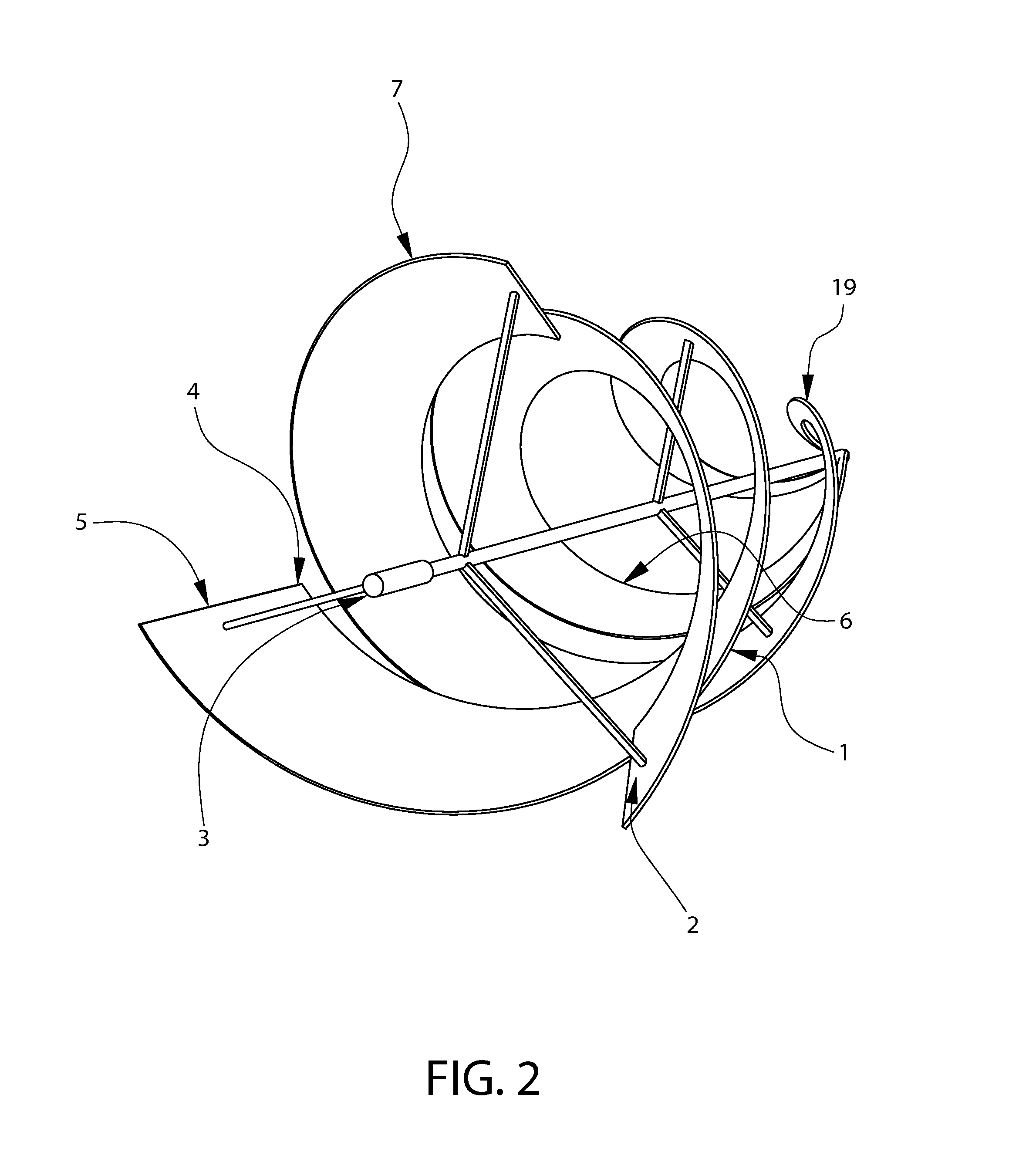

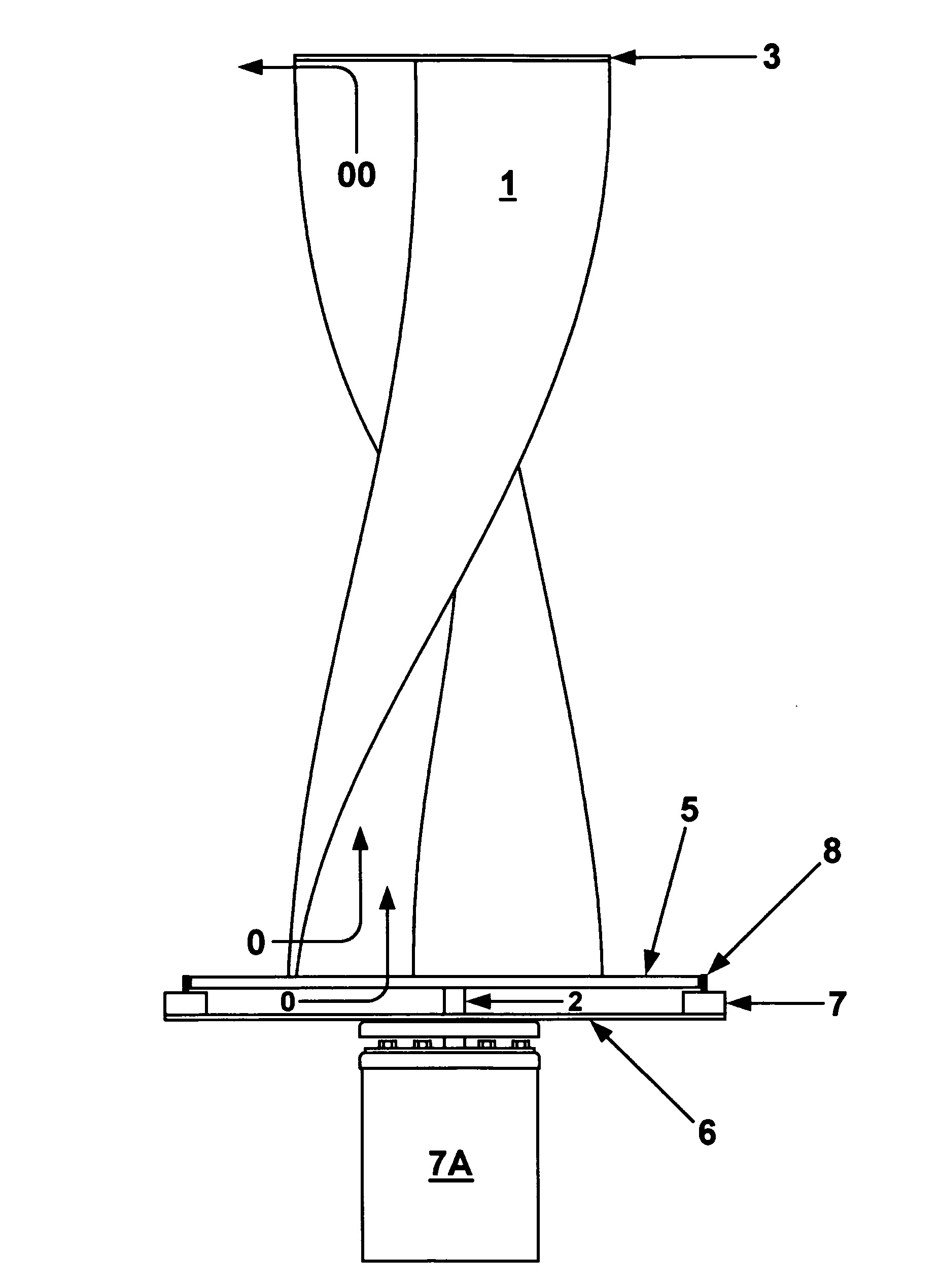

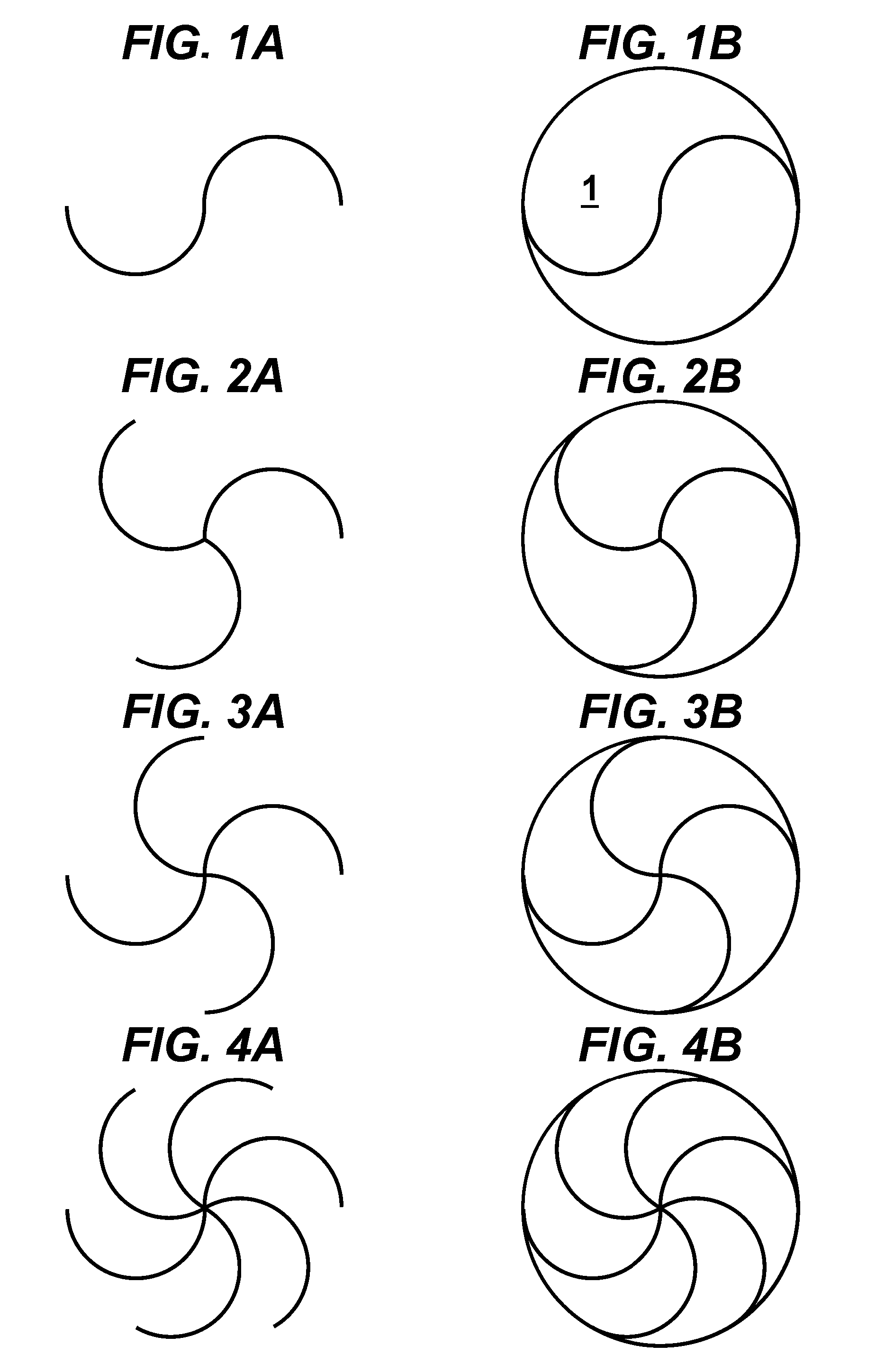

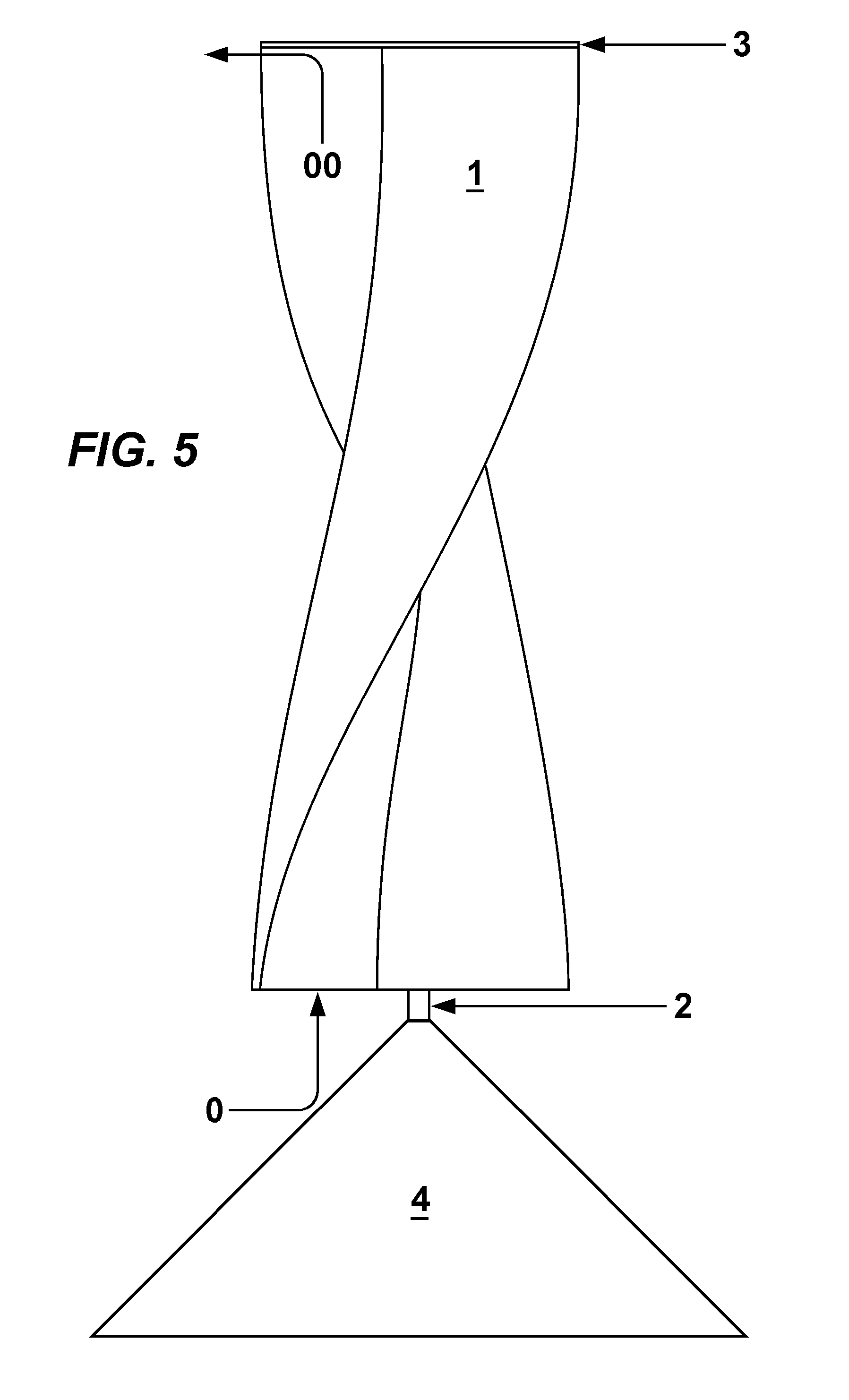

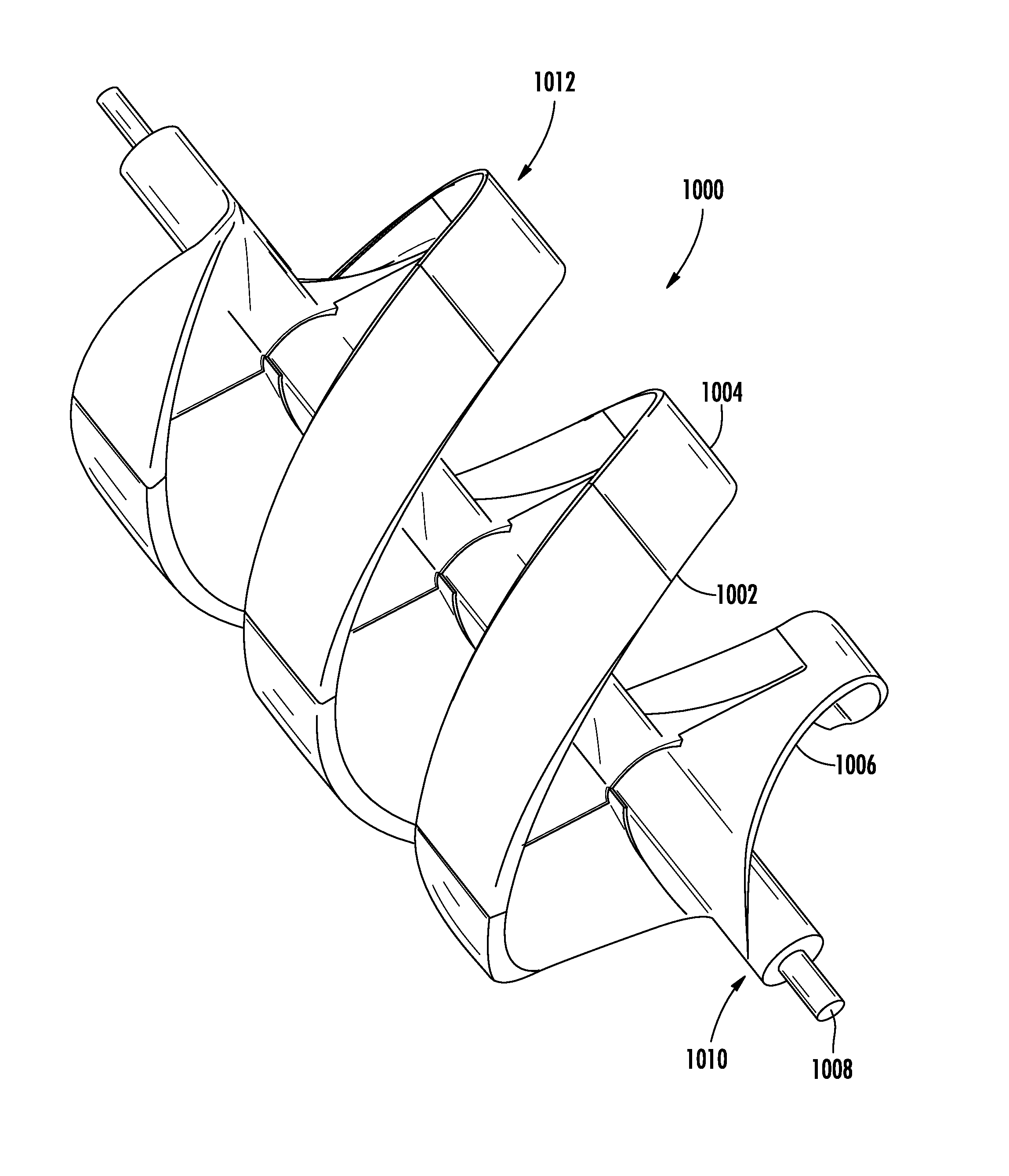

Helix Turbine System and Energy Production Means

InactiveUS20110006542A1Improve efficiencyEasy to capturePropellersWind motor controlScrew turbineDrive shaft

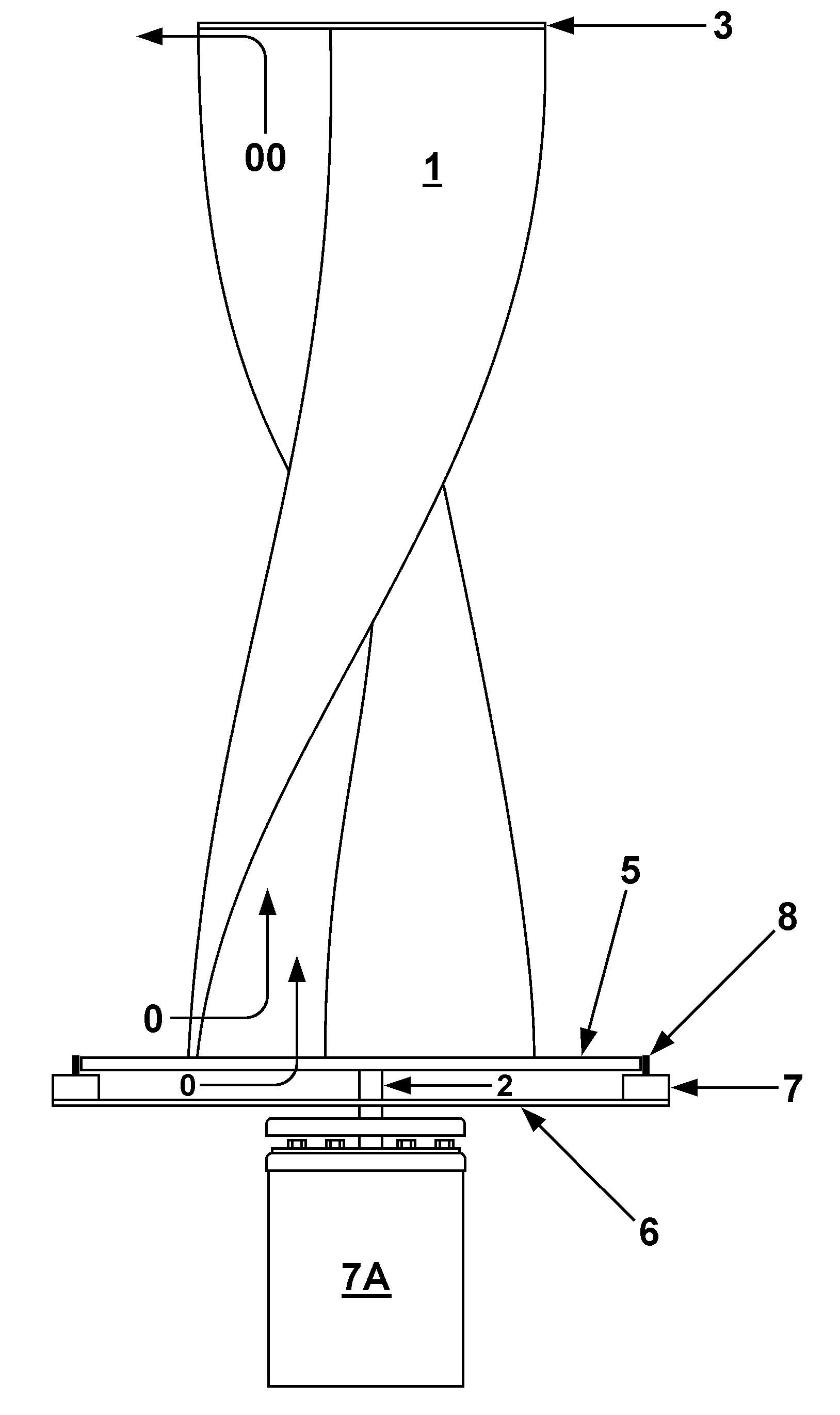

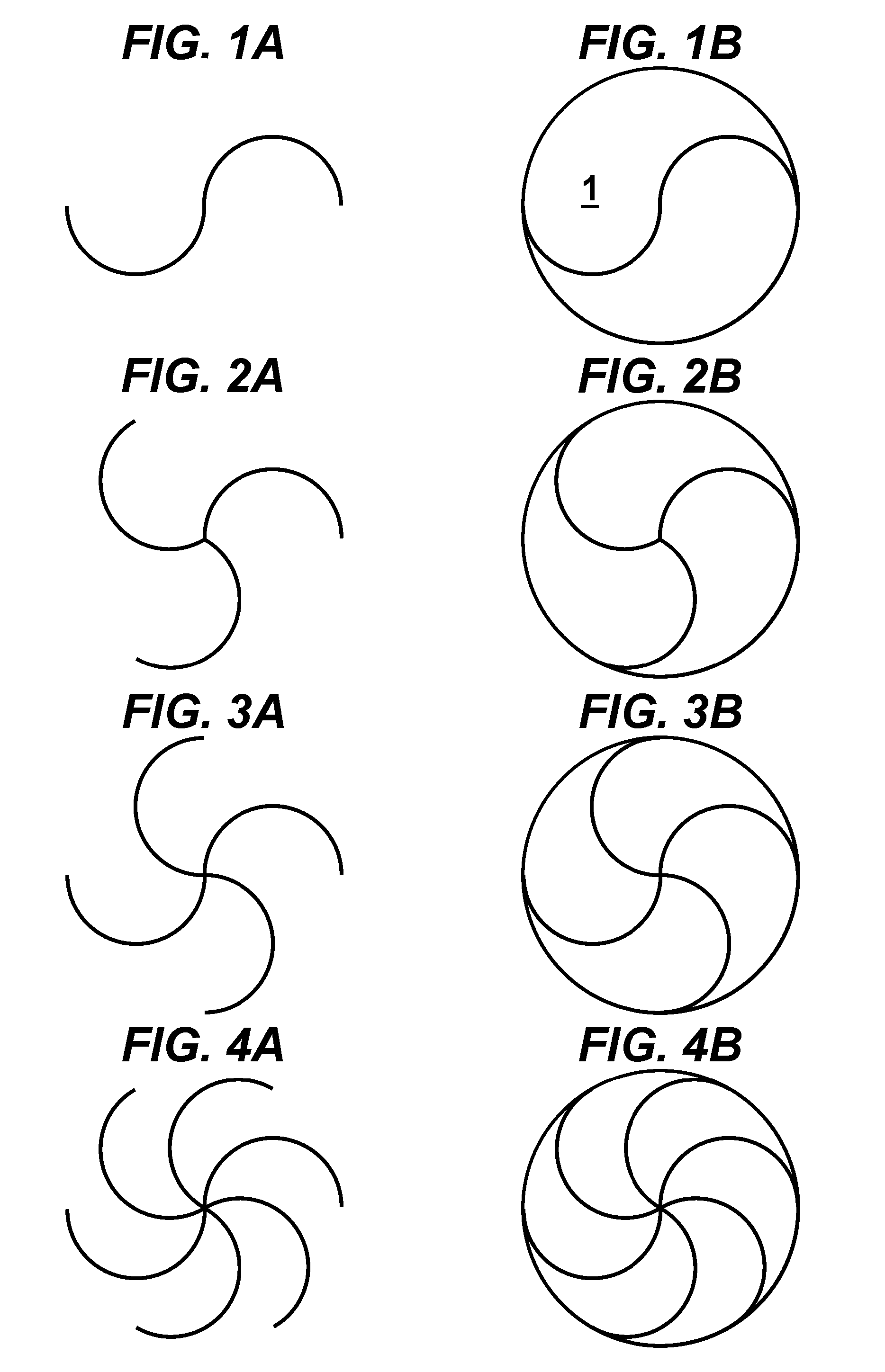

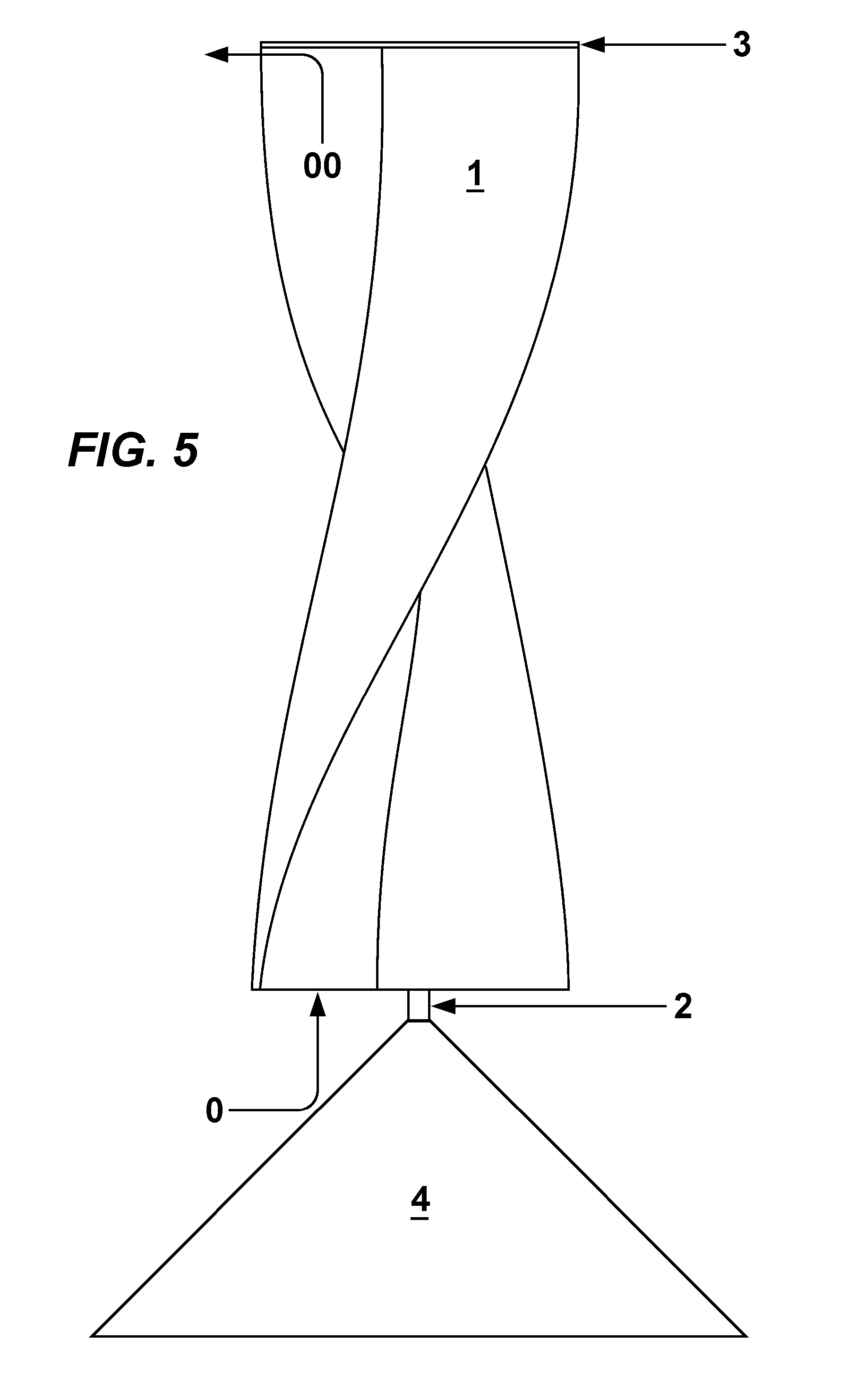

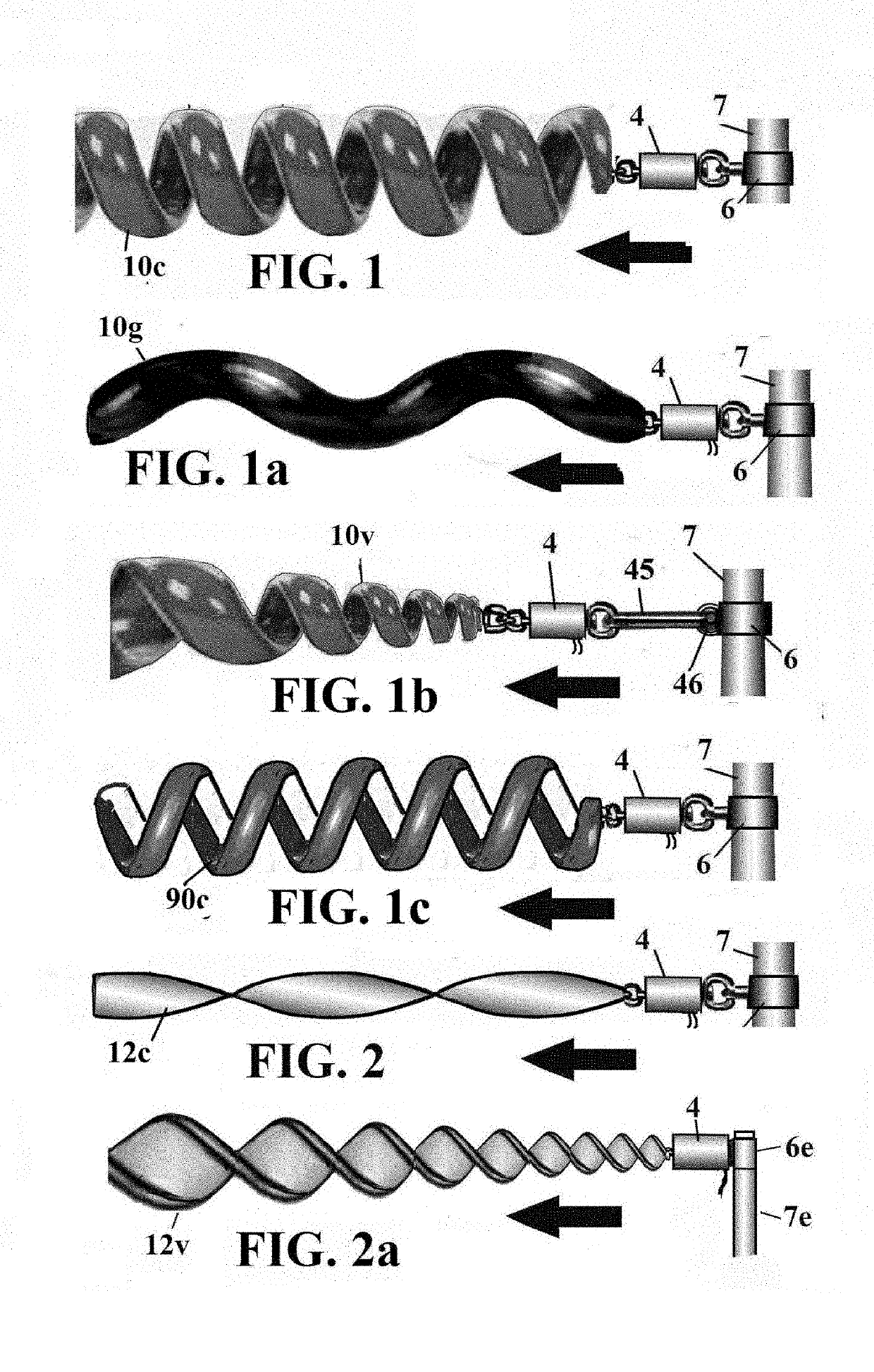

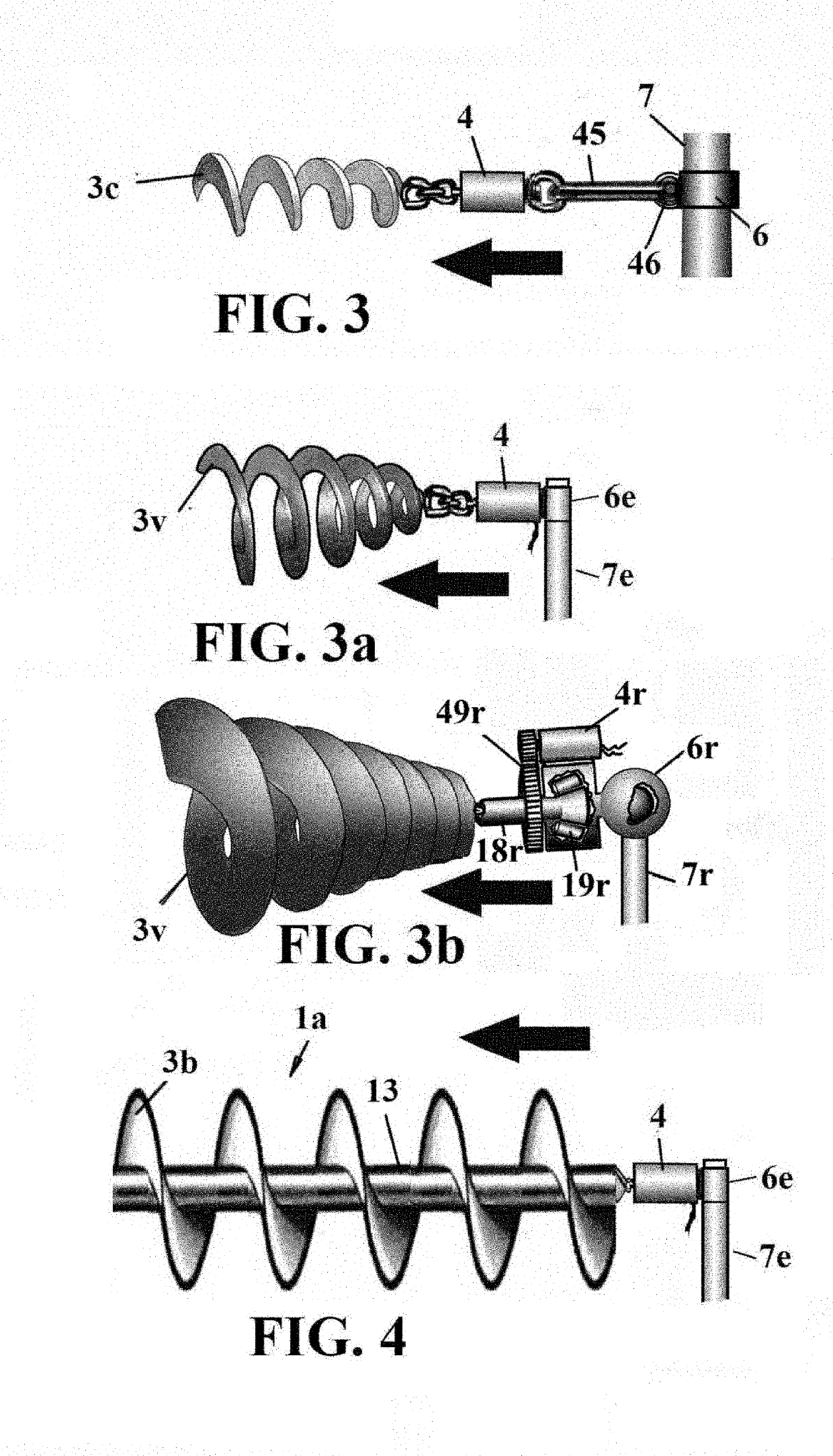

A helical turbine with a circular member attached to one end for redirecting axially flowing fluid into perpendicularly flowing fluid. A fluid diverter for redirecting substantially perpendicular flowing fluid into axially flowing fluid. A hollow circular member attached to an opposite end of the turbine allowing substantially axial flowing fluid into one end of turbine. A drive shaft of at least one generator is in continuous contact with the peripheral edge of the solid or hollow circular member producing faster rpm. A turbine assembly mounted on a rooftop utilizing accelerated wind. Fluid diverters increasing fluid flow into the helical turbine's receding blades. A fluid diverter preventing fluid from hitting turbine's oncoming blades. A tail section for maintaining optimal direction into oncoming fluid. Two counter rotating turbines where the attached circular member's edges are in continuous contact. Multiple turbine body assemblies, using different combinations of disclosed elements, produce multiple preferred embodiments.

Owner:BURRELL IV JAMES W

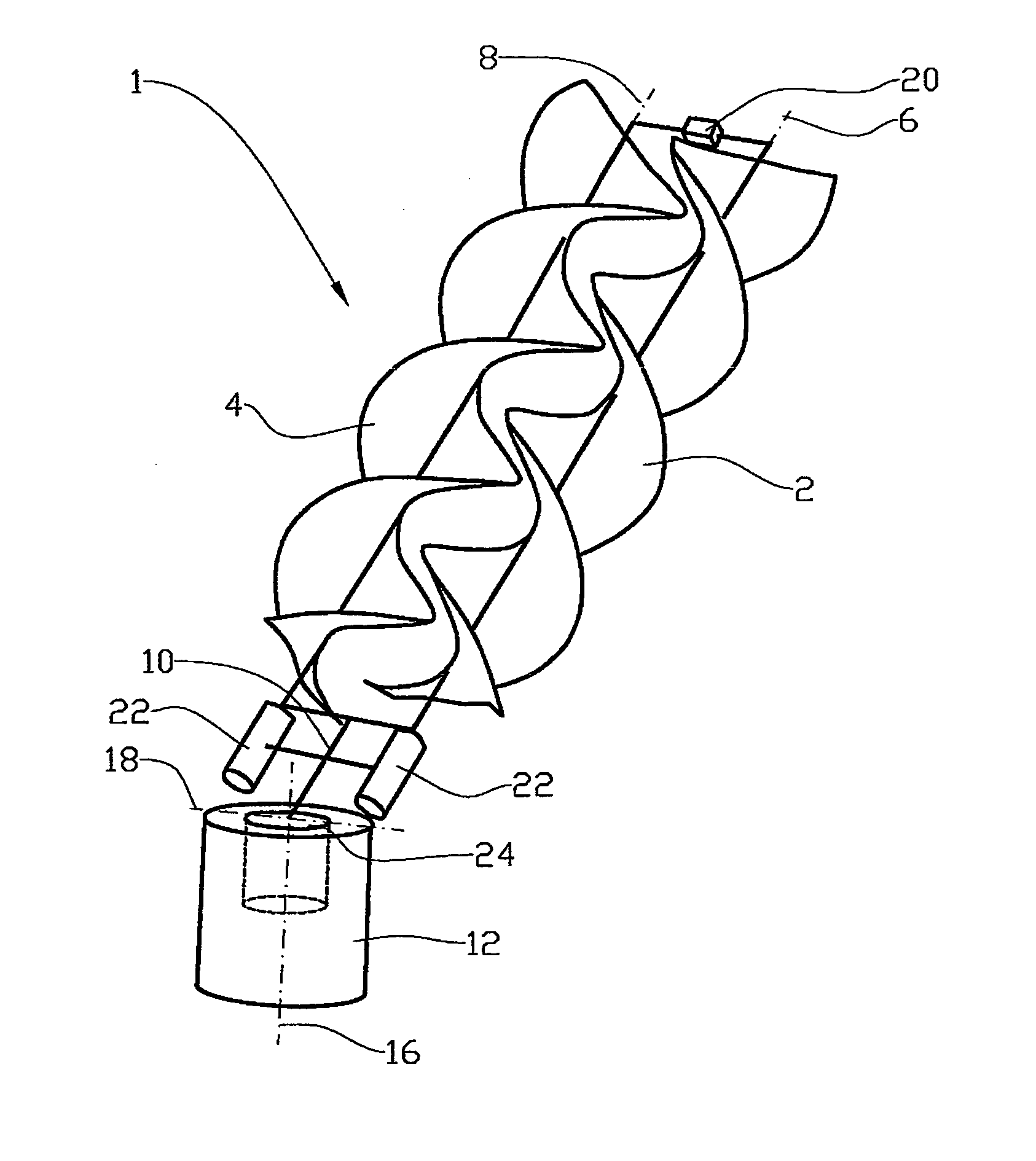

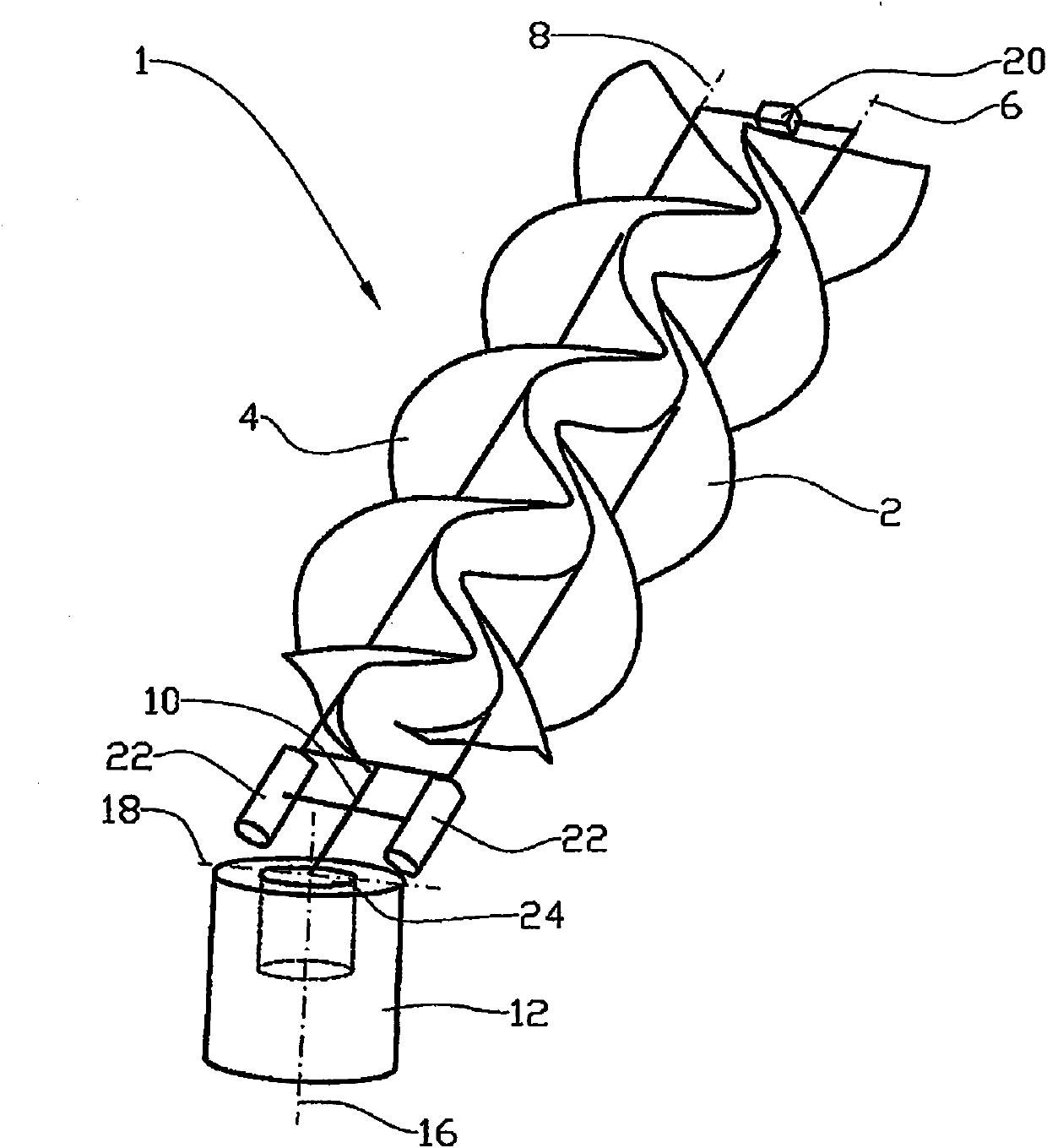

Spiral screw fluid turbine having axial void

A spiral turbine includes an axle configured to rotate and one or more spiral blades coupled to the axle by one or more support connections. Each spiral blade is formed around and outside of a conical inner space which is coaxial with the axle.

Owner:RAJAKARUNA UPPALA

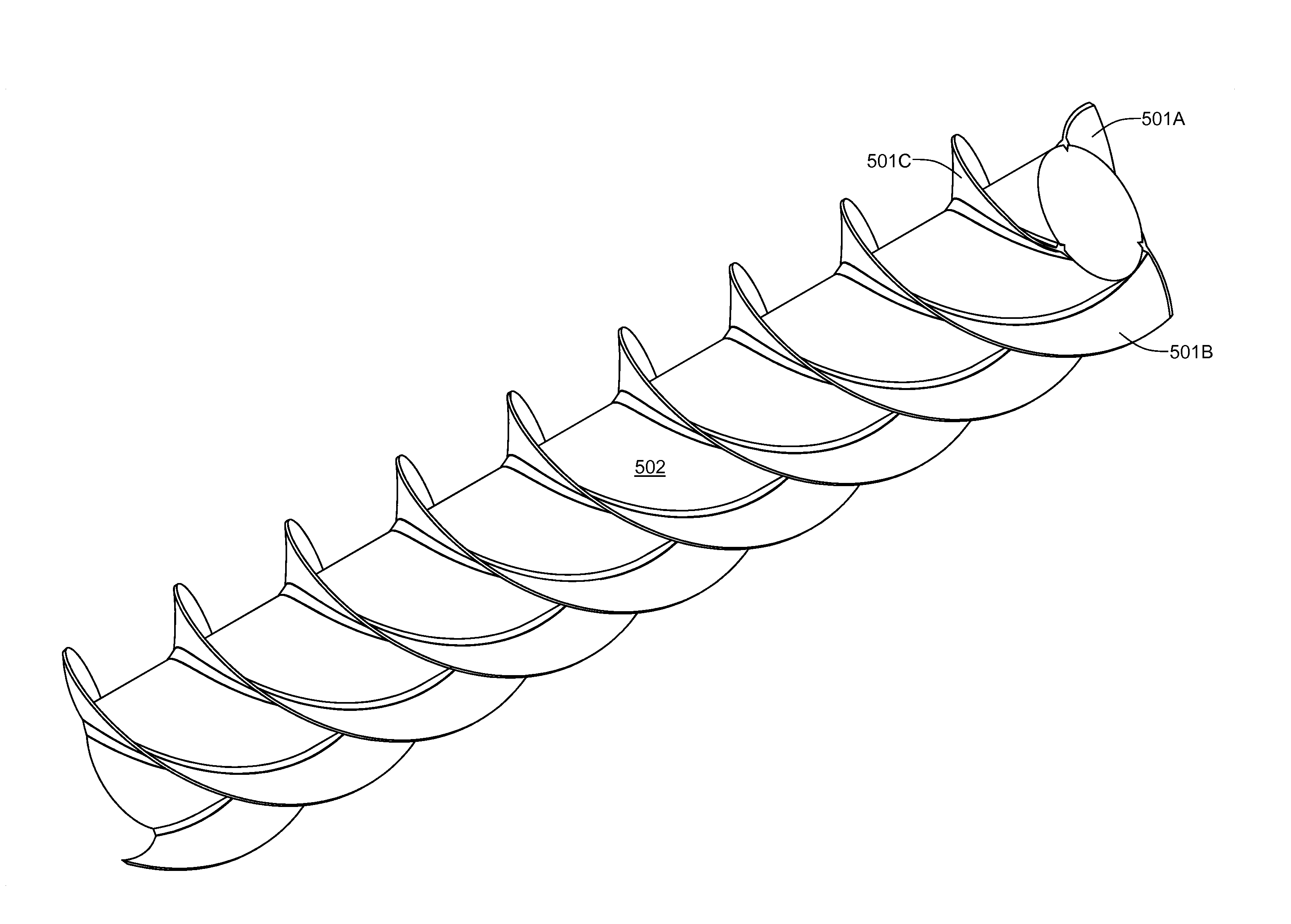

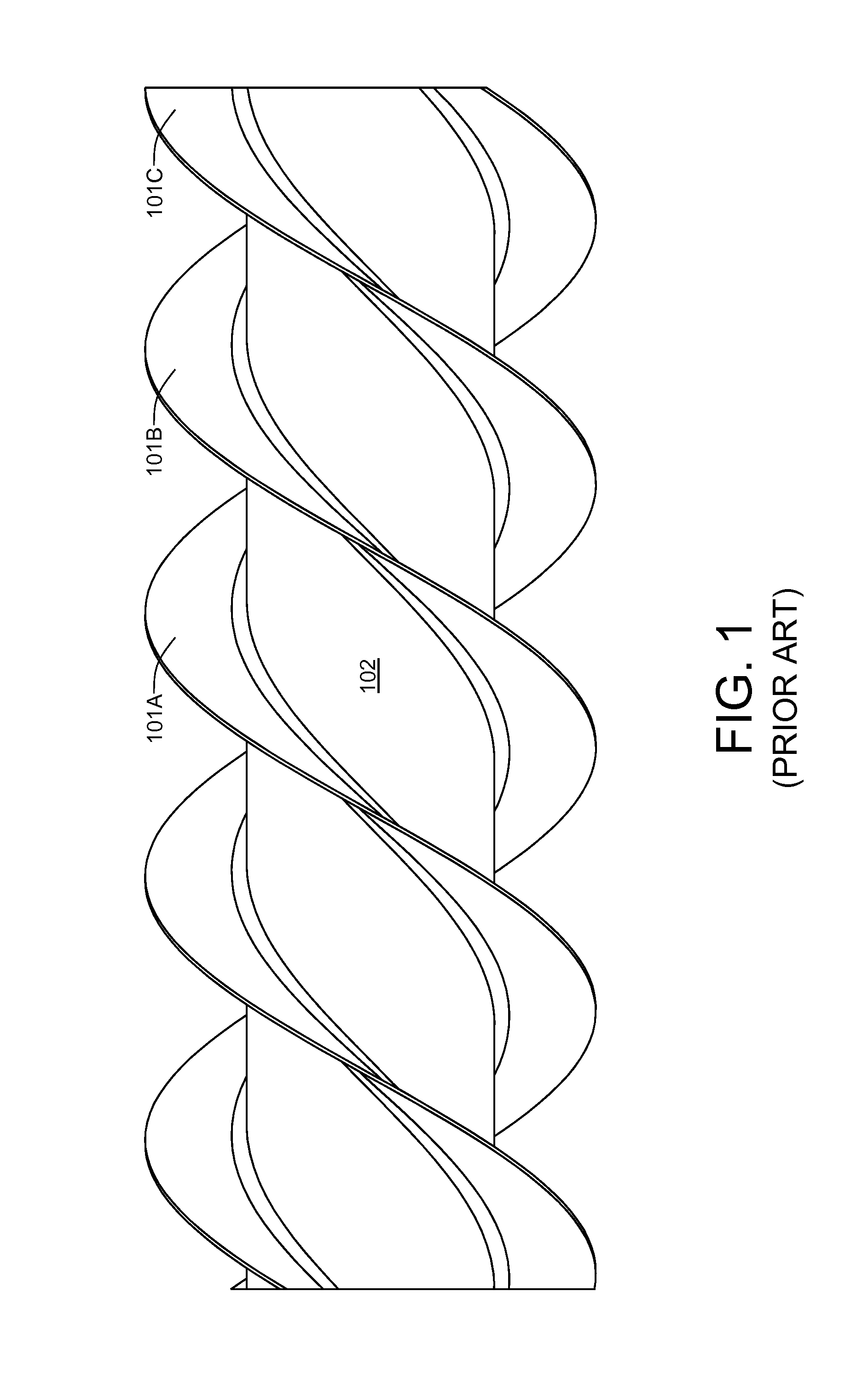

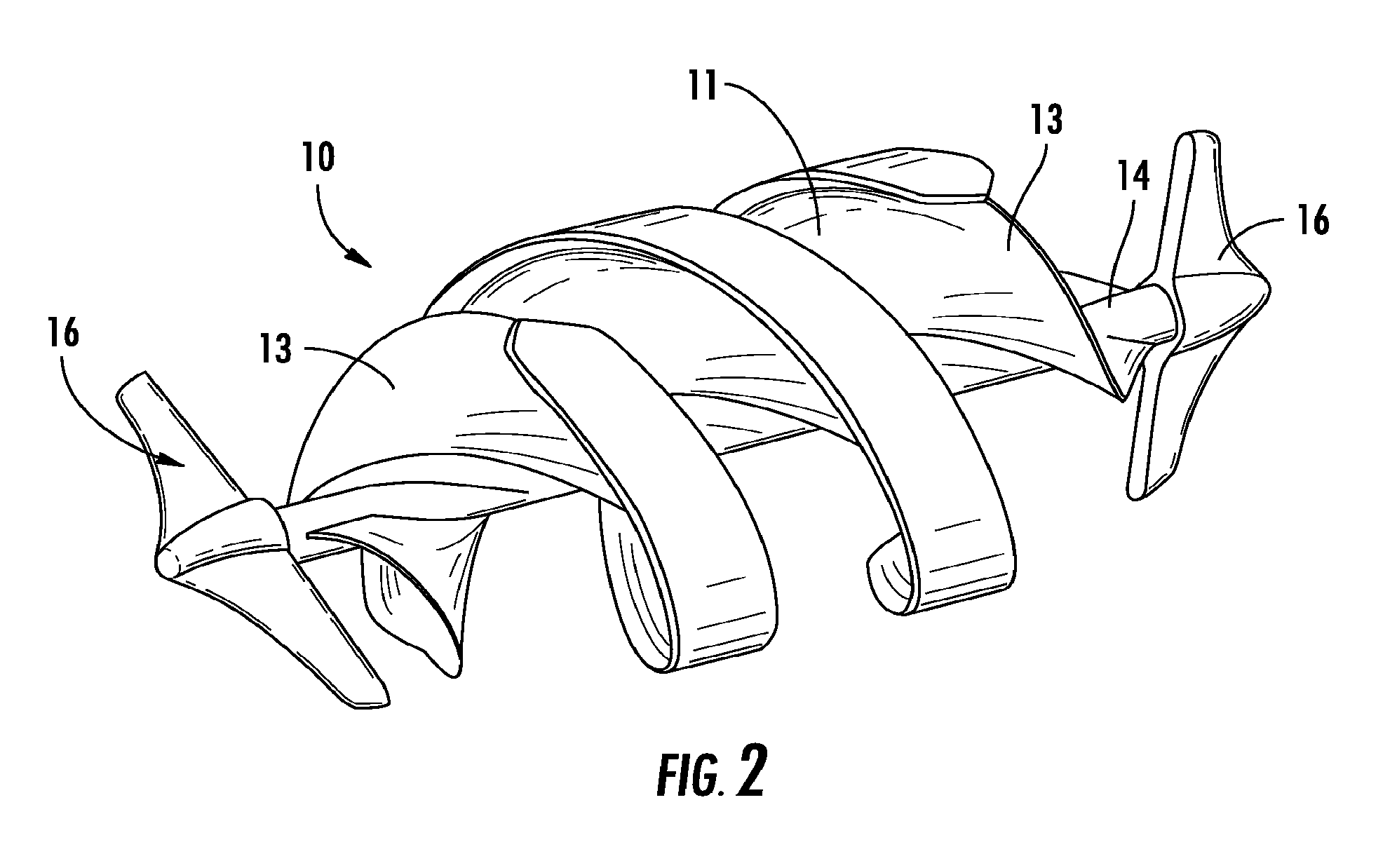

Archimedes screw turbine generator

InactiveUS20140265337A1Improve efficiencyEfficient powerGas turbine plantsHydro energy generationScrew turbineThree-phase

An Archimedean screw turbine generator of increased efficiency is disclosed. Rather than having the helical flighting of the turbine perpendicular to the central torque tube, this design incorporates cupped or cambered flighting. This increases the turbine's overall efficiency, as well as its efficiency across a broad range of fluid flows. The improved Archimedean screw turbine produces efficient power from about 5 percent of design flow to about 110 percent of design flow. In addition, design flow efficiency is 9-10 percent better than existing Archimedean screw generators. Prior art turbines of the Archimedean screw type operate efficiently only near design-rated flows. Most are turned off if flows drop more than 30 percent below deign-rated flow figures. For a presently-preferred embodiment of the invention, the screw axially rotates within a close-fitting half pipe. A three-phase permanent-magnet AC servo motor is used as a generator.

Owner:HARDING ROBERT WARD +1

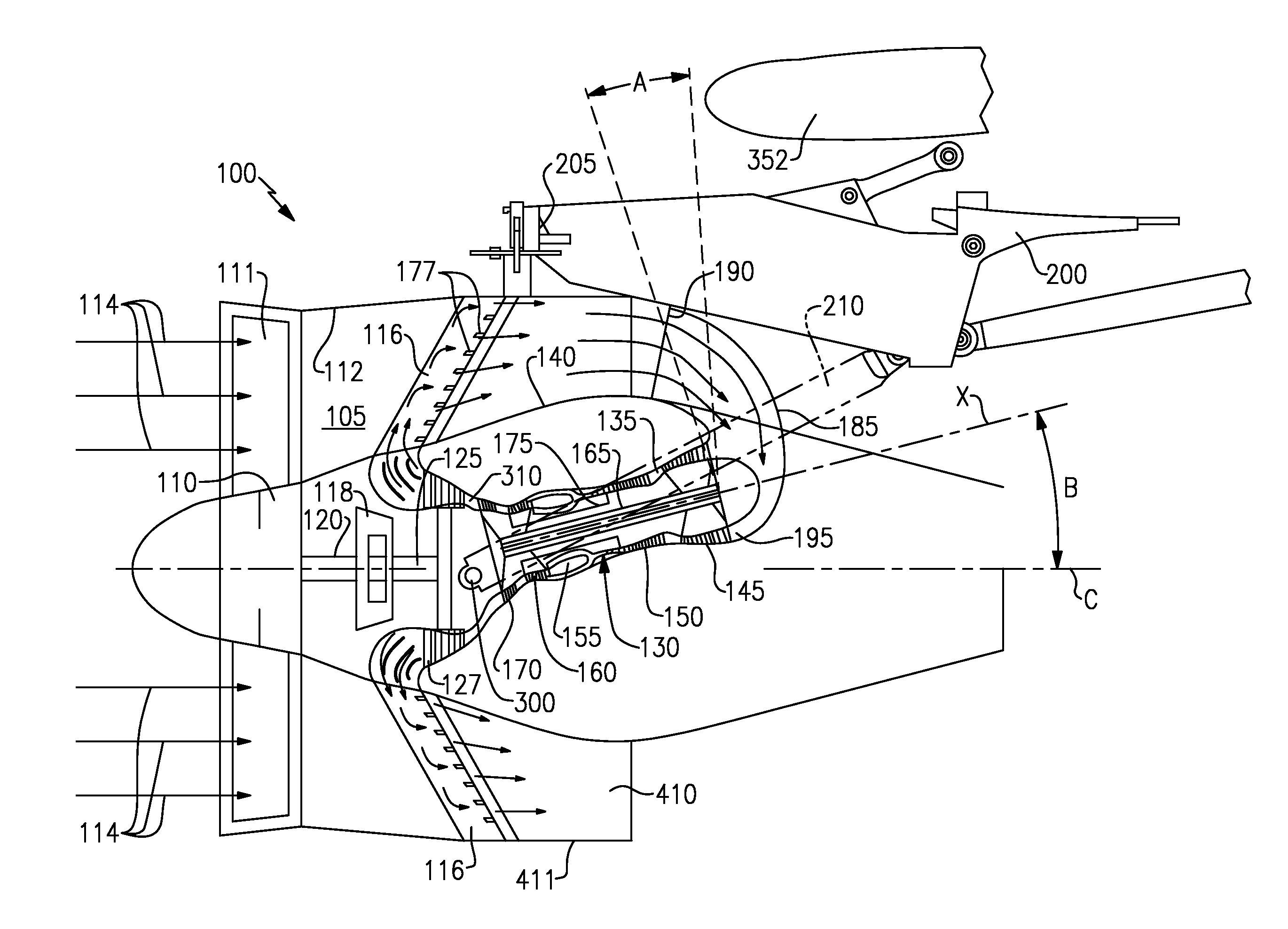

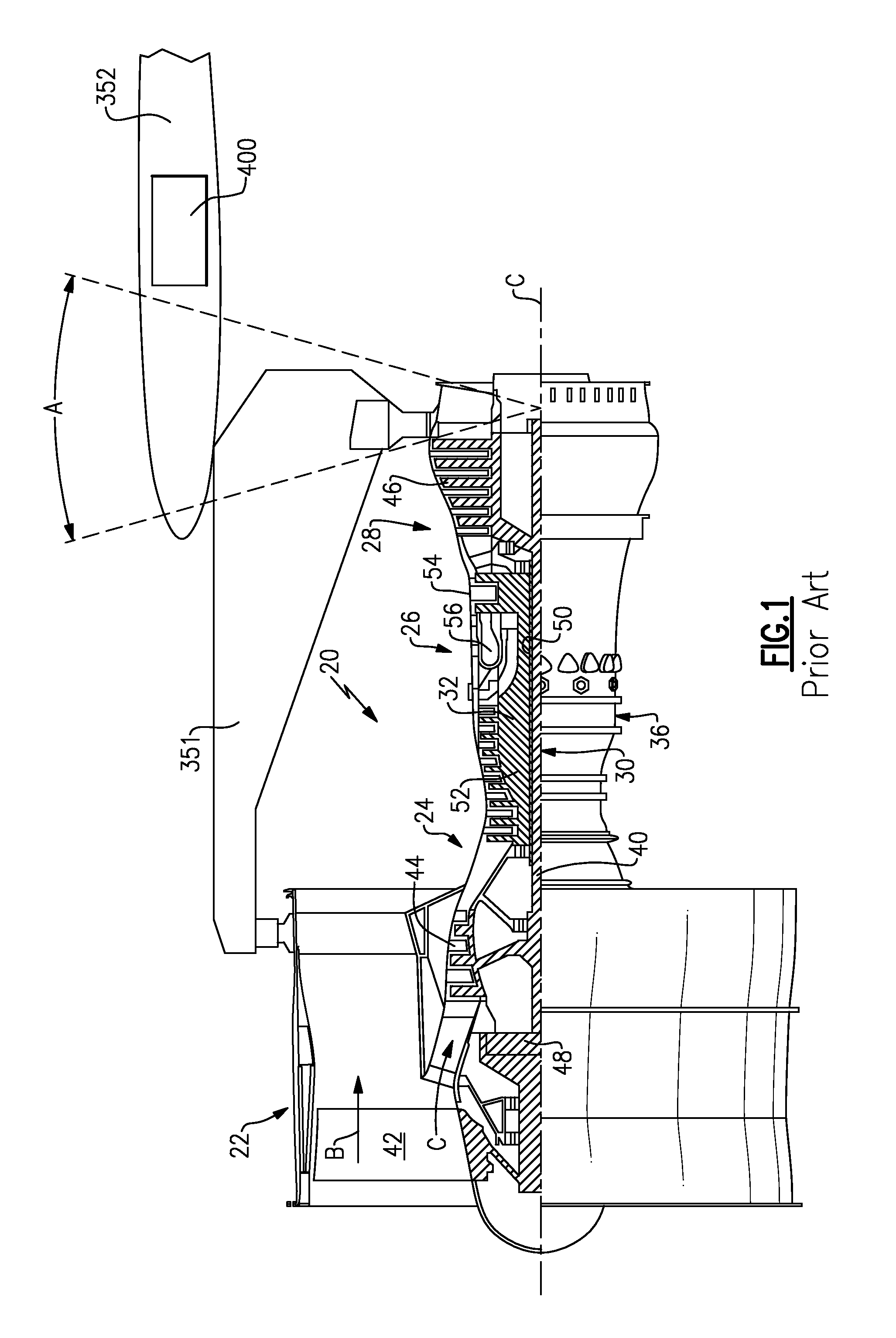

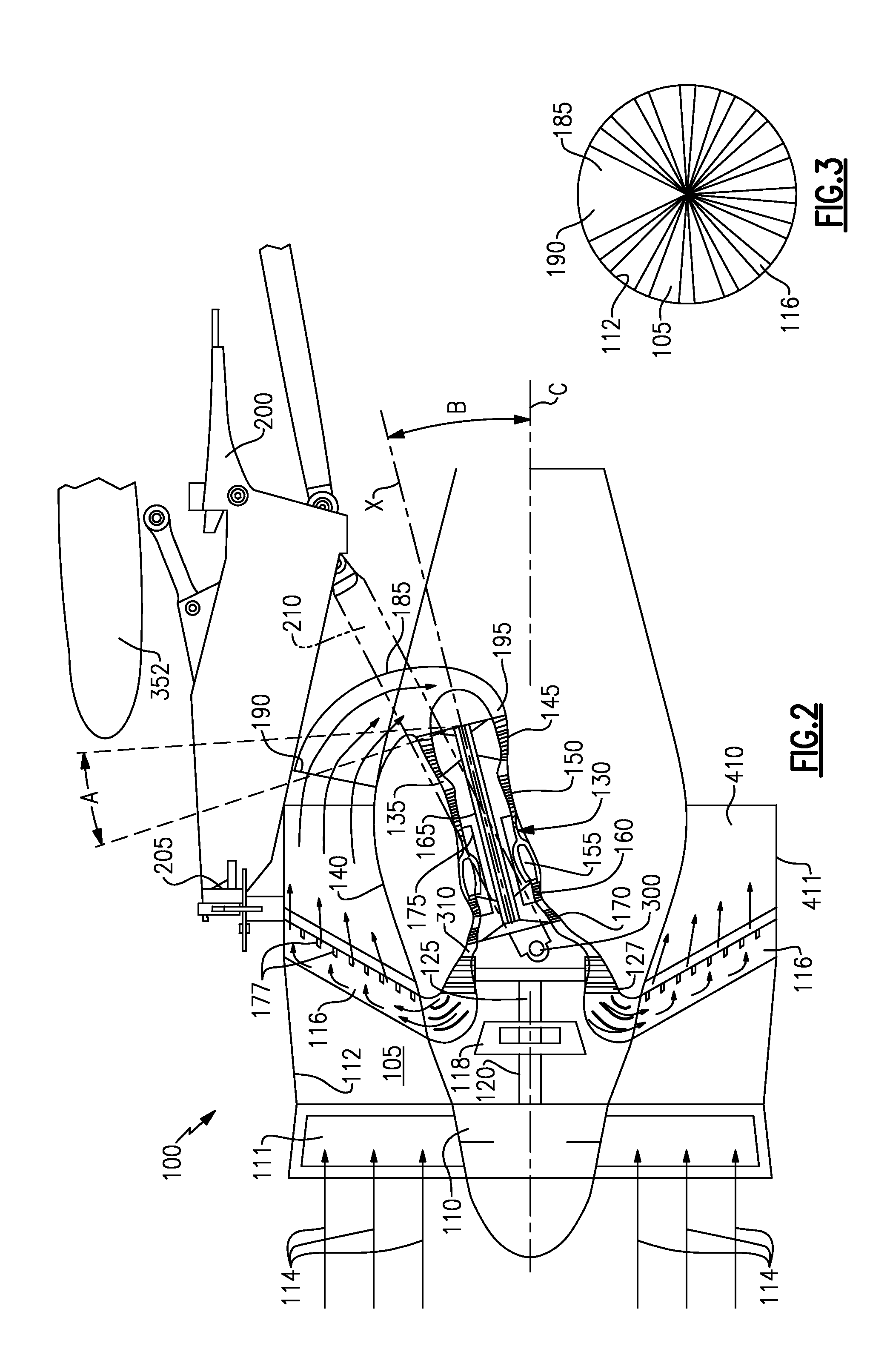

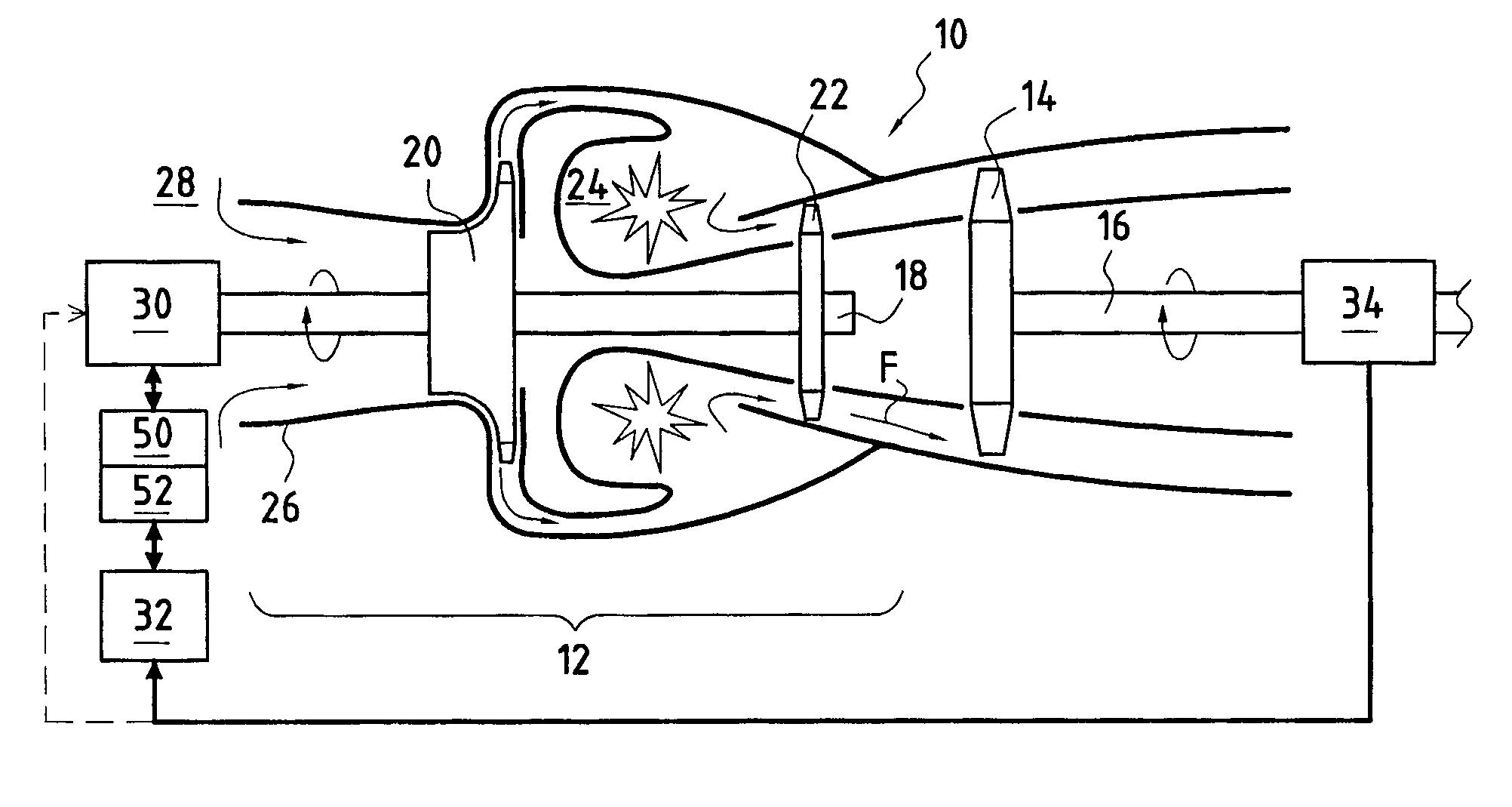

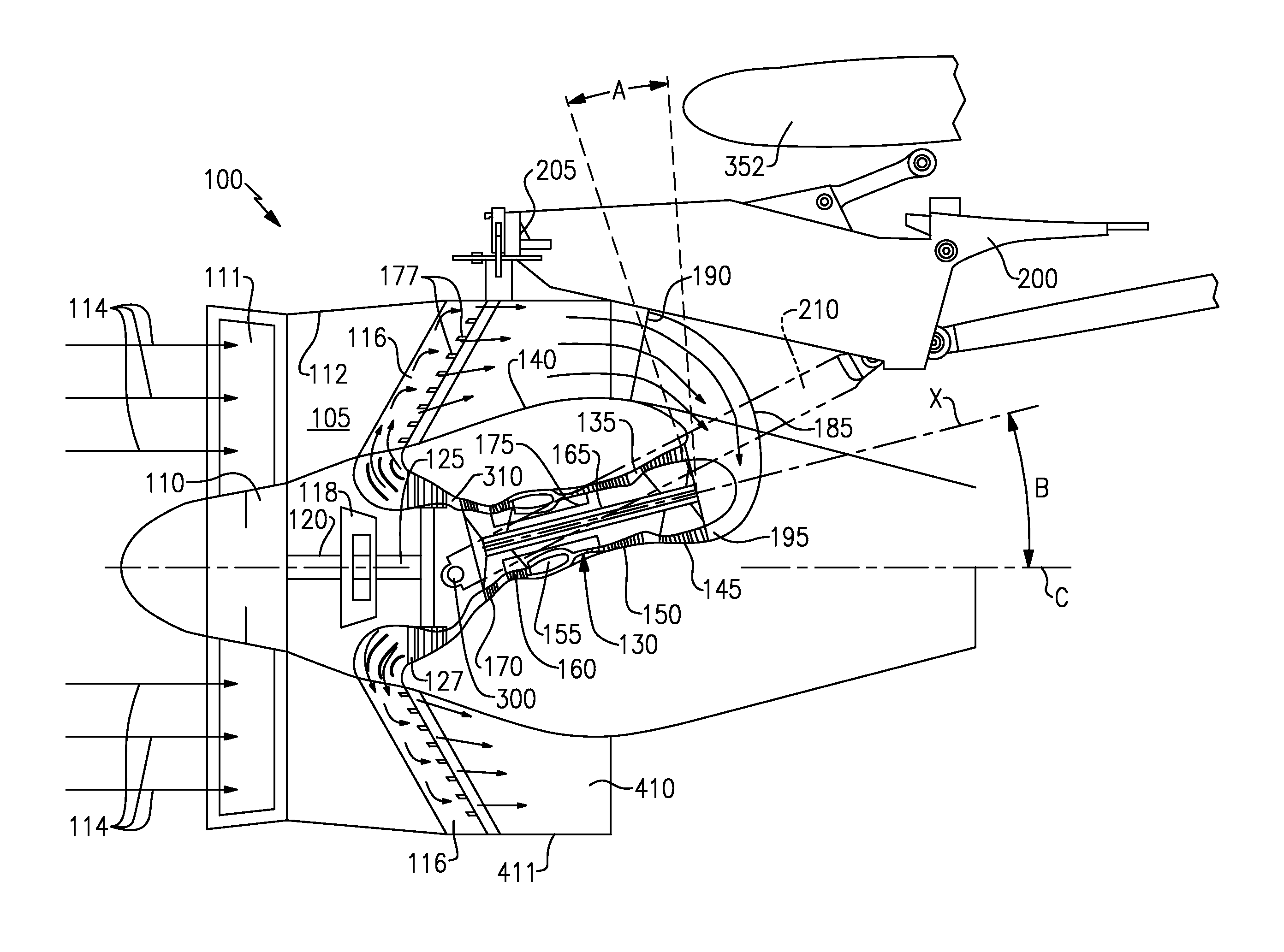

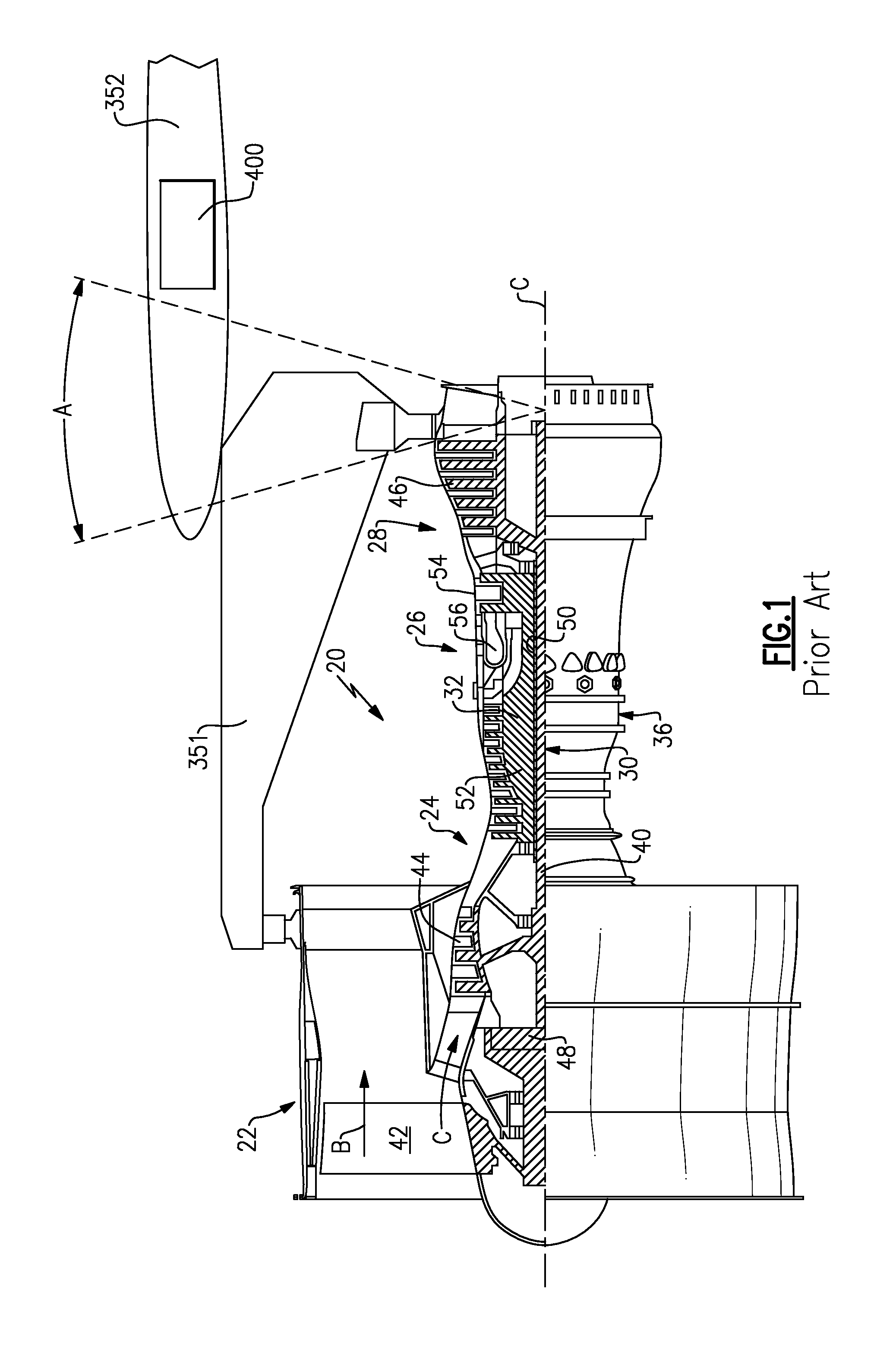

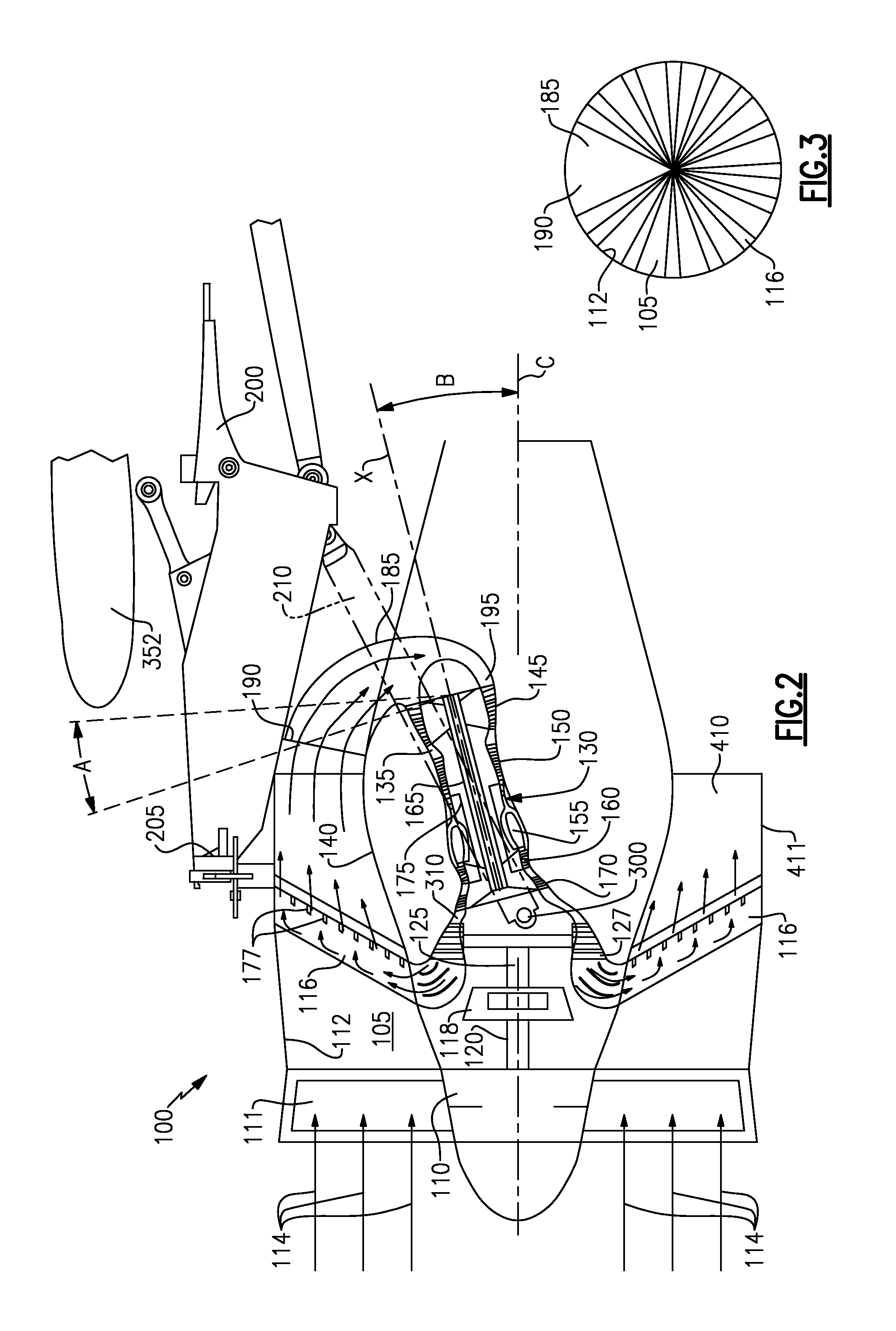

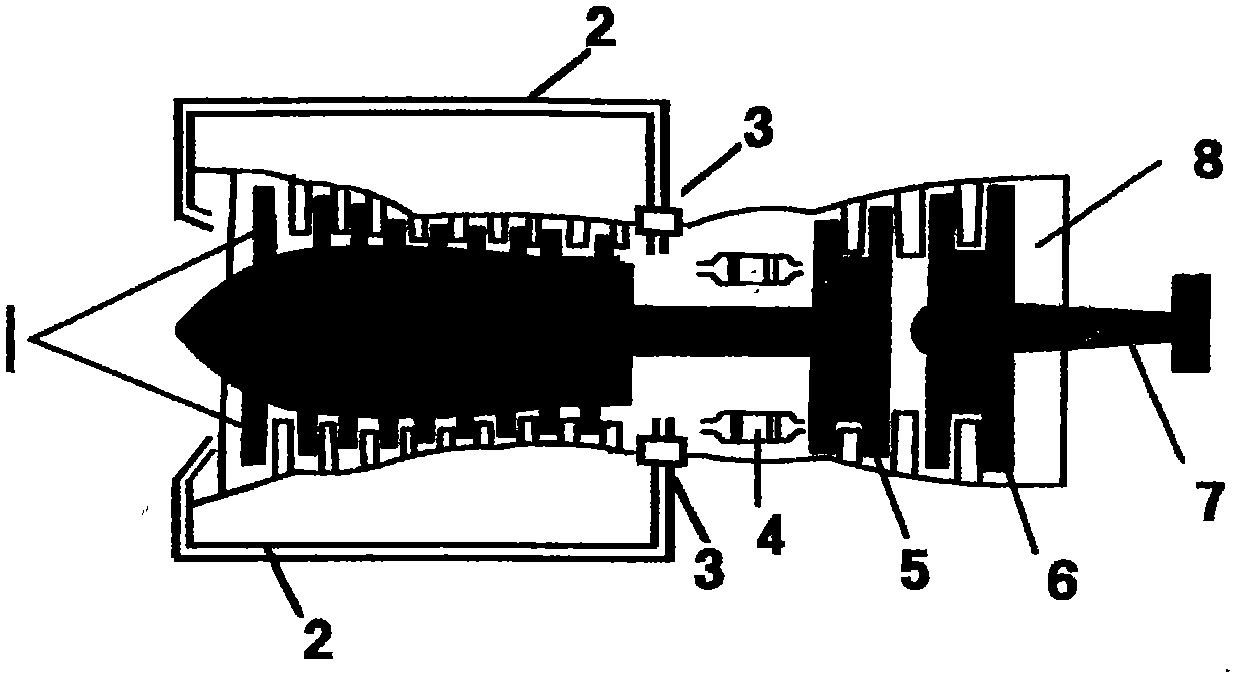

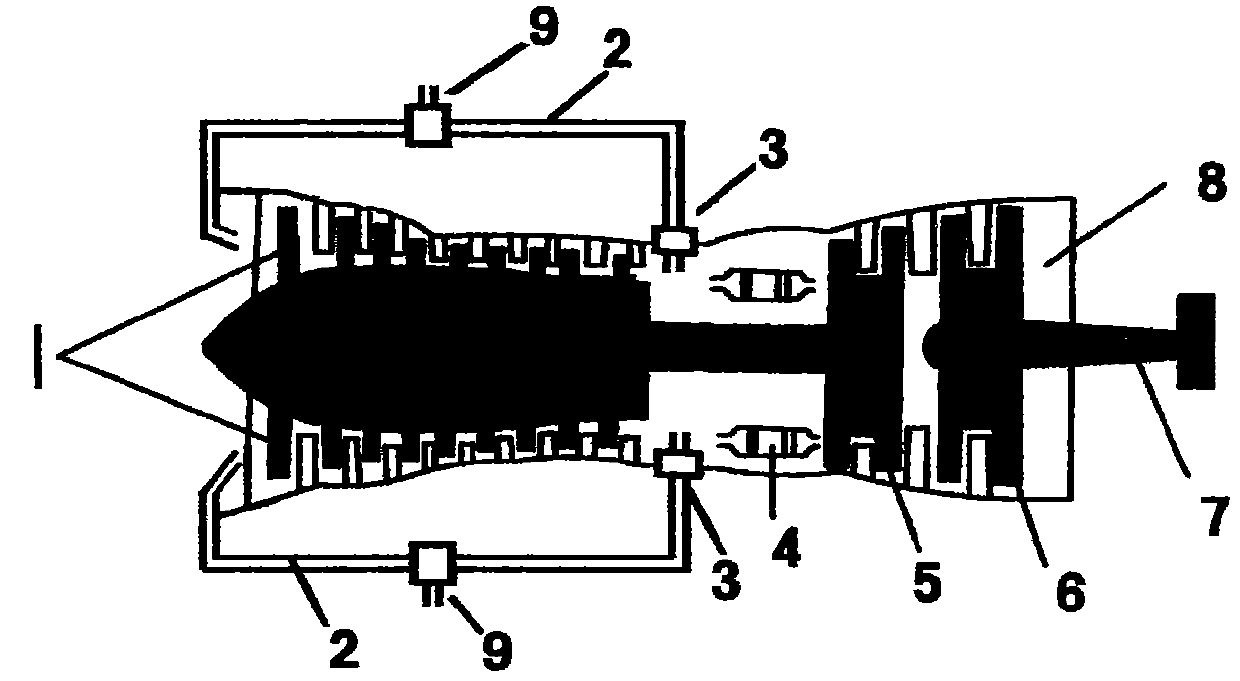

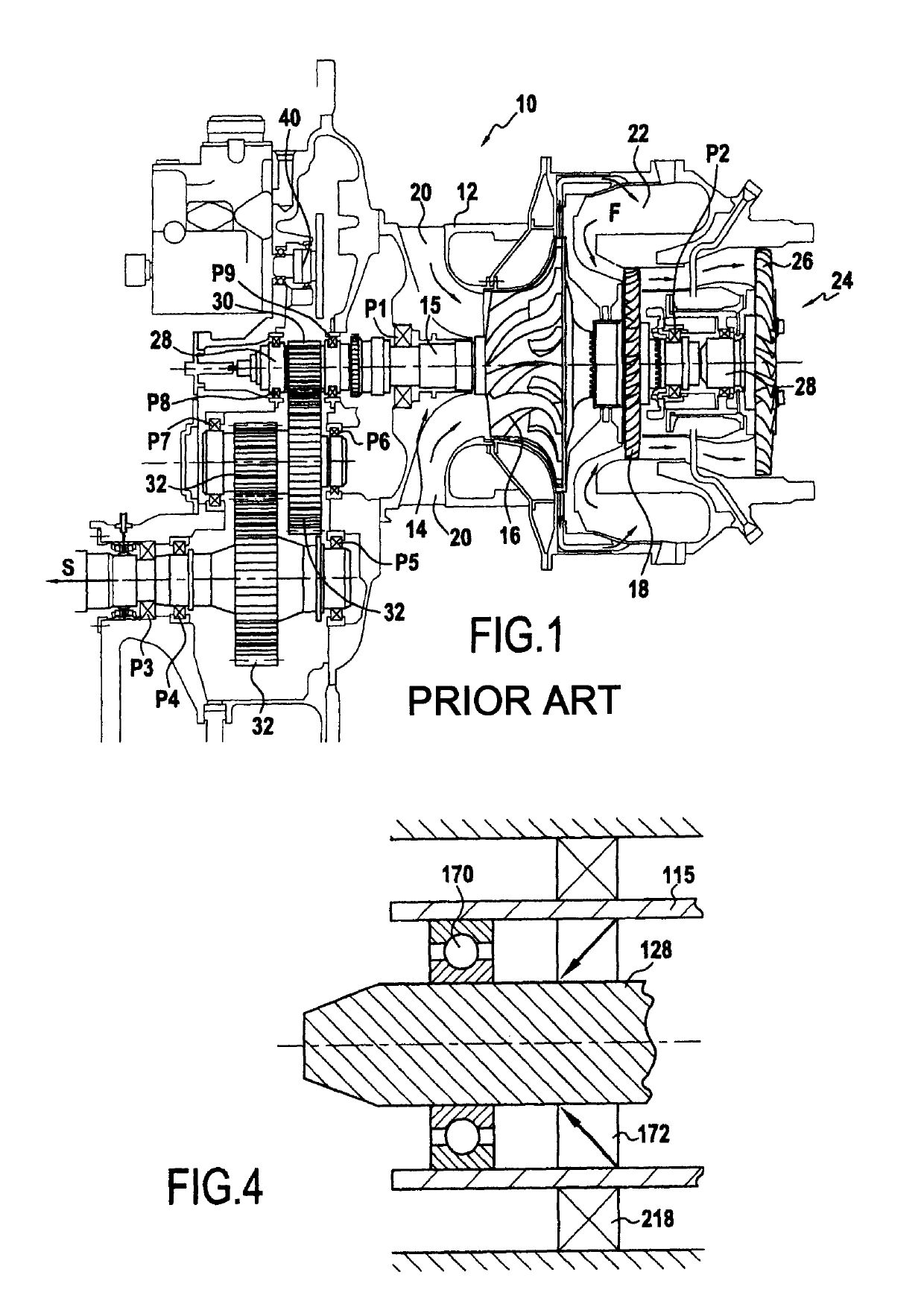

Gas turbine engine with modular cores and propulsion unit

A separate propulsion unit incorporating a free turbine and a fan receives gases from a plurality of core engines. The core engines each include a compressor, a turbine and a combustion section. The core engines in combination pass gases across the free turbine. A method is also disclosed.

Owner:RAYTHEON TECH CORP

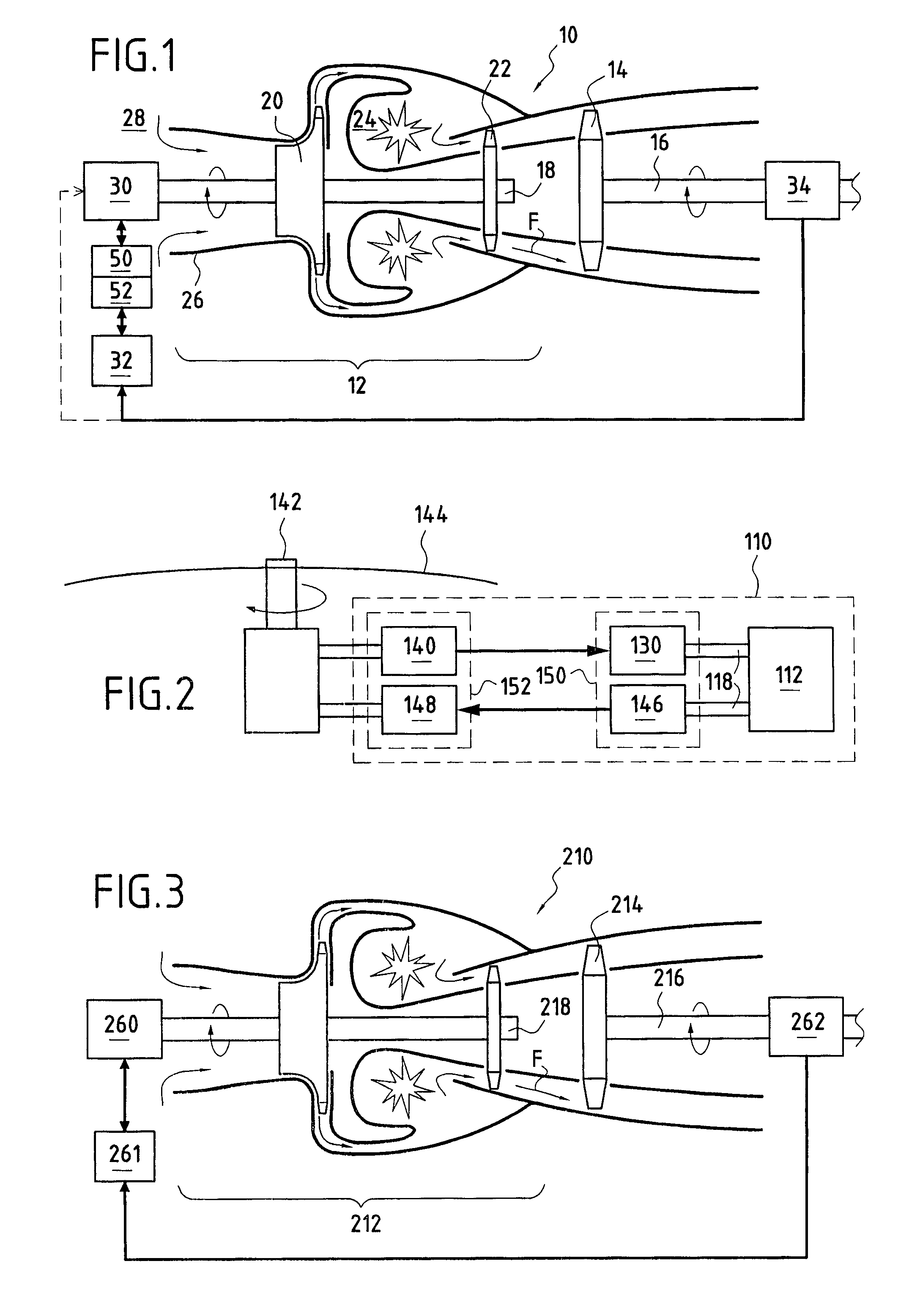

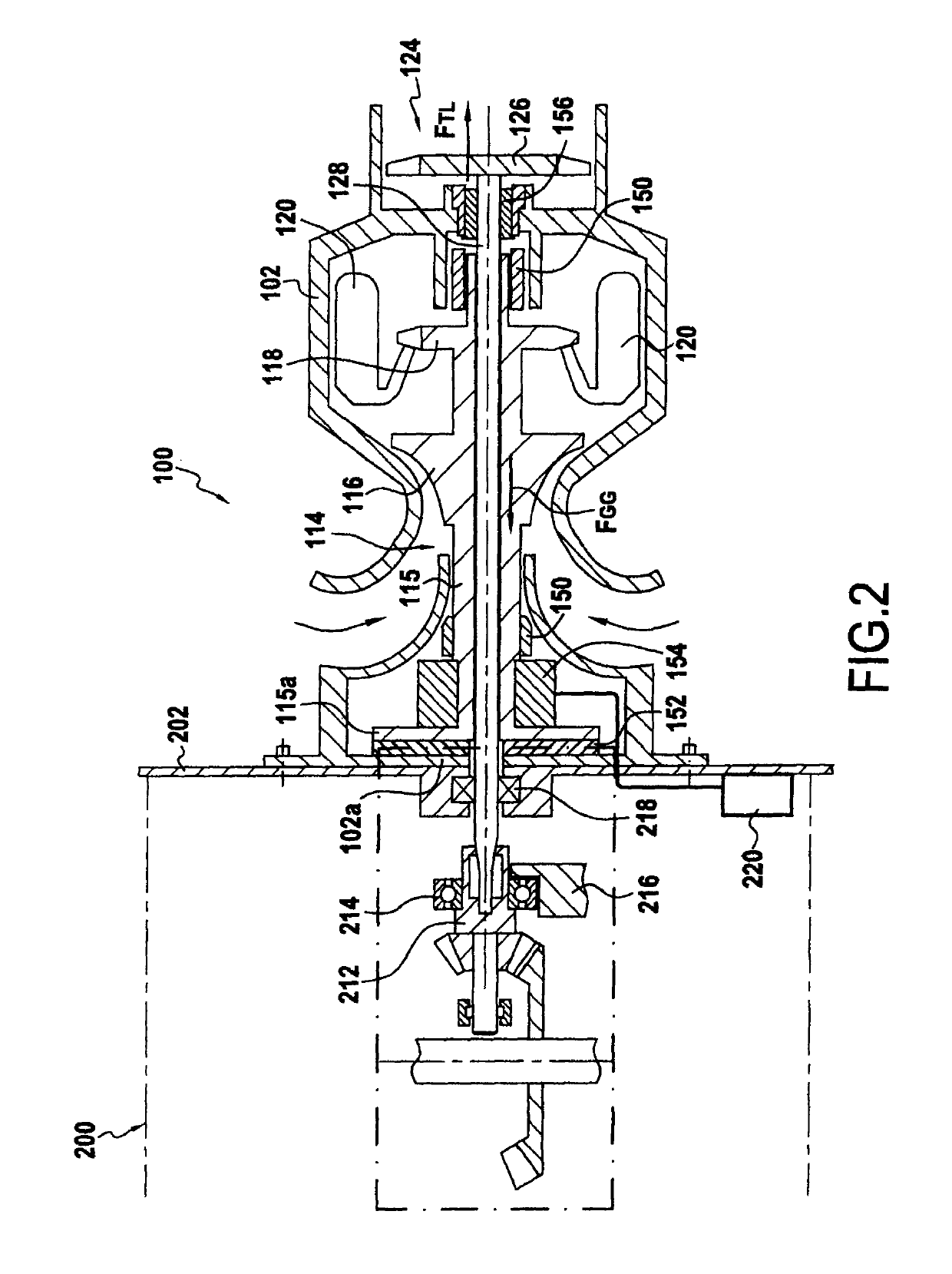

Assistance device for transient acceleration and deceleration phases

ActiveUS8201414B2Small surge marginSmall sizeEngine fuctionsTurbine/propulsion engine ignitionScrew turbineSignal generator

A turbine engine for a helicopter, including a gas generator and a free turbine driven in rotation by the gas flow generated by the gas generator is disclosed. The turbine engine further includes a motor / generator coupled to a shaft of the gas generator, to provide a quantity of additional rotational kinetic energy to the shaft during a stage of turbine engine acceleration, or to draw a quantity of rotational kinetic energy from the shaft during a stage of turbine engine deceleration.

Owner:SAFRAN HELICOPTER ENGINES

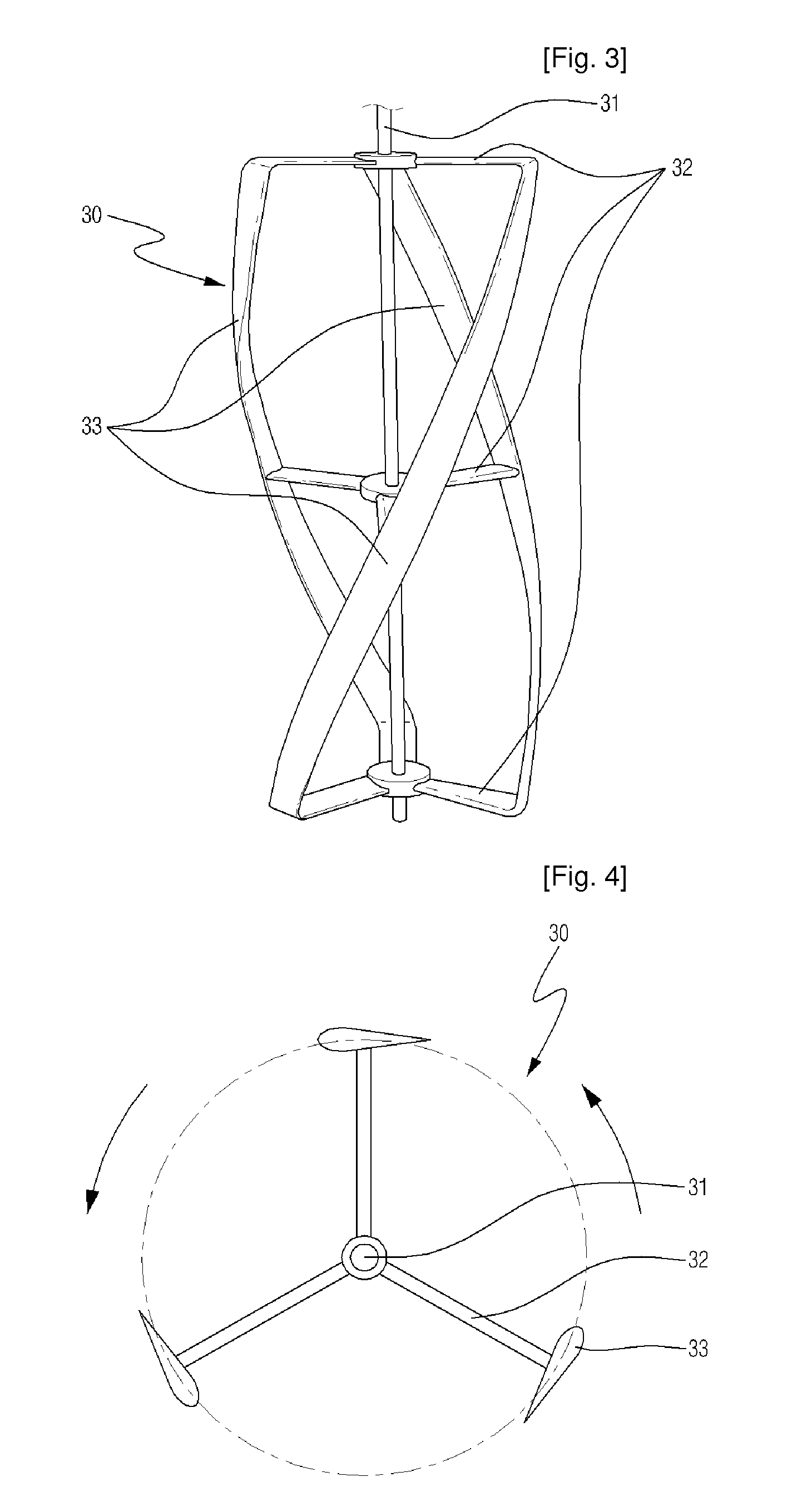

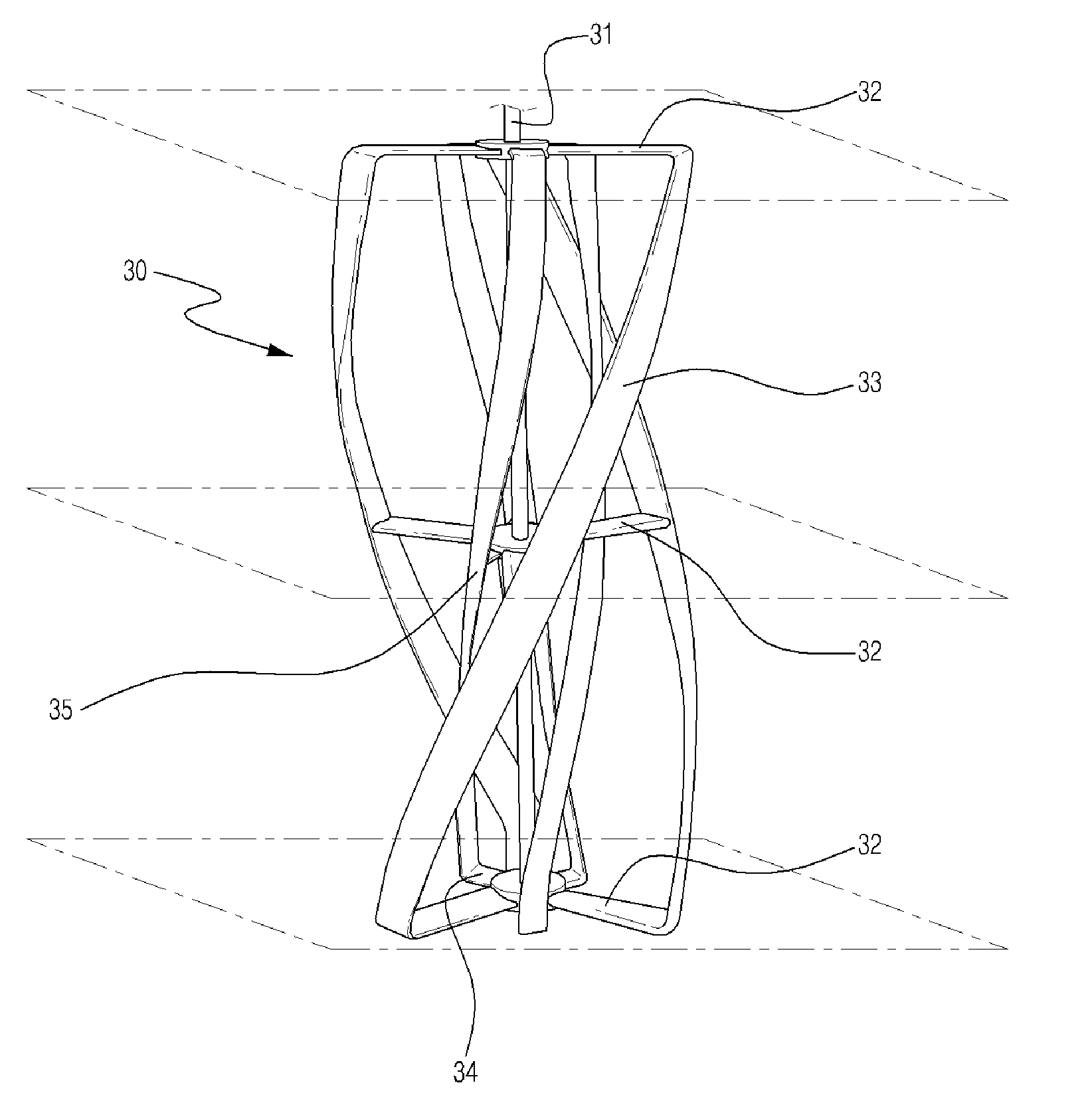

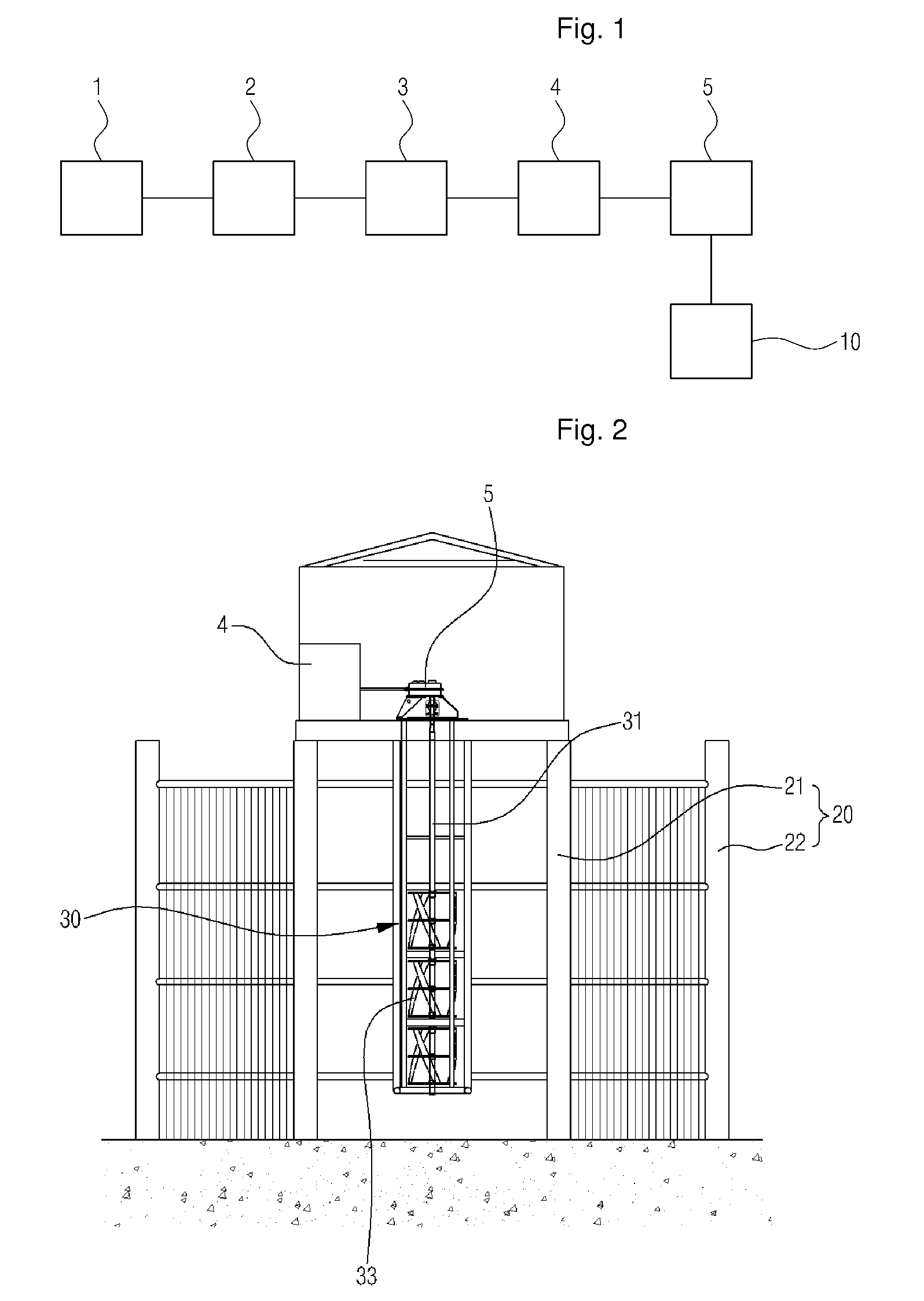

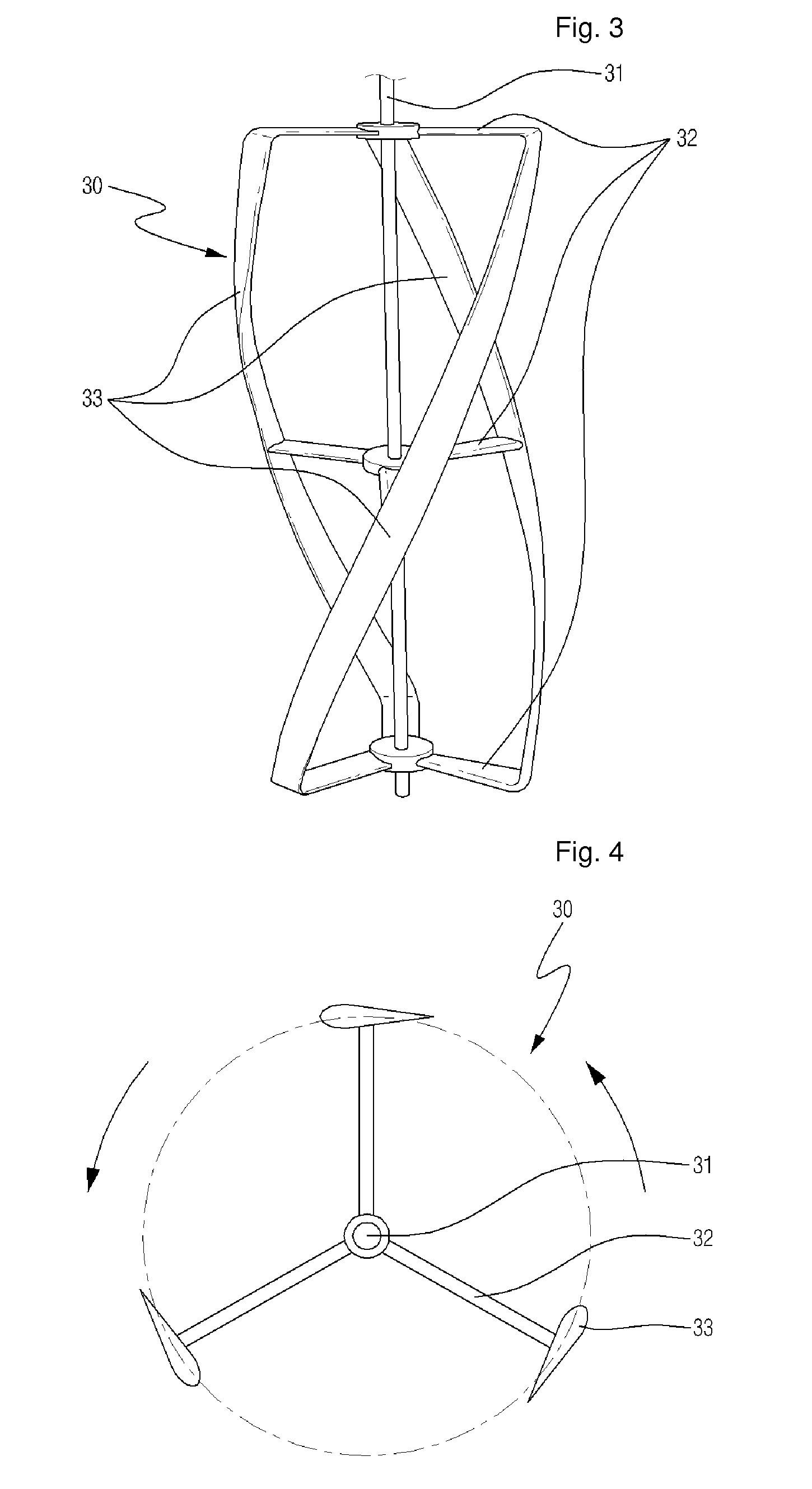

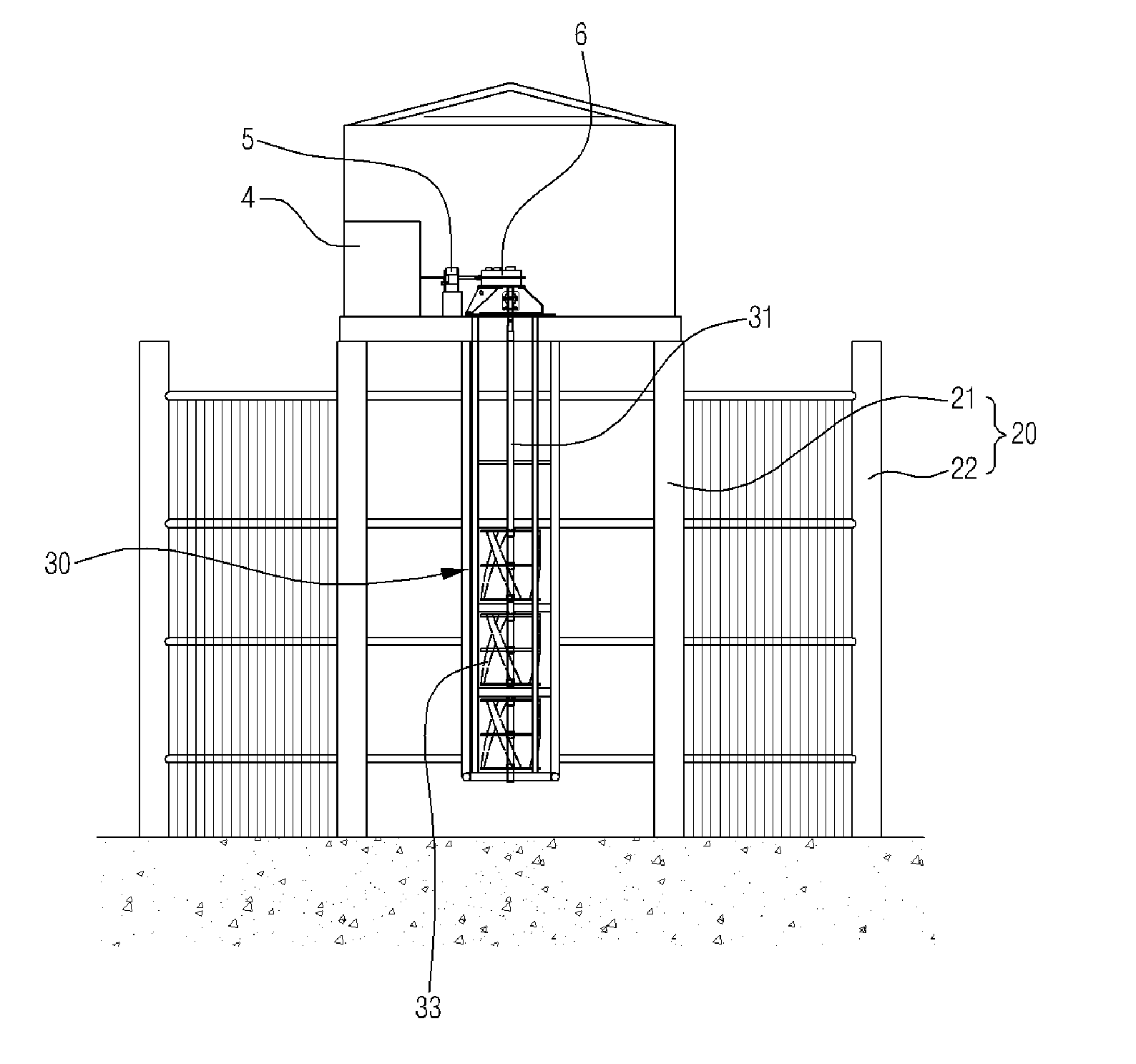

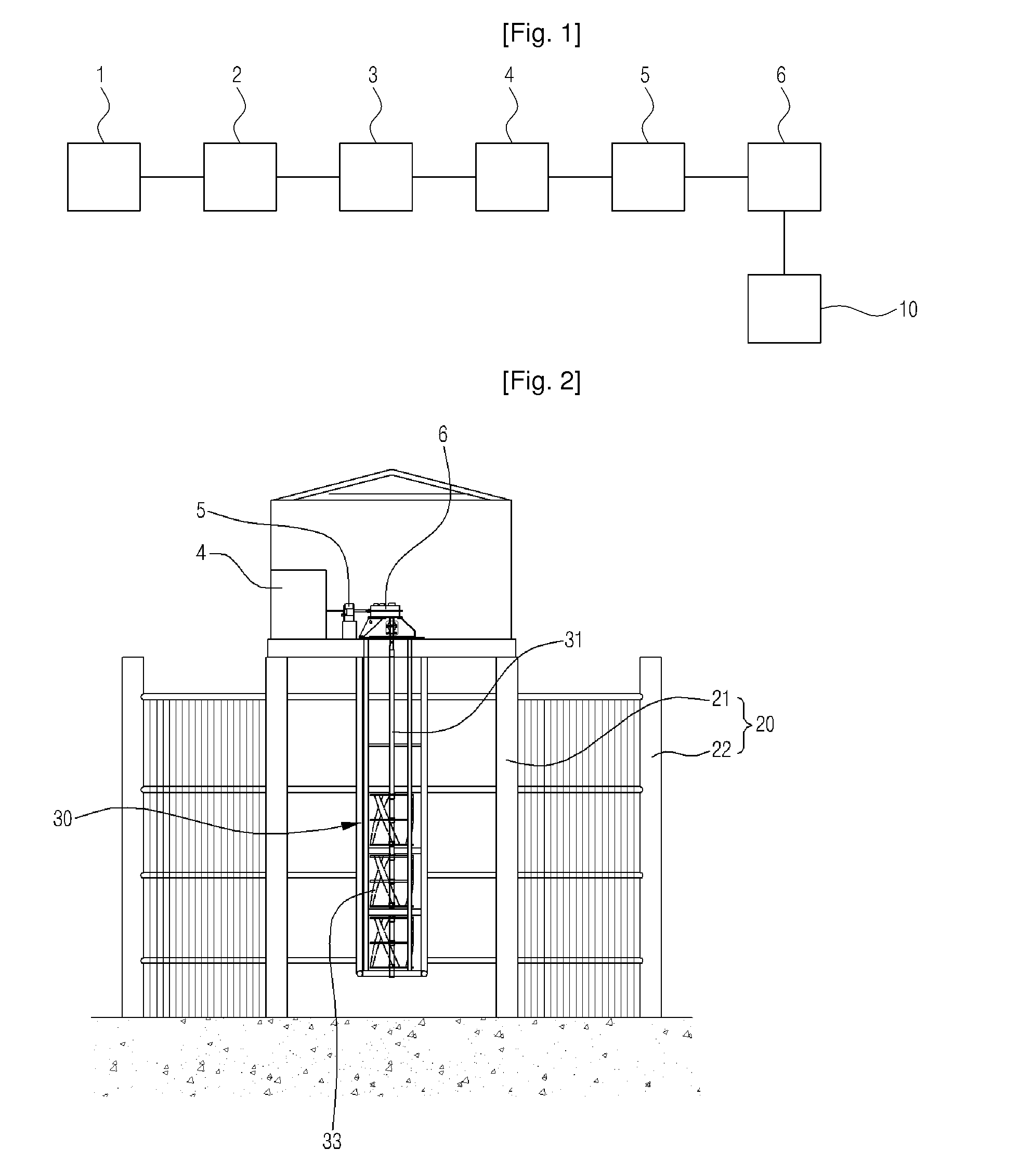

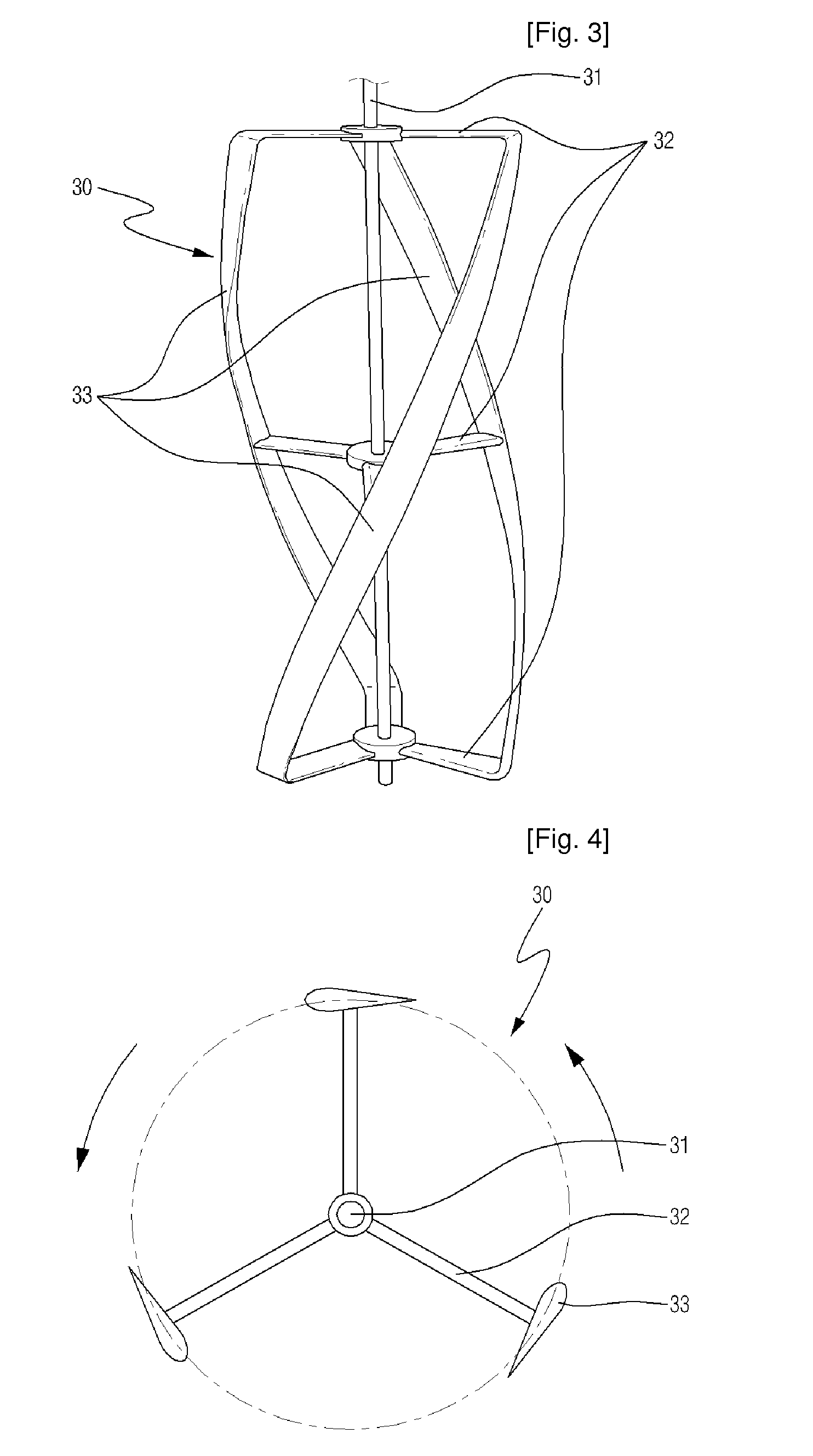

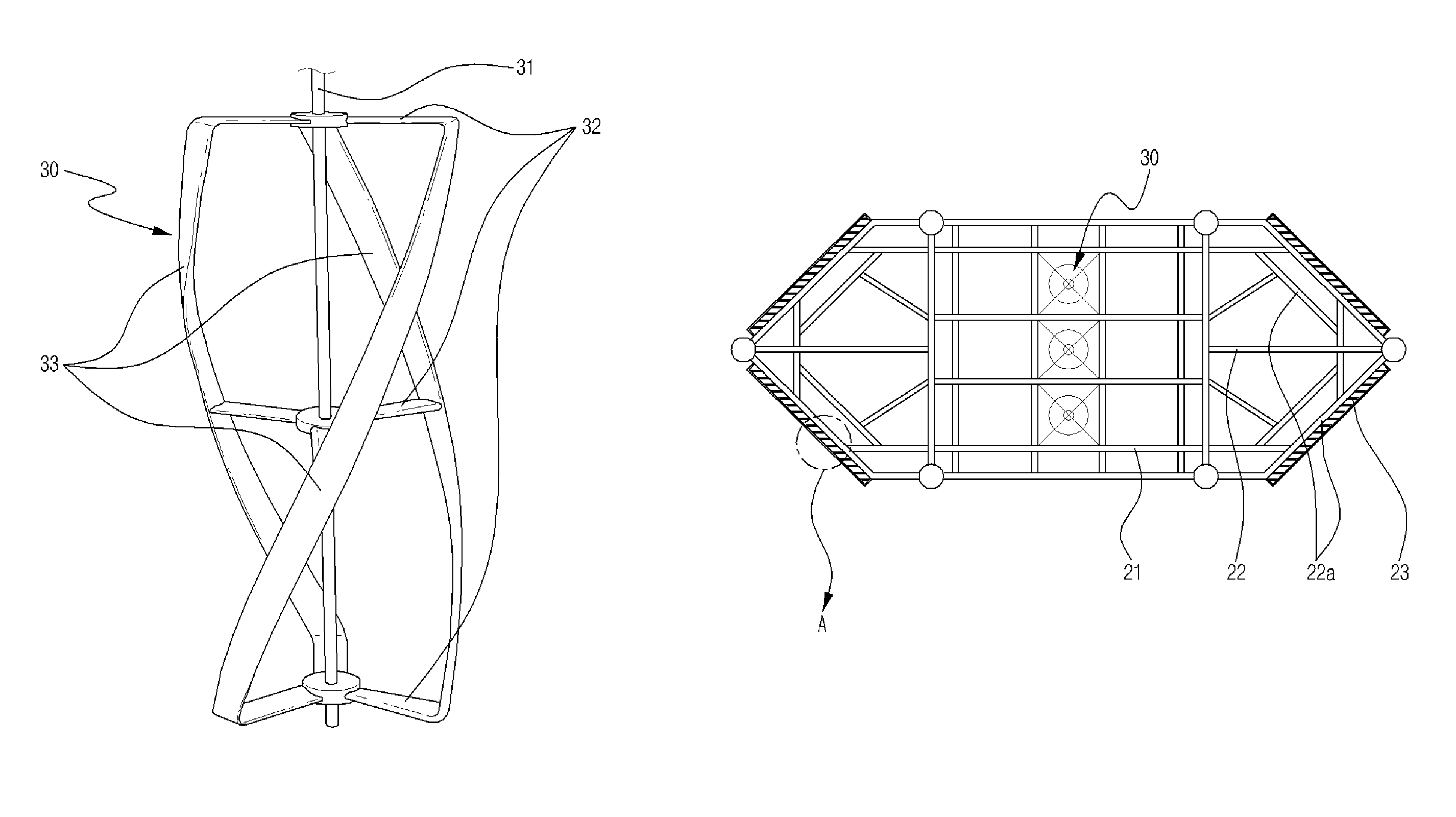

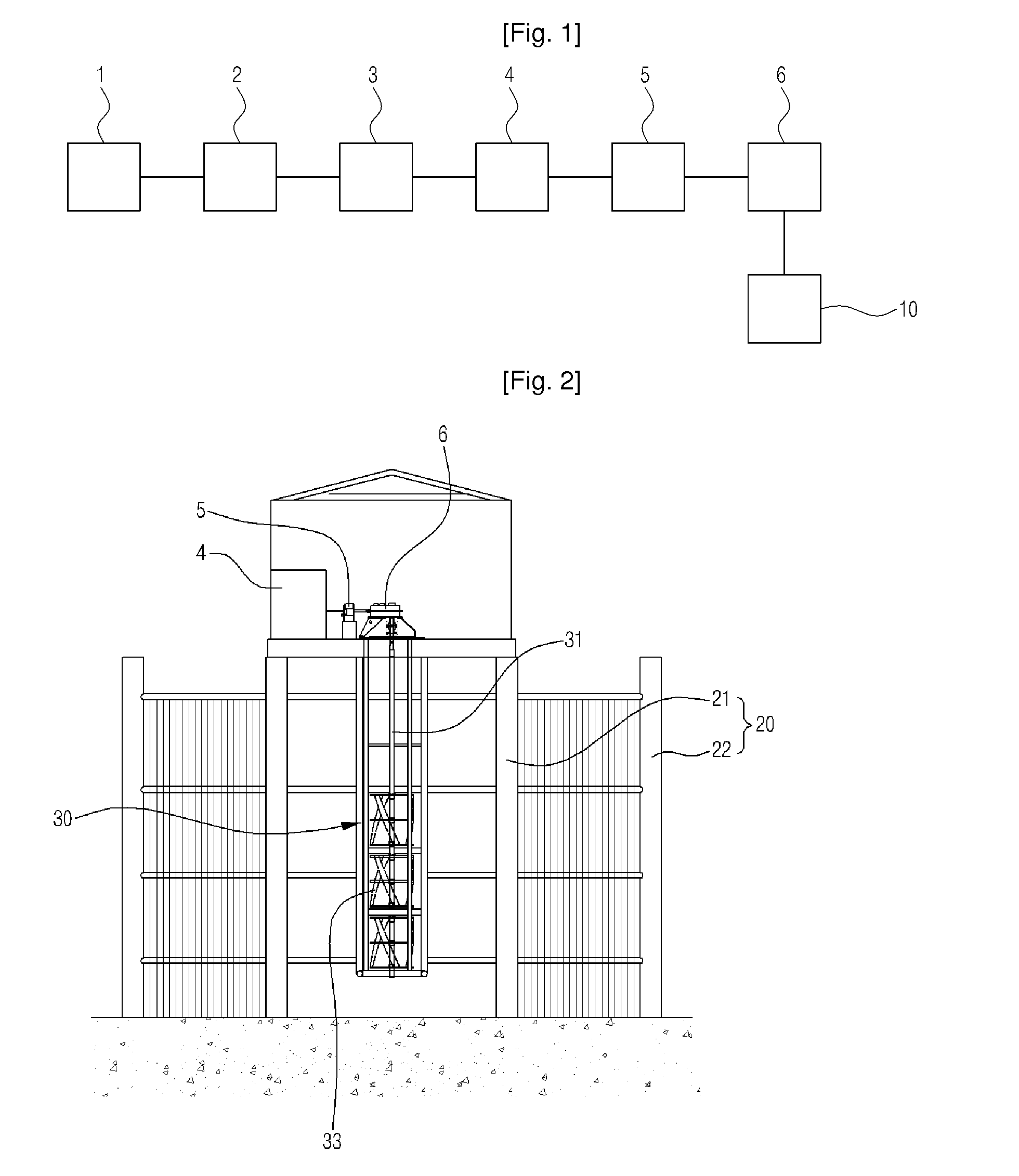

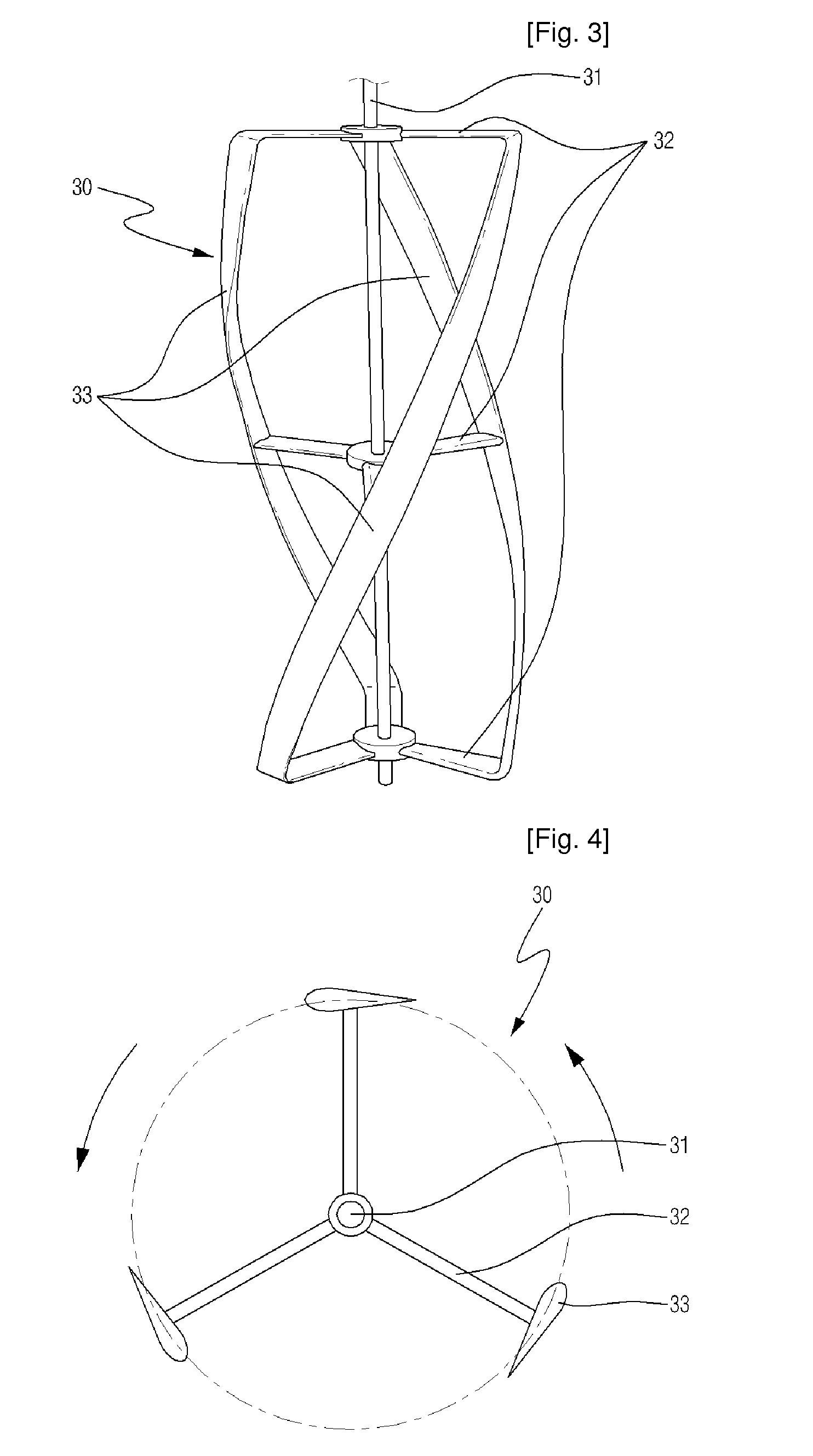

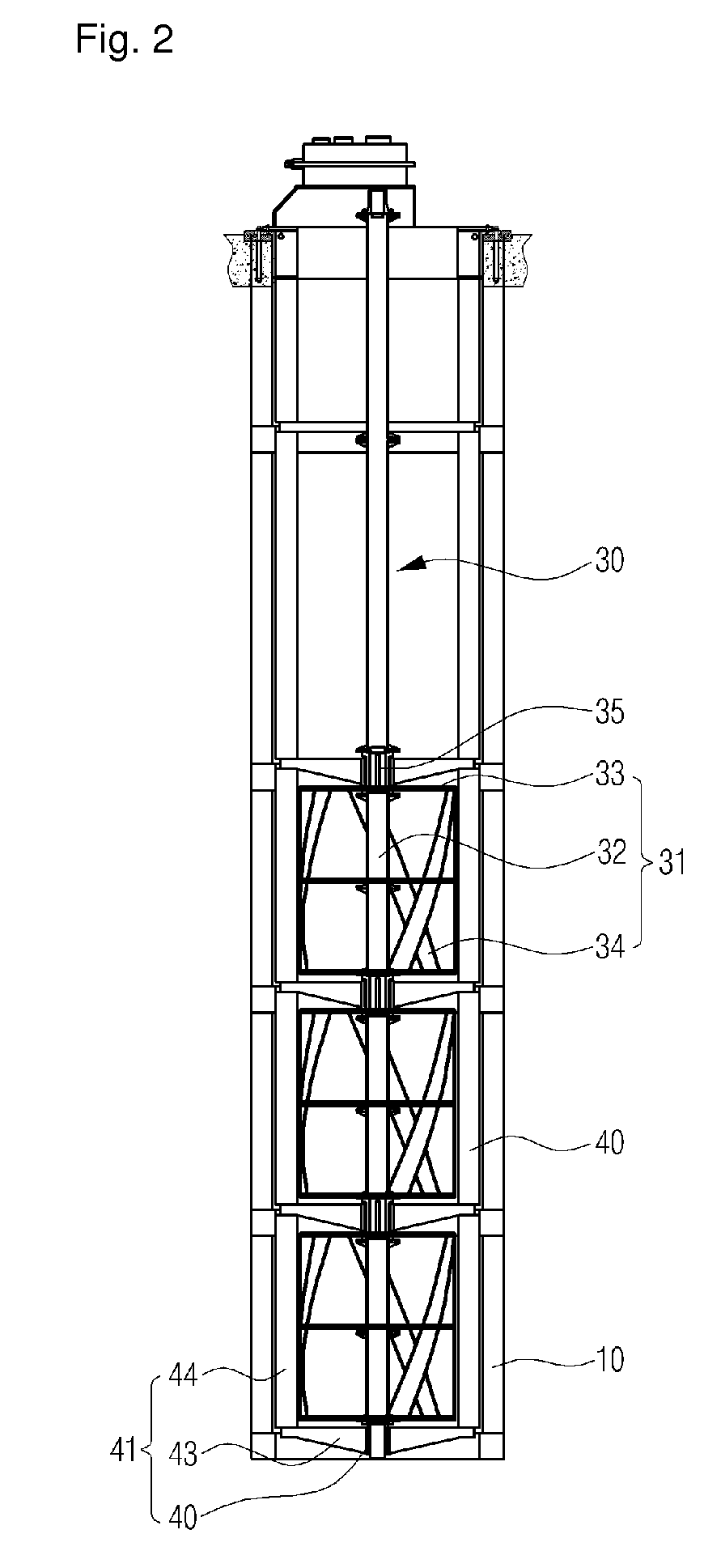

Power generation system using helical turbine

ActiveUS20100072752A1Reduce construction costsAvoid environmental pollutionPropellersEngine output effectElectricityScrew turbine

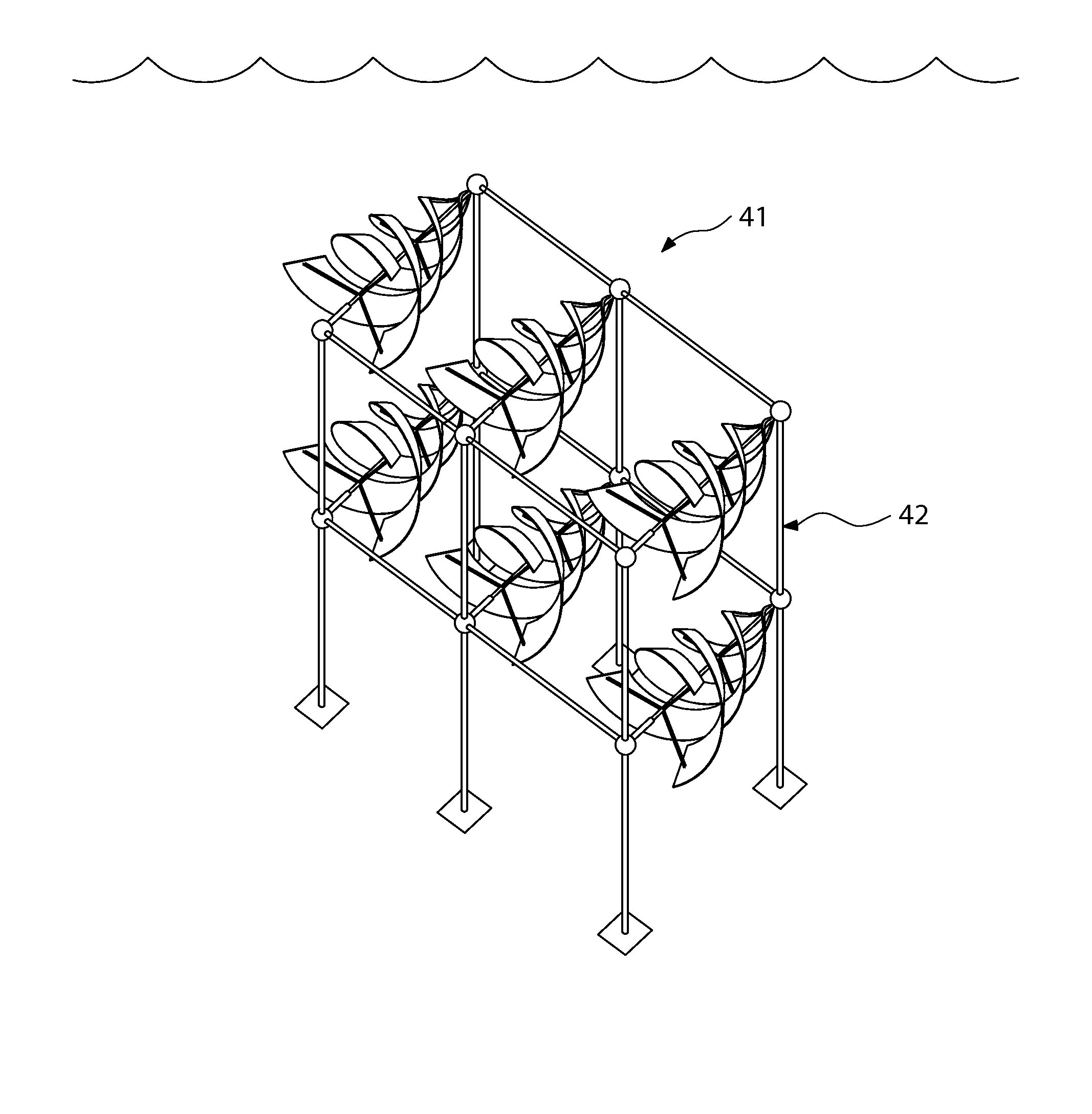

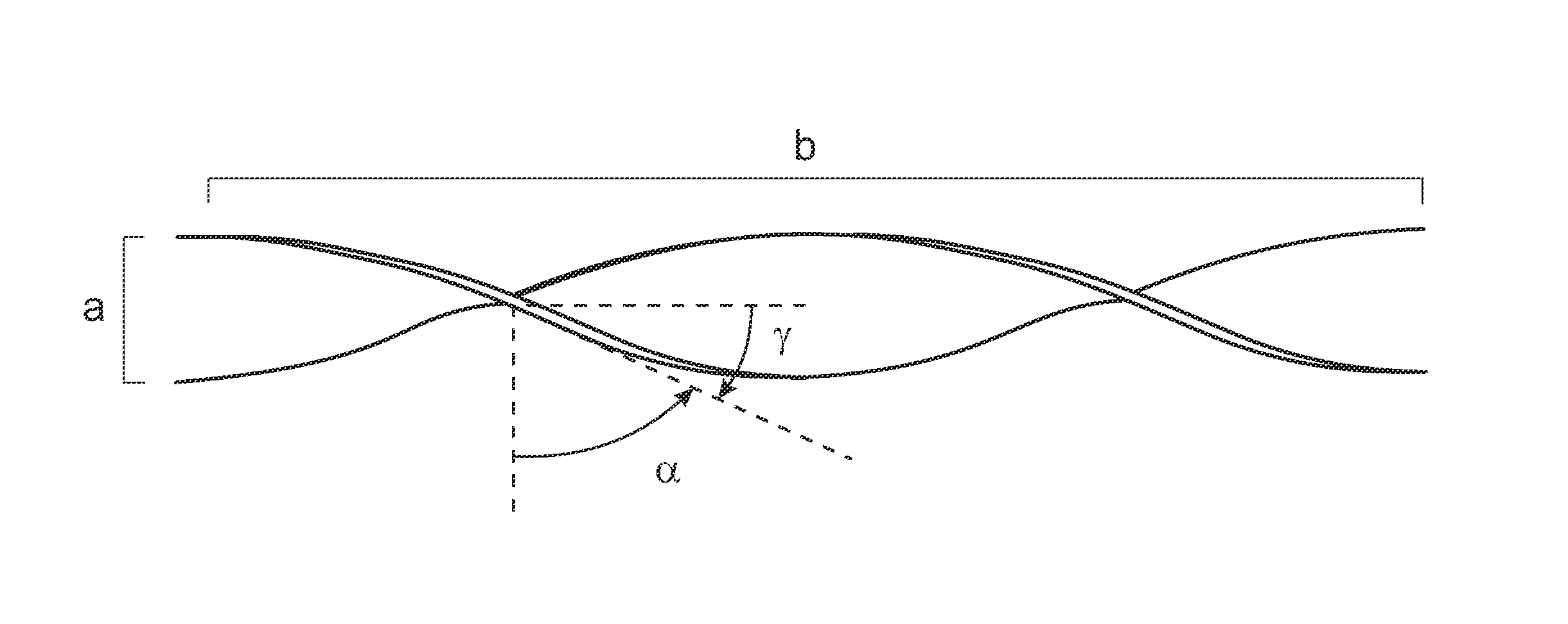

Disclosed is a helical turbine power generation system for generating electricity by using a helical turbine and an overload prevention generator, the system including: a helical turbine rotatably provided in a frame so as to continuously generate rotation force under unidirectional or multidirectional fluid flow; a step-up gear for increasing a rotational velocity of the helical turbine up to a level required for generating electricity; and an overload prevention generator for generating electricity by using the rotational velocity transferred from the step-up gear, and for preventing overload caused by a sudden increase in a rotational velocity. Therefore, it is possible to reduce equipment costs and to prevent environmental pollution.

Owner:KOREA OCEAN RES & DEV INST

Gas turbine engine with separate core and propulsion unit

A gas turbine engine includes a propulsion unit mounted to rotate about a first axis, and a core engine mounted to rotate about a second axis, and wherein the first and second axes are non-parallel. A gas turbine engine includes a propulsion unit driven by a free turbine which is adjacent to the propulsion unit and an associated fan, and having a gas generator core engine including a compressor, combustor and turbine section. A method is also disclosed.

Owner:RTX CORP

Power generation system using helical turbine

ActiveUS8308424B2Velocity increasesPrevent overloadPropellersEngine output effectElectricityScrew turbine

A helical turbine power generation system is configured to generate electricity by using a helical turbine and an overload prevention generator. More specifically, the helical turbine is rotatably provided in a frame so as to continuously generate a rotation force under unidirectional or multidirectional fluid flow and a step-up gear is configured to increase the rotational velocity of the helical turbine up to a level required for generating electricity. Additionally, an overload prevention generator is incorporated to generate electricity by using the rotational velocity transferred from the step-up gear thereby preventing an overload caused by a sudden increase in the rotational velocity of the turbine.

Owner:KOREA OCEAN RES & DEV INST

Turbine Arrangement

InactiveUS20100266406A1Increase profitReduce power outputEngine componentsWater wheelsScrew turbineBuoyancy

A turbine arrangement for extracting energy from flowing water, the turbine arrangement s including a screw turbine with a suspension means, buoyancy element and bottom mount, and necessary transmission elements for transmitting energy to a power machine, and the turbine arrangement including at least two parallel screw turbines.

Owner:FLUMILL

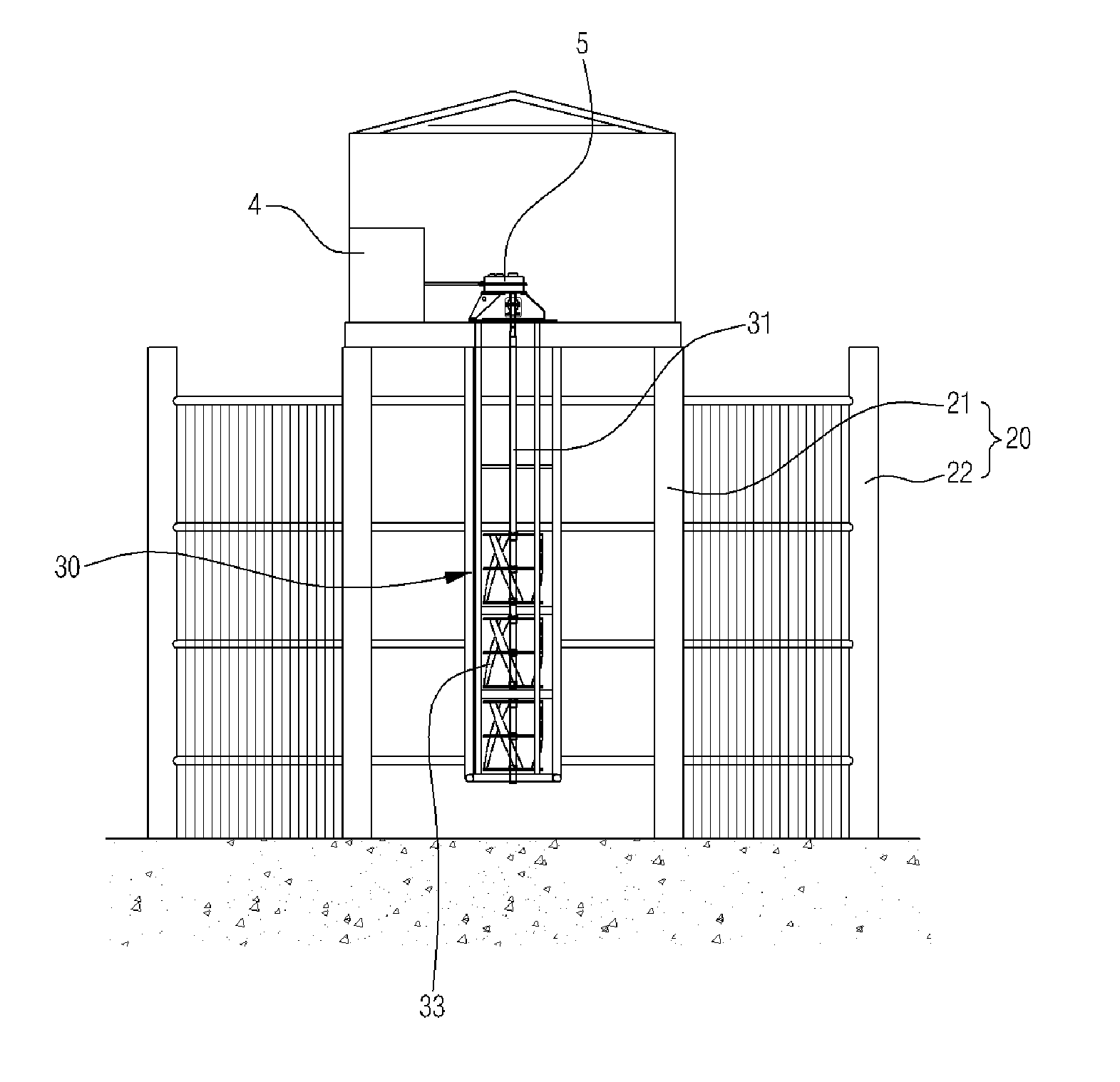

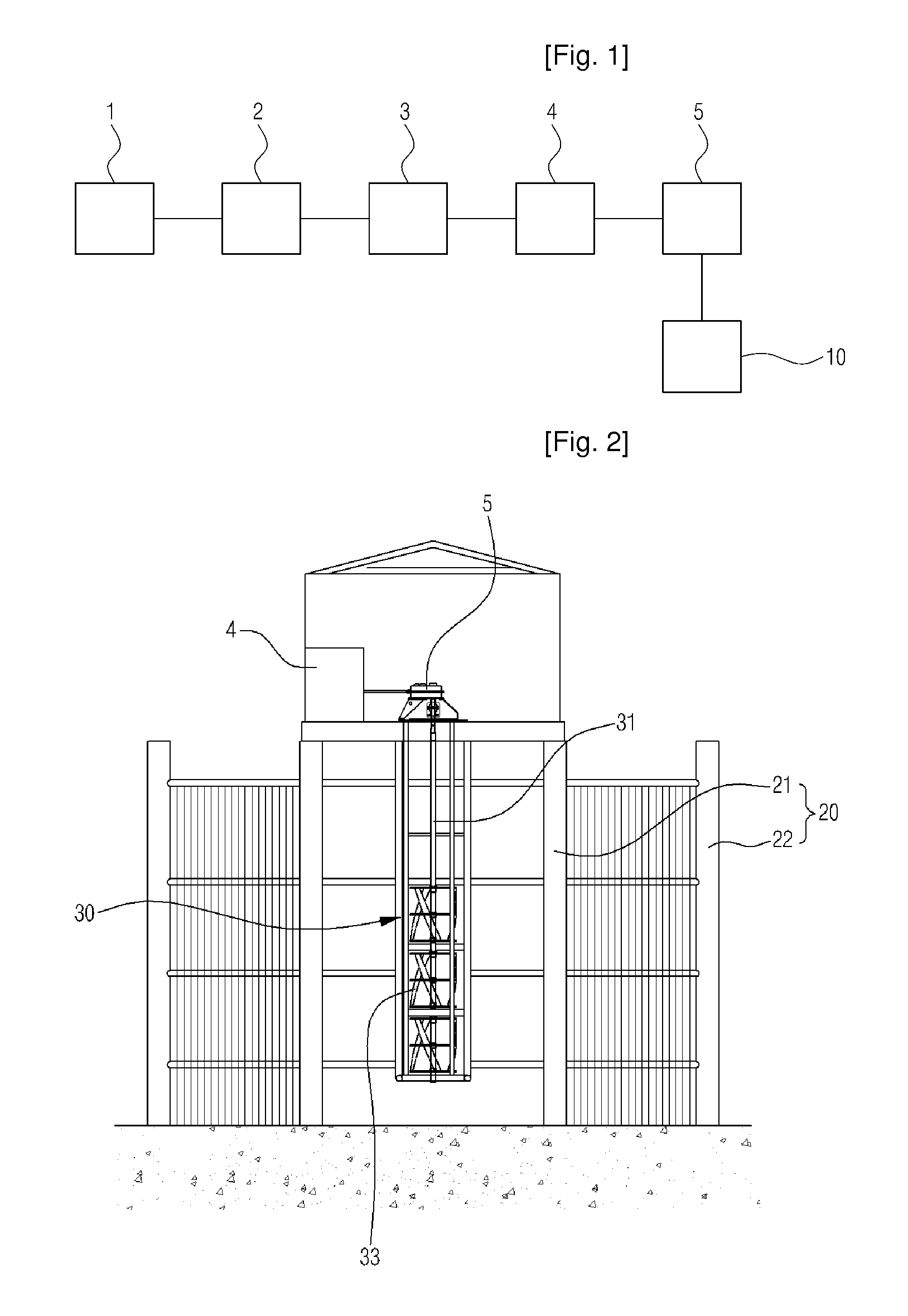

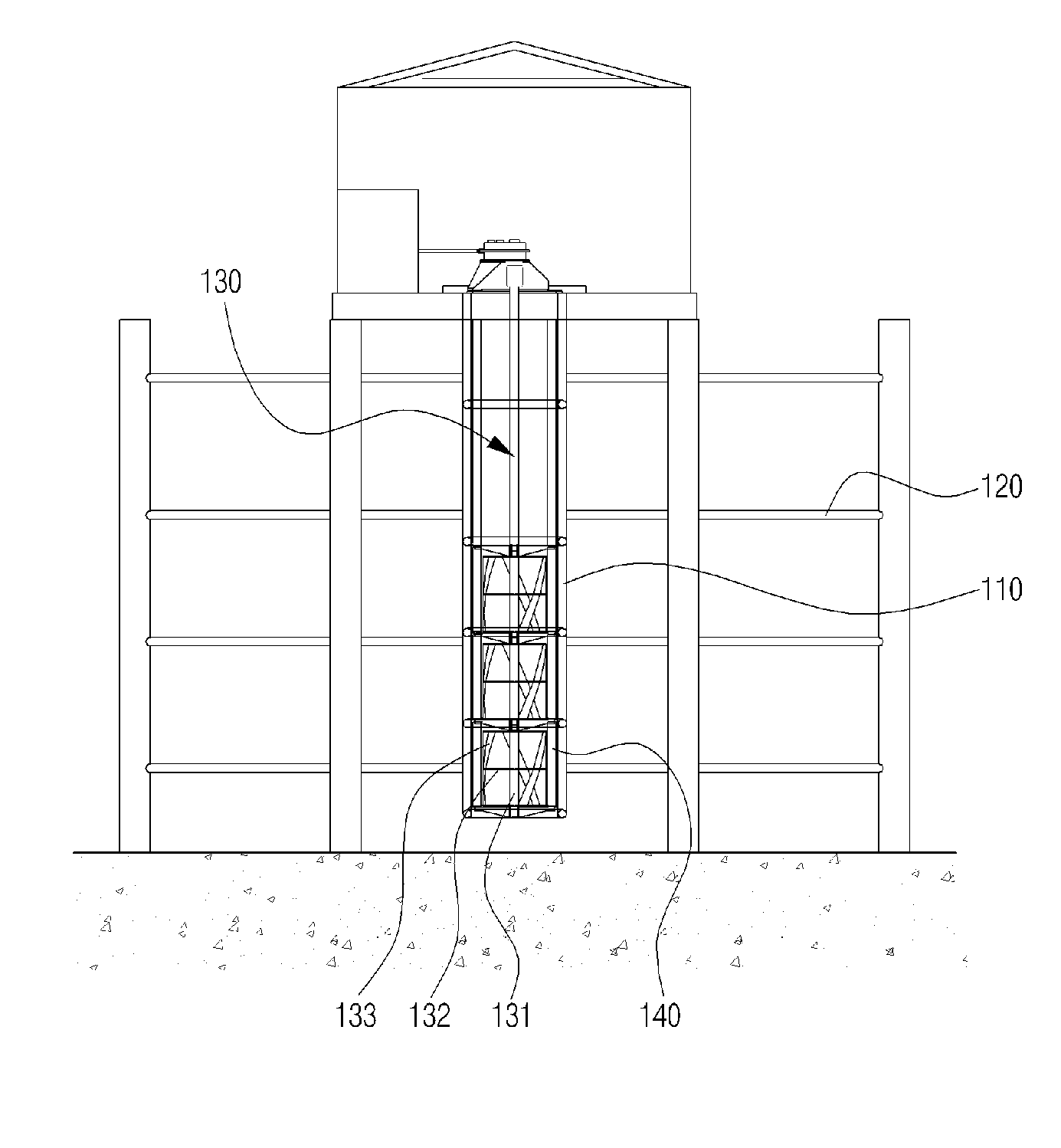

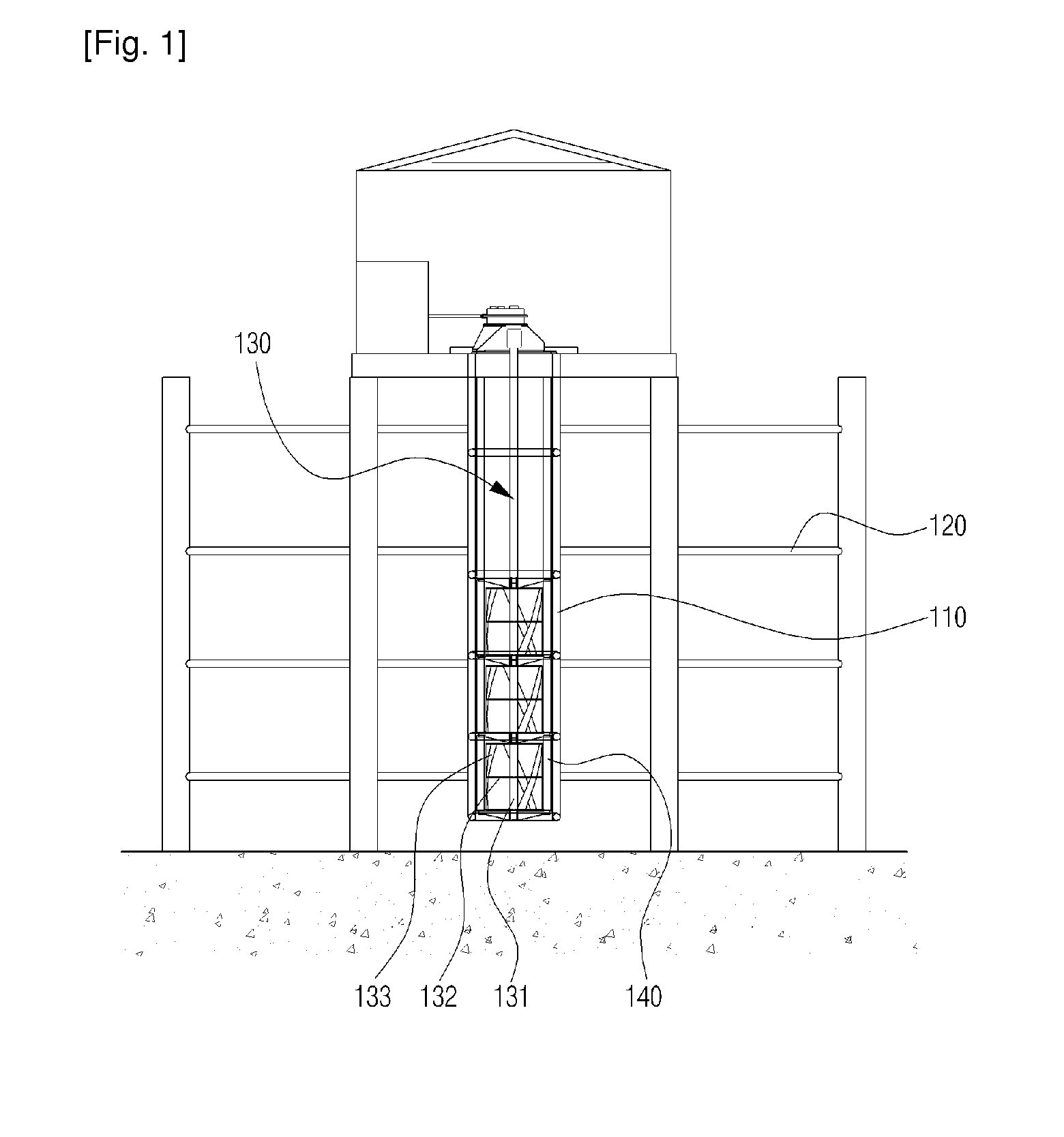

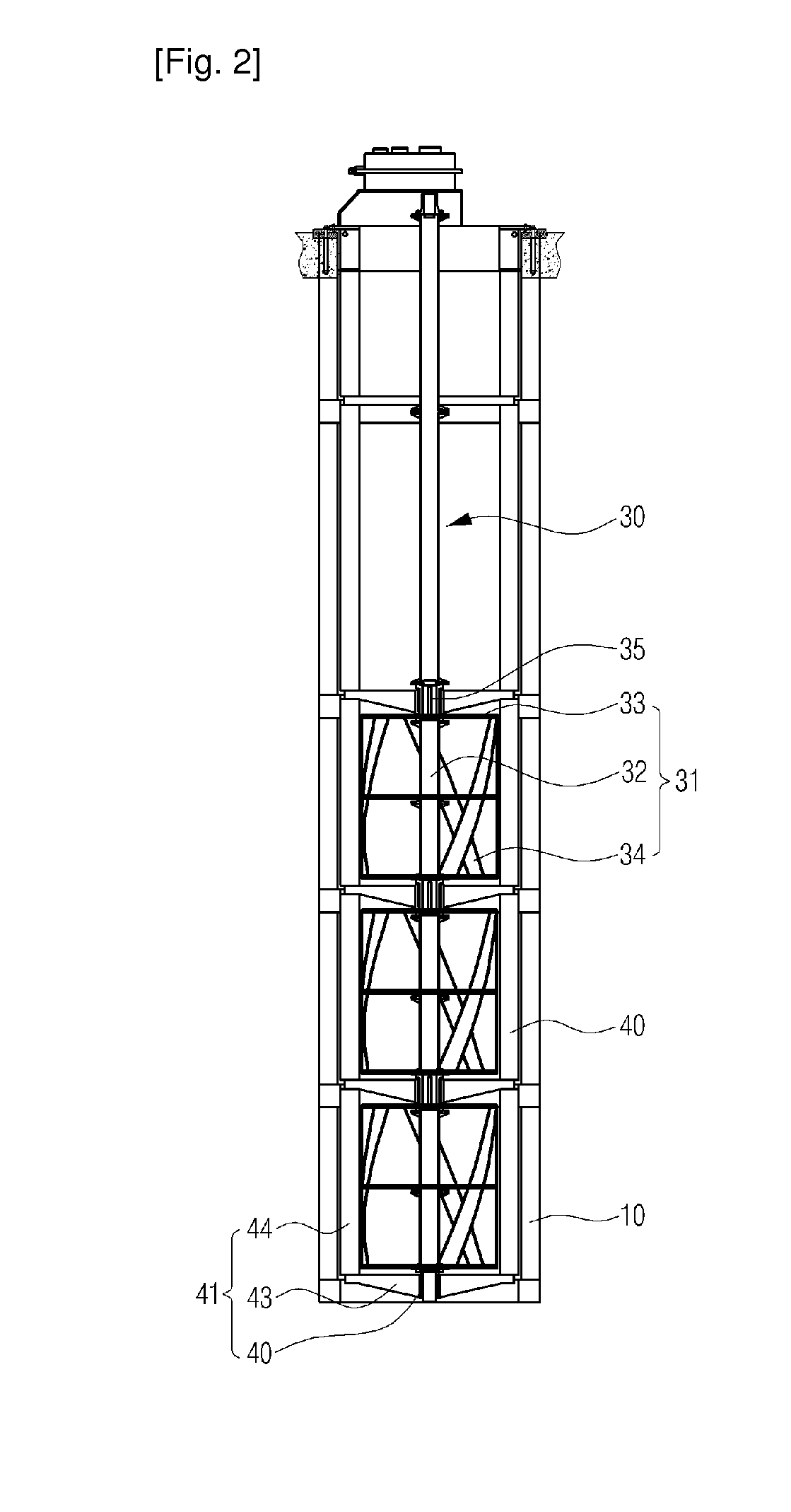

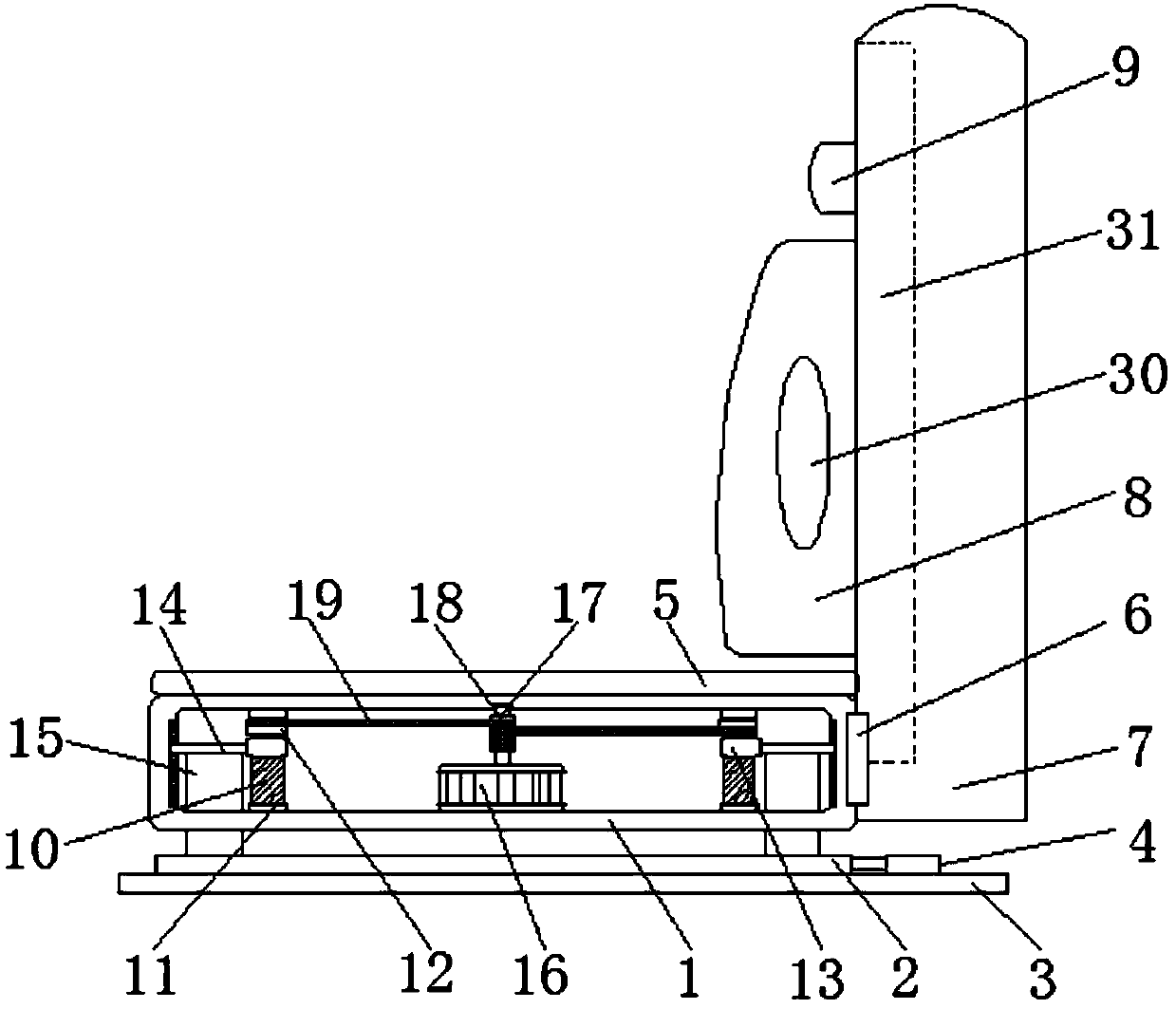

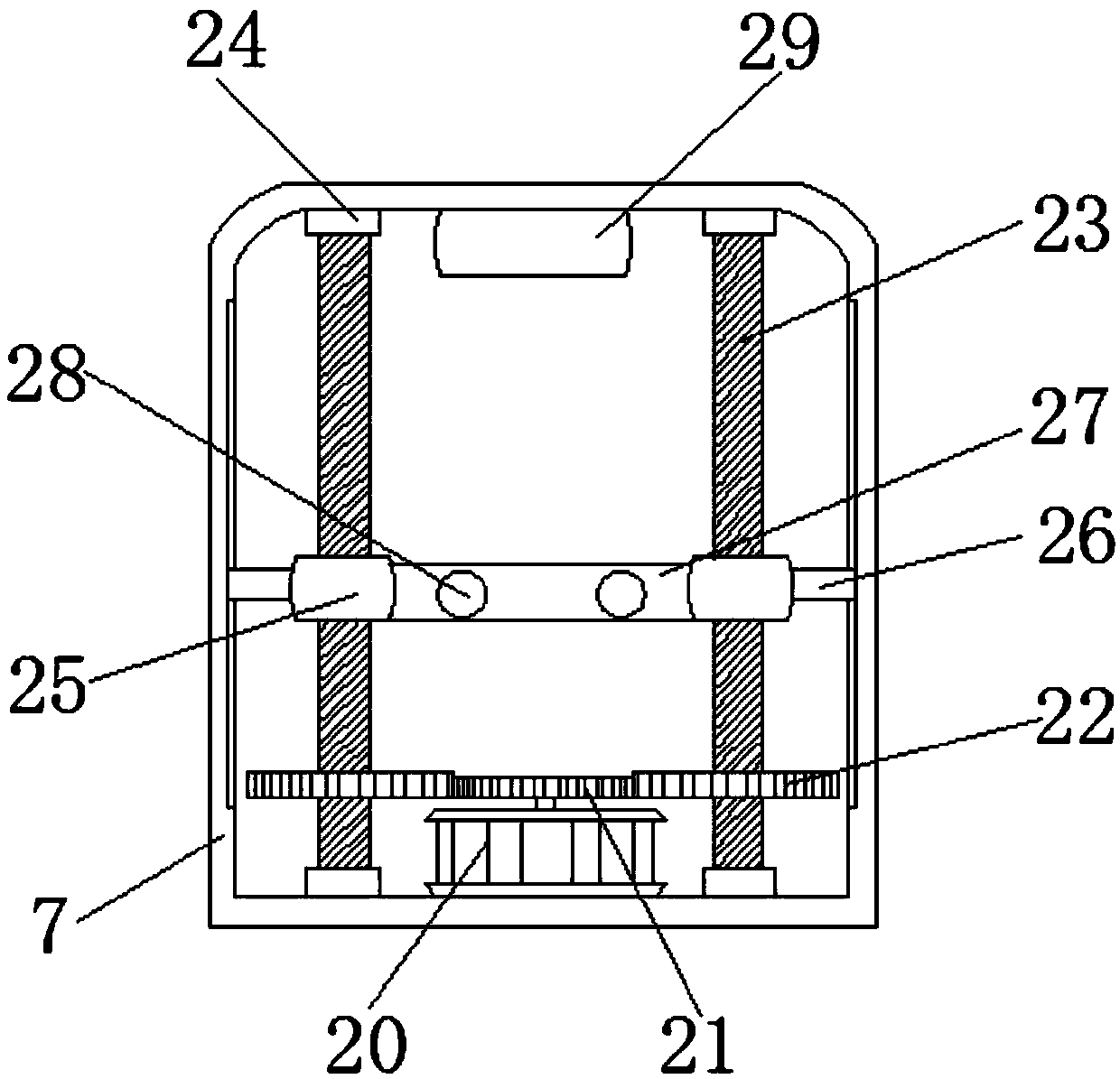

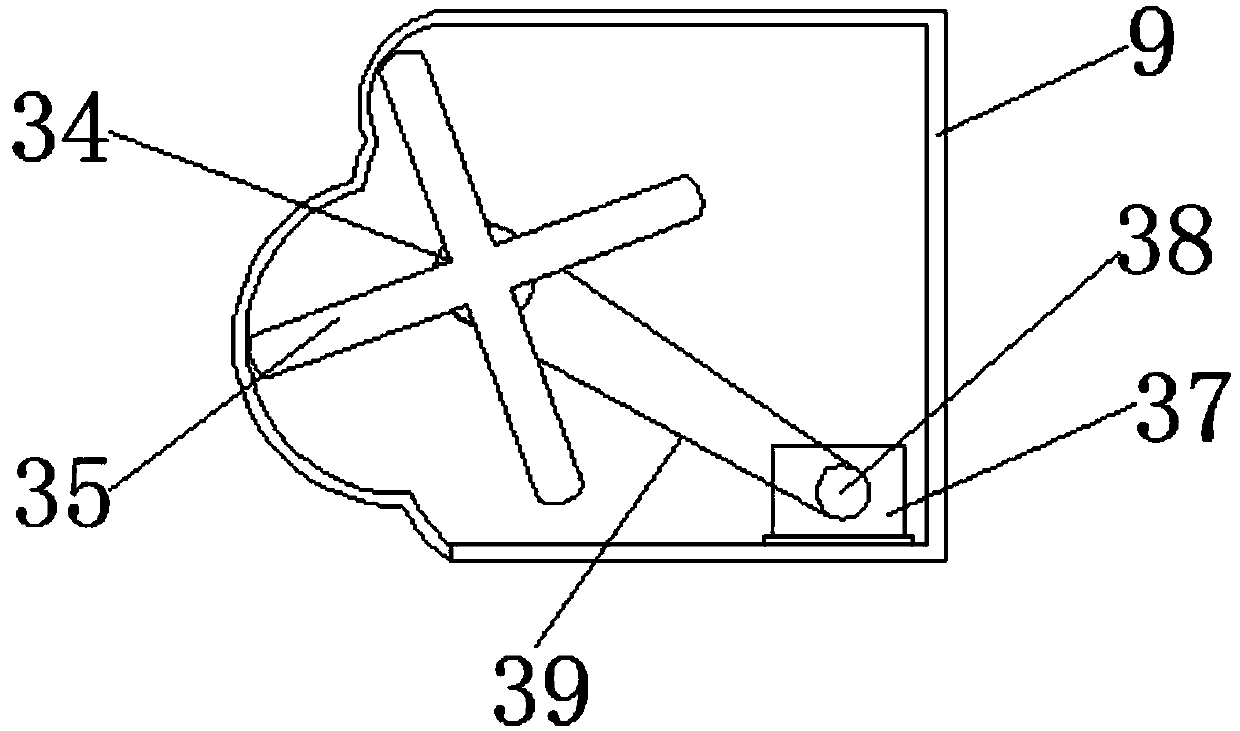

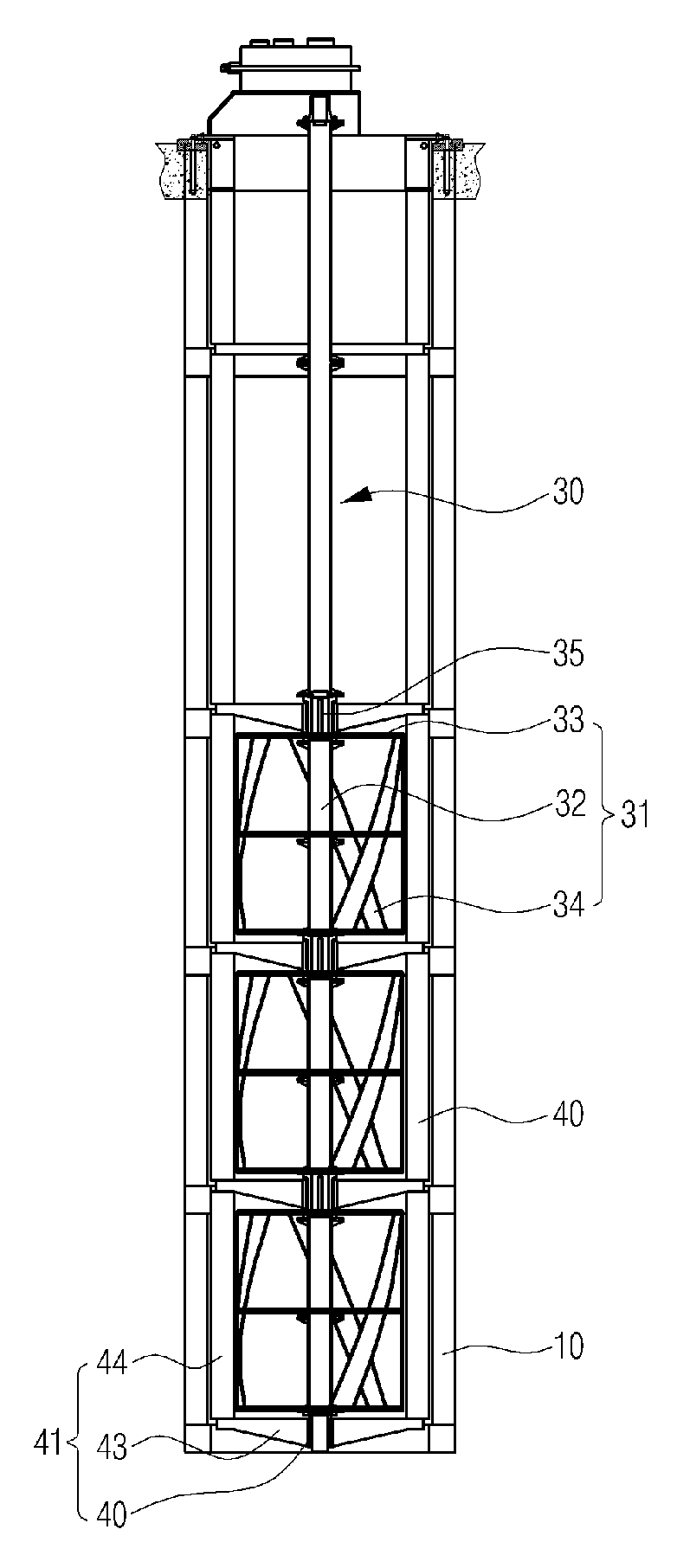

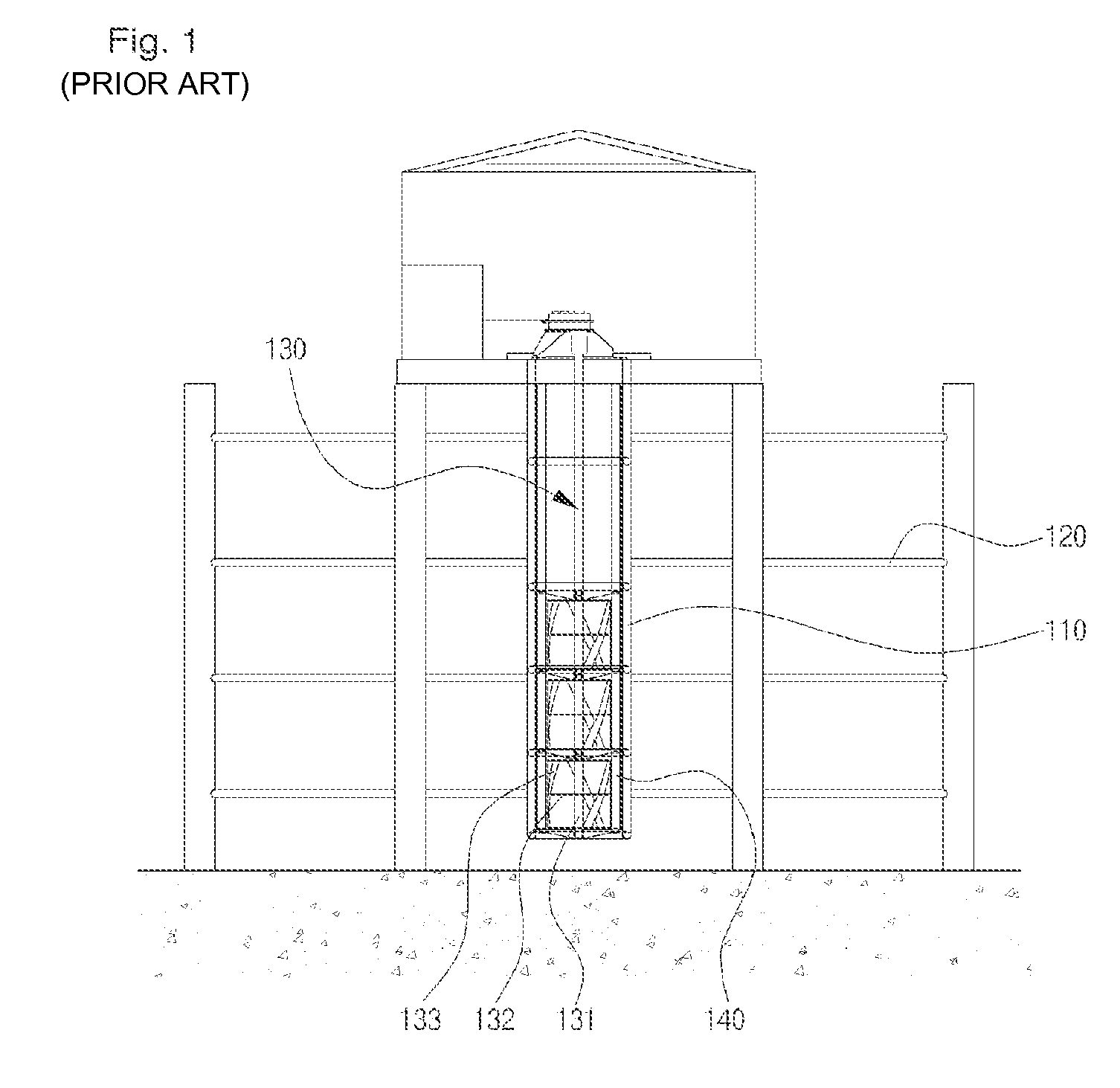

Maintenance system of helical turbine

InactiveUS20110091312A1Improve workabilityShorten the construction periodEngine manufacturePump componentsScrew turbineEngineering

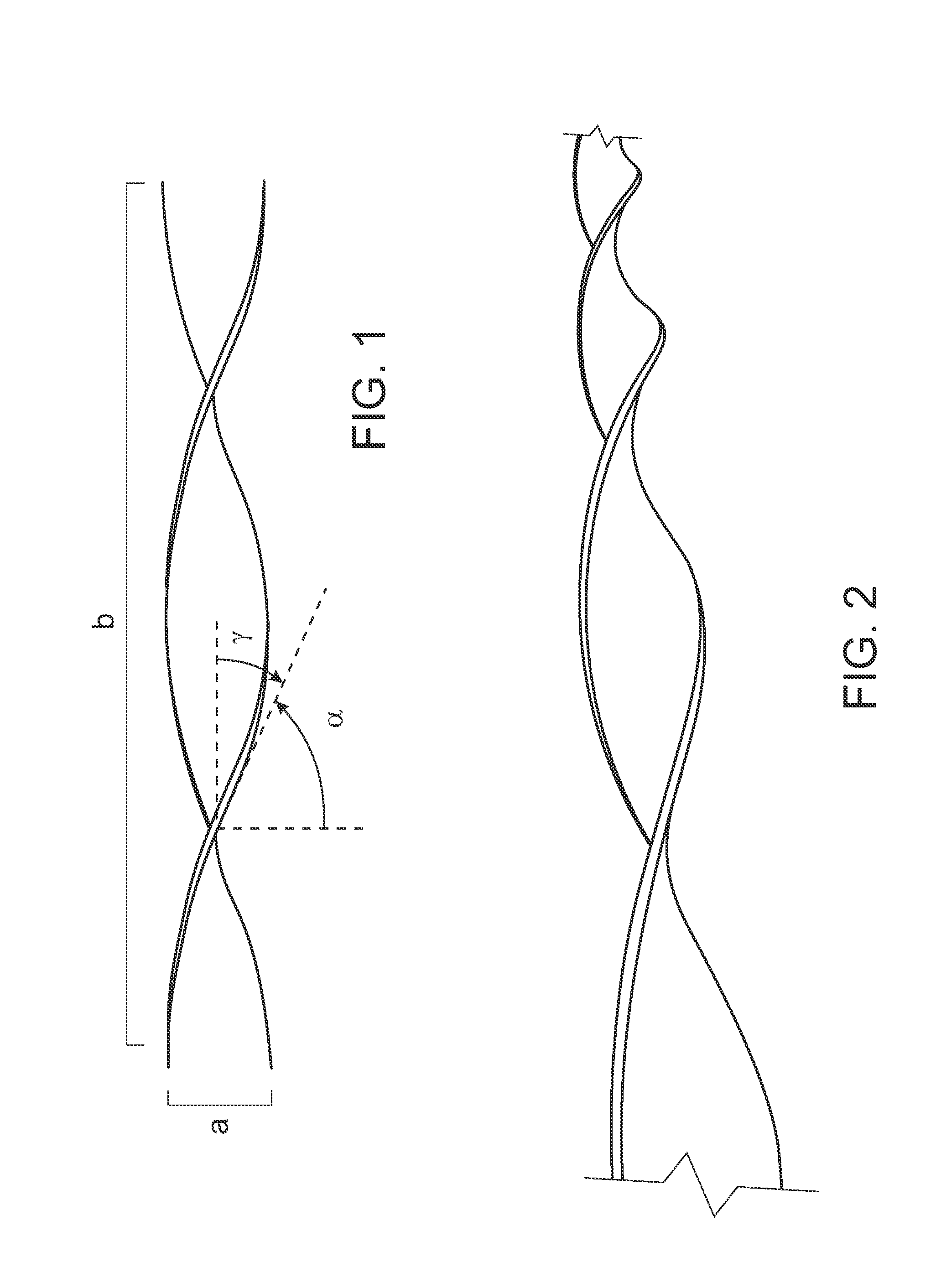

Disclosed is an assembled helical turbine system, which can prevent its assembly / disassembly from being hindered by a rotational force generated during the assembly / disassembly process. The assembled helical turbine system includes a helical turbine formed with a plurality of blades in such a manner as to continuously generate a rotational force under unidirectional or multidirectional fluid flow; a housing assembly for rotatably supporting the helical turbine while surrounding the helical turbine; stoppers formed on a peripheral surface of the housing assembly in such a manner as to protrude to a predetermined height from the peripheral surface; and a housing supporter for supporting the housing assembly in such a manner that the housing assembly can be inserted into and withdrawn from the housing supporter, the housing supporter having catch grooves that are recessed in a shape corresponding to the stoppers so as to fix the stoppers.

Owner:KOREAN OCEAN RES & DEV INST KORDI

Helix turbine system and energy production means

InactiveUS7976267B2Easy to captureImprove efficiencyPropellersWind motor controlScrew turbineDrive shaft

A helical turbine with a circular member attached to one end for redirecting axially flowing fluid into perpendicularly flowing fluid. A fluid diverter for redirecting substantially perpendicular flowing fluid into axially flowing fluid. A hollow circular member attached to an opposite end of the turbine allowing substantially axial flowing fluid into one end of turbine. A drive shaft of at least one generator is in continuous contact with the peripheral edge of the solid or hollow circular member producing faster rpm. A turbine assembly mounted on a rooftop utilizing accelerated wind. Fluid diverters increasing fluid flow into the helical turbine's receding blades. A fluid diverter preventing fluid from hitting turbine's oncoming blades. A tail section for maintaining optimal direction into oncoming fluid. Two counter rotating turbines where the attached circular member's edges are in continuous contact. Multiple turbine body assemblies, using different combinations of disclosed elements, produce multiple preferred embodiments.

Owner:BURRELL IV JAMES W

Power generation system using helical turbine

ActiveUS20100066091A1Reduce construction costsAvoid environmental pollutionWorking fluid for enginesMachines/enginesElectricityHigh rate

Disclosed is a helical turbine power generation system for generating electricity by using a helical turbine and a synchronous generator, the system including: a helical turbine rotatably provided in a frame so as to continuously generate rotation force under unidirectional or multidirectional fluid flow; a step-up gear for increasing a rotational velocity of the helical turbine up to a level required for generating electricity; a fluid coupling for preventing the rotational velocity increased by the step-up gear from increasing above a required velocity at a temporarily high rate of fluid flow; and a synchronous generator for generating electricity by using the rotational velocity transferred from the fluid coupling. Therefore, it is possible to reduce equipment costs and to prevent environmental pollution.

Owner:KOREA OCEAN RES & DEV INST

Car seat for more comfortable driving

The invention provides a car seat for more comfortable driving and relates to the technical field of car seats. The car seat for more comfortable driving comprises a seat, wherein a foam-rubber cushion is adhered to the top of the seat; a bottom plate is arranged at the bottom of the seat; the bottom plate is embedded in a clamping groove arranged on a base at the bottom of the bottom plate; an electrohydraulic push rod is welded to the top of the base; a telescopic part of the electrohydraulic push rod is welded to one side of the bottom plate; one side of the seat is fixedly connected with one side of a backrest and the position near the bottom of the seat through a seat bending adjustment device; and two side wings near the edges the backrest are adhered to the side, near the seat, of the backrest. The car seat for more comfortable driving drives screw turbines to move up and down through the rotation of screw rods driven by a seat motor and screw sliding rods drive lifting and lowering rods to extend and retract at the bottom of the seat, so as to control the entire seat to be lifted and lowered. The adjustable height of the seat can facilitate the use of occupants in various shapes. At the same time, the position of a headrest is adjustable so as to improve the driving comfort.

Owner:绍兴柯桥雷霄机械科技有限公司

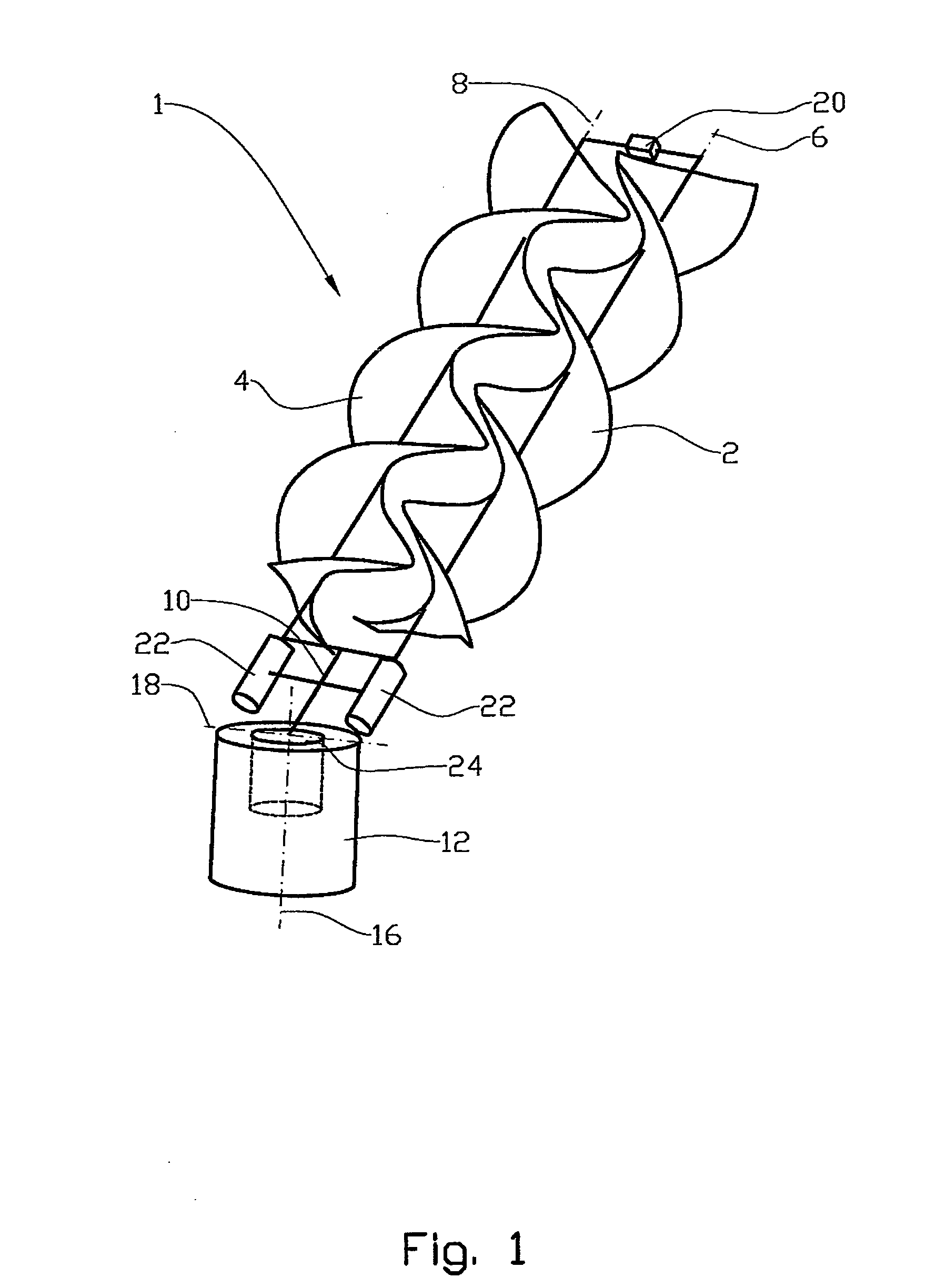

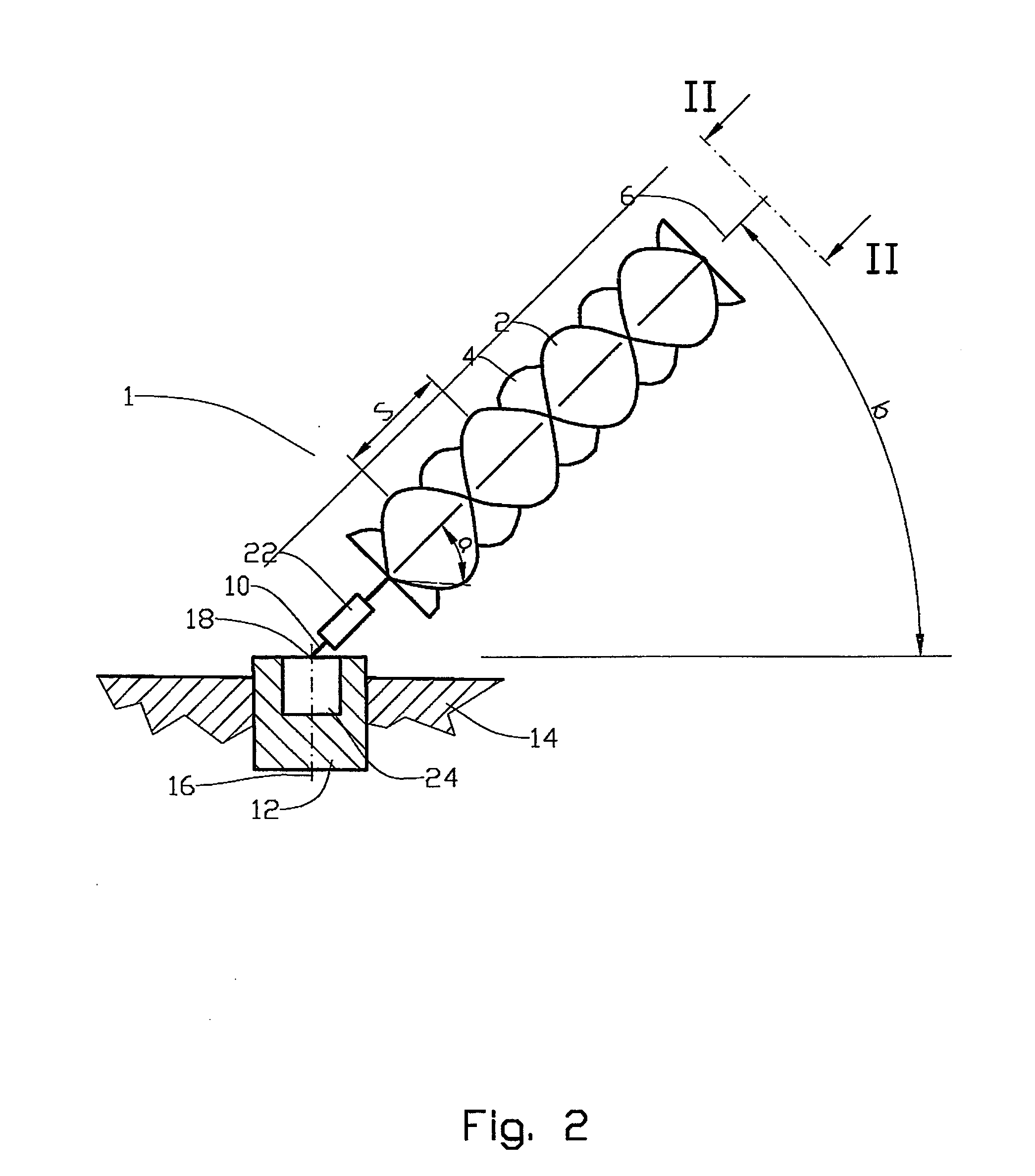

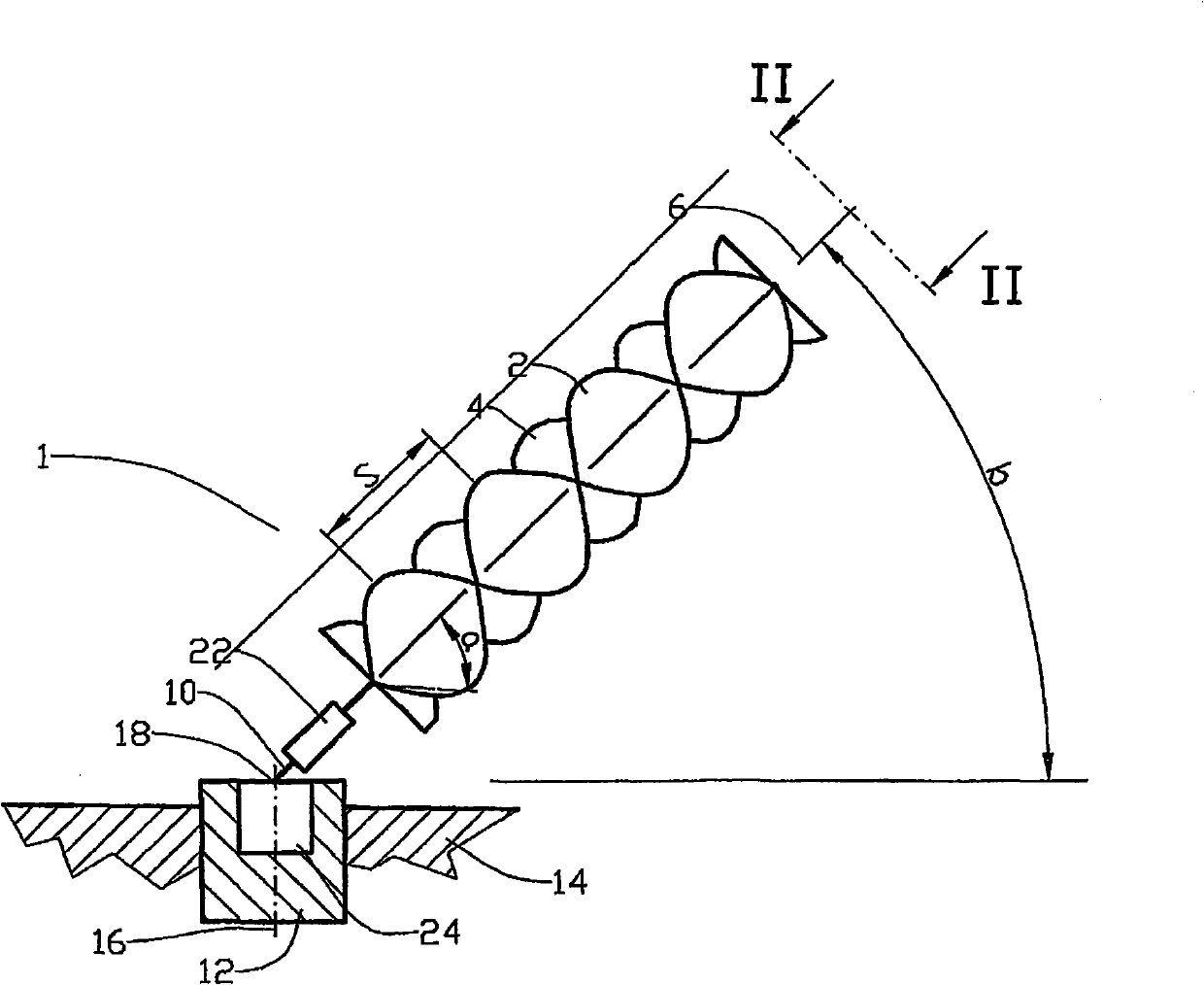

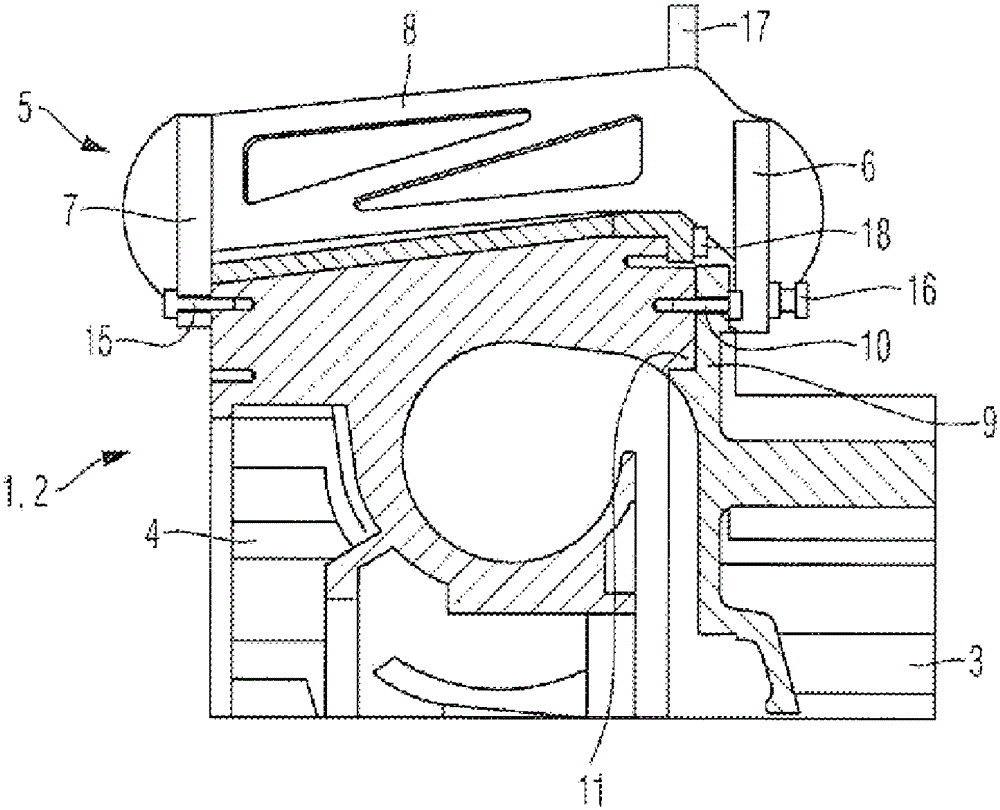

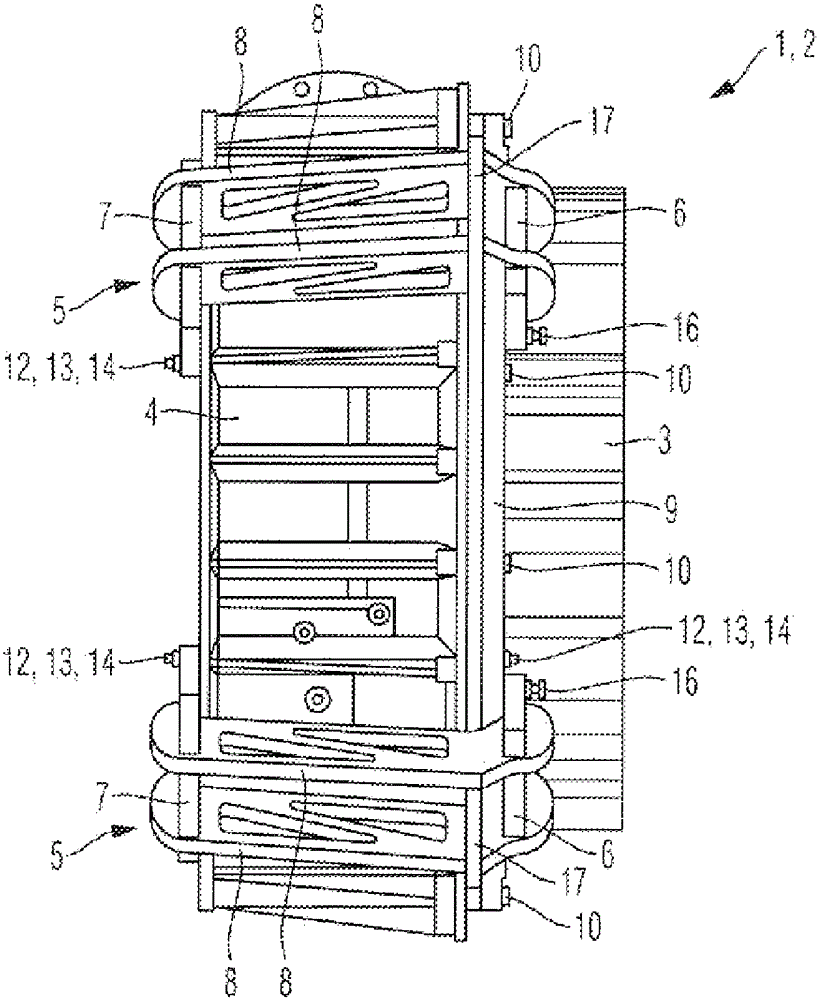

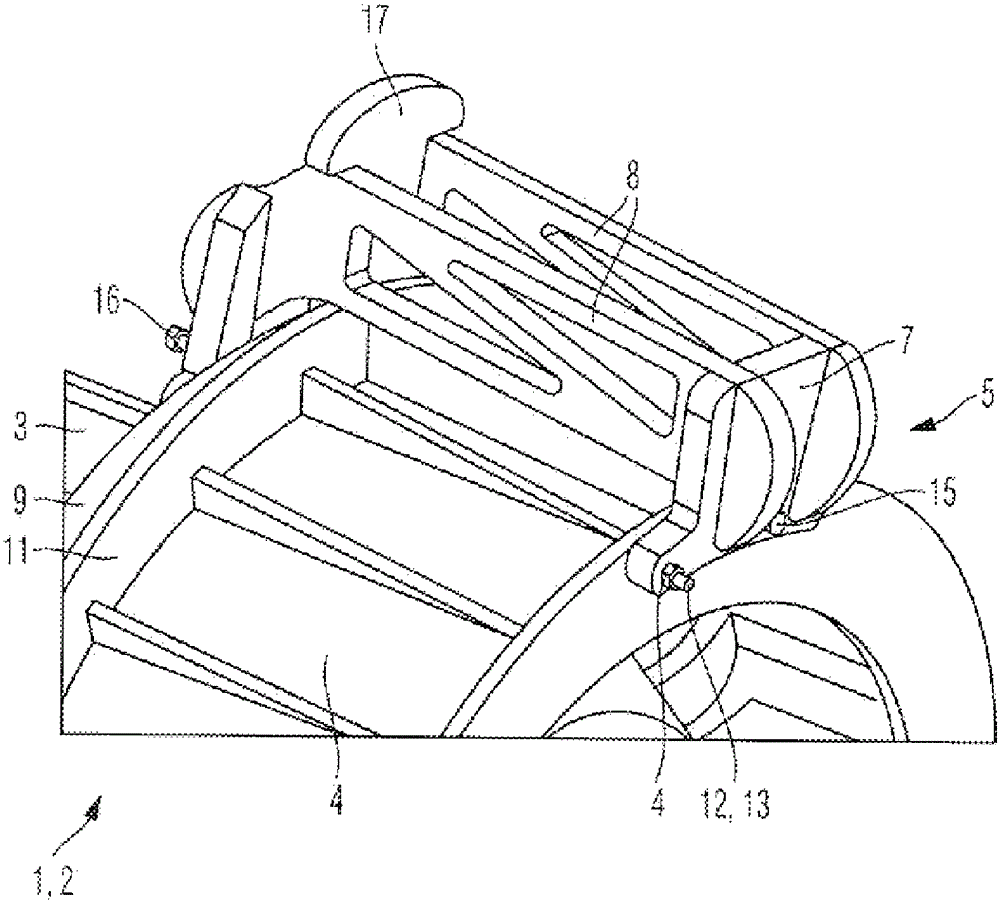

Turbine arrangement

InactiveCN101910622ASimple taskSimple structureMachines/enginesEngine componentsScrew turbineBuoyancy

A turbine arrangement (1) for extracting energy from flowing water, the turbine arrangement including a screw turbine (2, 4) with a suspension means (10), buoyancy element and bottom mount (12), and necessary transmission elements for transmitting energy to a power machine (22), and the turbine arrangement (1) including at least two parallel screw turbines (2, 4).

Owner:弗卢米尔有限公司

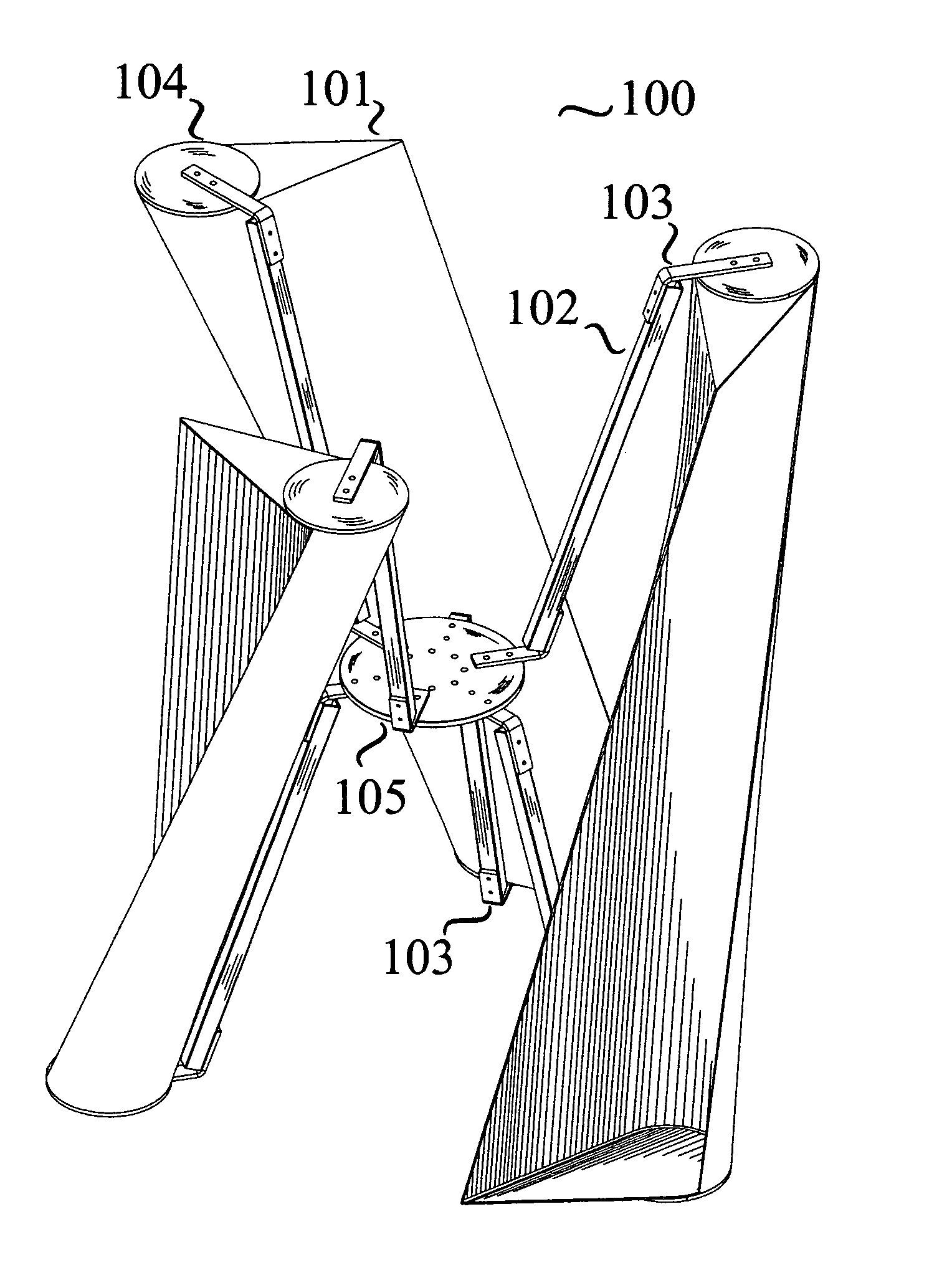

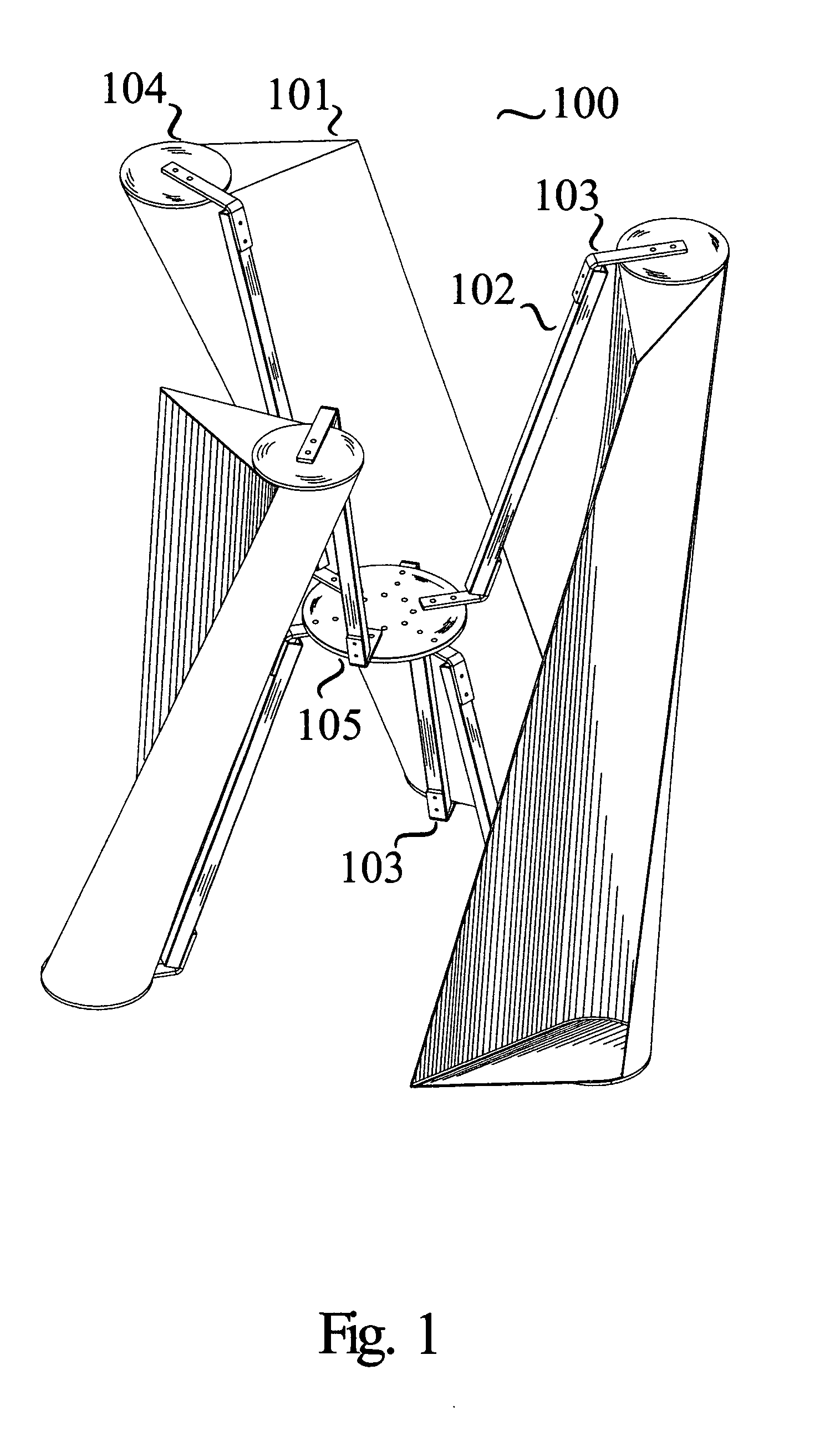

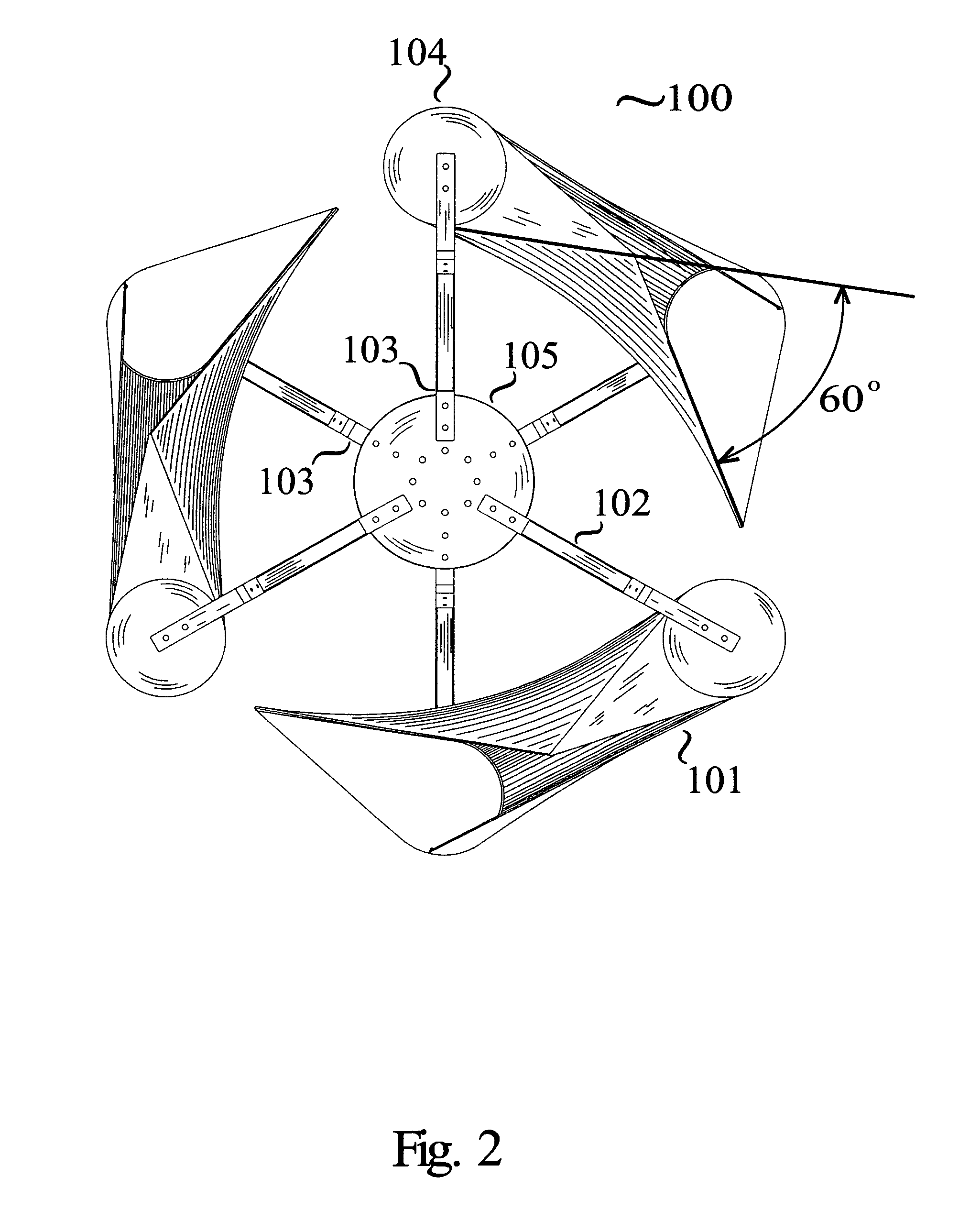

Hvata-hybrid vertical axis turbine assembly operable under omni-directional flow for power generating systems

A hybrid, vertical axis helical turbine assembly capable of providing unidirectional rotation under an omni-directional low speed obverse fluid flow (gas or liquid), respectively gas flow is disclosed. The assembly comprises a minimum (but not limited to) of three hybrid (airfoil enhanced helical vane profile) wings, which are substantially spaced from the vertical axis (Z) and circumferentially spaced from one another. Each hybrid wing is fixed to the center hub in a rigid position by two or more arms, which are symmetrically located from each other in conjunction with the hub's horizontal axis (X). The hybrid, vertical axis helical turbine assembly provides high torque at very low wind speed because of the absolute symmetric airfoil enhanced helical vane profile wing, which design maintain adaptive lift to drag ratio over the one rotational revolution time line in coincidence of the upwind direction. These characteristics make the hybrid, vertical axis helical turbine assembly suitable for urban off grid and grid tie applications in low wind speed areas and areas of reputable wind turbulence.

Owner:GOCHEV KIRIL STEFANOV

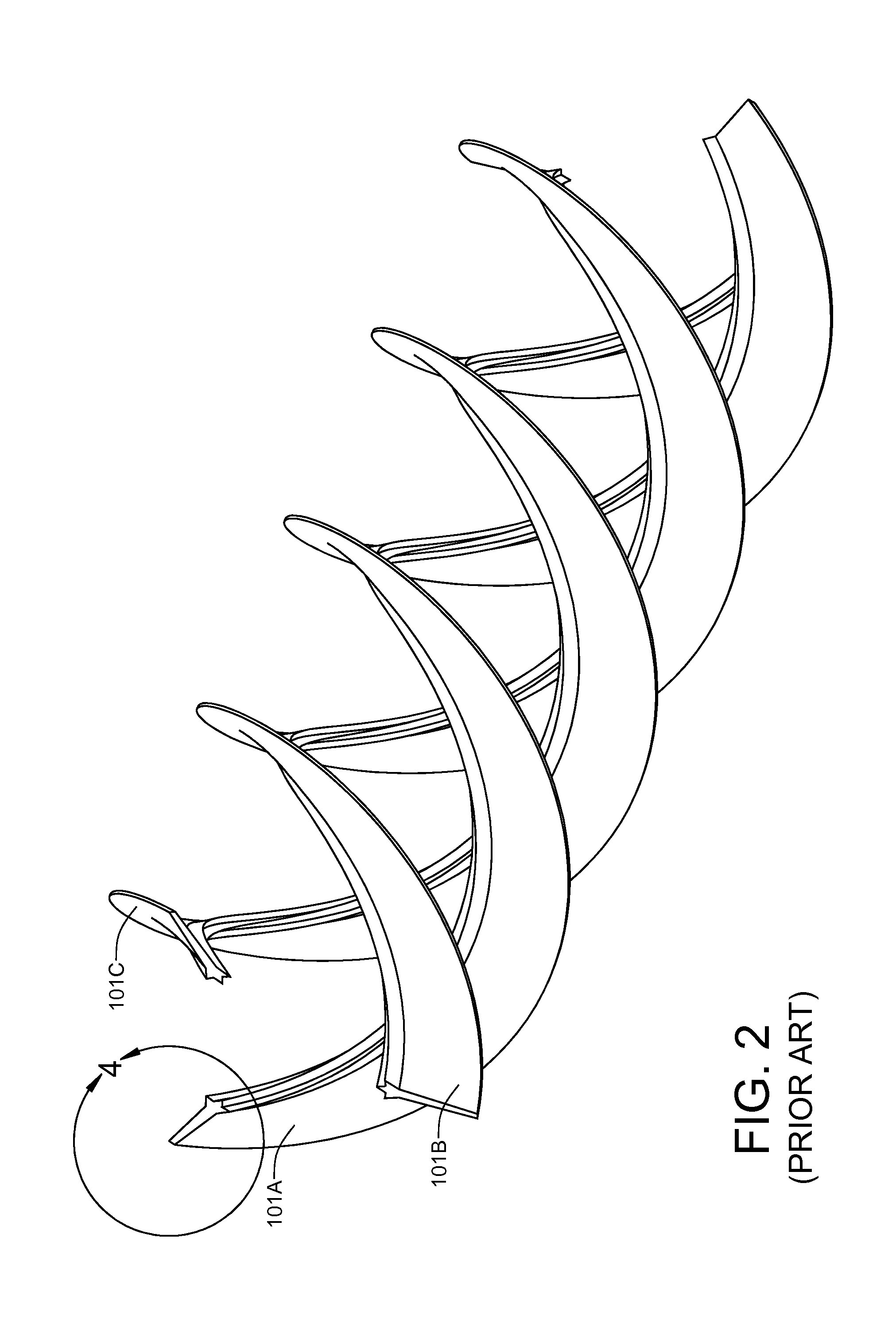

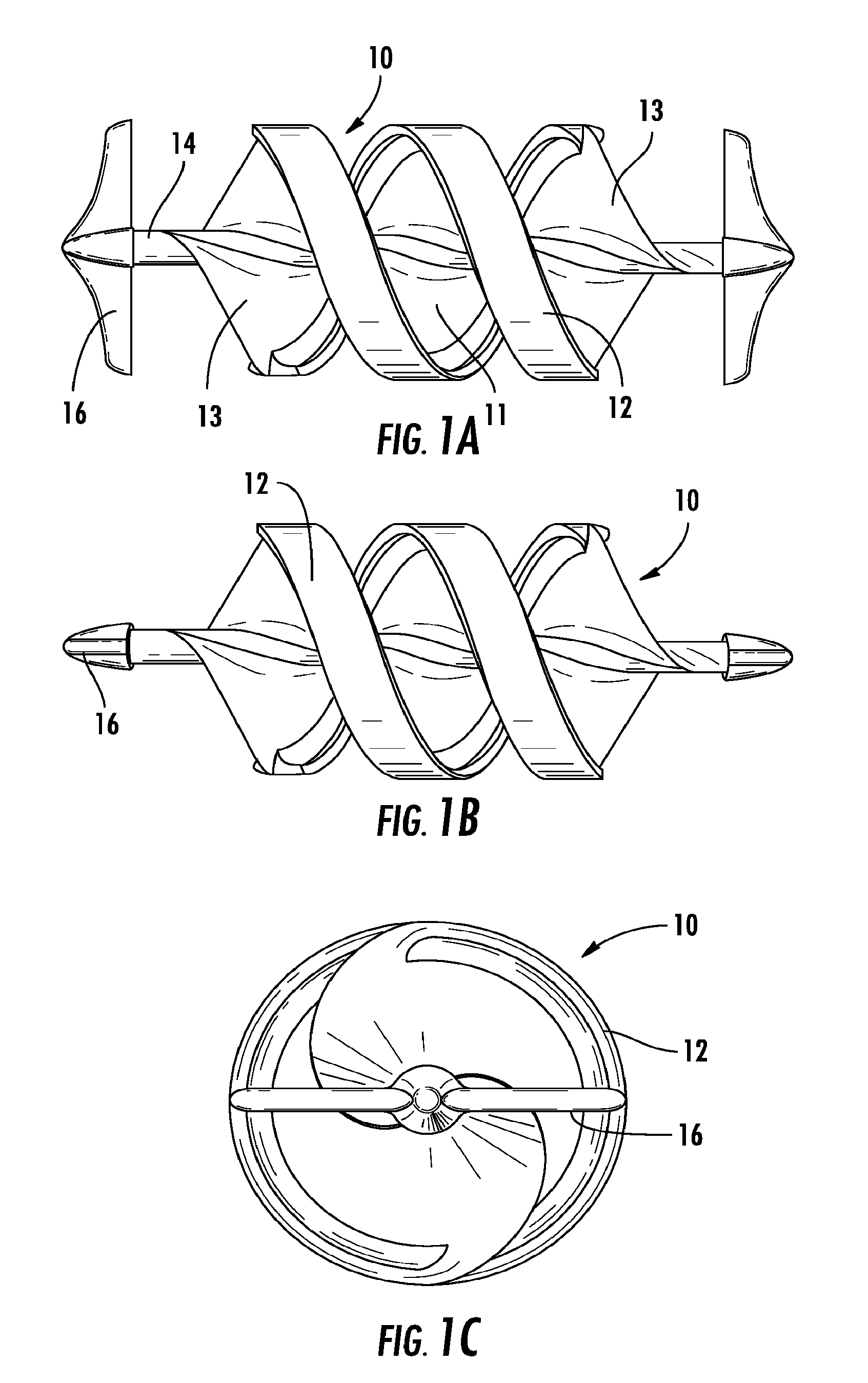

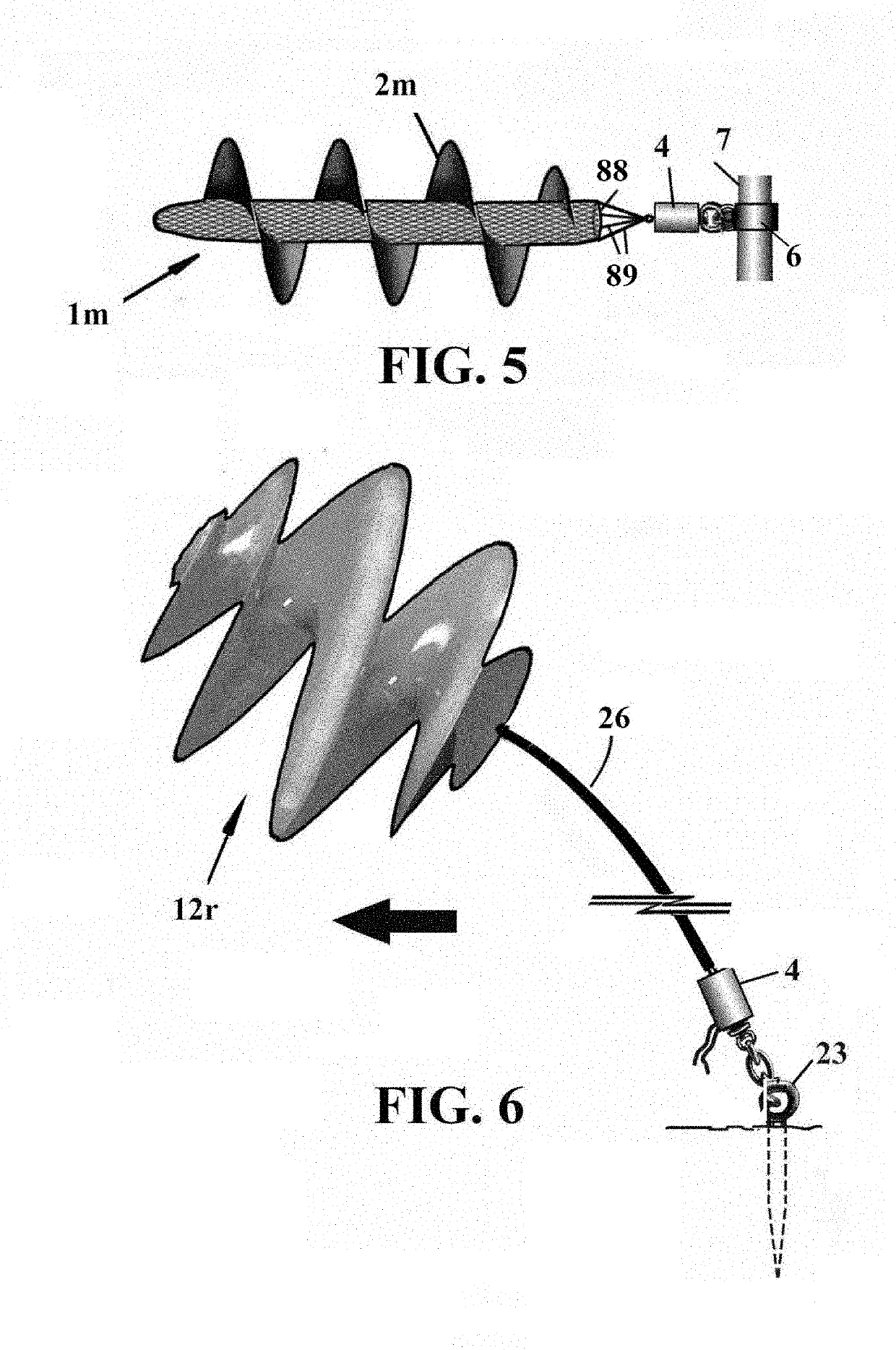

Tapered helical auger turbine to convert hydrokinetic energy into electrical energy

ActiveUS8152464B2Reduce turbulencePromote generationPropellersWind motor controlTidal waterScrew turbine

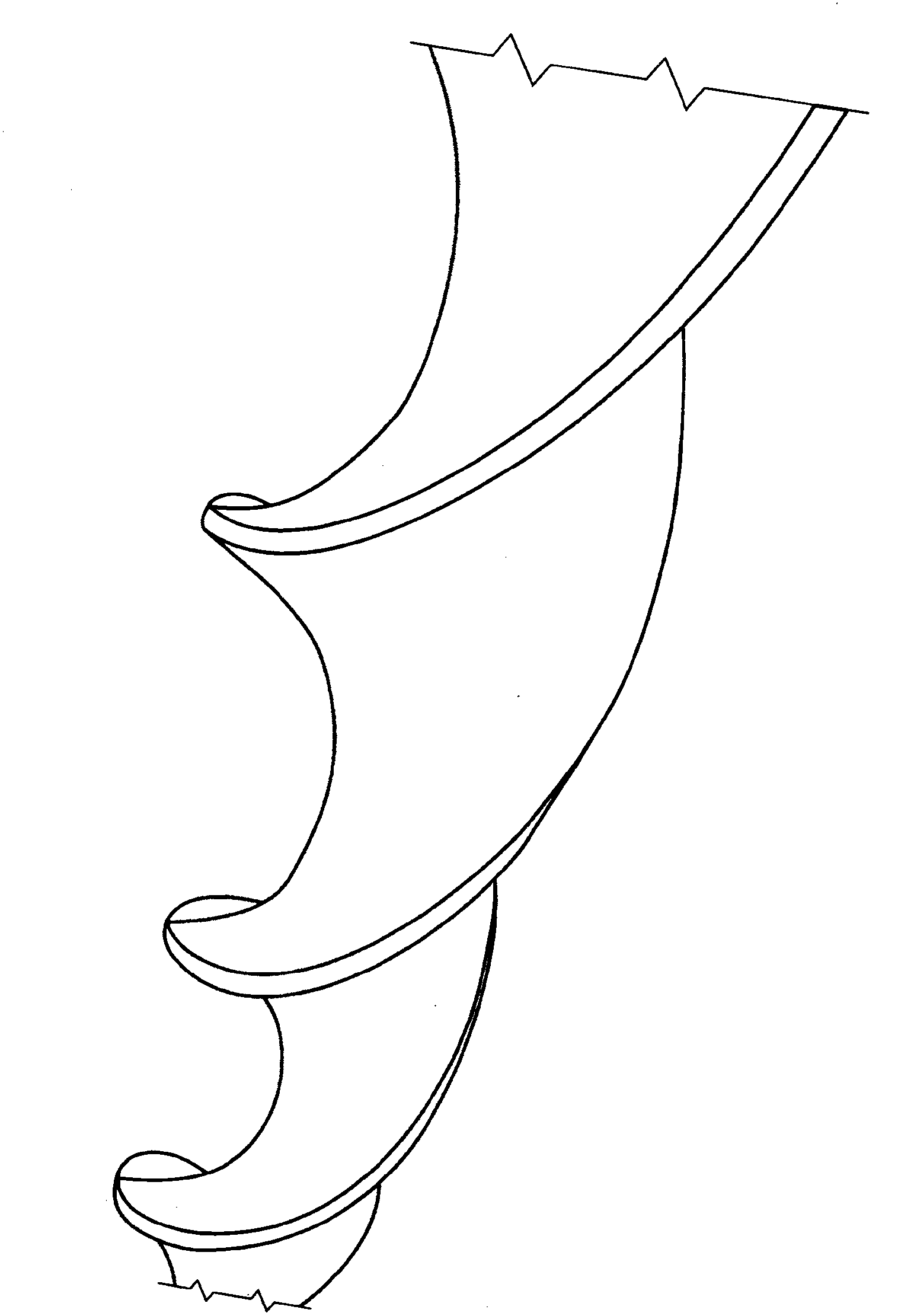

A helical auger turbine and hydrokinetic device for use with electrical generators for producing electricity. A helical turbine blade may be mounted on a central shaft, and a flange extending perpendicularly to an edge of the turbine blade. The helical auger may be a multi-section auger having radial sections covering a radial arc of between 45 degrees and 180 degrees, and that are rotational molded with identical center sections. The auger may have tapered end sections. The radial and end sections may be interlockingly mounted onto the central shaft to enable the complete transfer of torque captured by the helical auger by a moving fluid media, such as a tidal water flow, to the central shaft. The adjacent surfaces of the radial and end sections may be flush with one another to reduce disruptions of the moving fluid flowing over the completed helical auger and rotating the assembled helical auger.

Owner:ANDERSON JR WINFIELD SCOTT

Power generation system using helical turbine

ActiveUS8222761B2Reduce construction costsAvoid environmental pollutionWorking fluid for enginesMachines/enginesElectricityHigh rate

Disclosed is a helical turbine power generation system for generating electricity by using a helical turbine and a synchronous generator, the system including: a helical turbine rotatably provided in a frame so as to continuously generate rotation force under unidirectional or multidirectional fluid flow; a step-up gear for increasing a rotational velocity of the helical turbine up to a level required for generating electricity; a fluid coupling for preventing the rotational velocity increased by the step-up gear from increasing above a required velocity at a temporarily high rate of fluid flow; and a synchronous generator for generating electricity by using the rotational velocity transferred from the fluid coupling. Therefore, it is possible to reduce equipment costs and to prevent environmental pollution.

Owner:KOREA OCEAN RES & DEV INST

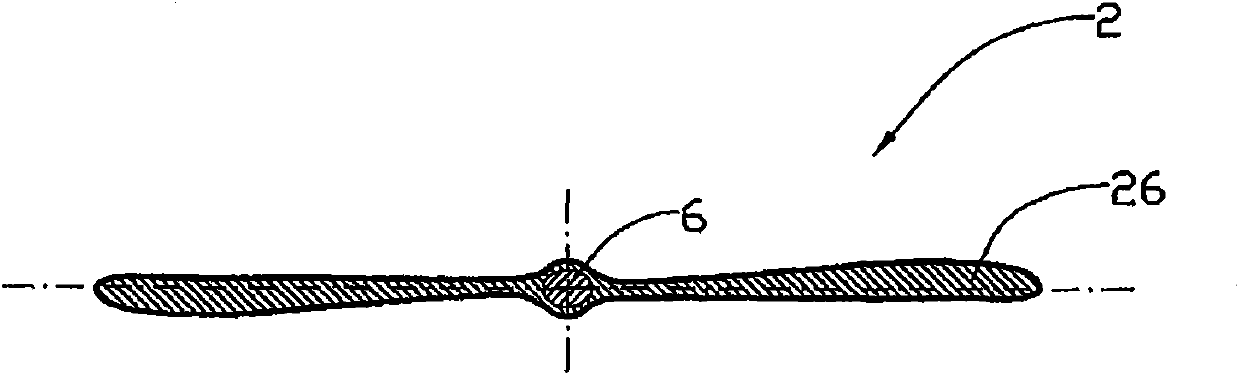

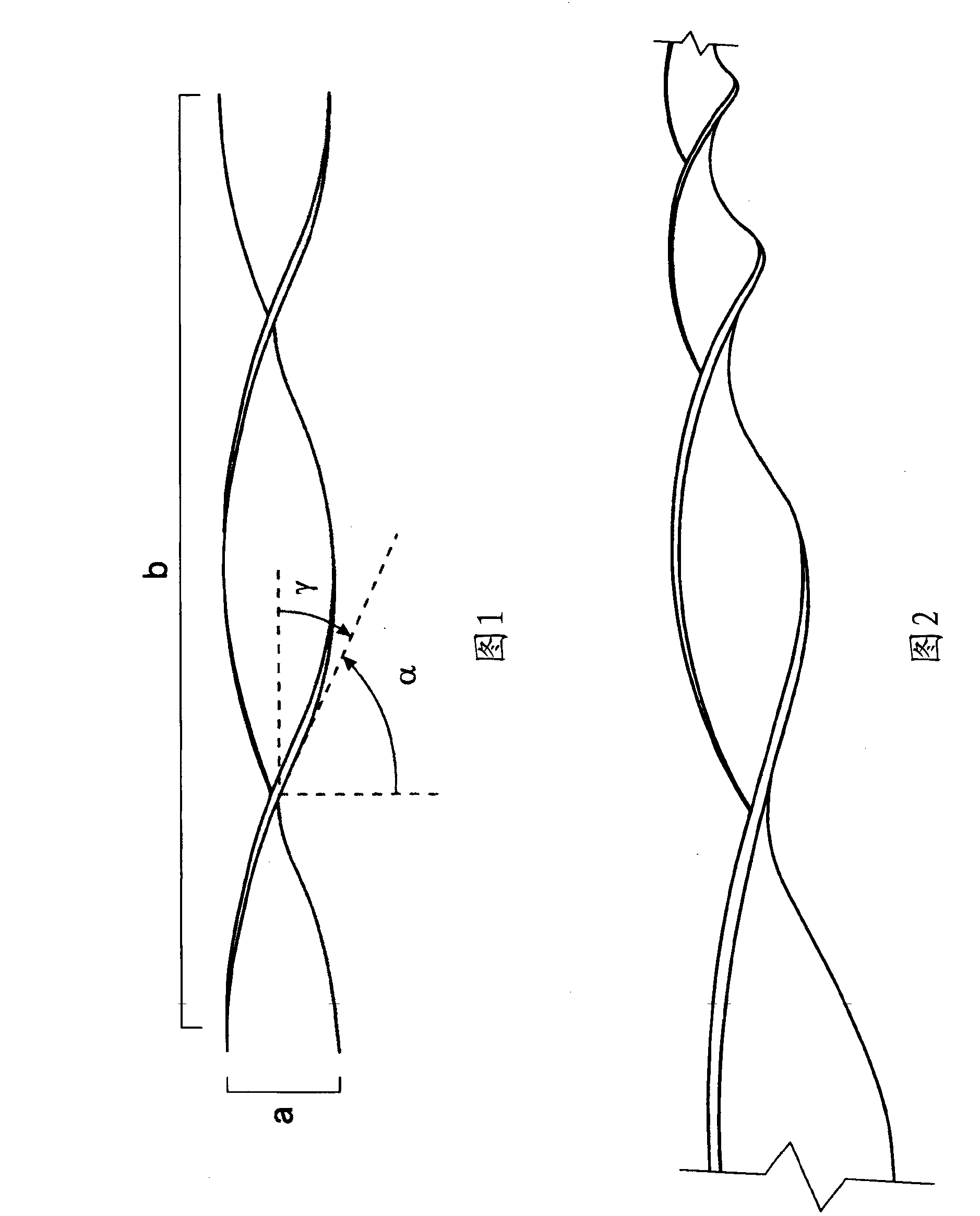

Screw turbine and method of power generation

InactiveUS20130177424A1Smooth rotationPromote resultsPropellersPump componentsElectricityScrew turbine

A screw turbine comprising a helical turbine blade mounted for axial rotation, a mount associated with the helical turbine blade and mounting the helical turbine blade for axial rotation, and a generator associated with the helical turbine blade which converts energy imparted to the helical turbine blade to electricity, wherein the diameter of the helical turbine blade is less than the lead of the helical turbine blade and wherein said screw turbine is adapted to permit lateral exchange of fluid in use.

Owner:WEBBER GREGORY MARK

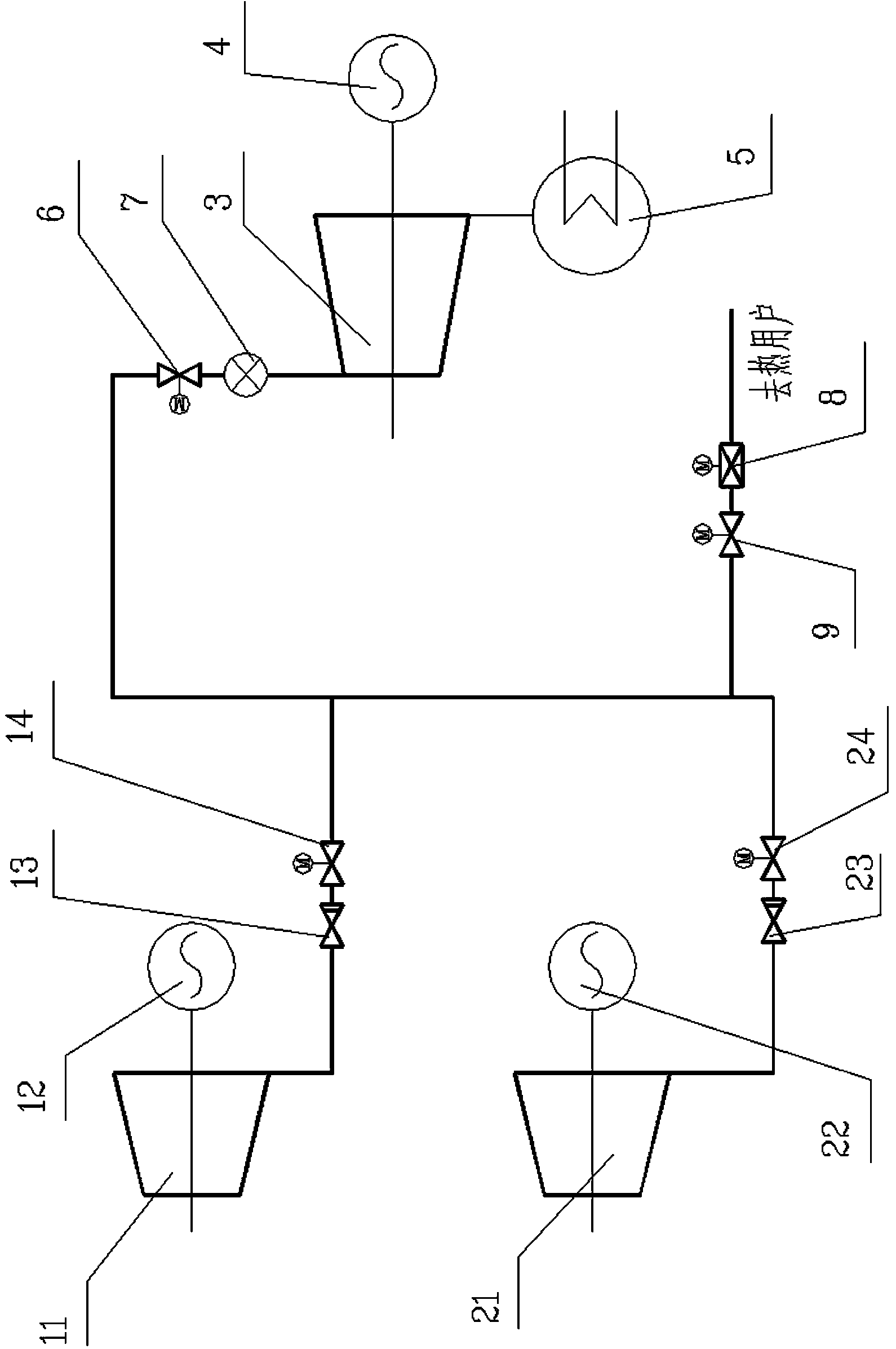

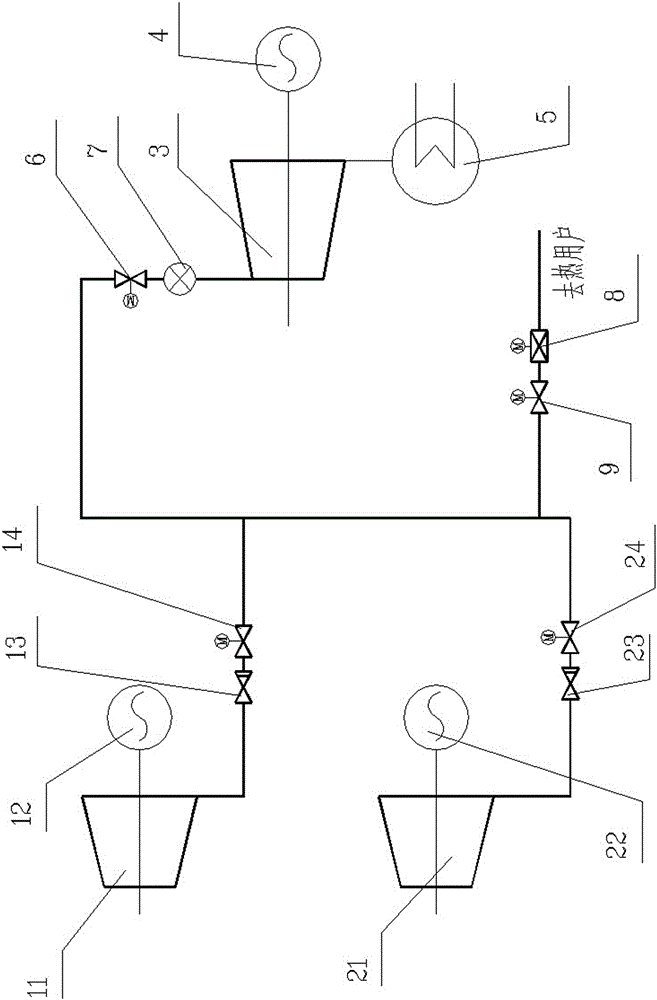

Method for solving combined heat and power generation, split-shaft heat supply turbine generating set, and operating method of split-shaft heat supply turbine generating set

InactiveCN103883364AImprove thermal efficiency of power generationImprove operational flexibilityEngine componentsSteam engine plantsScrew turbineCogeneration

Disclosed is a method for solving combined heat and power generation, a split-shaft heat supply turbine generating set, and an operating method of the split-shaft heat supply turbine generating set. The split-shaft heat supply turbine generating set comprises at least two turbines, including front turbines and rear turbines; each front turbine is a backpressure turbine or extraction backpressure turbine; each rear turbine is an all-condensing low-pressure turbine; the front turbines and the rear turbines are connected through a pipeline; a to-user pipeline is disposed on the pipe for connecting the front and rear turbines; the pipelines are controlled through a pipeline controller; each front turbine is provided with one turbine generator; each rear turbine is provided with one turbine generator and a condenser. The backpressure turbine and low-pressure parameter all-condensing turbine technology is utilized, the two types of turbines are subjected to split-shaft combination, and backpressure, extraction condensing and all-condensing operations can be achieved; in the backpressure operation mode, heat and power generating efficiency of the set can be greatly increased; in the extraction condensing or all-condensing operation mode, operational flexibility of the set can be greatly improved.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

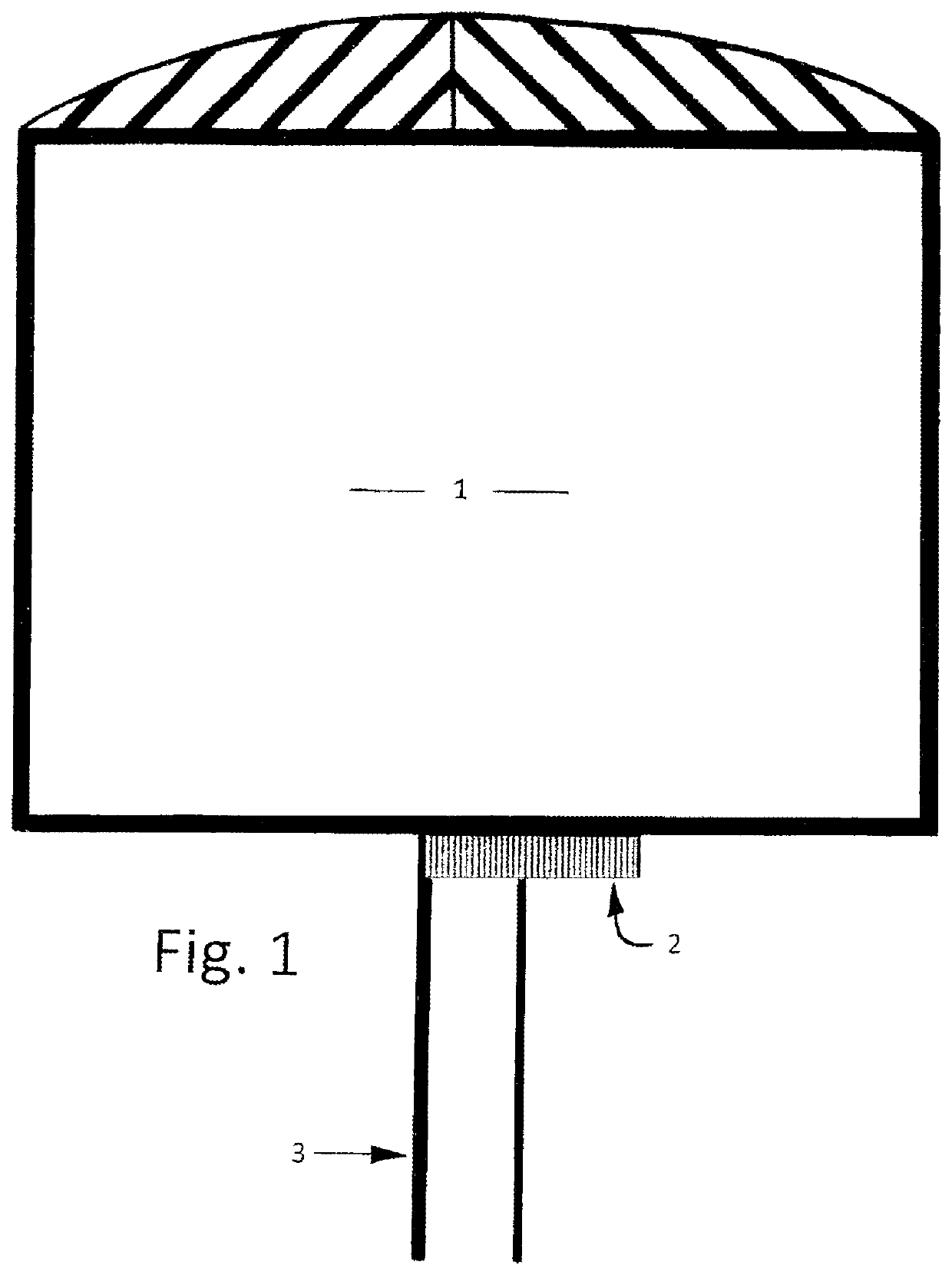

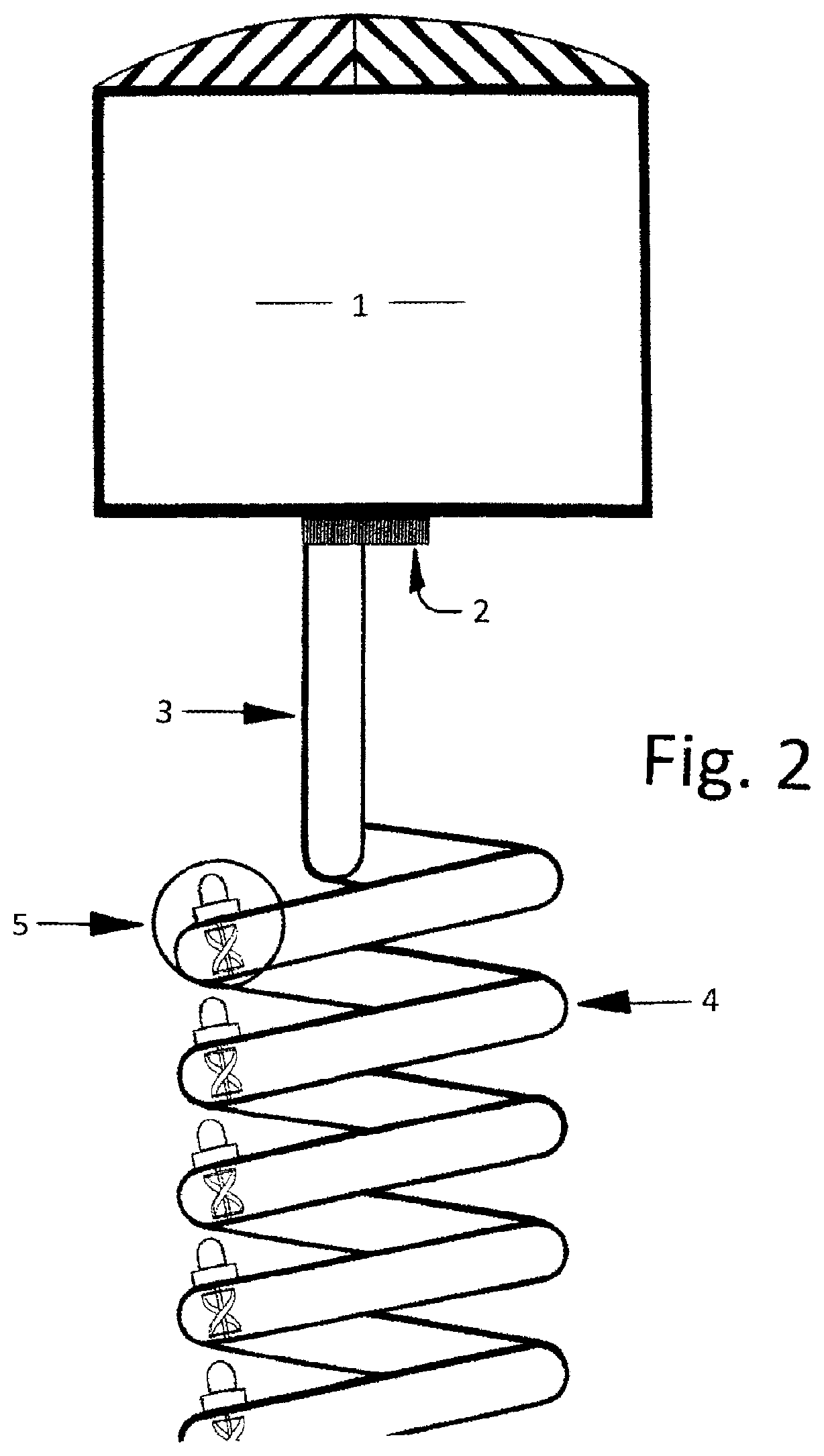

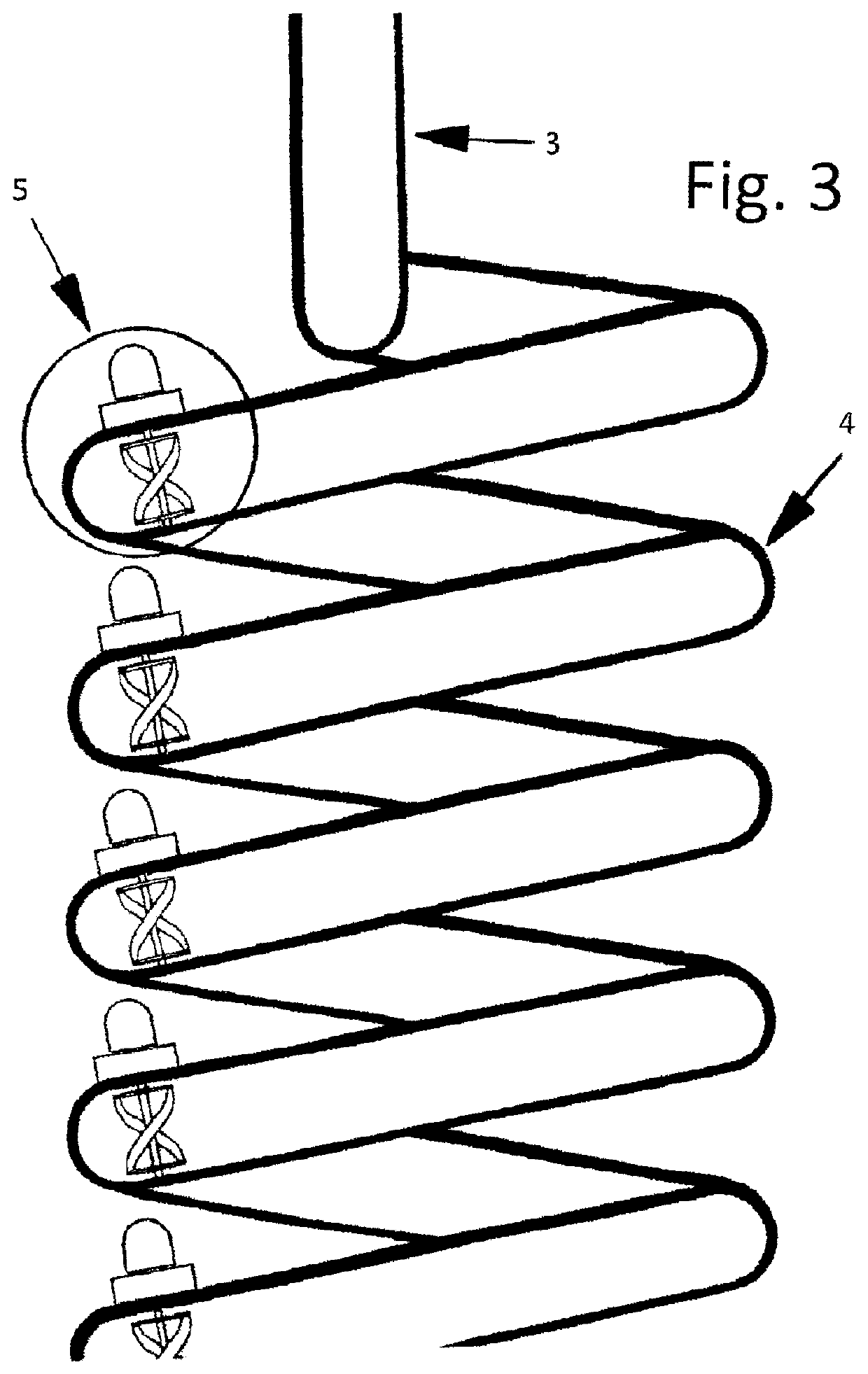

System For Capturing the Energy of Fluid Currents

ActiveUS20190178224A1High level of performanceAvoid disrupting navigationWorking fluid for enginesHydro energy generationScrew turbineCoil spring

A system for capturing the energy of fluid currents, using axial turbines with one free end and the other end fastened to a mechanical element or electric generator, characterized in that the turbines comprise coil springs, helically twisted plates or crossbeams, complete helical turbines with their shafts or just their blades, which capture the energy of wind or water, with their shaft or fastened end actuating an electric generator or mechanical system. In all cases the blades around the rotation axis of the turbines have an inclination such that they generate a torque in the same direction and the turbines are automatically oriented by the water or air currents, like weather vanes.

Owner:SAIZ MANUEL M

Ffwn clean energy power plant

PendingUS20220010763A1Improve efficiencyIncrease power outputHydro energy generationMachines/enginesWater storage tankHigh pressure water

Gravity and hydrostatic pressure are natural forces that have considerable force generating capabilities which can make significant contributions during the operation of a FFWN 24 / 7 / 365, baseload, 100% clean energy power plant. When these natural forces are combined with compressed air in the upper part of an elevated storage tank containing a liquid and the partial vacuum created by powerful pumps to produce a targeted water flow rate velocity of about 31.3 m / s through the entire length of a coiled section of pipe containing one or more helical turbines in each coil that are connected to an external generator, the electricity produced during a power producing cycle by all the turbines / generators when combined will be considerably more than the power ultimately consumed by the pumps to return the highly pressurized water in a ground level tank back to the storage tank utilizing a return tank and simple water displacement.

Owner:VON BARGEN EDWARD

Turbine shaft engine

InactiveCN103967618AIncrease intake pressureGreat power to weight ratioGas turbine plantsJet propulsion plantsAxial compressorExhaust valve

A turbine shaft engine comprises axial-flow compressors, evaporative combustors, a turbine, a free turbine, a drive shaft, an exhaust nozzle and the like, and is characterized by further comprising by-pass pipes and internal exhaust valves, and external exhaust valves are mounted or are not mounted in pipes outside the engine and between air inlets and air outlets of the by-pass pipes; and when the engine is started for operation, the internal exhaust valves are opened, the supercharge ratios of the axial-flow compressors are increased and kept unchanged by means of the by-pass pipes and through opening and closing of the internal exhaust valves or the internal exhaust valves and the external exhaust valves, the increased supercharge ratios are not larger than the mechanical strength limit which can be borne by the axial-flow compressors, the turbine and the free turbine, the turbine inlet temperature is kept unchanged, that is, the supercharge ratios and a power weight ratio are increased, the oil consumption rate is reduced, however, the number of stages of the axial-flow compressors and the turbines is not increased, and the turbine inlet temperature is not improved.

Owner:李吉光

Maintenance system of helical turbine

InactiveUS8807917B2Prevent rotationEasy to implementPropellersWind motor controlScrew turbineAssembly disassembly

Disclosed is an assembled helical turbine system, which can prevent its assembly / disassembly from being hindered by a rotational force generated during the assembly / disassembly process. The assembled helical turbine system includes a helical turbine formed with a plurality of blades in such a manner as to continuously generate a rotational force under unidirectional or multidirectional fluid flow; a housing assembly for rotatably supporting the helical turbine while surrounding the helical turbine; stoppers formed on a peripheral surface of the housing assembly in such a manner as to protrude to a predetermined height from the peripheral surface; and a housing supporter for supporting the housing assembly in such a manner that the housing assembly can be inserted into and withdrawn from the housing supporter, the housing supporter having catch grooves that are recessed in a shape corresponding to the stoppers so as to fix the stoppers.

Owner:KOREAN OCEAN RES & DEV INST KORDI

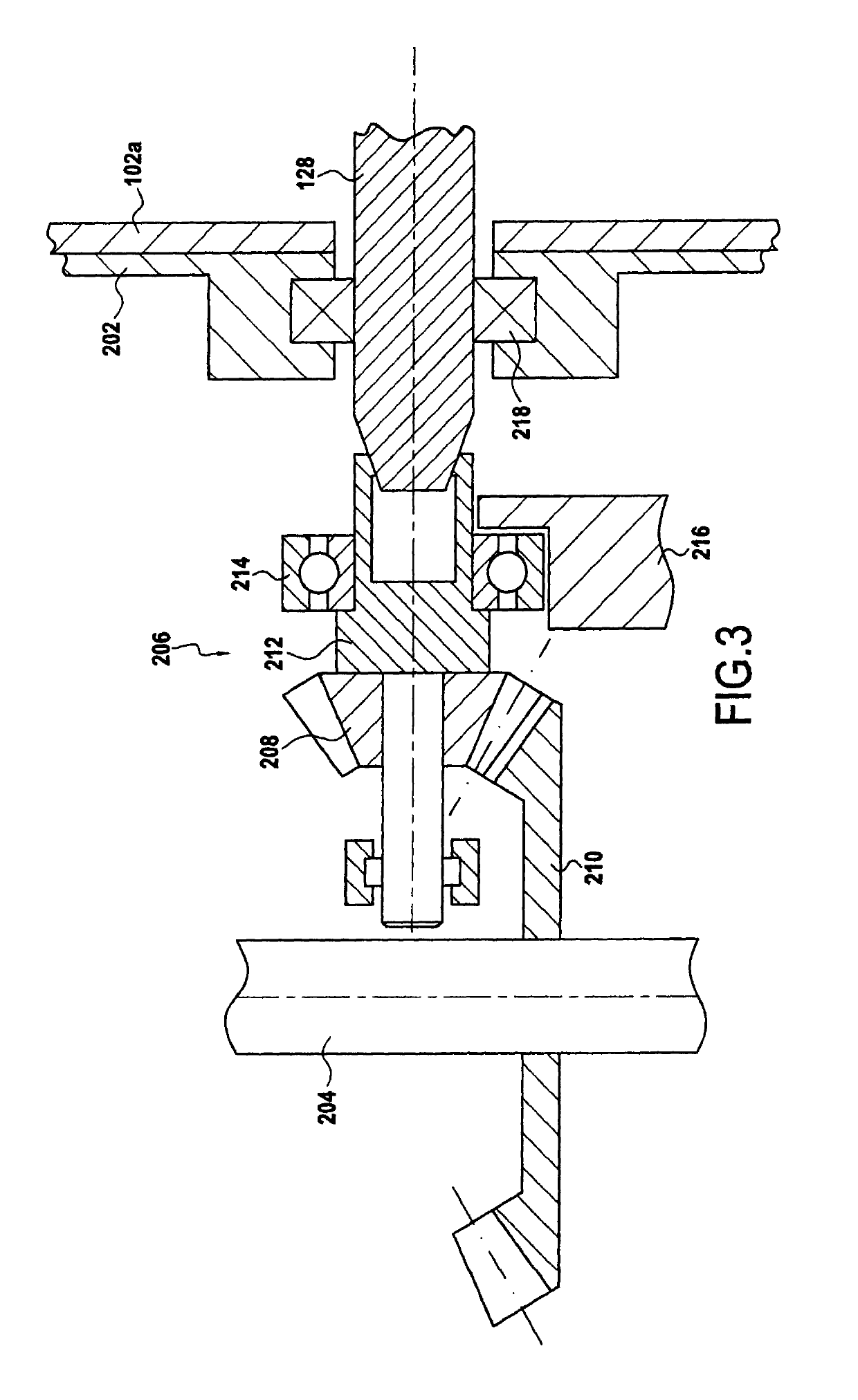

Non-lubricated architecture for a turboshaft engine

ActiveUS10336442B2Small sizeShorten speedGas turbine plantsEfficient propulsion technologiesGas generatorScrew turbine

A turbine engine for a helicopter, the helicopter including a main gearbox, a rotor, and a speed-reducing device housed entirely within the main gearbox of the helicopter while also being connected to the rotor, the turbine engine including a casing, a gas generator with a gas generator shaft, and a free turbine for being driven in rotation by a gas stream generated by the gas generator, the free turbine including a free turbine shaft. When the turbine engine is fastened to the gearbox of the helicopter, the free turbine shaft extends axially into the main gearbox of the helicopter to be connected directly to the speed-reducing device.

Owner:SAFRAN HELICOPTER ENGINES

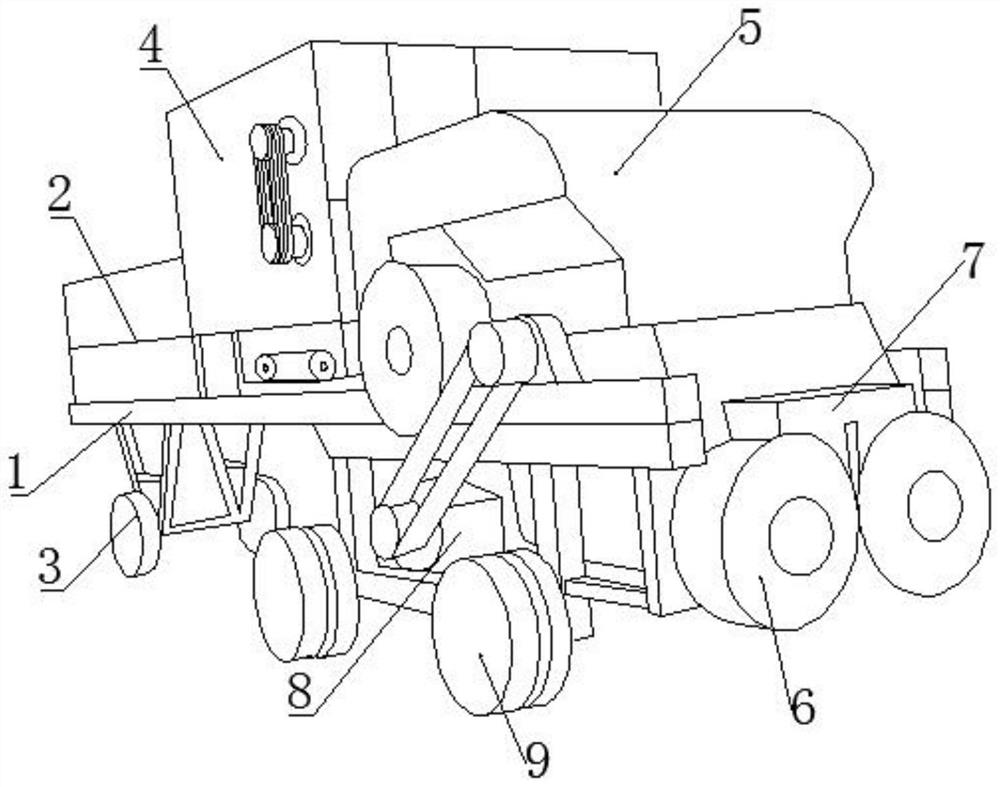

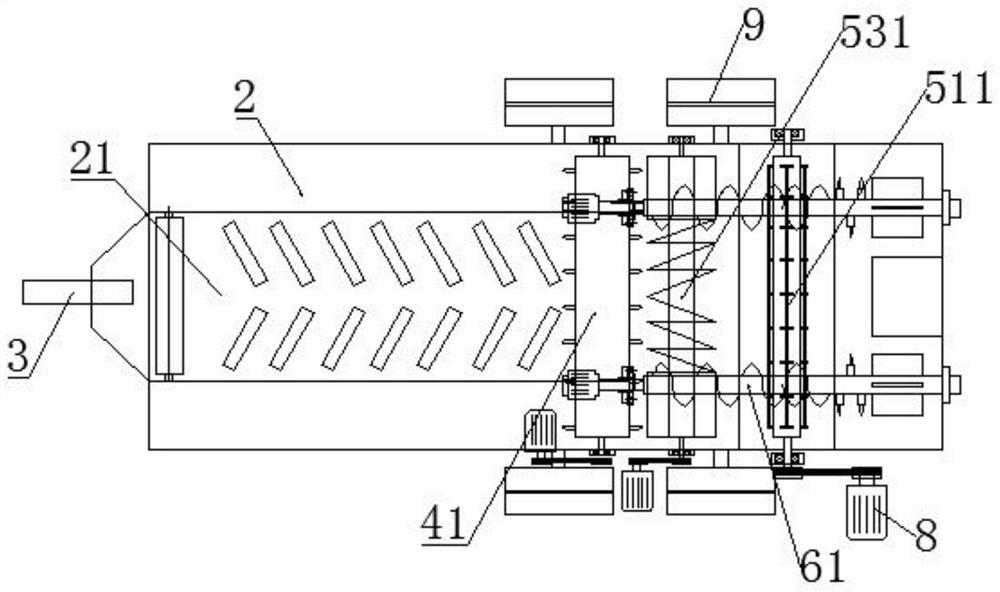

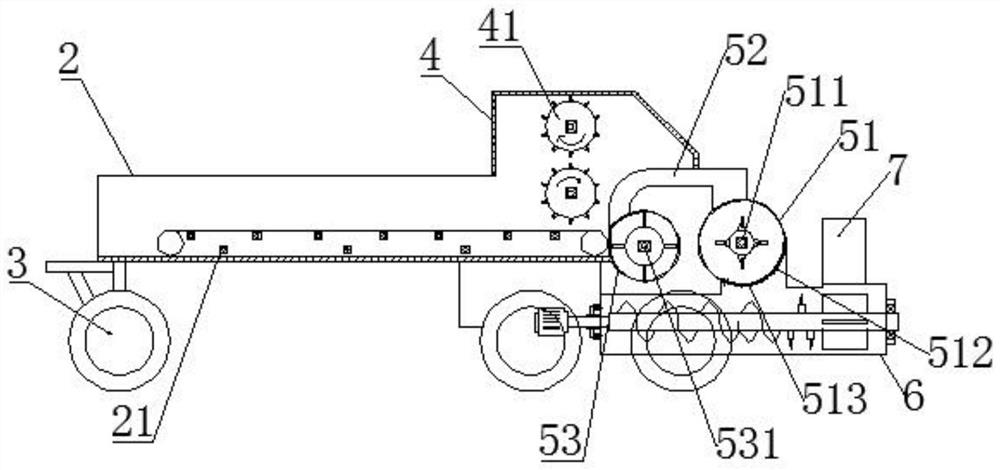

Pull-type heavy mobile straw rubbing and crushing machine

The invention relates to the technical field of agricultural equipment, and particularly discloses a pull-type heavy mobile straw rubbing and crushing machine. The pull-type heavy mobile straw rubbingand crushing machine comprises a rack, wherein a feeding box is fixed onto the upper portion of the front end of the rack through bolts, a feeding conveyor belt is arranged on the bottom of the interior of the feeding box, a first crushing bin is welded to an end portion of the feeding box, cutters are rotatably installed in the first crushing bin, a self-suction spiral turbine distributing and conveying mechanism is welded to the lower ends of the rear sides of the cutters, two longitudinal discharging boxes are connected below the self-suction spiral turbine distributing and conveying mechanism side by side, and pants-shaped discharging pipes are welded to tail portions of the two longitudinal discharging boxes. The pull-type heavy mobile straw rubbing and crushing machine has the beneficial effects that straw can be subjected to multi-stage crushing, the crushing speed is high, the pull-type heavy mobile straw rubbing and crushing machine has a good effect, and the working efficiency is high; the machine design is qualified, movement is convenient, and the stability is good; an inner cavity of the machine is large, and the straw can be prevented from being wound, so that the resistance is reduced; and a feeding opening and discharging openings can be blocked so that dust pollution can be reduced, and thus the pull-type heavy mobile straw rubbing and crushing machine has a good environmental protection effect.

Owner:庞士俊

Screw turbine and method of power generation

A screw turbine comprising a helical turbine blade mounted for axial rotation, a mount associated with the helical turbine blade and mounting the helical turbine blade for axial rotation, and a generator associated with the helical turbine blade which converts energy imparted to the helical turbine blade to electricity, wherein the diameter of the helical turbine blade is less than the lead of the helical turbine blade and wherein said screw turbine is adapted to permit lateral exchange of fluid in use.

Owner:乔治·马克·韦伯

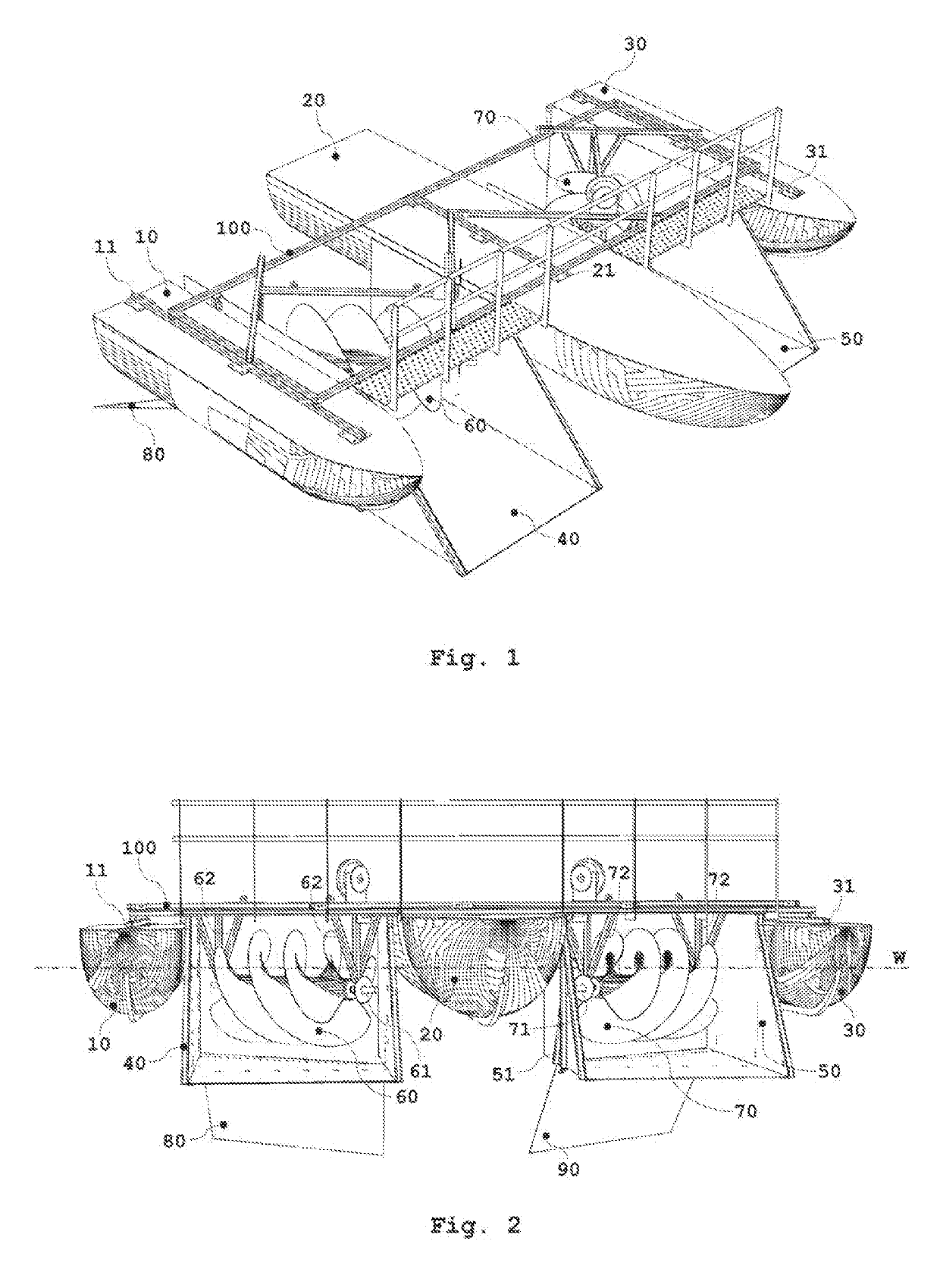

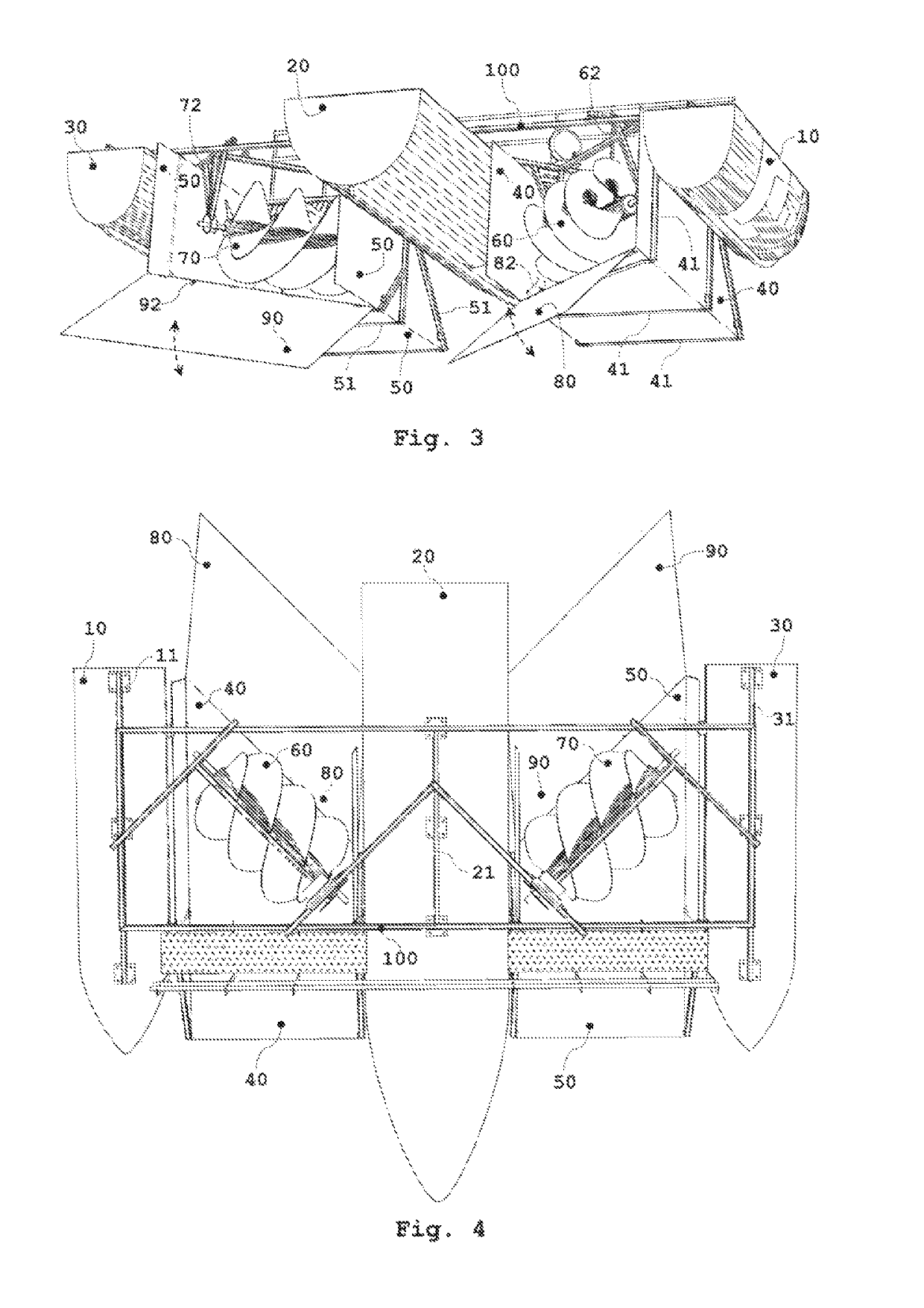

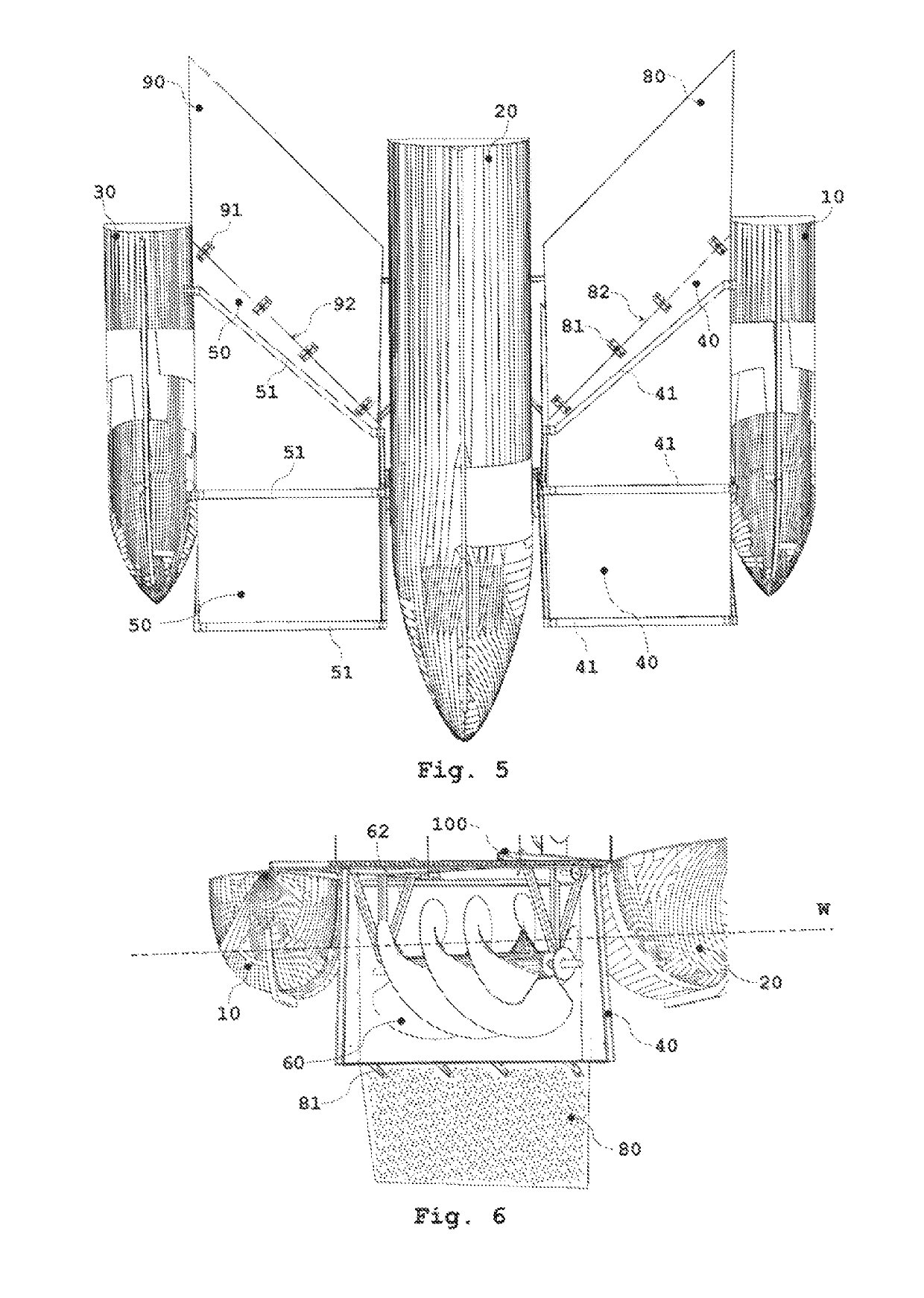

Floating screw turbines device

ActiveUS20190309724A1Maximize fluid velocityEngine fuctionsWorking fluid for enginesScrew turbineWater flow

A floating screw turbine device with adjustable rear deflectors / diffusors is disclosed. Three pontoons, spaced apart, carry water ducts in which screw turbines are mounted. Screw turbines, mounted in a V configuration, have mirror symmetrical pitches of the screws measured over the centre of symmetry that passes through the central pontoon. Such a configuration minimizes the vibration of the device. Rear deflectors / diffusors have an adjustable pitch relative to the floors of the water ducts by which they can affect the water flow velocity through the water ducts. In one embodiment, the optimum pitch is selected according to the previously performed computational fluid dynamics simulation for the device, where the pitch is changed using hydraulic or electromechanical actuators. In another variant an artificial neural network is taught to model a global function of the system dynamics in order to achieve optimal operation.

Owner:UPRAVLJANJE KAOTICNIM SUSTAVIMA D O O

Waste gas turbocharger

InactiveCN105370328AImprove protectionClamp assembly is simplePump componentsEngine fuctionsScrew turbineTurbocharger

A waste gas turbocharger is provided with a turbine for expanding exhaust gas and for recovering energy, and having a compressor (1) for compressing charge air with the aid of the energy obtained in the turbine, said turbine a multi-part, A joint of a screw turbine housing and in the comprises turbine housing positioned turbine rotor, said compressor (1) has a multi-part, a joint of a screw compressor housing (2) and one positioned in the compressor housing and coupled to the turbine rotor compressor rotor, and said housing parts of the multi-piece compressor housing (2) and / or housing parts of the multi-part turbine casing by means of at least one each of a clamp holder (5) are clamped.

Owner:MAN ENERGY SOLUTIONS SA

Method for solving combined heat and power generation, split-shaft heating steam turbine generator set and operation method

InactiveCN103883364BImprove thermal efficiency of power generationImprove operational flexibilityEngine componentsSteam engine plantsScrew turbineCogeneration

Disclosed is a method for solving combined heat and power generation, a split-shaft heat supply turbine generating set, and an operating method of the split-shaft heat supply turbine generating set. The split-shaft heat supply turbine generating set comprises at least two turbines, including front turbines and rear turbines; each front turbine is a backpressure turbine or extraction backpressure turbine; each rear turbine is an all-condensing low-pressure turbine; the front turbines and the rear turbines are connected through a pipeline; a to-user pipeline is disposed on the pipe for connecting the front and rear turbines; the pipelines are controlled through a pipeline controller; each front turbine is provided with one turbine generator; each rear turbine is provided with one turbine generator and a condenser. The backpressure turbine and low-pressure parameter all-condensing turbine technology is utilized, the two types of turbines are subjected to split-shaft combination, and backpressure, extraction condensing and all-condensing operations can be achieved; in the backpressure operation mode, heat and power generating efficiency of the set can be greatly increased; in the extraction condensing or all-condensing operation mode, operational flexibility of the set can be greatly improved.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

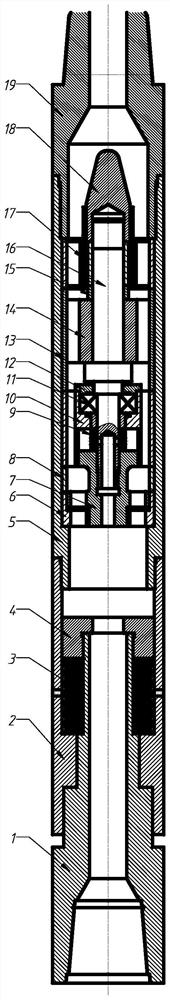

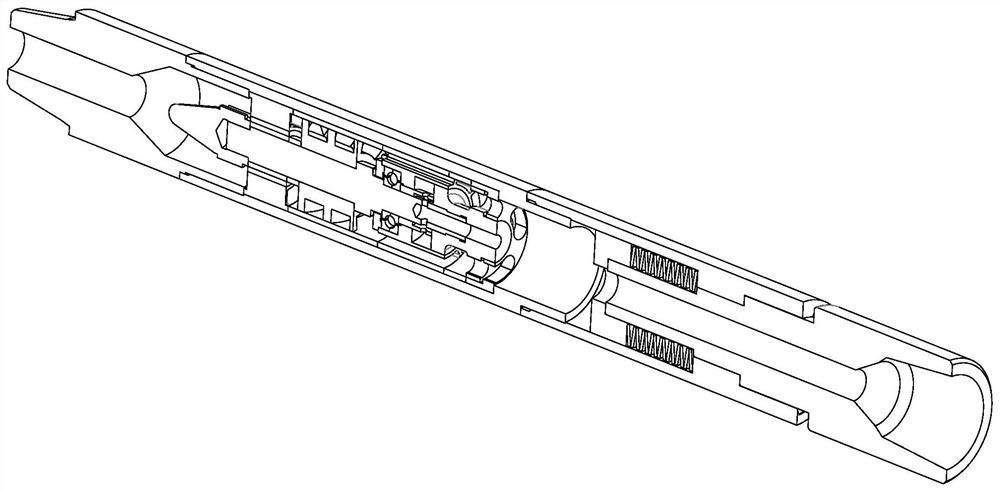

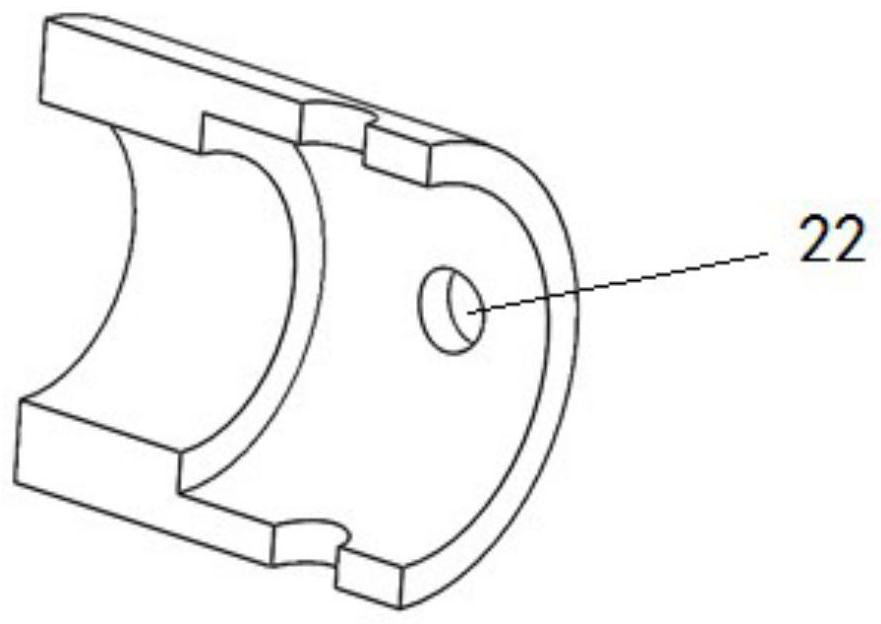

A pulse drill pressure generator

ActiveCN110905400BImprove rock breaking drilling efficiencyAvoid hard shock phenomenonBorehole drivesScrew turbineUpper joint

The invention relates to a pulse WOB generator. The generator is composed of a pulse hydraulic pressure generation system and an impact type WOB transmission system. The pulse hydraulic pressure generation system includes an upper joint, an upper casing, a centering bearing, a screw turbine and a shaft. A valve system, the shaft valve system includes a turbine shaft, a bearing, a bearing end cover, a valve core, a valve seat and a balance sleeve, and the impact WOB transmission system includes a lower joint, a lower casing, a disc spring group and a pressure bearing head The generator forms periodic pulse hydraulic pressure and transmits the hydraulic pressure to the drill bit to form a periodically fluctuating WOB. The design structure of the WOB transmission system is simple, and the disc spring group will periodically change under the action of the periodically changing hydraulic pressure. Compression and elastic recovery can directly transmit the pulse hydraulic force to the bottom hole drill bit, with high pressure transmission speed and high efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com