Screw turbine and method of power generation

a technology of screw turbine and blade, which is applied in the direction of propellers, propulsive elements, water-acting propulsive elements, etc., can solve the problems of limit the efficiency that may be obtained using existing water turbines, and achieve the effect of facilitating blade rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The invention will now be described in more detail with reference to the accompanying drawings. It should be appreciated that the following is provided by way of exemplification only and should not be construed as limiting on the invention in any way. In the drawings:

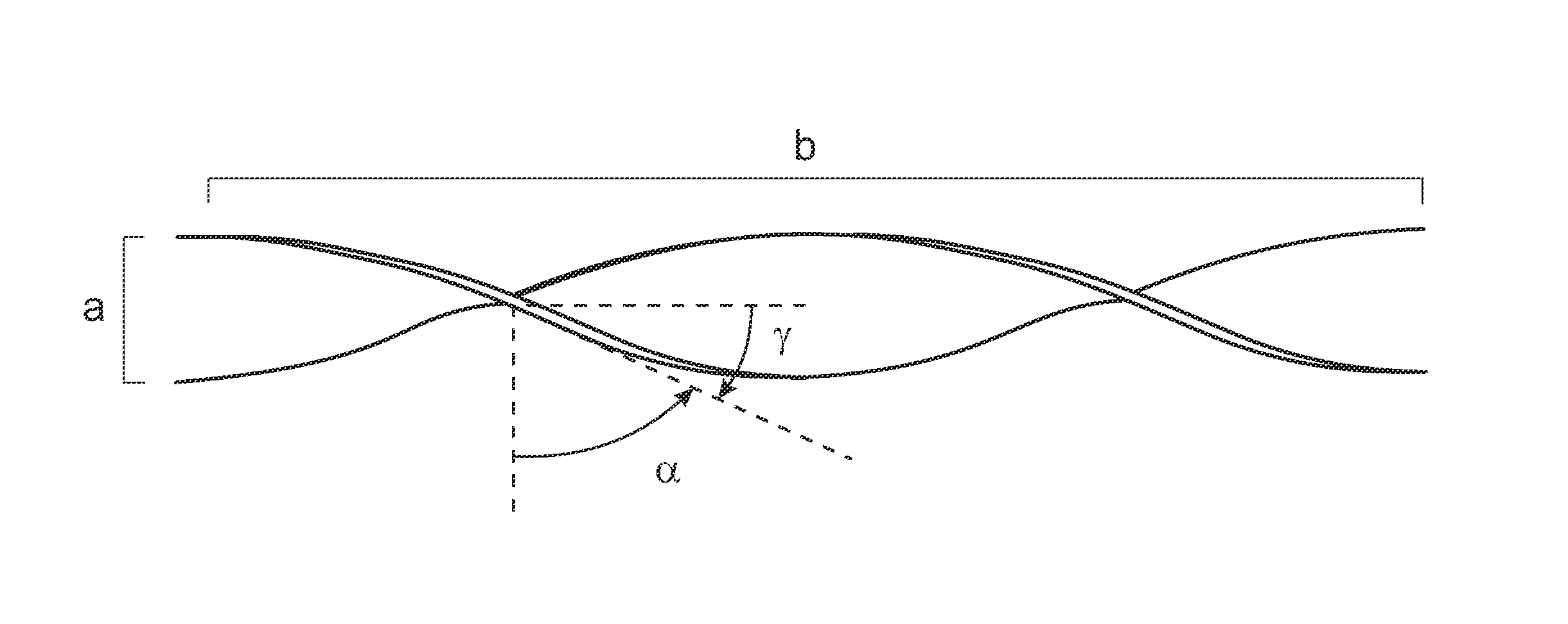

[0038]FIG. 1 illustrates a side view of a helical turbine blade; and

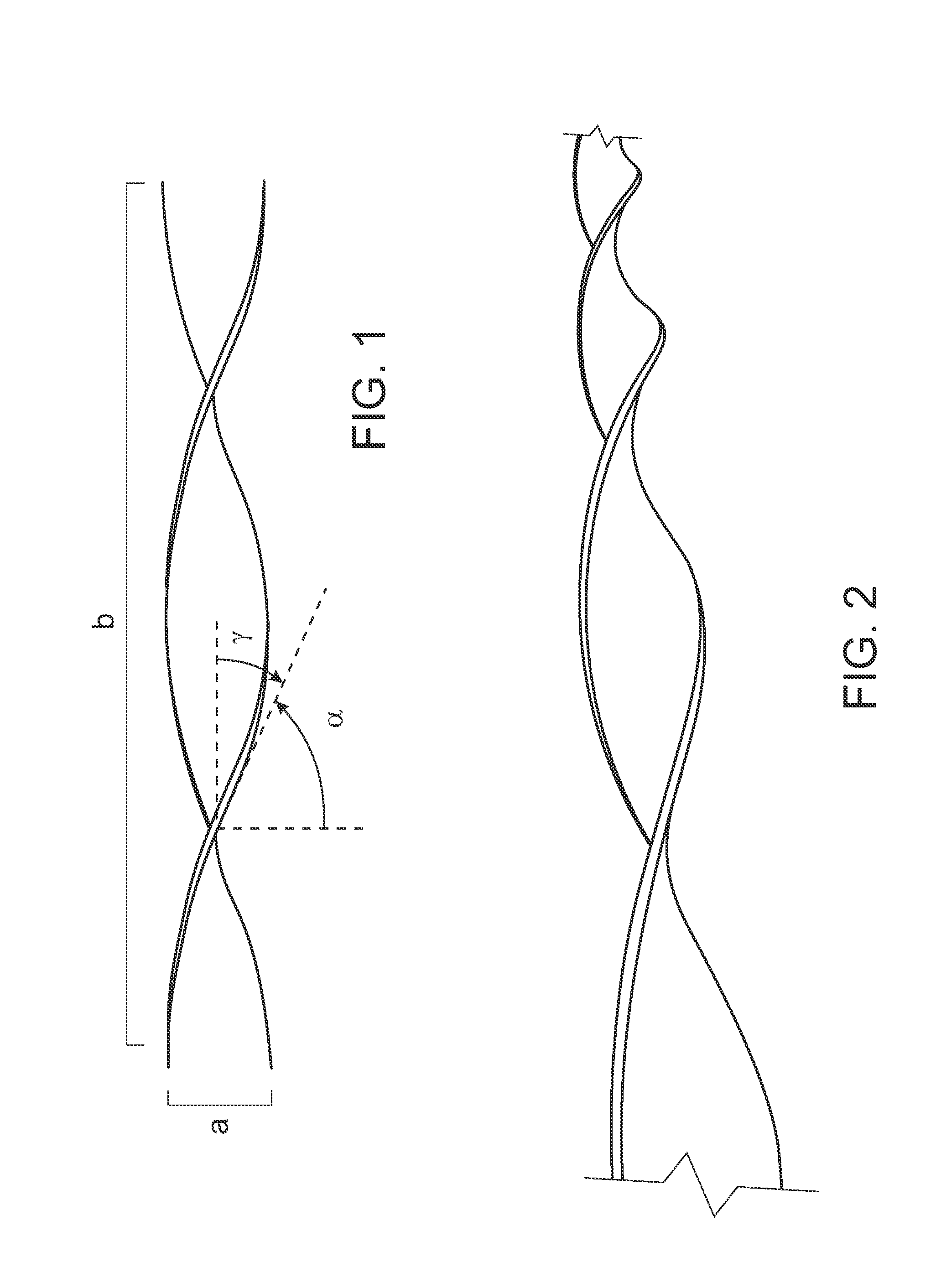

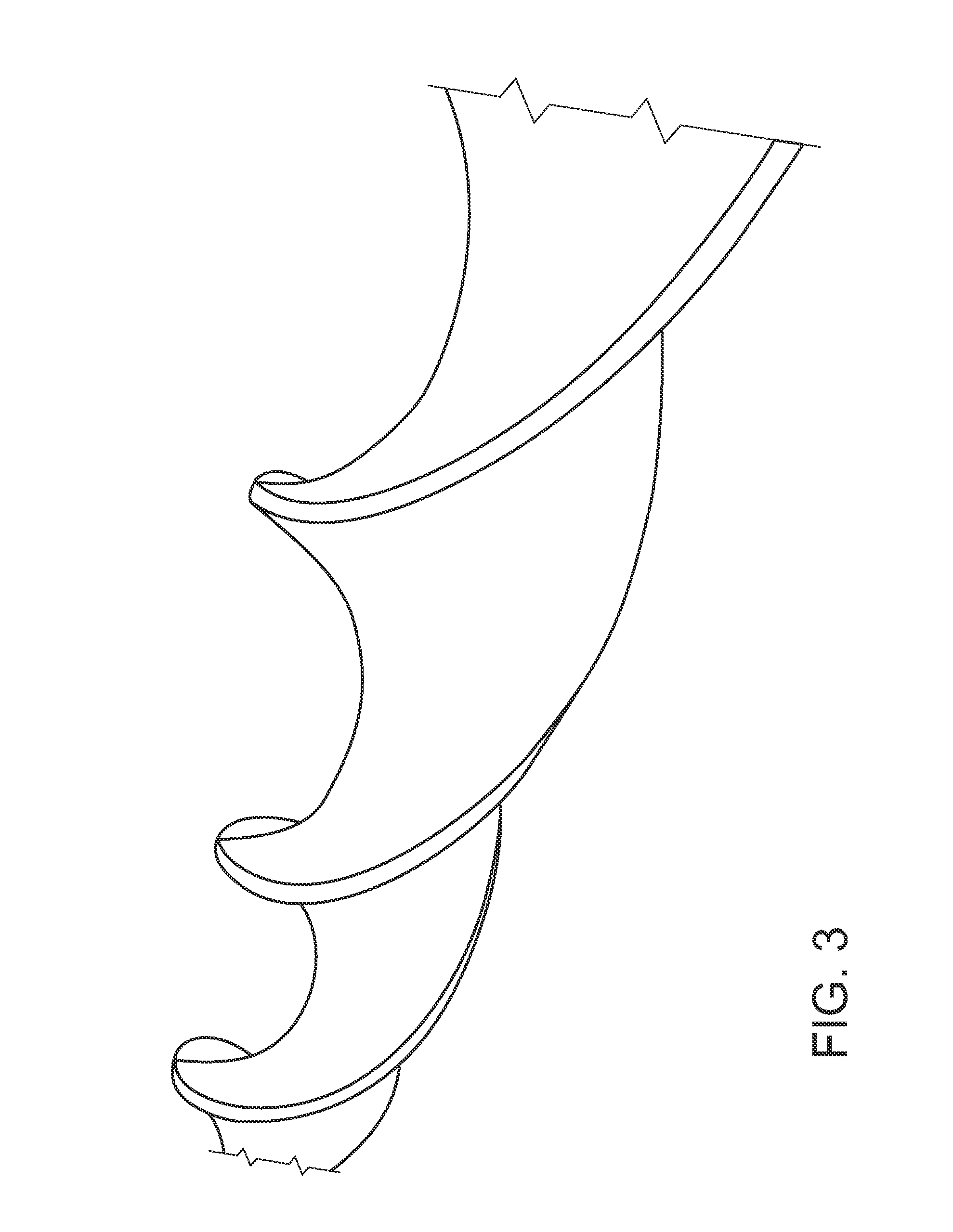

[0039]FIGS. 2 and 3 illustrate perspective views of a helical turbine blade.

[0040]Referring to the figures, the helical turbine blade takes the form of an axleless helix. Effectively, the helical turbine blade is constituted by a strip of material, for example steel or other suitable material, which is twisted along its length. The twists are relatively gentle, and therefore the helix angle y relatively small. Consequently, the lead angle a is relatively large. This is particularly the case compared with conventional screw turbines, the blades of which are generally provided with a much greater degree of raking.

[0041]The diameter “a” of the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com