Method for solving combined heat and power generation, split-shaft heating steam turbine generator set and operation method

A technology of steam turbine generator and heating steam turbine, which is applied in the direction of steam engine devices, engine components, machines/engines, etc., which can solve the problems of complex structure and expensive price, and achieve the goal of improving reliability, reducing cost, and improving thermal efficiency of power generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

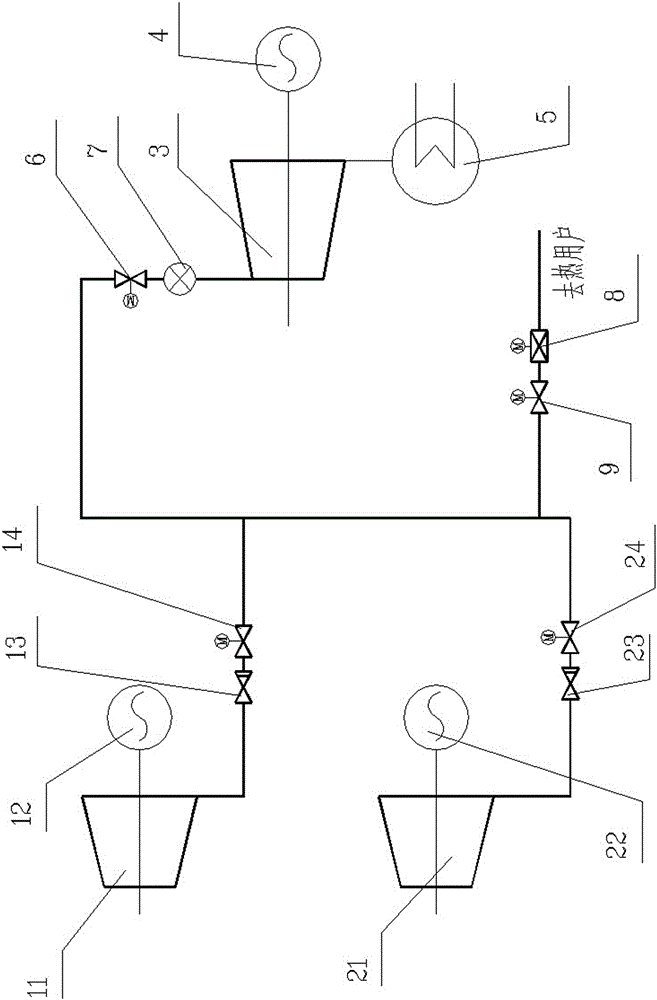

[0027] A method for solving cogeneration of heat and power by using a conventional steam turbine generator set, comprising the following steps:

[0028] A. Select at least one back-pressure steam turbine or extraction back-pressure steam turbine, and at least one pure condensing low-pressure steam turbine for combined heat and power generation. Type steam turbine or extraction backpressure steam turbine is the front turbine, and pure condensing low-pressure steam turbine is the rear turbine; typical cases are described below.

[0029] B. Determine parameters:

[0030] Determine the heat user demand parameters, for example, the heat user demand parameters are 0.4MPa, 180°C, the maximum is 80.32t / h, the average is 60t / h, and the minimum is 12.5t / h;

[0031] Determine external heat supply parameters according to heat user demand parameters, 0.6MPa, 200°C, maximum 80.32t / h, average 60t / h minimum 12.5t / h;

[0032] Determine the external power supply parameters according to the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com