Combined power generation system based on waste incineration waste heat and optothermal and operation method thereof

A technology of waste incineration and combined power generation, applied in the directions of solar thermal power generation, separation methods, chemical instruments and methods, etc., can solve the problems of unsuitability for solar thermal power generation, low thermoelectric conversion efficiency, etc. The effect of high temperature corrosion and exhaust humidity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

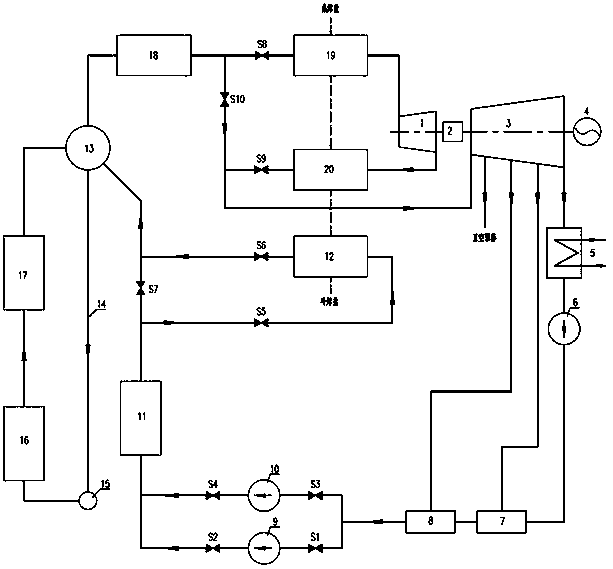

[0046] When the meteorological conditions meet the conditions of solar thermal power generation, the system operates at 100% of the rated load, the inlet temperature of the hot molten salt of the solar superheater 19 is 565°C, and the outlet temperature of the cold molten salt of the solar preheater 12 is 300°C. The water temperature at the inlet of economizer 11 is 130°C, the water temperature at the inlet of solar preheater 12 is 245°C, the superheated steam parameter at the outlet of solar superheater 19 is 15.3MPa / 540°C, and the steam parameter at the reheating and cold section of the steam turbine is 3.82MPa / 318 °C, heated to 400-450 °C by the solar reheater 20, enters the middle and low pressure cylinder 3 of the steam turbine to continue to work, and the steam pressure in the reheating section is the same as the steam pressure at the outlet of the waste heat boiler superheater of the waste heat boiler.

Embodiment 2

[0048] When the meteorological conditions cannot satisfy the solar thermal power generation, the solar heat exchange system and the steam turbine high-pressure cylinder are cut off, the waste incineration waste heat boiler operates independently, the water temperature at the inlet of the economizer 11 is 130°C, and the superheated steam parameter at the outlet of the waste heat boiler superheater 18 is 3.82MPa / 400-450°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com