Waste gas turbocharger

A technology of exhaust gas turbine and supercharger, which is applied in the direction of gas turbine device, machine/engine, engine function, etc. It can solve the problems of no protection for exhaust gas turbocharger and increased weight of exhaust gas turbocharger, and achieve simple enclosure Effect of protection or burst protection, simple enclosure protection, simple burst protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

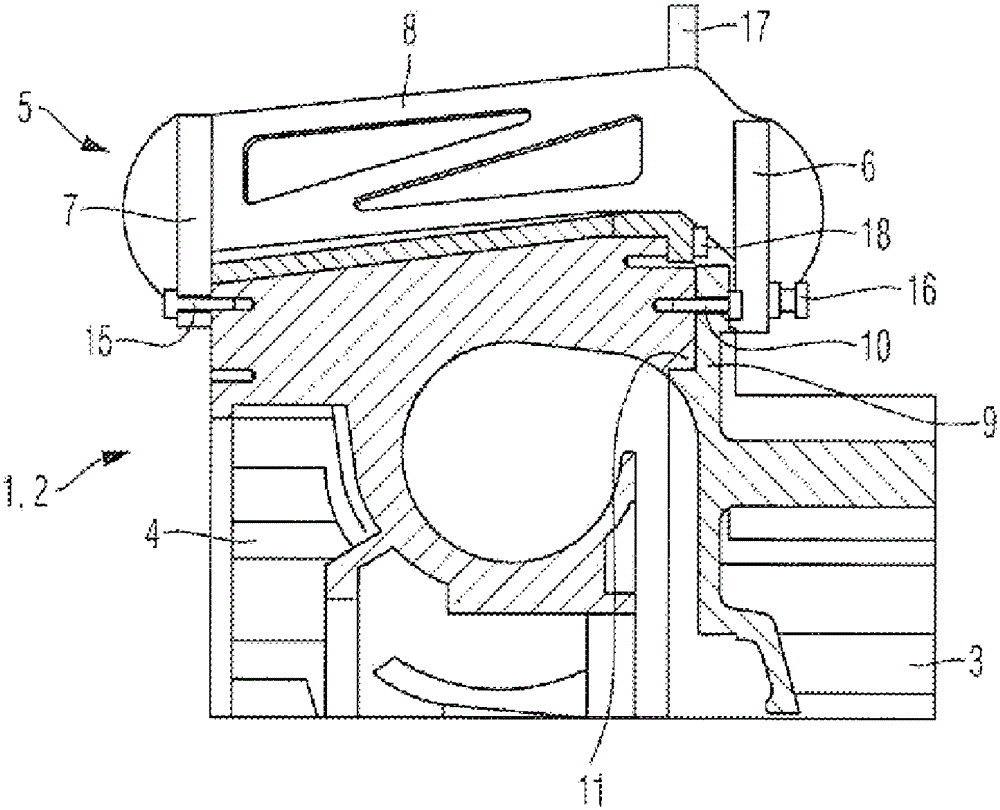

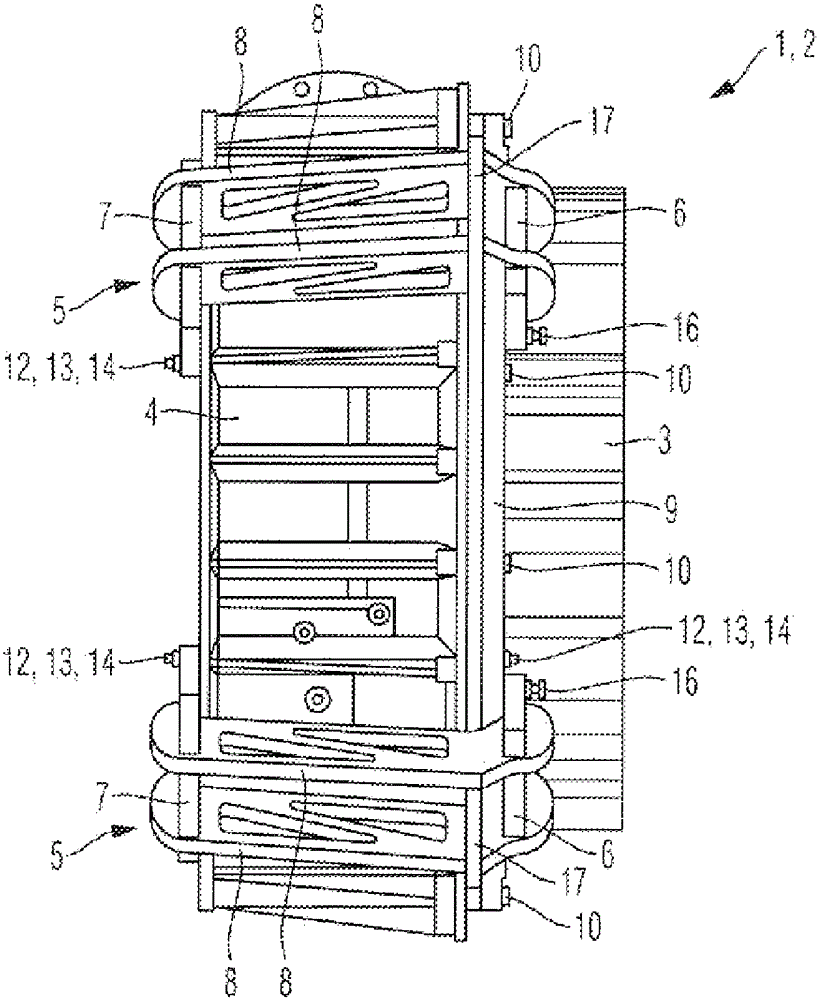

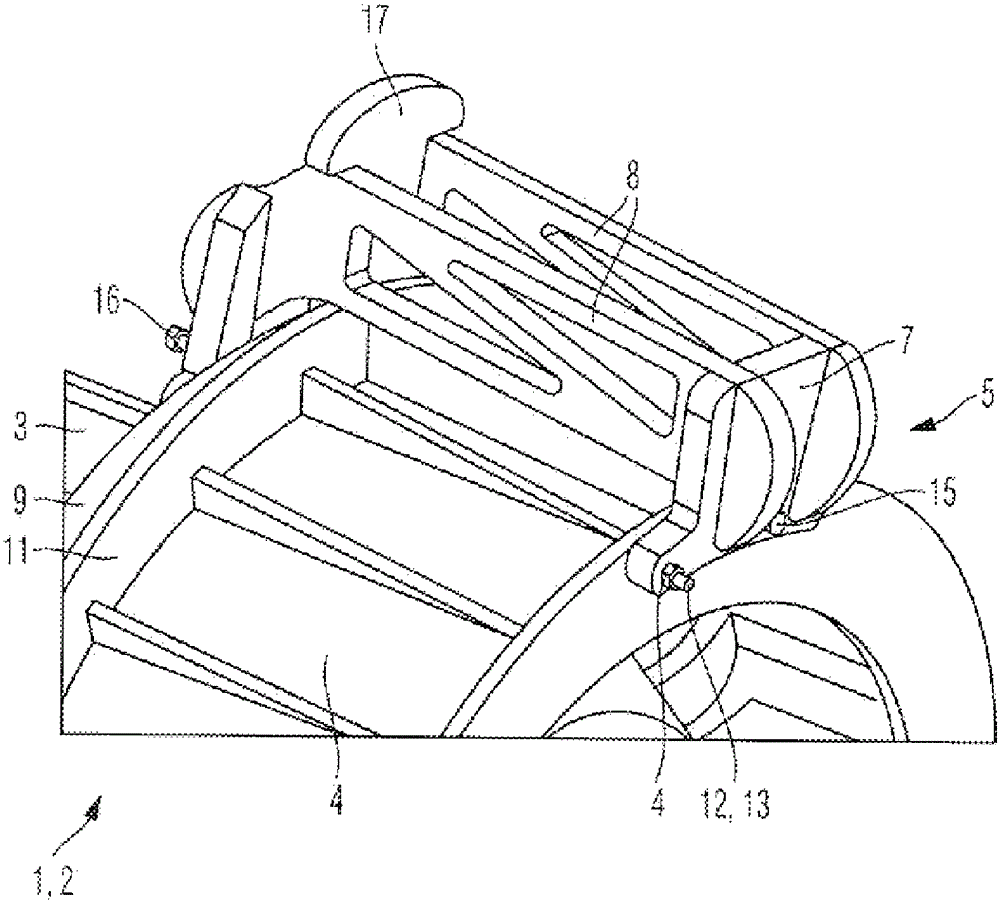

[0033] An exhaust turbocharger consists of a turbine and a compressor. The turbine of the exhaust gas turbocharger includes a multi-part turbine housing and a turbine rotor received in the turbine housing. The compressor of the exhaust gas turbocharger includes a compressor housing and a compressor rotor received in the compressor housing. The turbine rotor and compressor rotor are coupled to each other. The energy generated during the expansion of the exhaust gas in the region of the turbine is utilized in the compressor to compress the charge air.

[0034] figure 1 An excerpt of the exhaust gas turbocharger shown in the area of the compressor 1, ie the compressor housing 2, in which, in figure 1 The compressor housing 2 shown in is assembled from a bearing housing 3 and a volute 4 . figure 2 show through figure 1 A cross-sectional view of the compressor housing 2. image 3 shows a perspective view from the bearing housing 3, while Figure 4 A perspective view from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com