Compressed air foam and high pressure liquid dispersal system

A technology of compressed air foam and high-pressure liquid, applied in the direction of liquid injection device, cleaning method using liquid, cleaning method and utensils, etc., can solve the problem of additional equipment pollution, and achieve the effect of eliminating complex equipment, compact size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

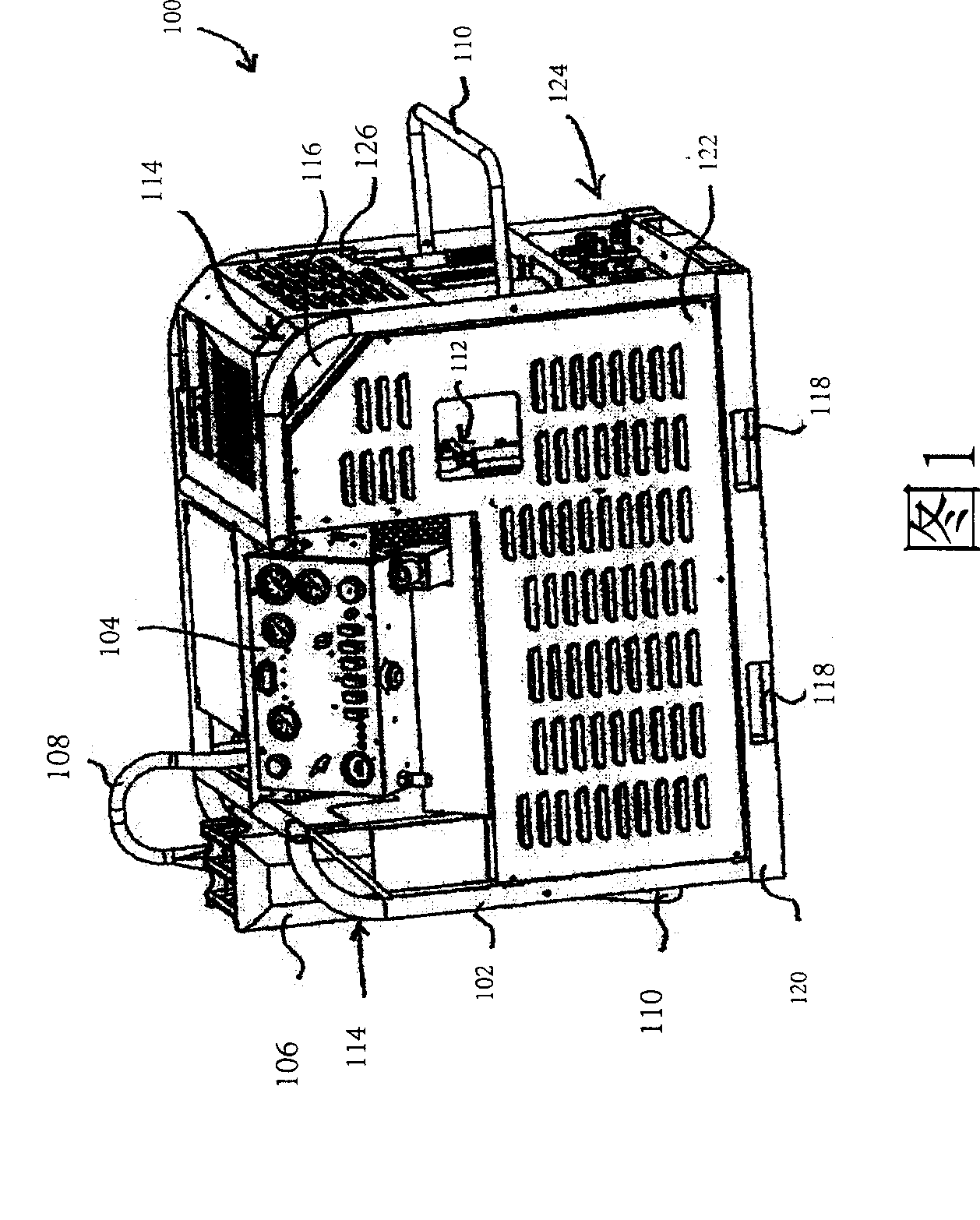

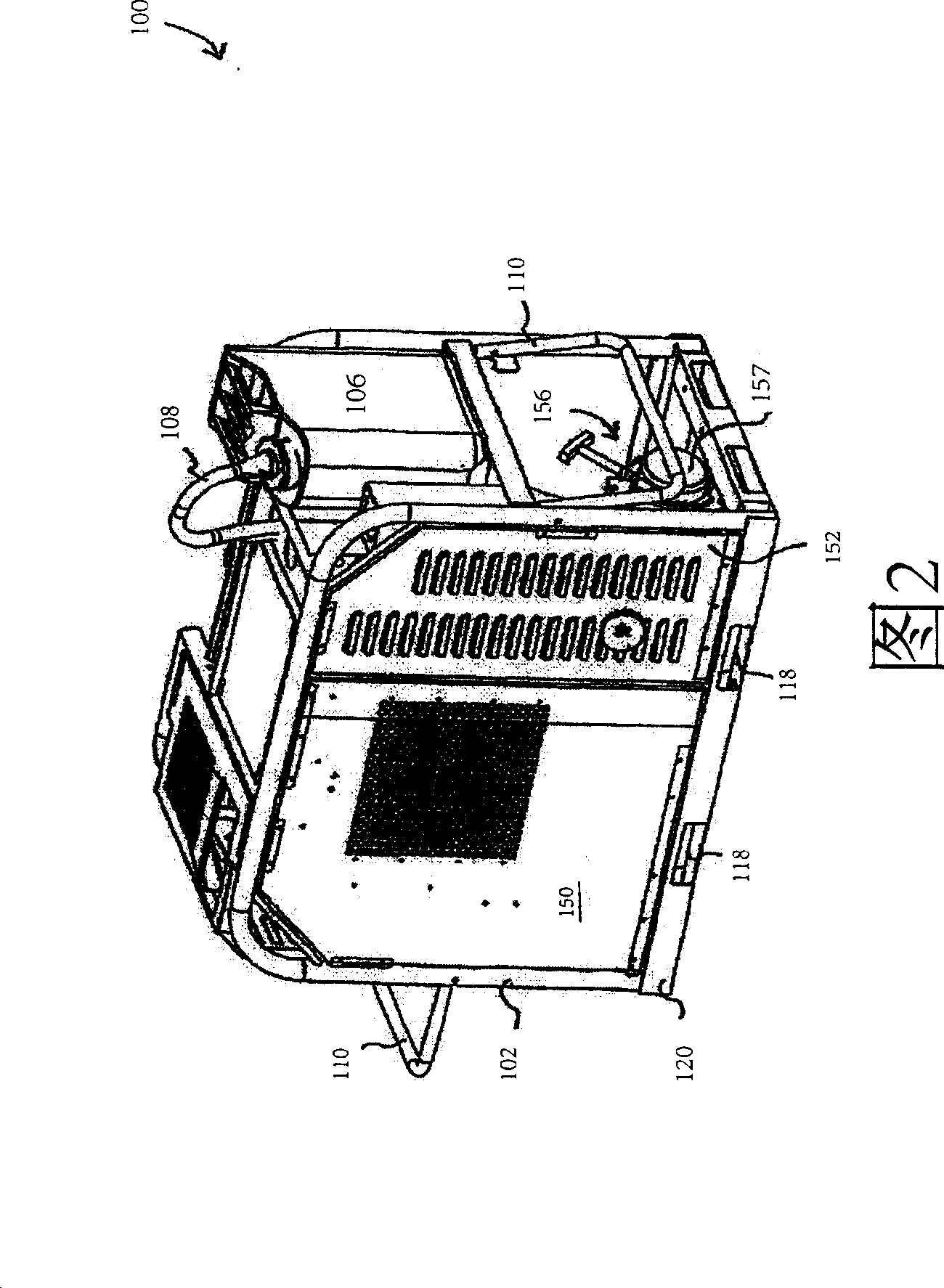

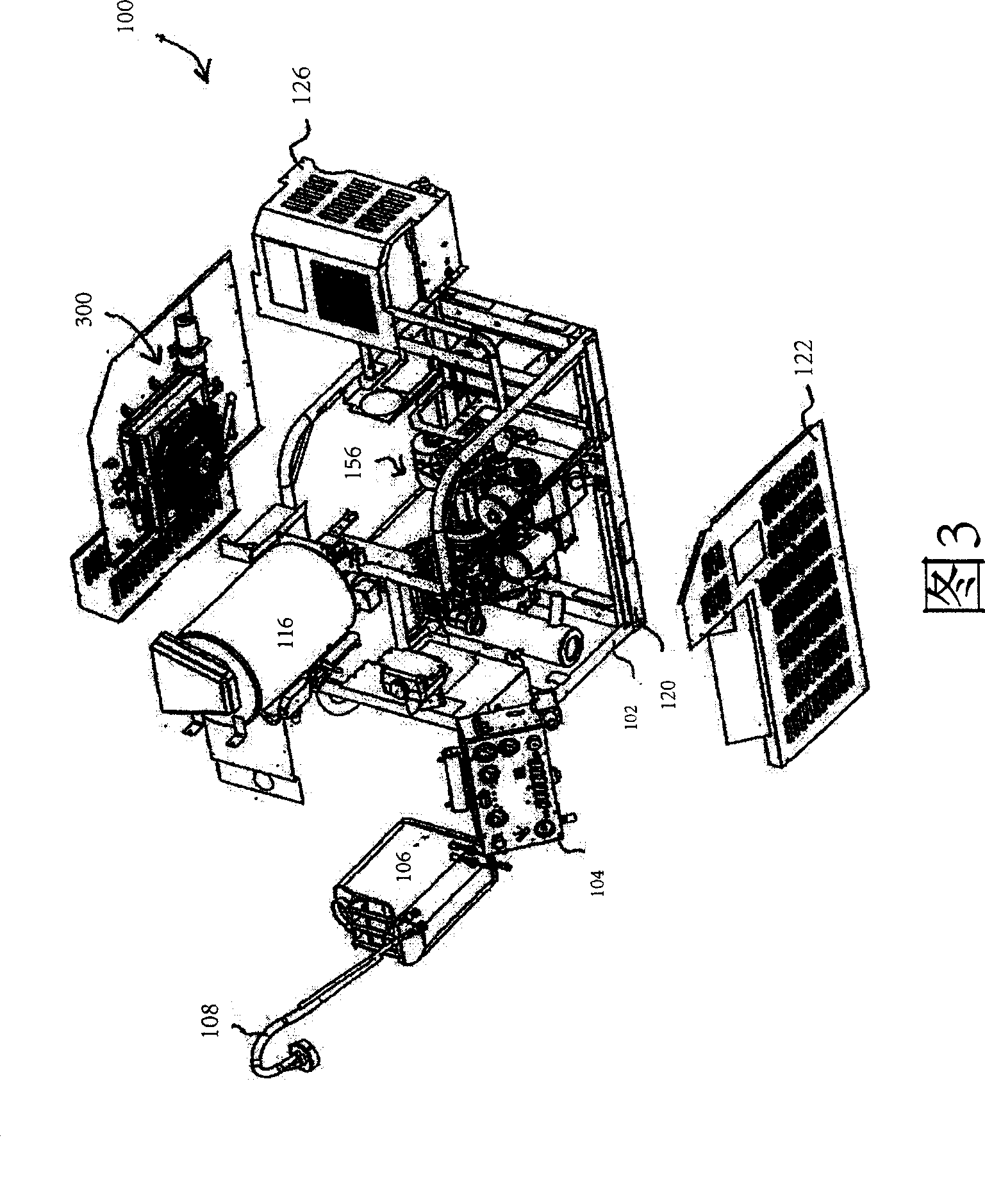

[0027] In accordance with the present compressed air foam and high pressure liquid distribution system ("CAF / HPLD system"), the CAF / HPLD system 100 can be easily transported and used in remote Location. In one aspect, the CAF / HPLD system 100 provides decontamination support for durable equipment, vehicles, terrain, tools, and aircraft. CAF / HPLD systems are also available with standard CBRN decontamination formulations and standard fire suppression equipment as well as Hazmat foam. When used as a decontamination system, the CAF / HPLD system 100 allows the user to efficiently apply decontamination agents to interior and exterior building applications as well as contaminated ground, roads, equipment and vehicles. An optional shower system that provides shower points for multiple persons is available.

[0028] CAF / HPLD systems also dispense fluids such as hot and cold soapy water and glycol-based de-icing fluid. CAF / HPLD system 100 preferably includes four subsystems, among othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com