Mechanically-pumping compressed gas foam fire-extinguishing device

A compressed gas and foam fire extinguishing technology, applied in fire rescue and other fields, can solve the problems of complex control system, high energy consumption, inaccurate mixing ratio measurement, etc., and achieve the effect of accurate mixing ratio, strong adaptability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

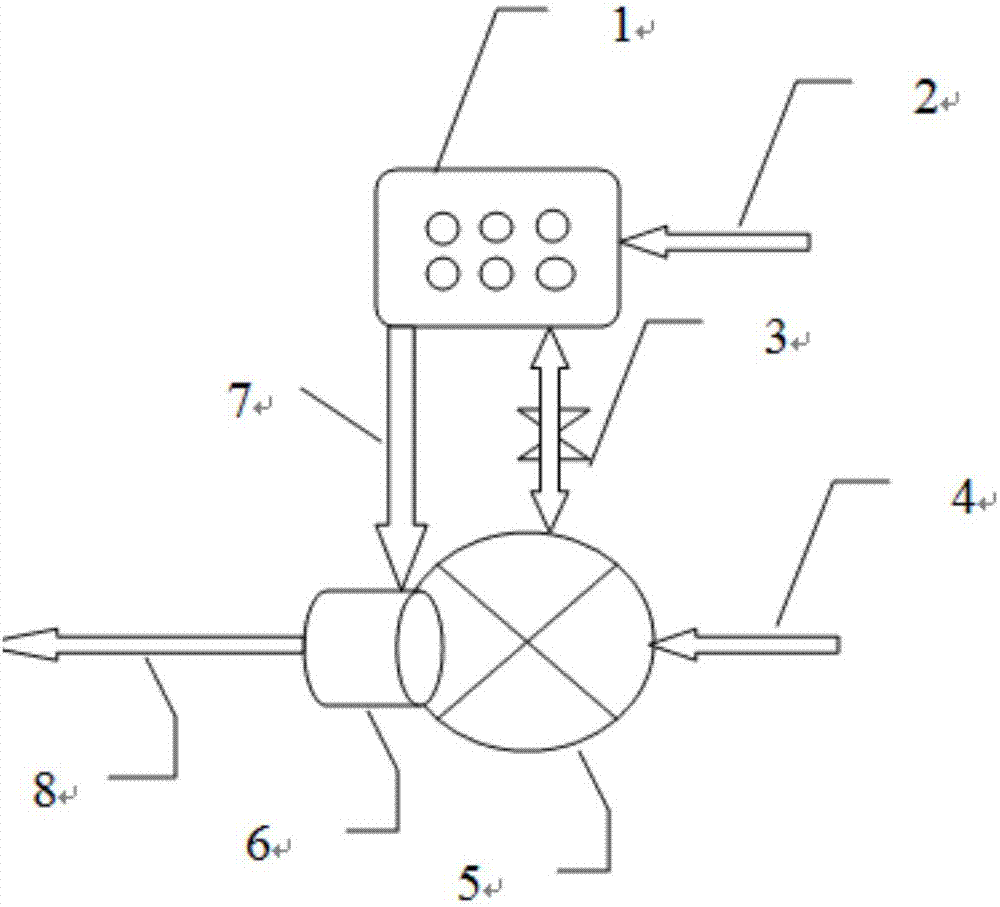

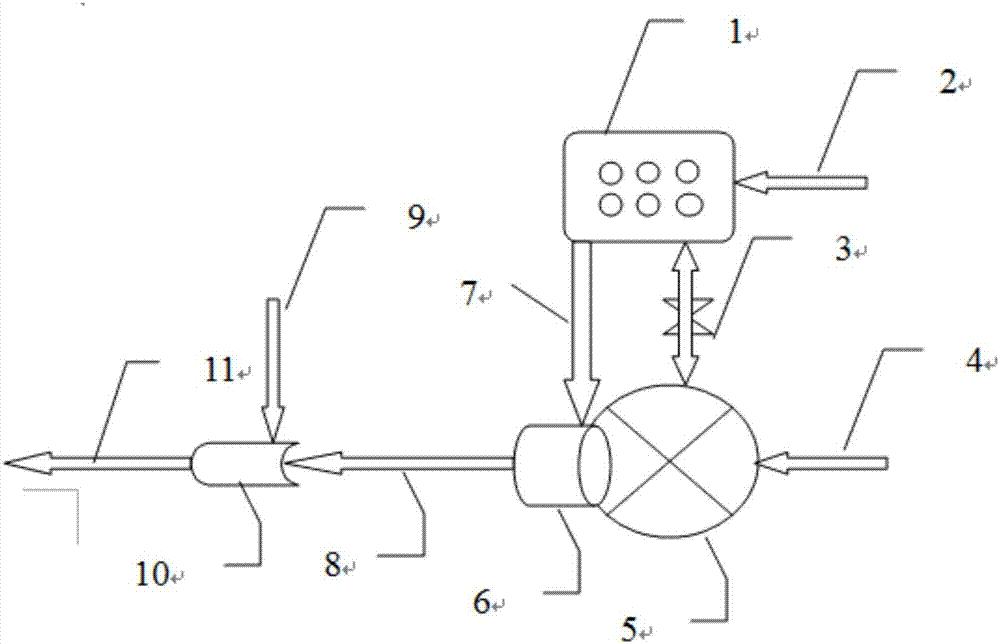

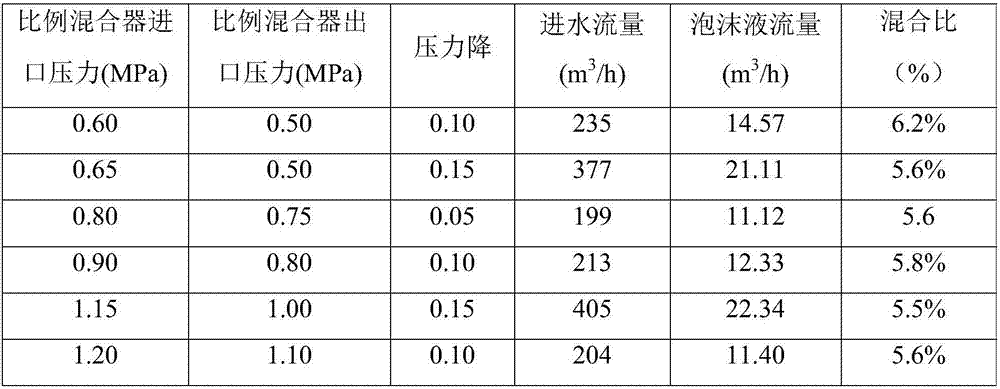

[0016] Such as figure 1 As shown, a mechanically pumped compressed gas foam fire extinguishing device includes a mechanically pumped foam proportional mixing device, a foam generator and a foam delivery pipeline, mainly including 1 foam liquid pump, 2 foam raw liquid inlet, 3 connecting shafts, 4 fire pressure water source, 5 water turbine, 6 mixing chamber, 7 foam stock liquid outlet, 8 foam mixed liquid inlet, 9 air source, 10 foam generator, 11 foam delivery pipeline. The foam liquid pump is connected to the foam liquid inlet, which is used to continuously provide the foam liquid pump with foam liquid; the water turbine is connected to the foam liquid pump and the fire pressure water source, and is used to provide pressure water for the water turbine to generate kinetic energy to drive the foam liquid pump to run; at the outlet of the water turbine The foam mixture generated by the mixing chamber is connected to the foam generator for the foam mixture supplied to the foam g...

Embodiment 2

[0023] 1 Foam liquid pump, 2 Foam raw liquid inlet, 3 Connecting shaft, 4 Fire-fighting pressure water source, 5 Water turbine, 6 Mixing chamber, 7 Foam raw liquid outlet, 8 Foam mixed liquid inlet, 9 Air source, 10 Foam generator, 11 Foam delivery pipe road.

[0024] Fill the raw liquid storage tank with 3% foam fire extinguishing agent, the inlet and outlet pipe diameters of the foam proportional mixing device and the foam generator are both DN200, and the compressed gas is composed of a group of 40L compressed air cylinders with a pressure of 10Mpa, which are collected after decompression in the header.

[0025] The 3% foam fire extinguishing agent enters the foam liquid pump 1 from the liquid inlet 2, starts the water pump, and the water from the fire pressure water source 4 enters the water turbine 5, and the water turbine 5 drives the foam liquid pump 1 to rotate, and opens the water-foam liquid selection valve to make the foam The raw liquid enters the mixing chamber 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com