Integrated LED (Light-emitting Diode) sealing machine

A colloidal and chemical technology, applied in the field of integrated LED sealing machine, can solve the problems of colloid temperature imbalance, slow moving speed, low production efficiency, etc., and achieve the effect of maintaining accuracy, reasonable product structure and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

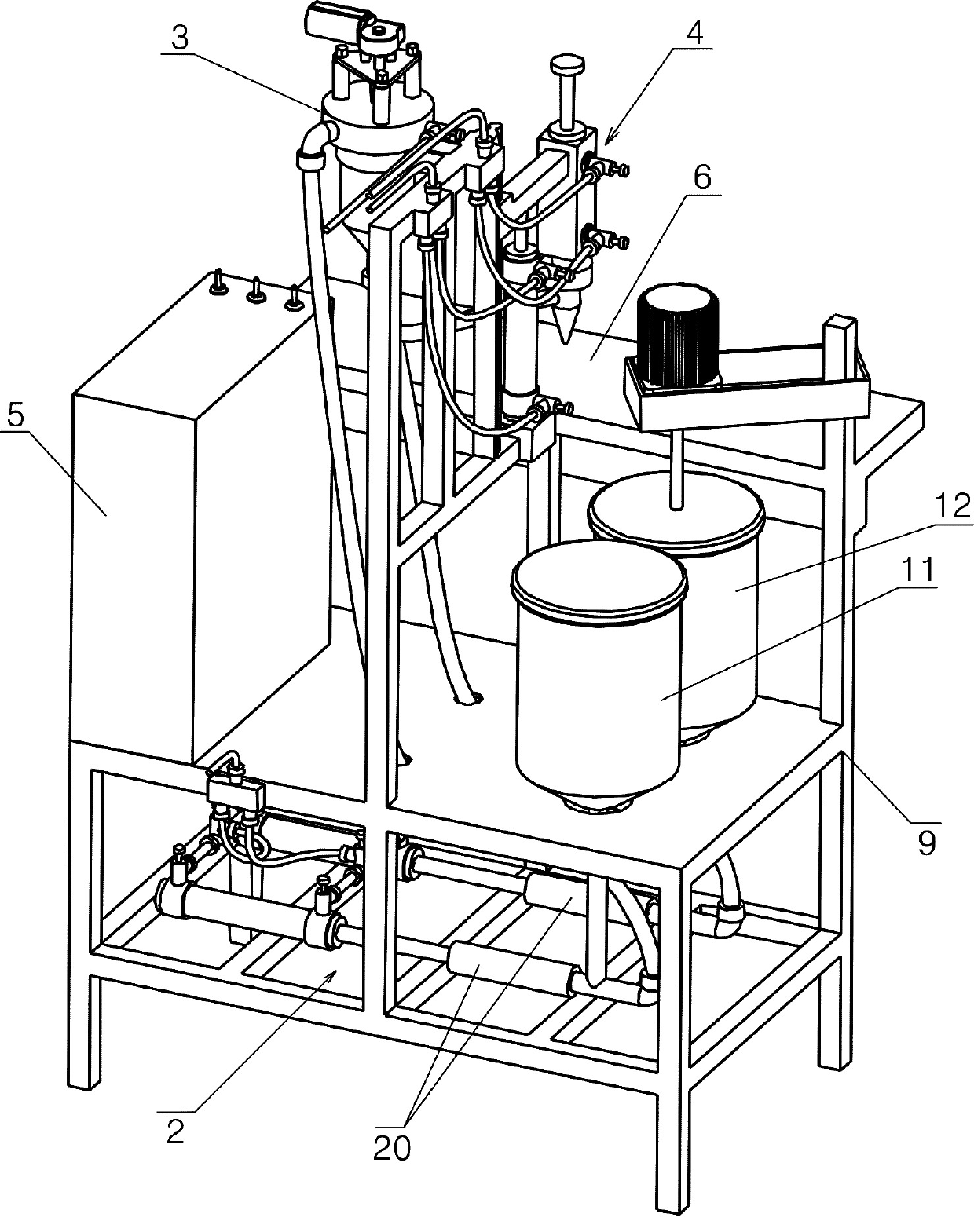

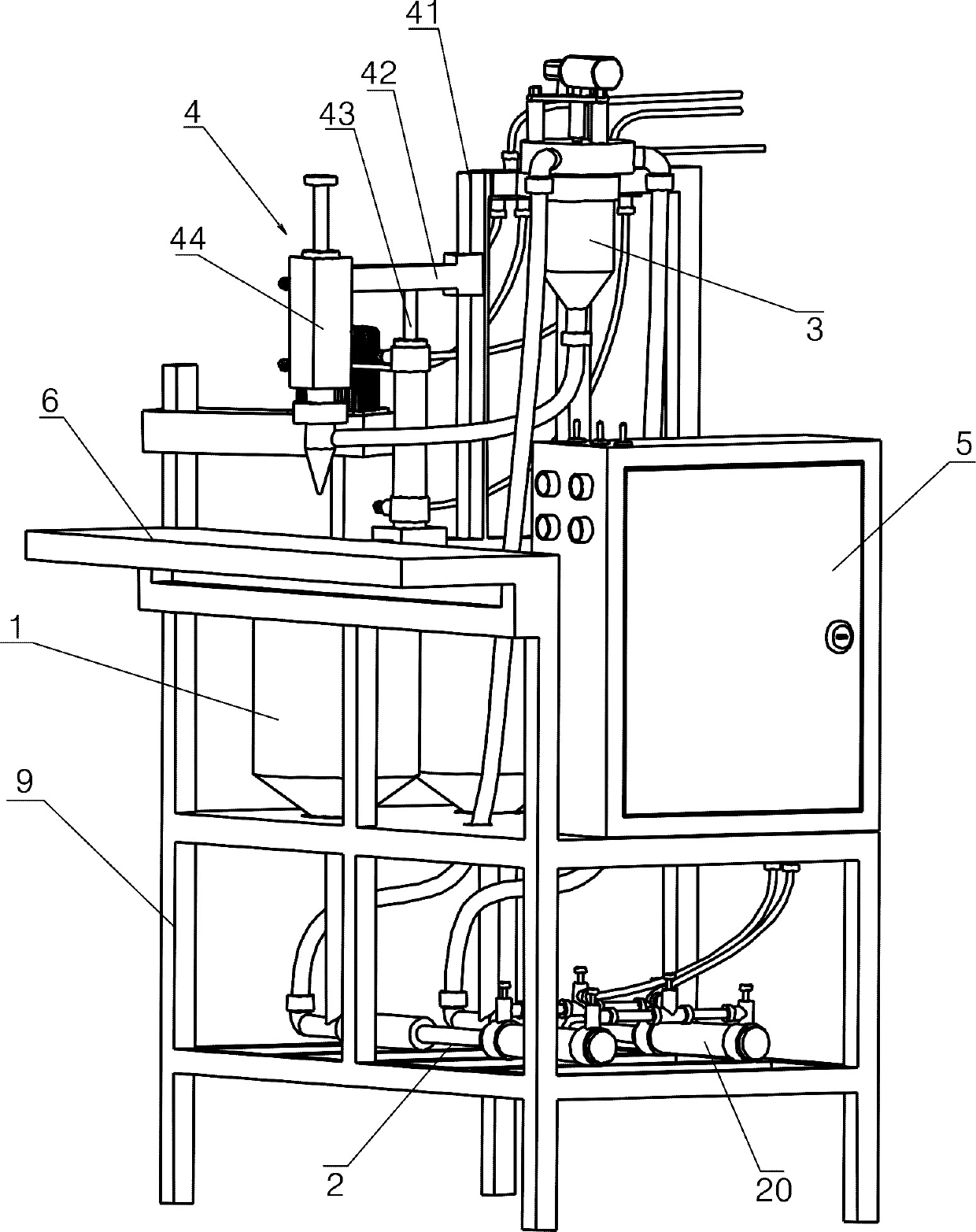

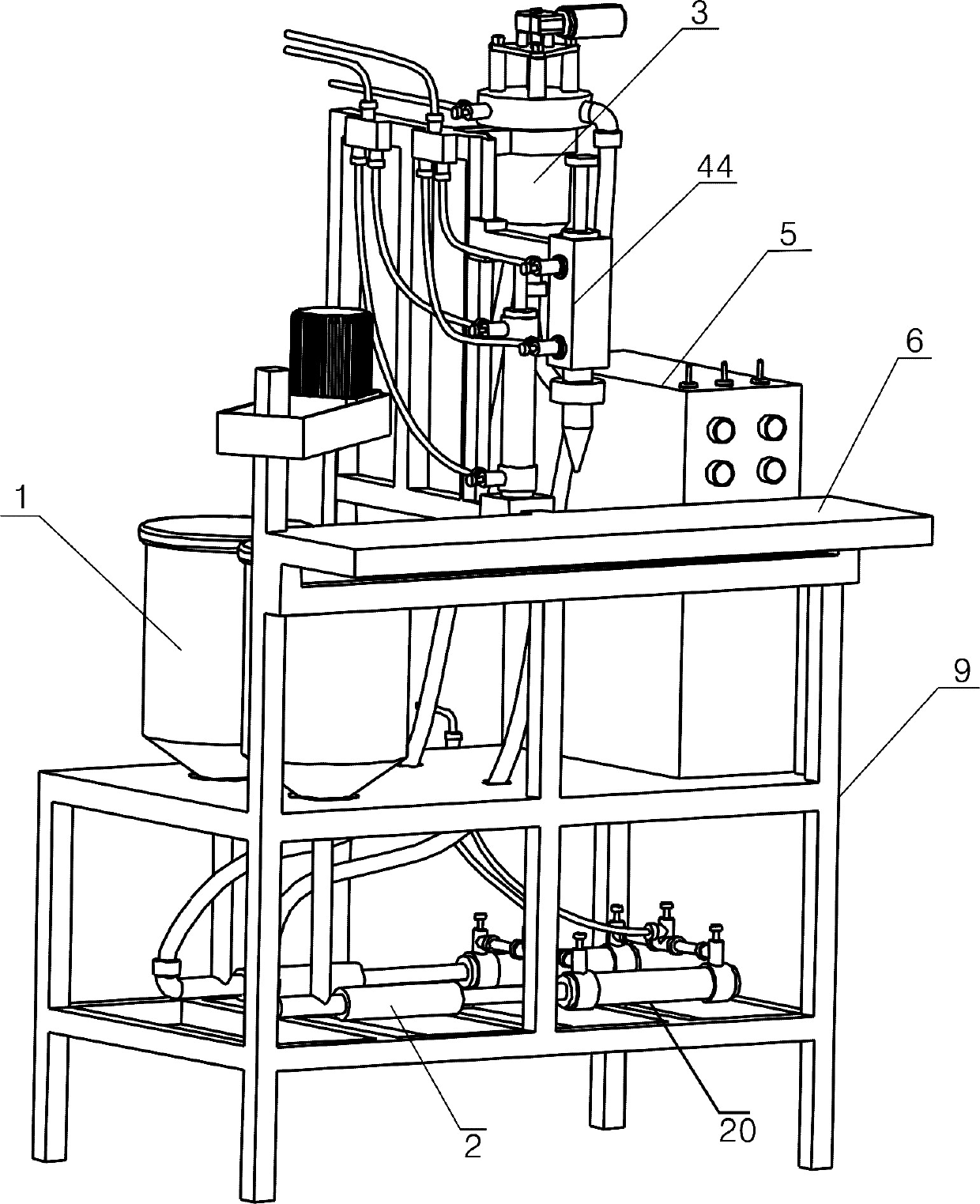

[0023] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0024] The embodiment of the present invention provides an integrated LED solid-sealing machine, which is used for performing multi-component, precise and controlled dispensing and sealing of chemical resin on LED products. Glue storage device 1, colloid transportation device 2, colloid mixing and stirring device 3, and glue dispensing device 4 with a certain range of movement stroke. The glue storage device 1 has a plurality of mutually independent chambers corresponding to accommodate glue dispensing and sealing Various mounting solvents required;

[0025] The glue storage device 1, the colloid transportation device 2, the colloid mixing and stirring device 3, and the glue dispensing device 4 are sequentially connected, and various embedding solvents are transported to the colloid mixing device 2 by the colloid transportation device 2. In the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com