Rotor mechanically-pumping type foam proportionally-mixing device

A proportional mixing device and mechanical pump technology, which is applied in the direction of rotary piston machinery, mechanical equipment, rotary piston type/swing piston type pump combination, etc., can solve the problems of large volume, achieve small volume, reduce installation space, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The rotor mechanical pump-in foam proportional mixing device of the present invention will be described in detail below in conjunction with examples and accompanying drawings.

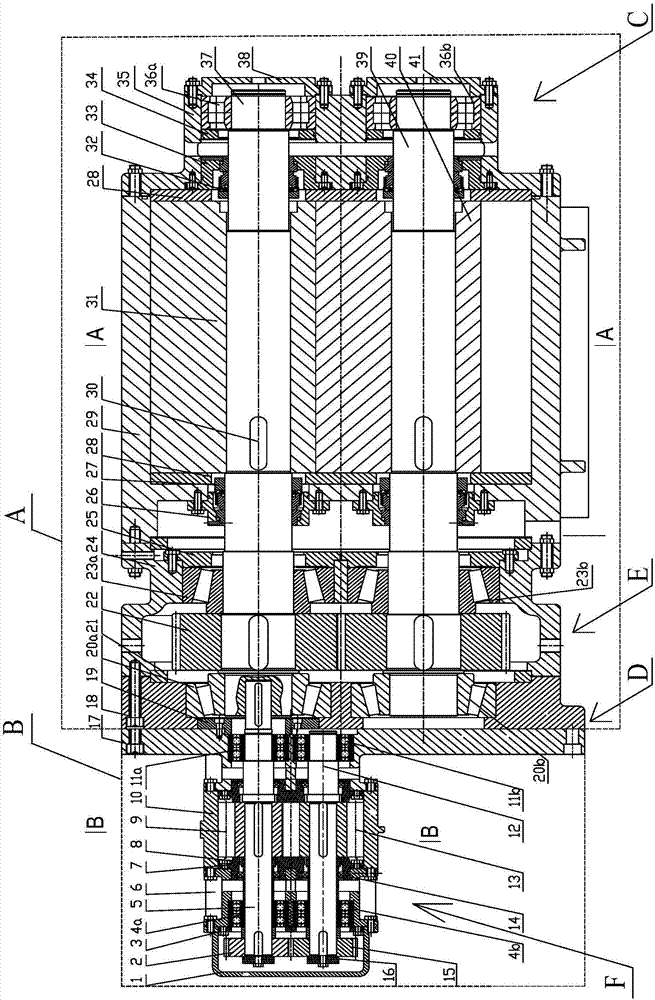

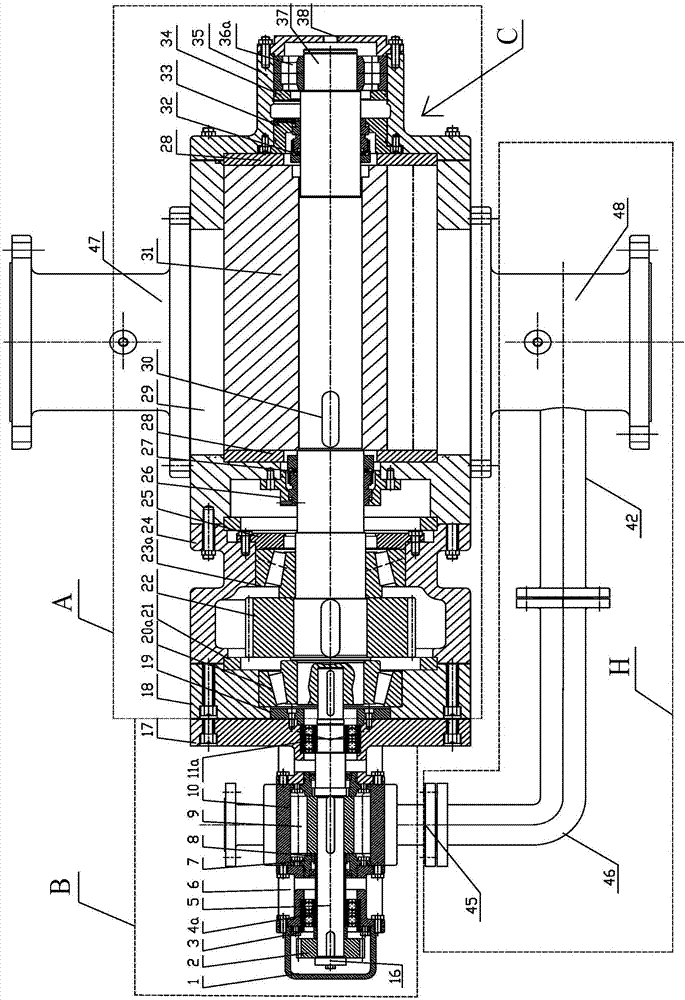

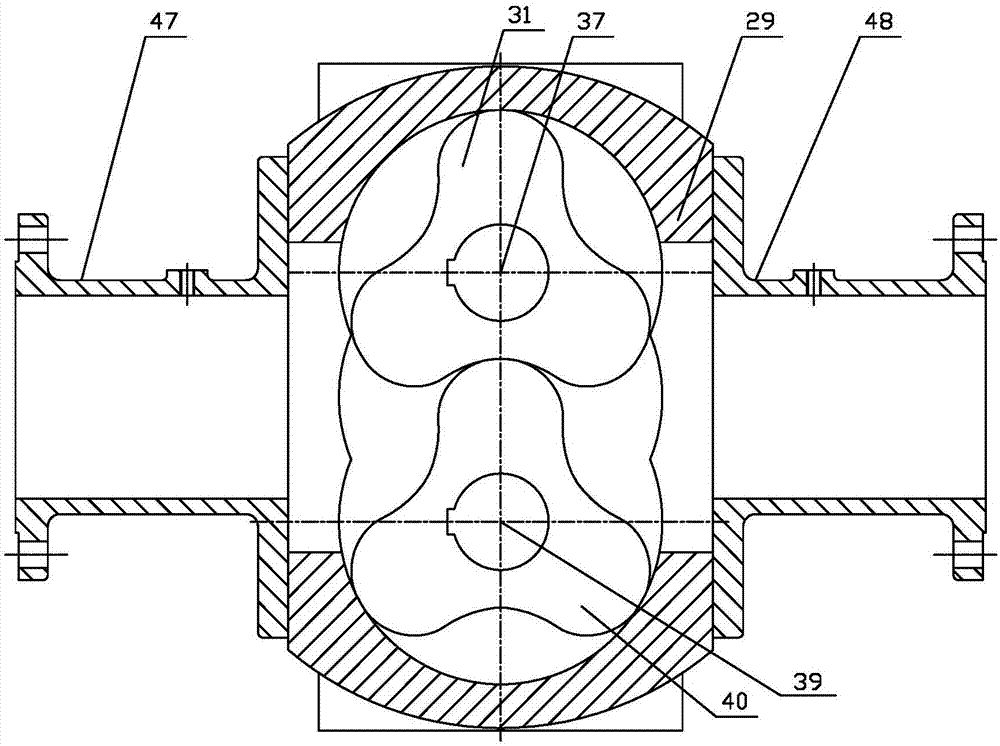

[0070] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the rotor mechanical pump-in foam proportional mixing device of the present invention includes: a hydraulically driven rotor turbine A powered by fire-fighting water, through an intermediate bearing mechanism D and the drive output of the hydraulically driven rotor turbine A The shaft is connected to the foam gear pump B used to pressurize the normal-pressure foam and discharge it, and the water outlet of the hydraulically driven rotor turbine A and the liquid outlet of the foam gear pump B are respectively connected to the fire-fighting mixture for outputting the fire-fighting mixture. Mechanism H, wherein, the hydraulically driven rotor type water turbine A has a master-slave double-rotor structure, and a constant gap is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com