Method for proportionally mixing powder

A powder and production formula technology, applied in the field of powder mixing, can solve the problems of prone to errors, large proportioning workload, unqualified production materials, etc., and achieves the effect of increasing production speed, accurate proportioning and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

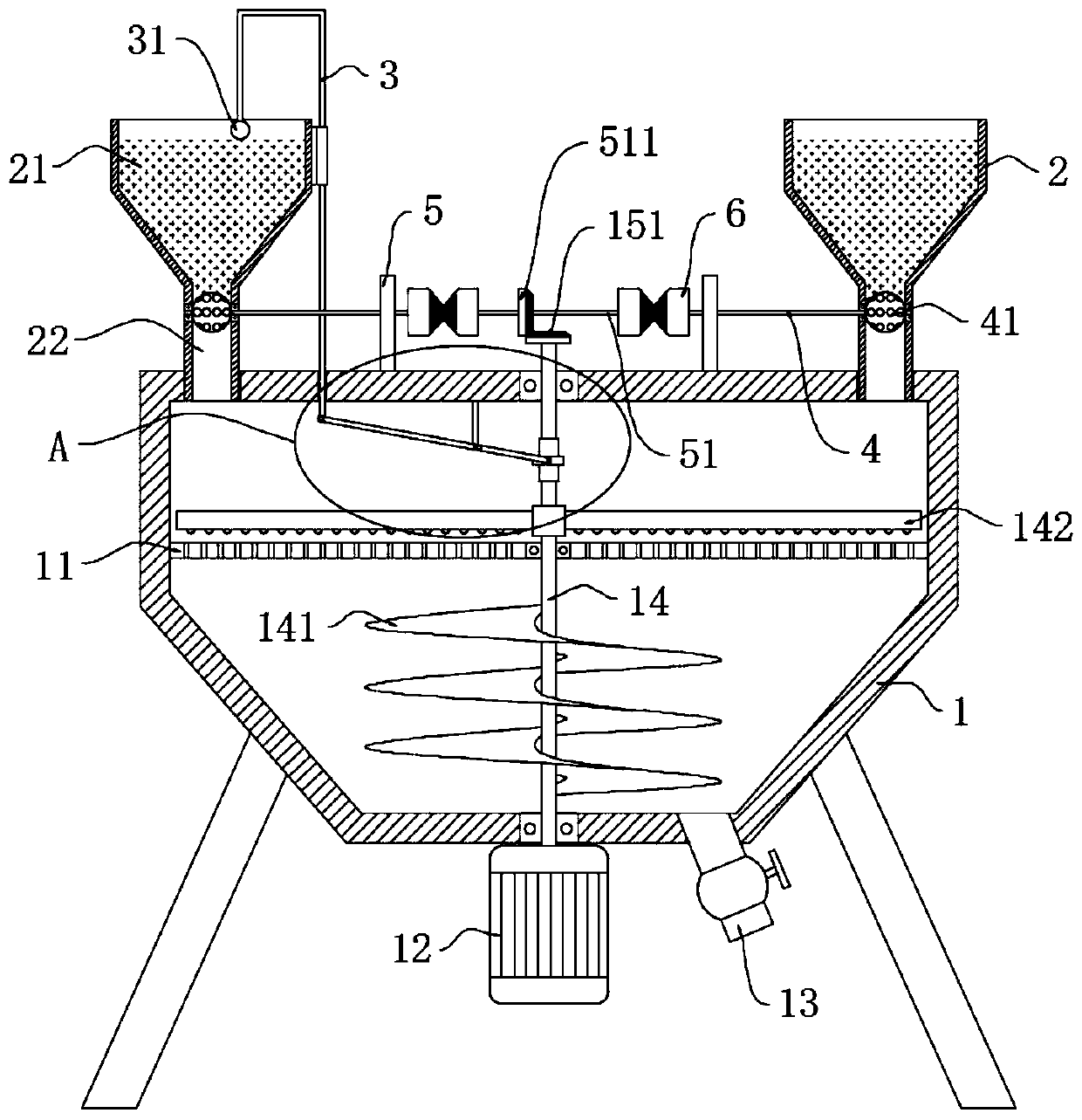

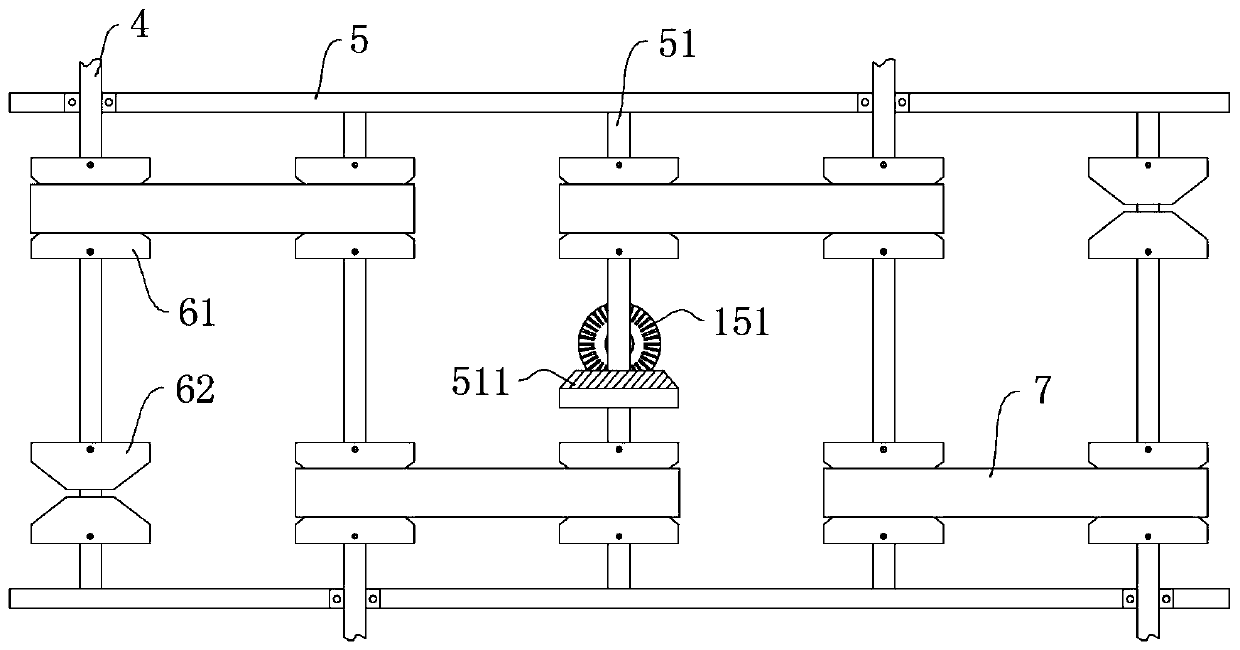

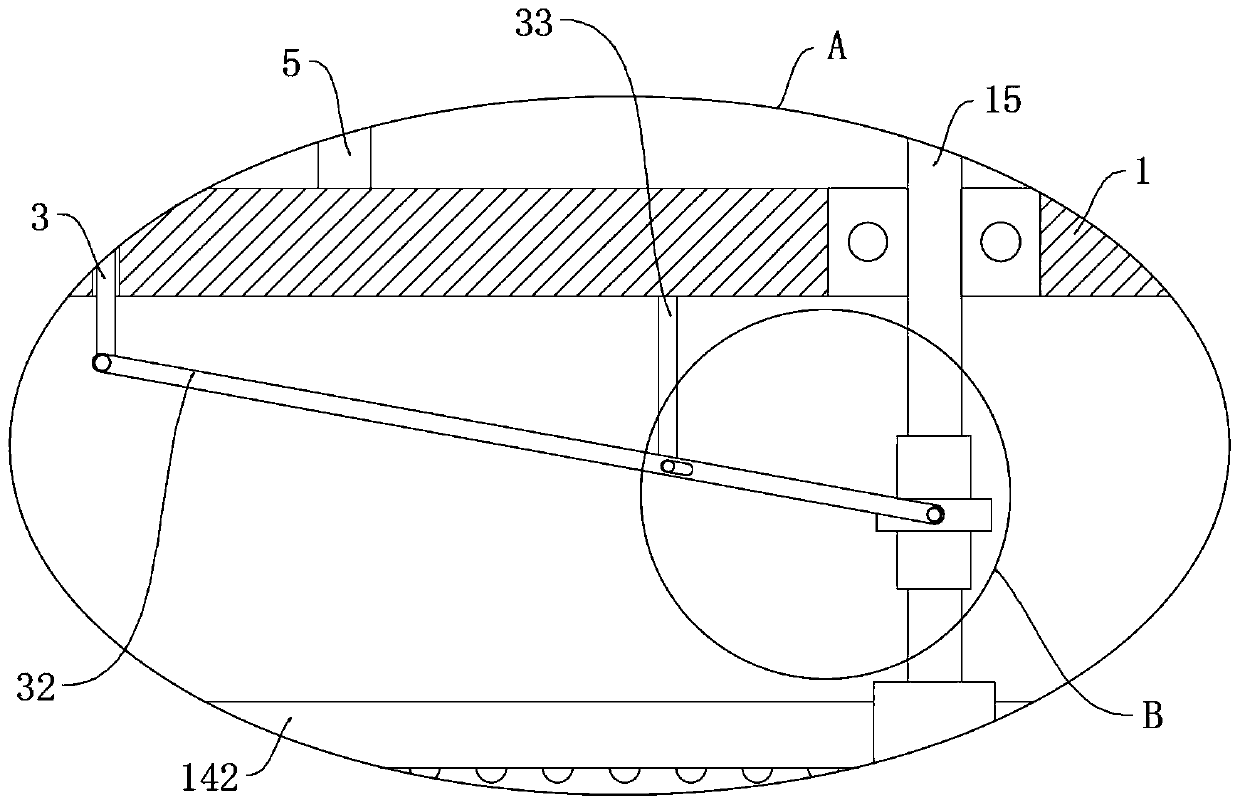

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0042] refer to Figure 1-7 , a method for powder proportioning mixing, mainly comprising the following mixing steps:

[0043] a: Raw material preparation; according to the mixed production formula, various powder materials are prepared adequately, and the proportion is prepared based on the powder material with the smallest amount;

[0044] b: Feeding; add the prepared powders into the feed hopper 21 respectively, and add the powder with the largest amount into the feed hopper 21 where the gravity ball 31 is placed, and then make the gravity ball 31 be located on the powder with the largest amount surface;

[0045] c: Ratio adjustment; adjust the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com