Multi-stage stirrer

A technology for mixers and stirring motors, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., which can solve the problem of difficulty in achieving uniform shearing and rapid mixing at the same time, poor sound insulation, and inability to continuously mix and discharge materials. And other problems, to achieve good sound insulation effect, good sealing, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

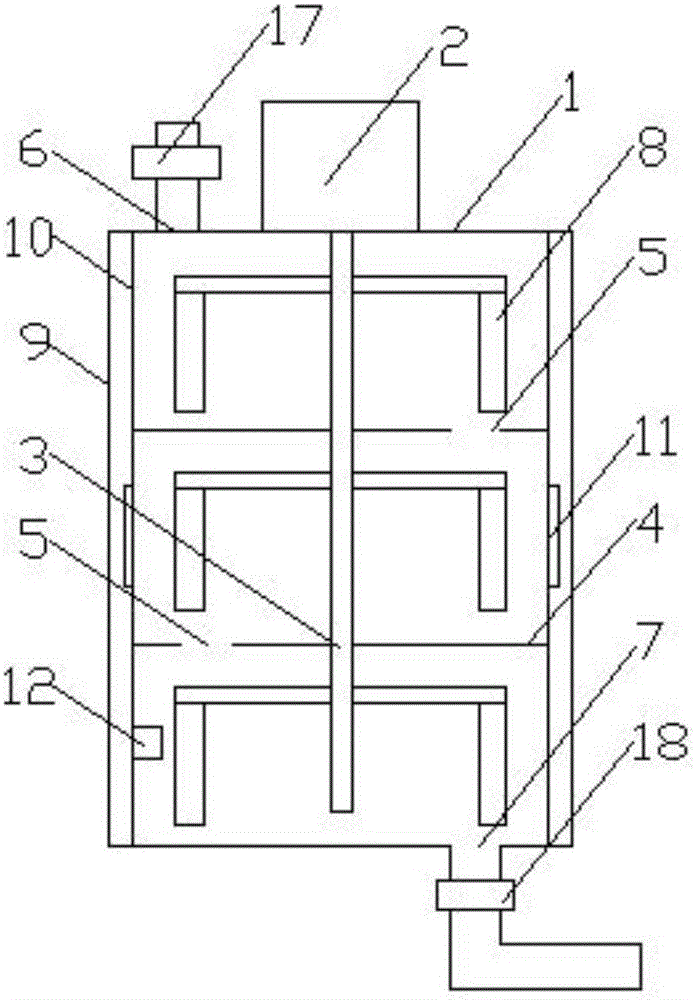

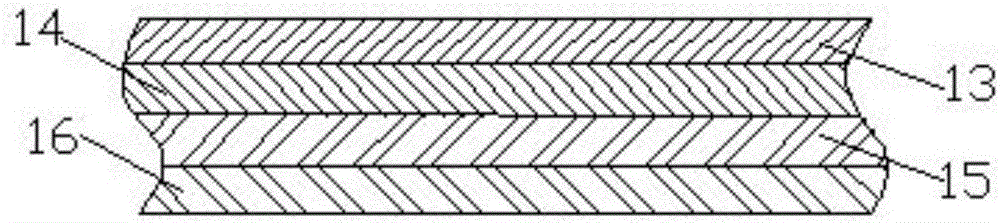

[0023] like figure 1 , figure 2 Shown, a kind of multi-stage mixer, comprises casing 1 and is arranged on the stirring motor 2 above casing, and the rotating shaft 3 of described stirring motor 2 is arranged in described casing 1; Described casing 1 is from top to The bottom is divided into multi-layer compartments, and the partition plate 4 of each compartment is provided with a discharge port 5, the top of the casing 1 is provided with a feed port 6, and the bottom of the casing 1 is provided with a total discharge port 7 , the feed port 6, the discharge port 5 and the total discharge port 7 are arranged in a bow shape; the rotating shaft 3 in each layer of the compartment is provided with a stirring impeller 8; the casing 1 includes an outer wall 9 and Inner wall 10, a plurality of temperature regulating devices 11 are distributed circumferentially between the outer wall 9 and the inner wall 10; a temperature sensor 12 is arranged in the lowest compartment of the casing 1...

Embodiment 2

[0025] like figure 1 , figure 2 Shown, a kind of multi-stage mixer, comprises casing 1 and is arranged on the stirring motor 2 above casing, and the rotating shaft 3 of described stirring motor 2 is arranged in described casing 1; Described casing 1 is from top to The bottom is divided into multi-layer compartments, and the partition plate 4 of each compartment is provided with a discharge port 5, the top of the casing 1 is provided with a feed port 6, and the bottom of the casing 1 is provided with a total discharge port 7 , the feed port 6, the discharge port 5 and the total discharge port 7 are arranged in a bow shape; the rotating shaft 3 in each layer of the compartment is provided with a stirring impeller 8; the casing 1 includes an outer wall 9 and Inner wall 10, a plurality of temperature regulating devices 11 are distributed circumferentially between the outer wall 9 and the inner wall 10; a temperature sensor 12 is arranged in the lowest compartment of the casing 1...

Embodiment 3

[0028] like figure 1 , figure 2 Shown, a kind of multi-stage mixer, comprises casing 1 and is arranged on the stirring motor 2 above casing, and the rotating shaft 3 of described stirring motor 2 is arranged in described casing 1; Described casing 1 is from top to The bottom is divided into multi-layer compartments, and the partition plate 4 of each compartment is provided with a discharge port 5, the top of the casing 1 is provided with a feed port 6, and the bottom of the casing 1 is provided with a total discharge port 7 , the feed port 6, the discharge port 5 and the total discharge port 7 are arranged in a bow shape; the rotating shaft 3 in each layer of the compartment is provided with a stirring impeller 8; the casing 1 includes an outer wall 9 and Inner wall 10, a plurality of temperature regulating devices 11 are distributed circumferentially between the outer wall 9 and the inner wall 10; a temperature sensor 12 is arranged in the lowest compartment of the casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com