Scroll device integrating a feed pump

a technology of a scroll device and a feed pump, which is applied in the direction of roller bearings, rotary piston engines, bearings, etc., can solve the problems of high temperature change sensitivity, deformation and displacement of scrolls, and significant limitations on the rotational speed which may be achieved, so as to prevent thermal deformation of scrolls, prevent thermal deformation, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

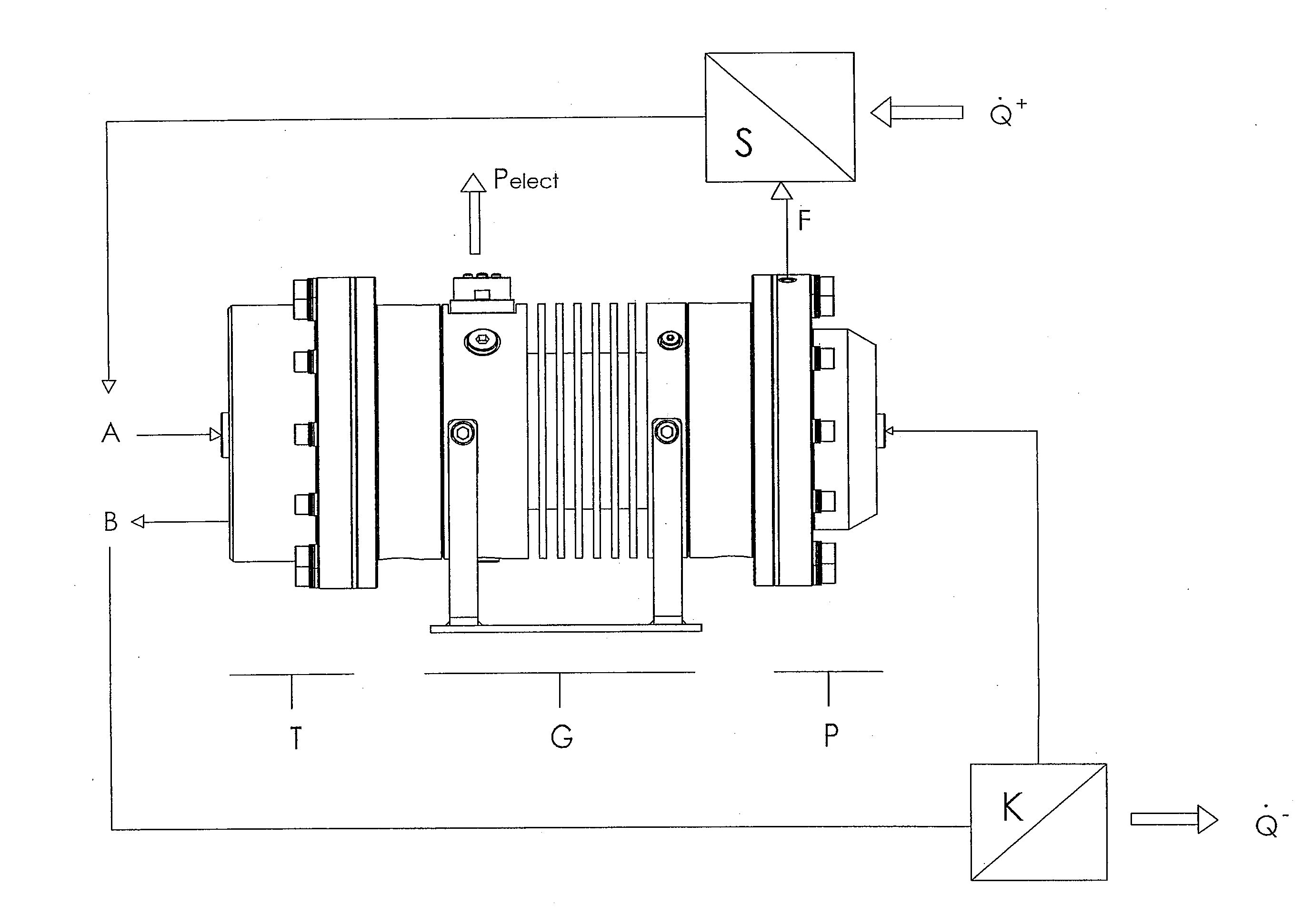

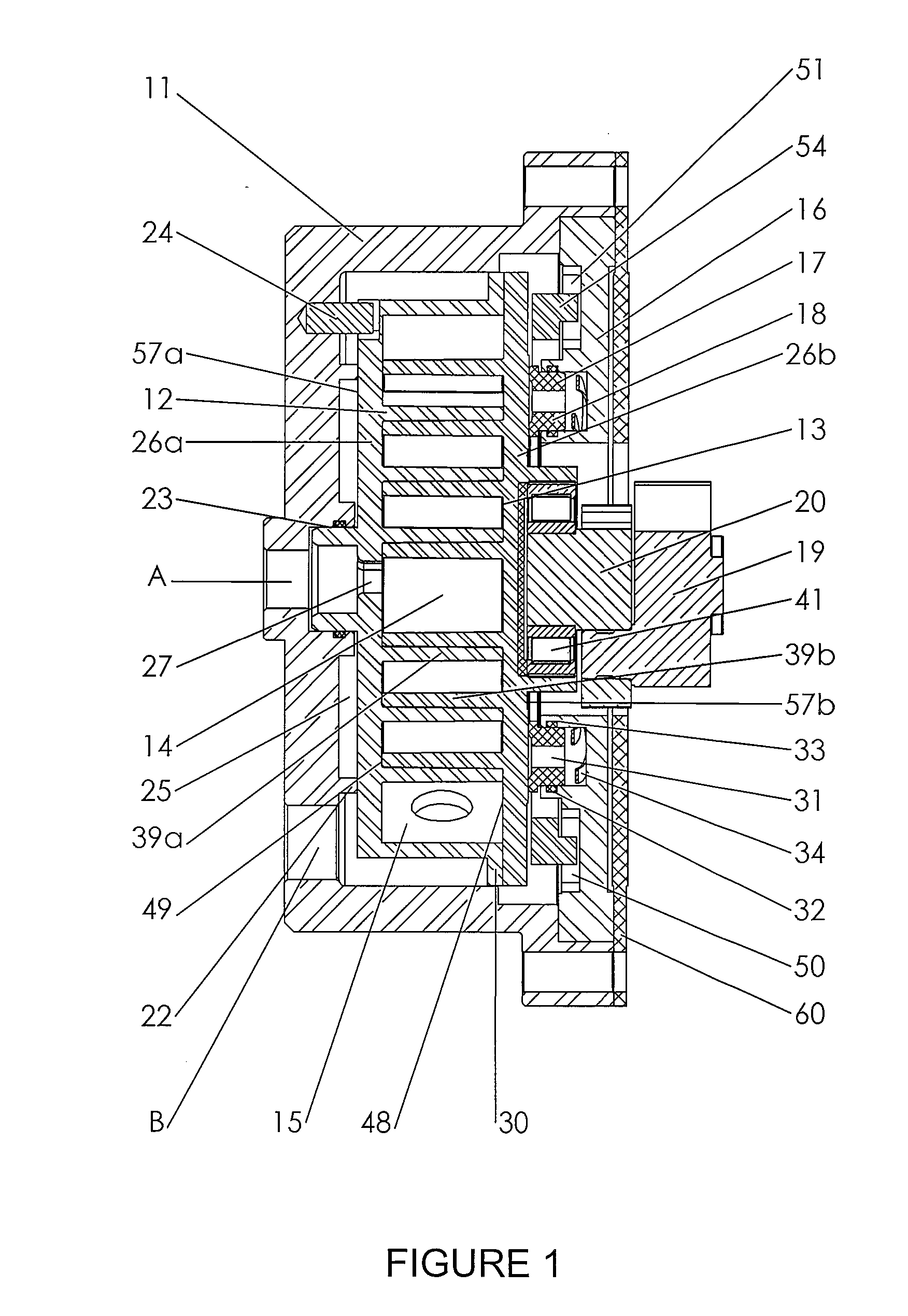

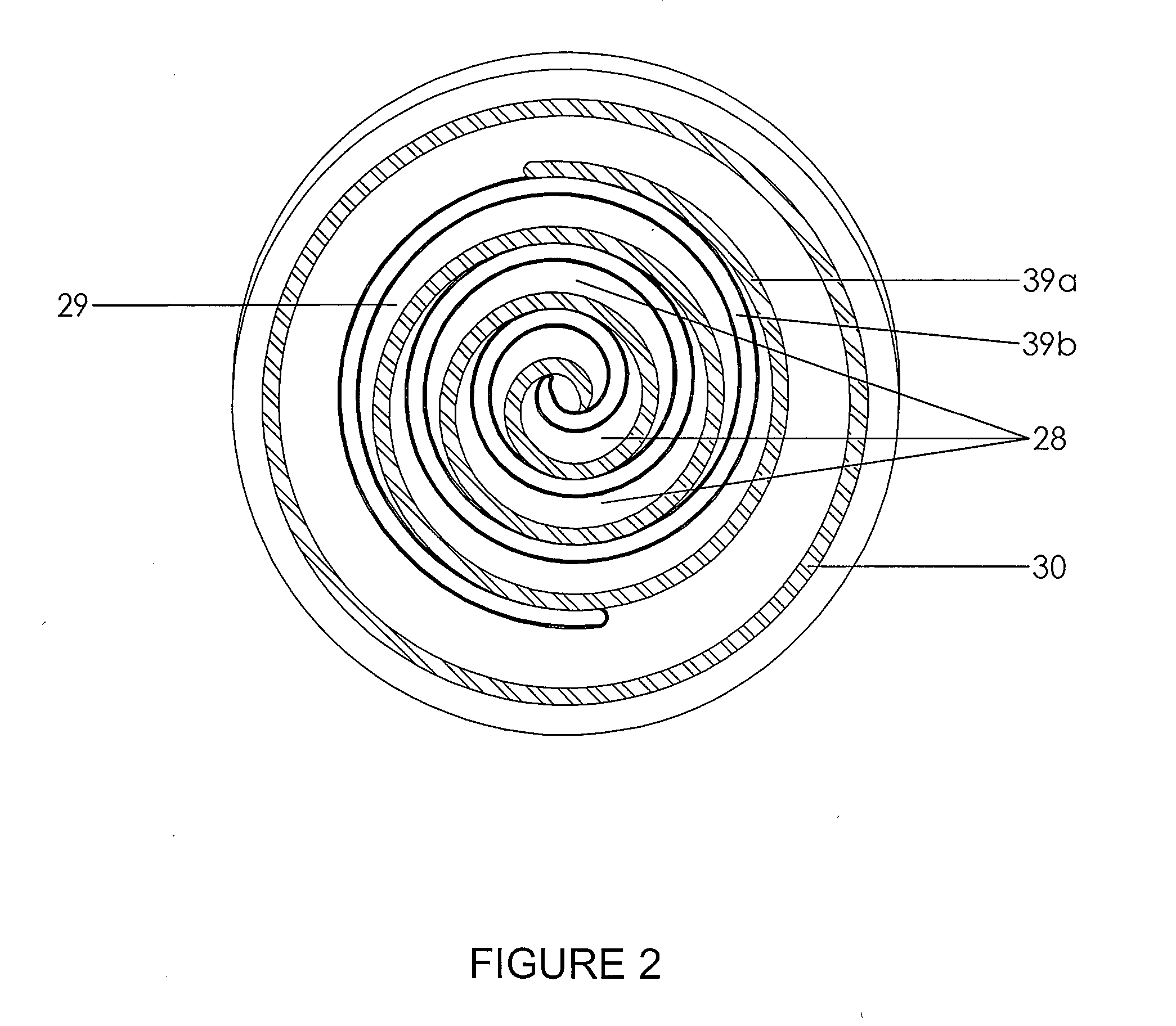

[0041]In the following description of the scroll device according to the present invention, for reasons of convenience, reference will primarily be made to a configuration with one or two expander stages, except for FIG. 10, wherein the second stage comprises a feed pump. However, it is clear that each stage of the scroll device which represents a scroll module may operate either as an expander or as a compressor. It will also be understood that it is possible to have a configuration with a single stage possibly coupled with an electric device, the module alone being able to be used as an expander or a compressor. For this purpose, it will be further noted that the second stage is preferably modular, i.e. interchangeable, so as to allow a modification of the operation of the device. However, alternatively, the second stage may be integral with the remainder of the device, i.e. non-modular.

[0042]The present description will now be provided as non-limiting examples in connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com