Spray coating method for producing dielectric ceramic powder body and obtained products thereof

A ceramic powder and dielectric technology, applied in the field of electronic ceramic powder, can solve the problems of low drying temperature, loss of barium ions, long production cycle, etc., and achieve the effects of ultra-high uniformity, good dispersion and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

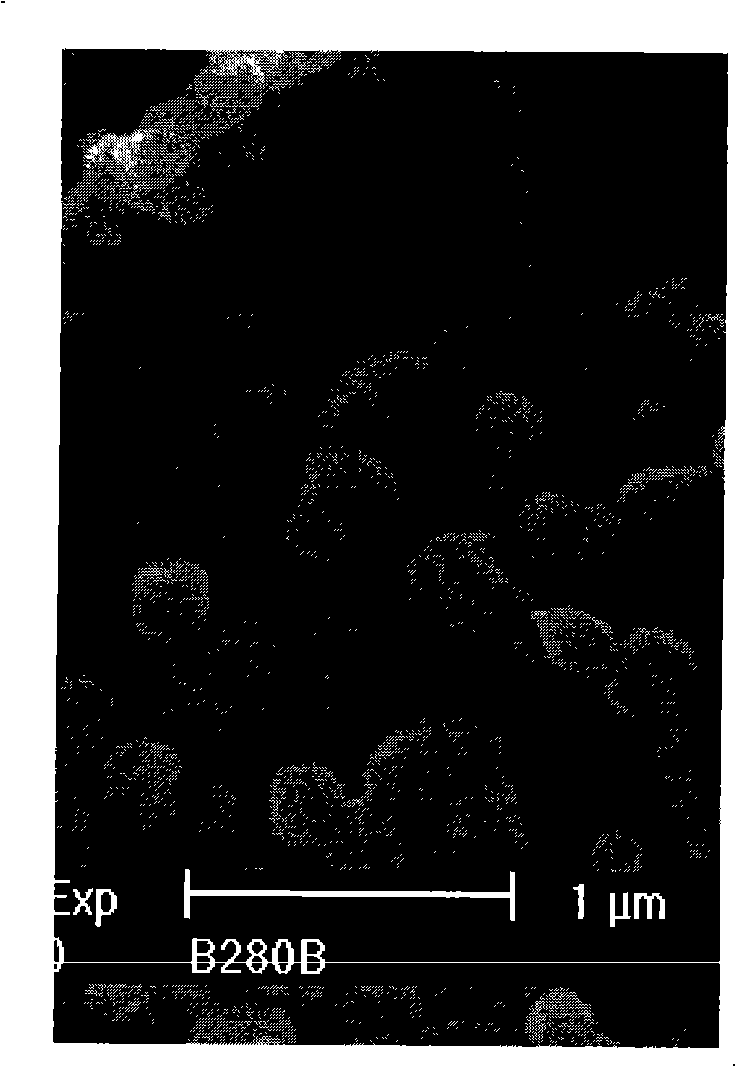

[0016] In this example, BT powder with a particle size of 300nm to 350nm prepared by the hydrothermal method is used as the main crystal phase, and the following formula composition and the spray coating method are used to prepare dielectric ceramics for MLCC with temperature characteristics conforming to the EIA-X7R standard Powder.

[0017] Dissolve 0.30Kg of polyacrylamide in 130Kg of deionized water at 25°C and put it into the ball mill, then add 100.00Kg of BT powder, cover and seal it, start the machine to disperse for 5 hours, and then completely discharge it into the plastic In the container is slurry A. Another weighed 2.33Kg of Ca (NO 3 ) 2 .4H 2 O, 5.25Kg of Y (NO 3 ) 3 .6H 2 O, 0.31Kg concentration is 50% Mn(NO 3 ) 2 Slurry, 0.88Kg of Mg(NO 3 ) 2 ·6H 2 O, 0.38Kg of Cu(NO 3 ) 2 ·6H 2 O. 1.00Kg of silica sol with a solid content of 40% is diluted with 100L deionized water to form a doped modified salt slurry, and then slowly added to the aforementioned ...

Embodiment 2

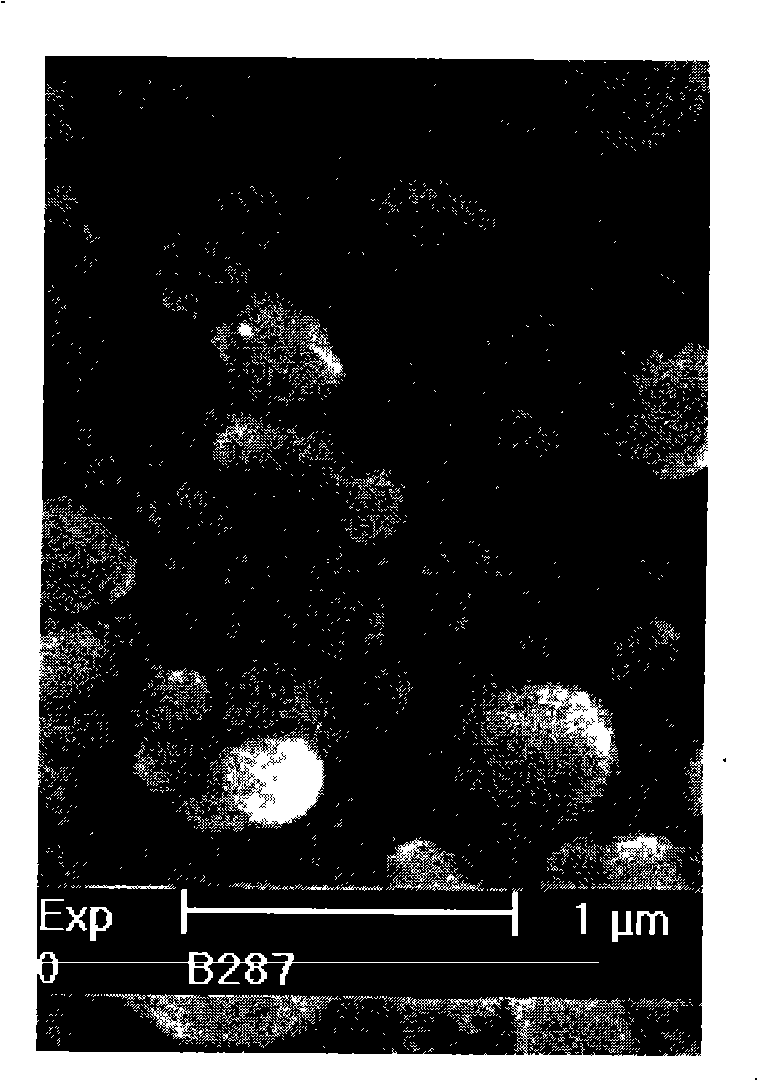

[0020] In this embodiment, the particle size is 200nm hydrothermal ultrafine cubic phase Ba(Ti 0.866 Zr 0.134 )O 3 (BTZ) is the main crystal phase, and the dielectric ceramic powder whose temperature characteristics meet the EIA-Y5V standard is prepared by the following formula composition and the spray coating method, and the nickel electrode multilayer ceramic is prepared by conventional casting method for performance verification.

[0021] Weigh 306g of Ca (NO 3 ) 2 . 4H 2 O, 135g weight of Y(CH 3 COO) 3 . 3.15H 2 O, 62g weight of Mn(CH 3 COO) 2 . 4H 2 O, the Mg(CH of 54g weight 3 COO) 2 . 4H 2 O, 30g weight of Cu(NO 3 ) 2 . 3H 2O, 267g solid content is the titania sol of 20wt%, 250g solid content is the AK0531 polymer dispersant of 20wt% silica sol and 30g, after adding deionized water 8.87Kg it is fully dissolved to obtain slurry A. In addition, weigh 20Kg of hydrothermal ultra-fine high-purity cubic phase BTZ with a particle size of about 200nm prepa...

Embodiment 3

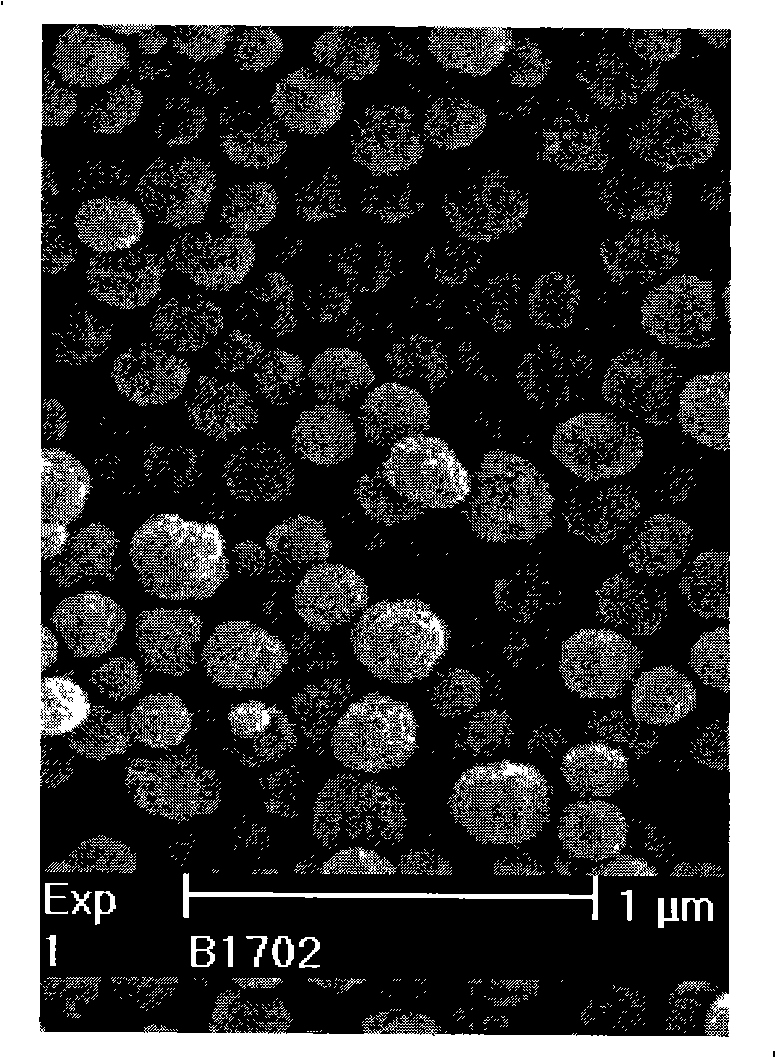

[0024] The present embodiment prepares the superfine Zn that particle size is 300nm by co-precipitation method 0.70 Mg 0.30 TiO 3 (ZMT) is the main crystal phase, and the electronic ceramic material whose temperature characteristics meet the EIA-COG standard is prepared with the following formula composition and the described spray coating method, and a multilayer ceramic capacitor is prepared with a conventional casting method and a silver paste with low palladium content Perform performance verification.

[0025] Weigh 100Kg of the main sintered block ZMT into the three-dimensional vibration mill, then add 100L of deionized water at 30°C, start the machine and grind for 8 hours to disperse into a slurry, and then discharge the material into a container with stirring, then add deionized water to adjust its The solid content is 45%, after weighing 30Kg of the slurry into another well-stirred container as A, and taking by weighing 97.3g of 50% manganese slurry and 40.5g of bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com