Turbine engine lubrication method and system

a technology for aviation turbomachines and lubricating methods, which is applied in the direction of non-positive displacement fluid engines, leakage prevention, pump control, etc., can solve the problems of increasing the weight of the turbomachine, consuming a large amount of lubricating oil, and reducing the efficiency of de-oiling, so as to achieve light weight and consume little oil or compressed air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

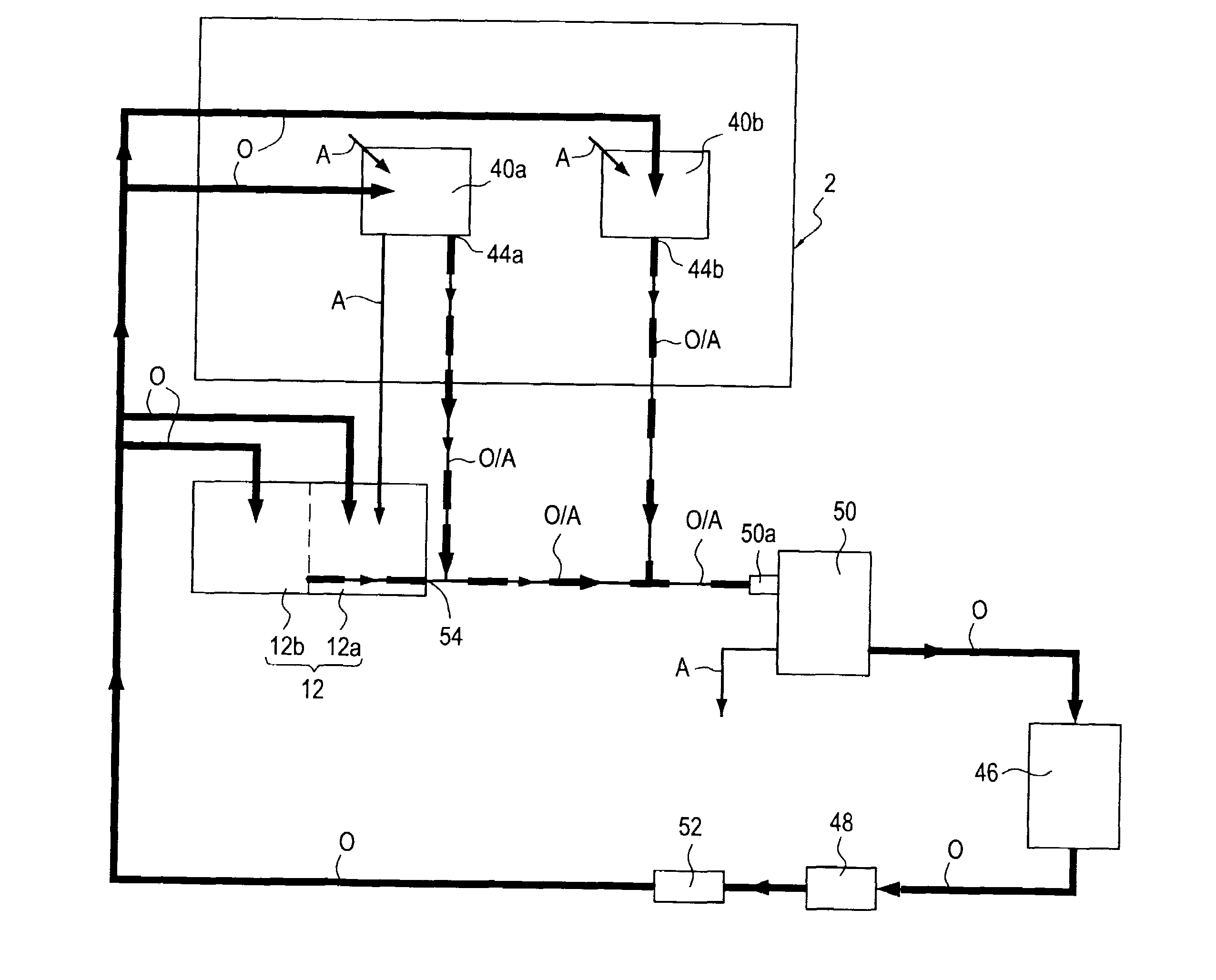

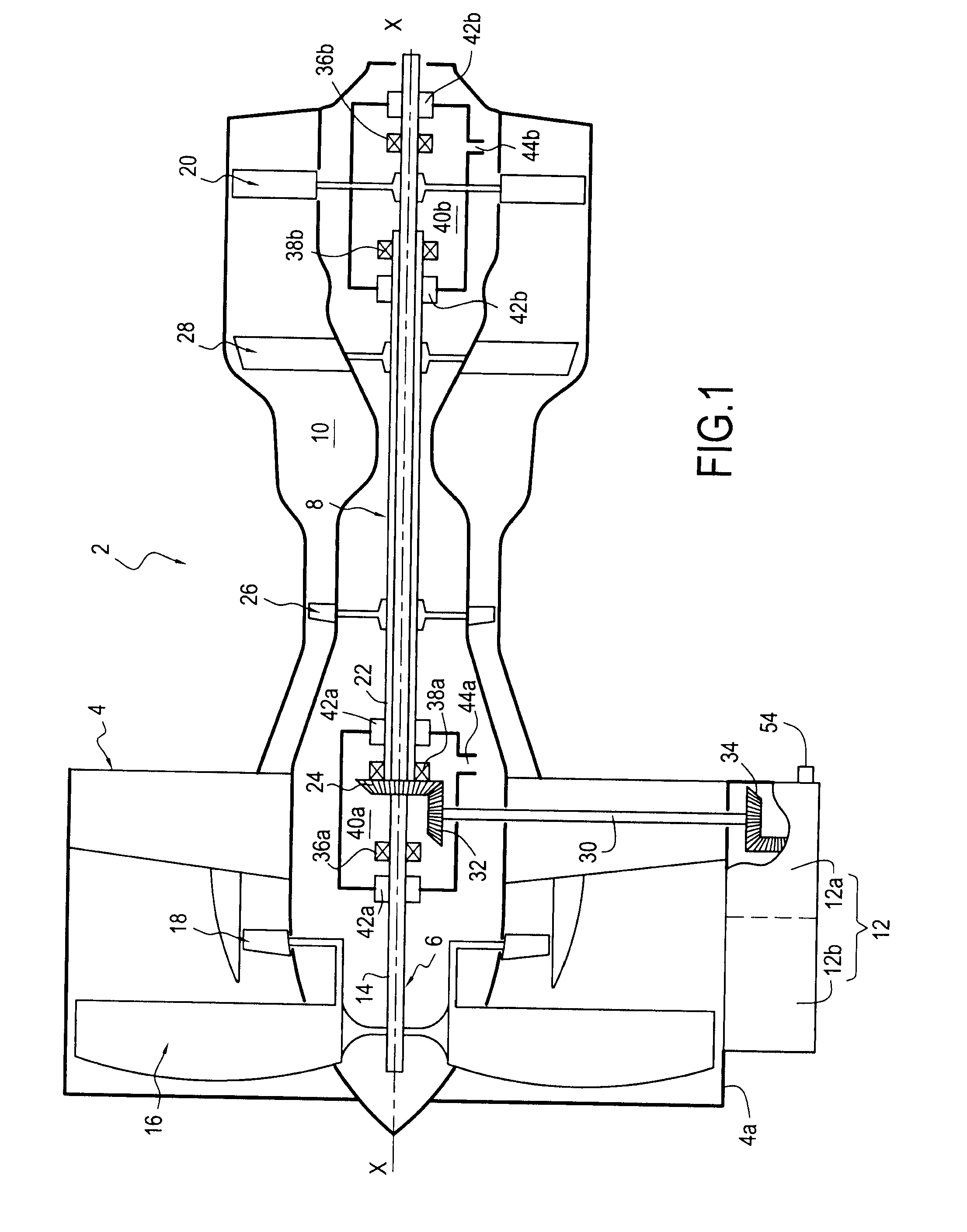

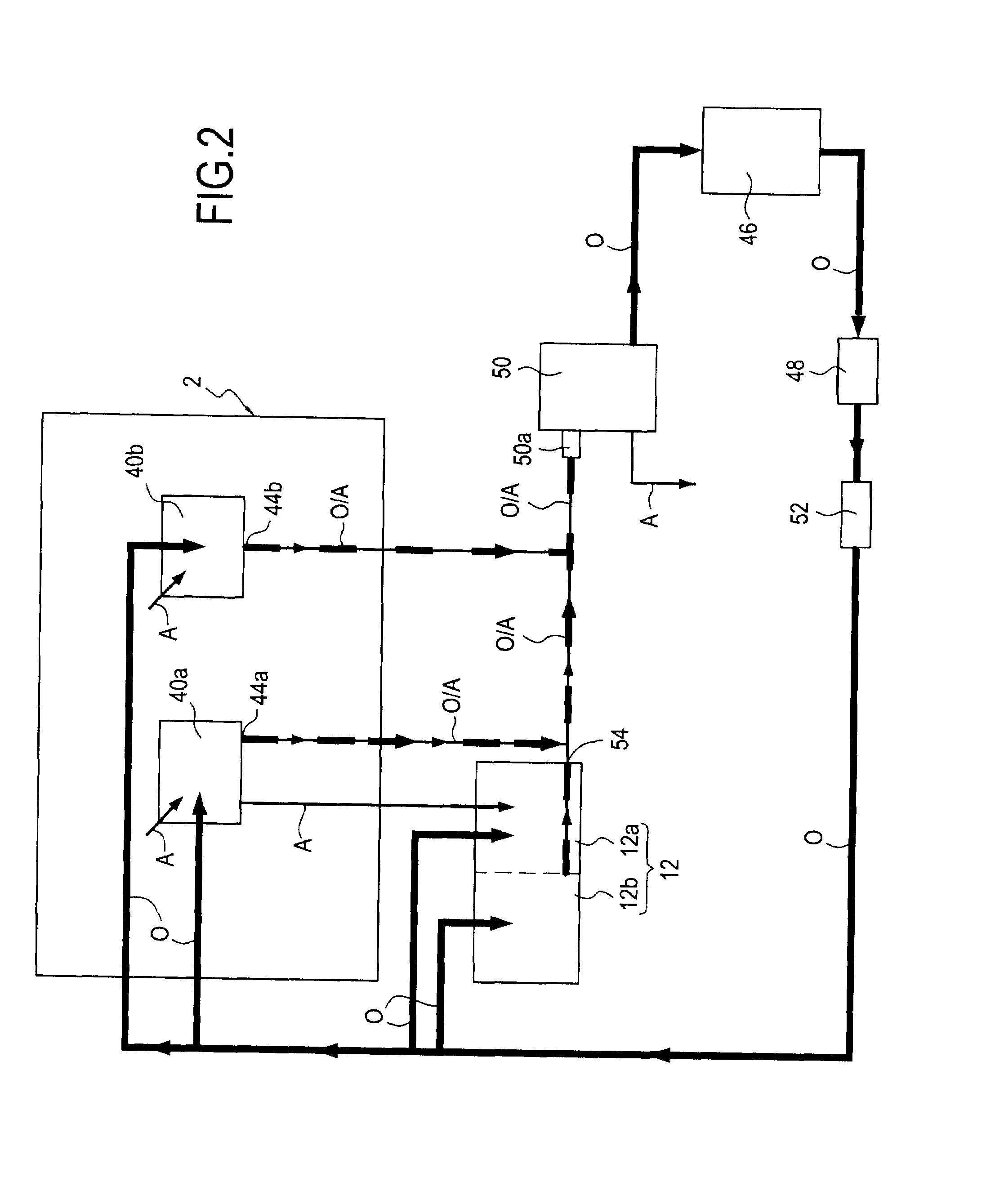

[0022]FIG. 1 is a diagram showing a portion of an aviation bypass turbomachine 2 in which the lubrication method and system of the invention can be implanted. Naturally, the present invention applies to any other type of turbomachine (single spool, triple spool, single-flow, industrial, etc.).

[0023]In well-known manner, the turbomachine 2 of longitudinal axis X-X comprises in particular a fan casing 4, a low-pressure spool 6, a high-pressure spool 8, a combustion chamber 10, and an accessory drive gearbox 12.

[0024]The low-pressure spool 6 comprises a low-pressure shaft 14 centered on the longitudinal axis X-X, a fan 16 mounted at the front end of the low-pressure shaft, a low-pressure compressor 18 fastened to the fan, downstream therefrom, and a low-pressure turbine 20 mounted on the rear end of the low-pressure shaft.

[0025]The high-pressure spool 8 comprises a high-pressure shaft 22 disposed concentrically around the low-pressure shaft 14, a bevel gear 24 mounted at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com