Novel graphene heat-conducting coating and preparation method thereof

A heat-conducting coating and graphene technology, applied in the field of coatings, can solve the problems of poor bonding performance between coatings and substrates, low service life, no thermal conductivity, etc., and achieve good wear resistance, good corrosion resistance, and good thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

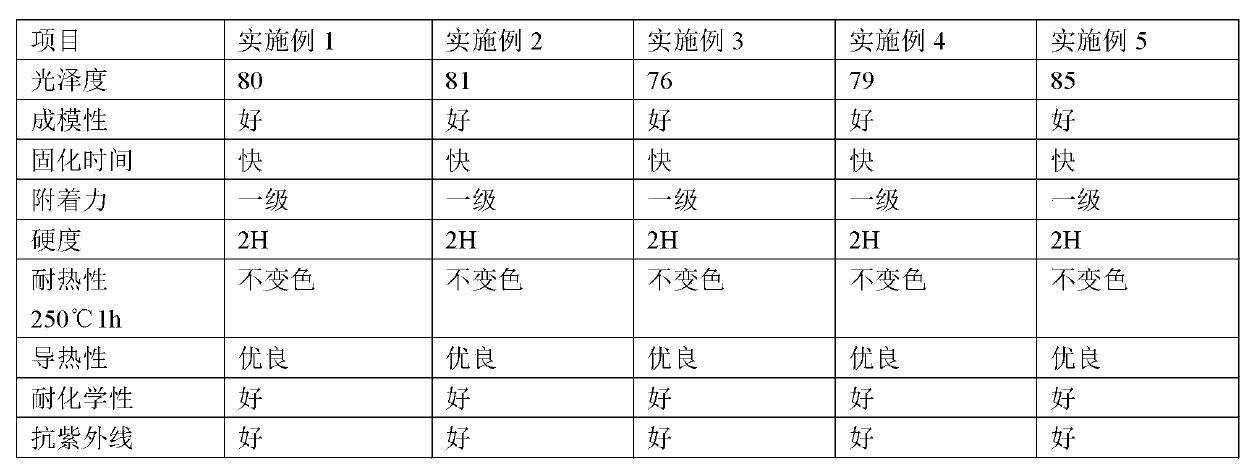

Examples

Embodiment 1

[0024] A new type of graphene thermal conductive coating, which is prepared by modifying graphene and nano-diamonds with a particle size of 20nm. The weight ratio of graphene and nano-diamonds is 5:1. The percentage of the total amount of thermally conductive coating is 5%. The other components account for 95% of the total amount of the new graphene thermally conductive coating, and the ratio of other components by weight is: 20 parts of silica sol, 20 parts of inorganic silicate, 1 part of copper fiber, dispersant 1 part, 0.1 part of leveling agent, 2 parts of defoamer. The components are mixed evenly by ultrasonic stirring according to the ratio.

Embodiment 2

[0026] A new type of graphene thermal conductive coating, which is prepared by modifying graphene and nano-diamonds with a particle size of 200nm. The weight ratio of graphene and nano-diamonds is 1:1. The percentage of total thermally conductive coating is 1.5%. The other components account for 98.5% of the total amount of the new graphene thermally conductive coating, and the proportions of other components by weight are: 50 parts of silica sol, 5 parts of inorganic silicate, 5 parts of copper fiber, dispersant 0.1 part, 2 parts of leveling agent, 0.1 part of defoamer. The components are mixed evenly by ultrasonic stirring according to the ratio.

Embodiment 3

[0028] A new type of graphene thermal conductive coating, which is prepared by modifying graphene and nano-diamonds with a particle size of 20nm. The weight ratio of graphene and nano-diamonds is 6:1. The percentage of the total amount of thermally conductive coating is 5%. Other components account for 95% of the total amount of the new graphene thermally conductive coating, and the proportions of other components by weight are: 20 parts of bisphenol A novolac epoxy resin, 30 parts of polyaniline, melamine formaldehyde resin 5 parts, epoxy acrylate 5 parts, copper fiber 3 parts, dispersant 1 part, leveling agent 0.1 part, defoamer 1 part. The components are mixed evenly by ultrasonic stirring according to the ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com