High thermal conductivity metal-based composite material with hierarchical structure, and preparation method thereof

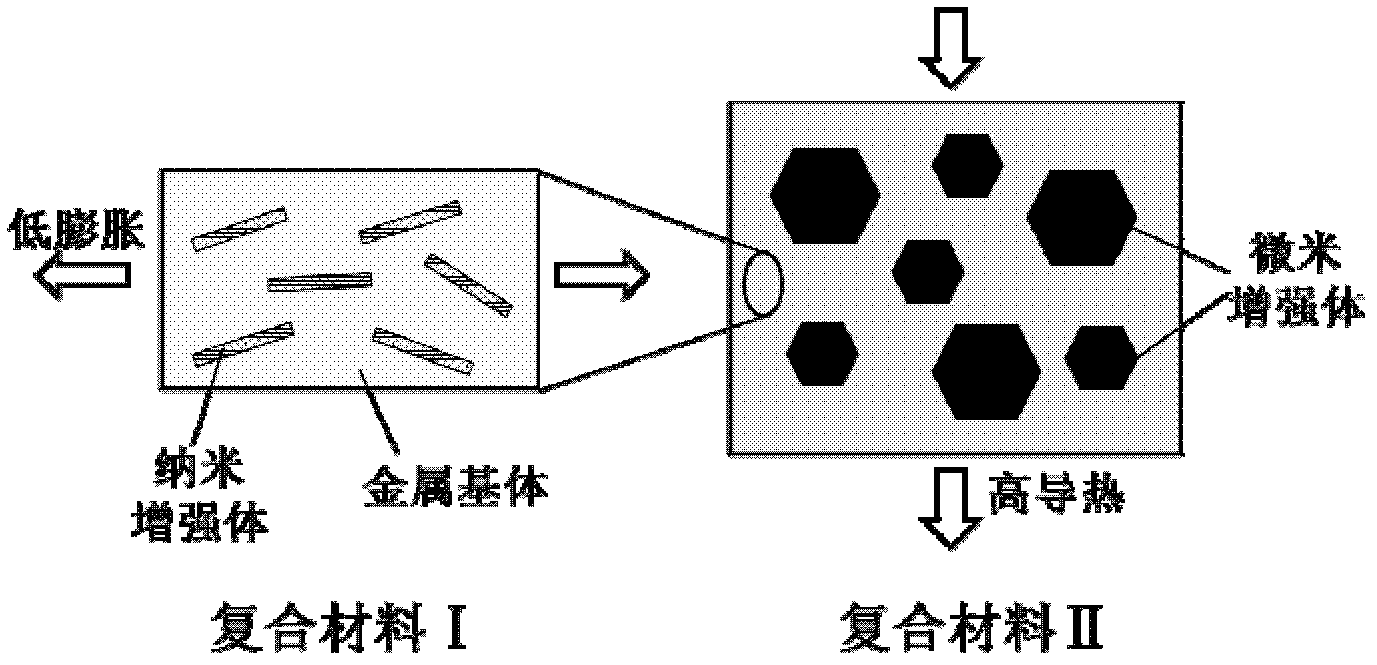

A composite material and hierarchical structure technology, which is applied in the field of high thermal conductivity metal matrix composite material and its powder metallurgy preparation, can solve the problems of difficulty in ensuring work stability and service life, decrease in damping performance of composite materials, and increase in brittleness of composite materials. The effect of increased controllability, improved damping performance, and low interfacial thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

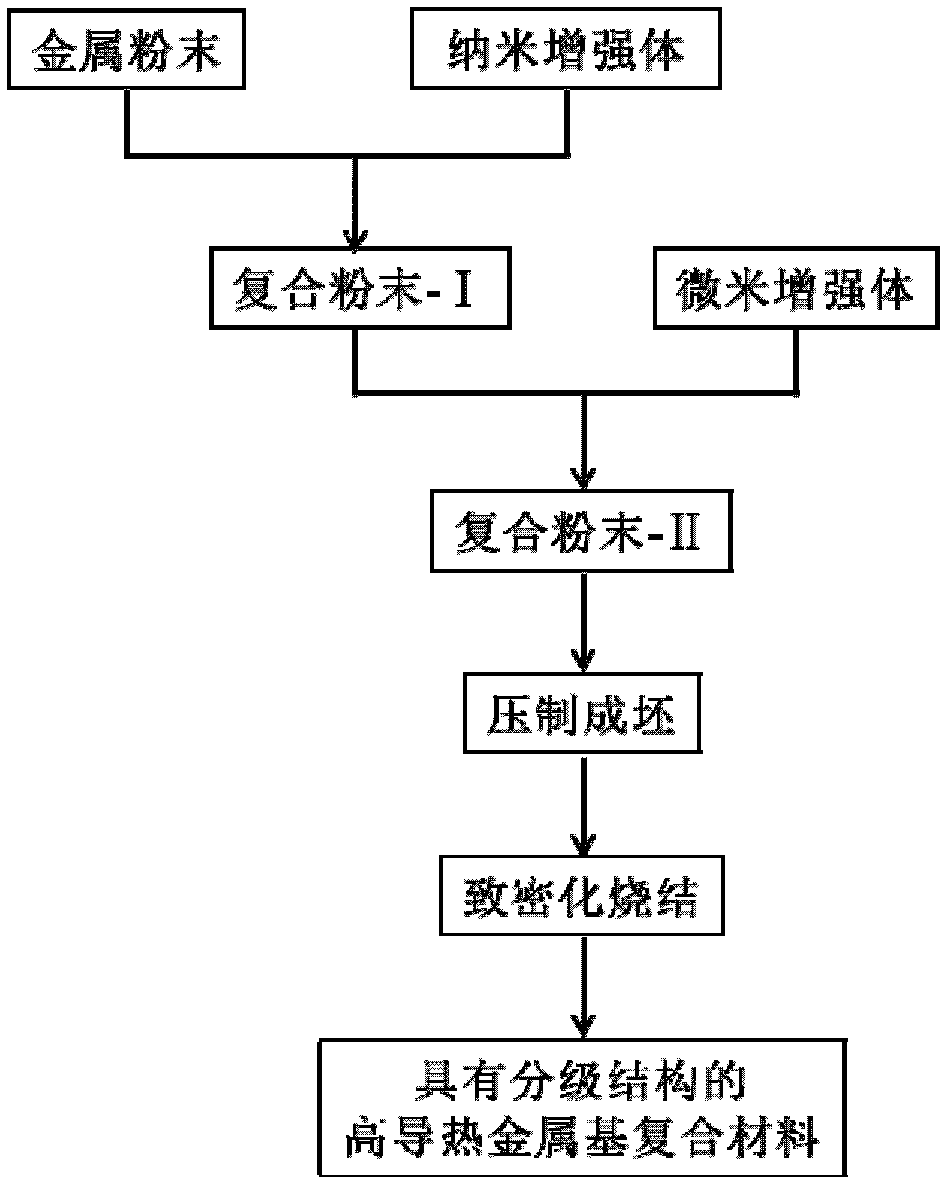

Method used

Image

Examples

Embodiment 1

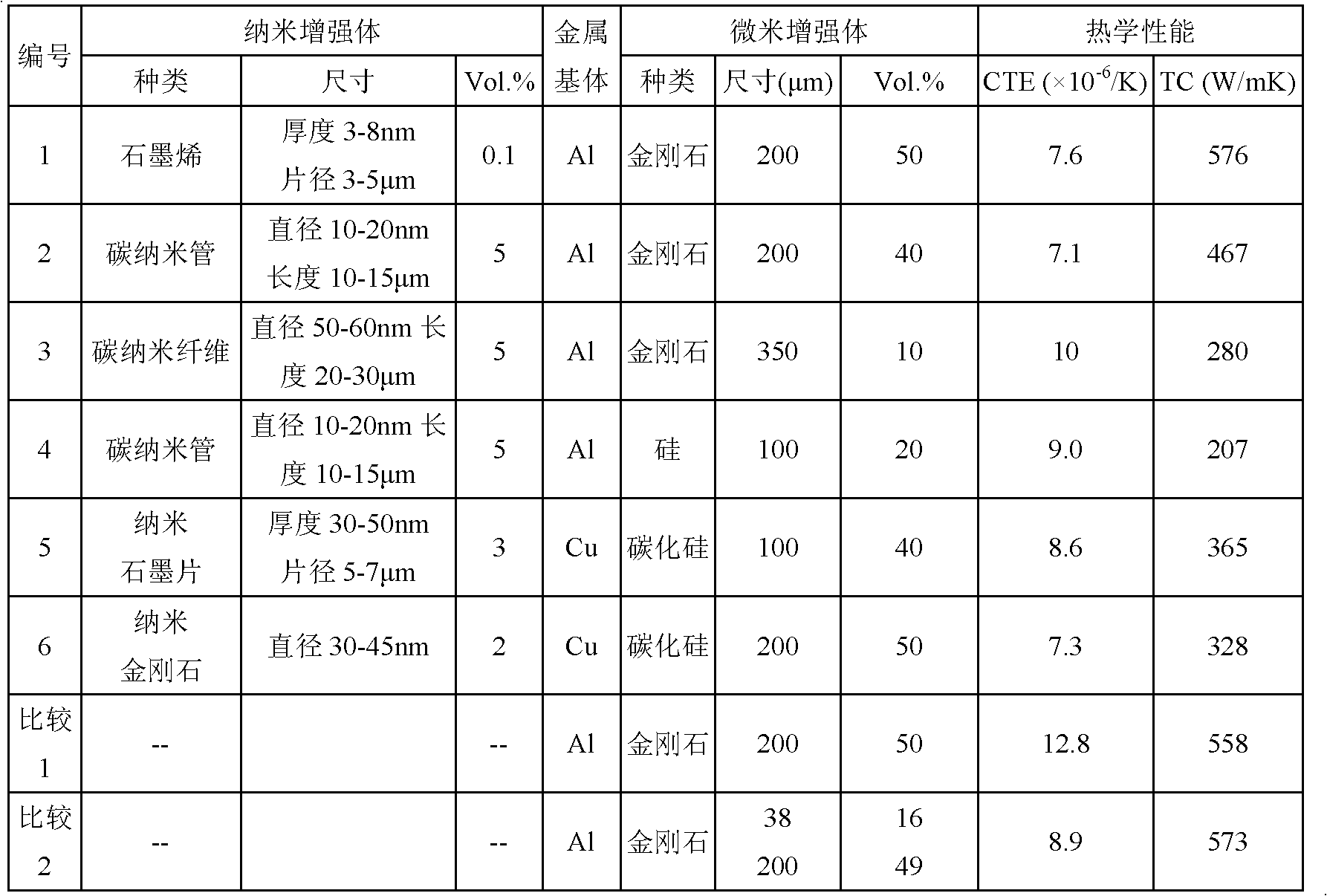

[0024] First, mix 0.1% graphene and metal aluminum powder uniformly to obtain composite powder-I, and then uniformly mix composite powder-I and 50% diamond to obtain composite powder-II; Vacuum hot pressing sintering was carried out at 640° C. for 60 minutes. The thermal expansion coefficient of the obtained material is 7.6×10 -6 / K, which basically meets the requirements of use, and the thermal conductivity is 576W / mK.

Embodiment 2

[0026] First, mix 5% carbon nanotubes and metal aluminum powder uniformly to obtain composite powder-I, and then uniformly mix composite powder-I and 40% diamond to obtain composite powder-II; Plasma sintering was performed at 580° C. for 10 minutes. The coefficient of thermal expansion of the obtained material is 7.1×10 -6 / K, which meets the requirements of use, and the thermal conductivity is 467W / mK.

Embodiment 3

[0028] First, mix 5% carbon nanofibers and metal aluminum powder uniformly to obtain composite powder-I, and then uniformly mix composite powder-I and 10% diamond to obtain composite powder-II; And vacuum hot pressing sintering was carried out at 640° C. for 60 minutes. The coefficient of thermal expansion of the obtained material is 10×10 -6 / K, which basically meets the requirements of use, and the thermal conductivity is 280W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com