Liquid chlorine vaporization system for phosphorus trichloride production

A technology of phosphorus trichloride and liquid chlorine, applied in the direction of gas/liquid distribution and storage, pressure vessels, equipment discharged from pressure vessels, etc., can solve the problems of liquid chlorine vaporization and difficult control, and achieve easy operation and prevention The effect of accumulation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

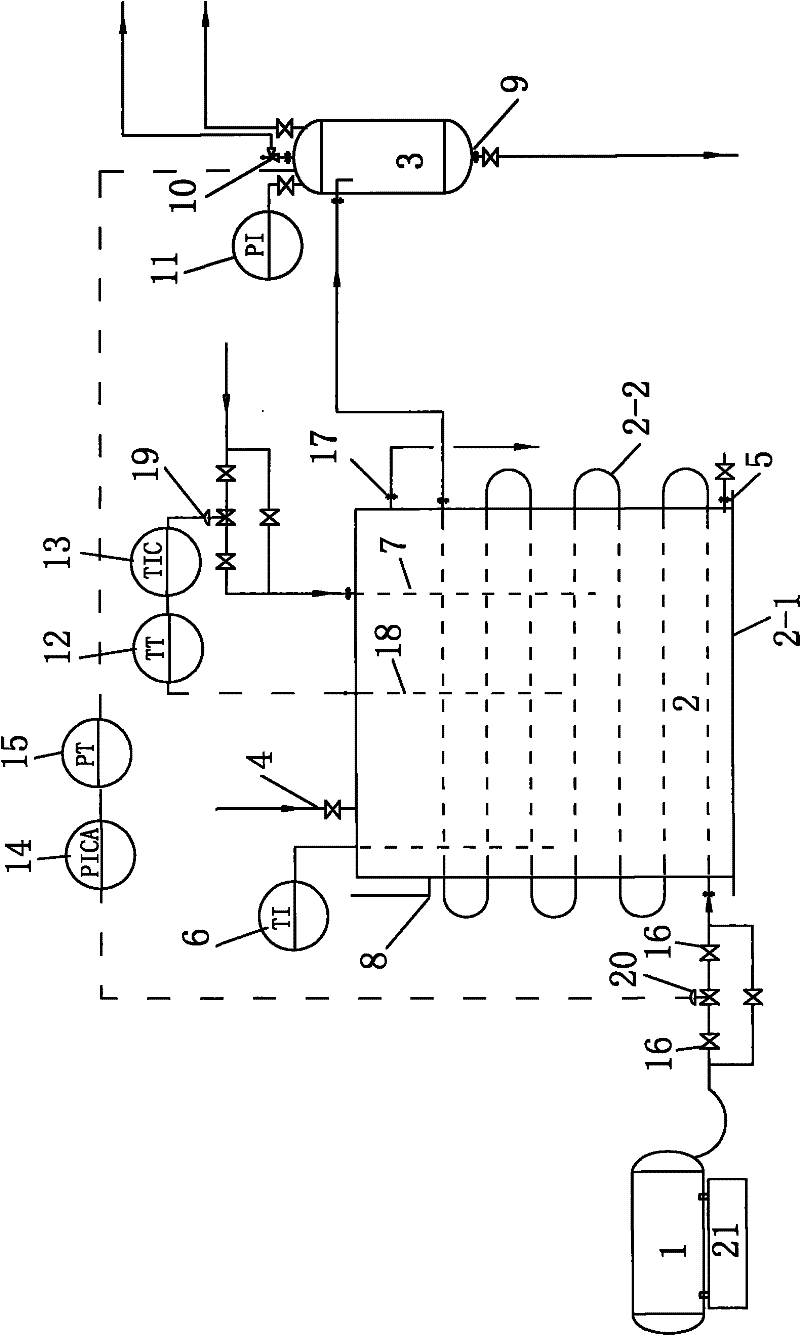

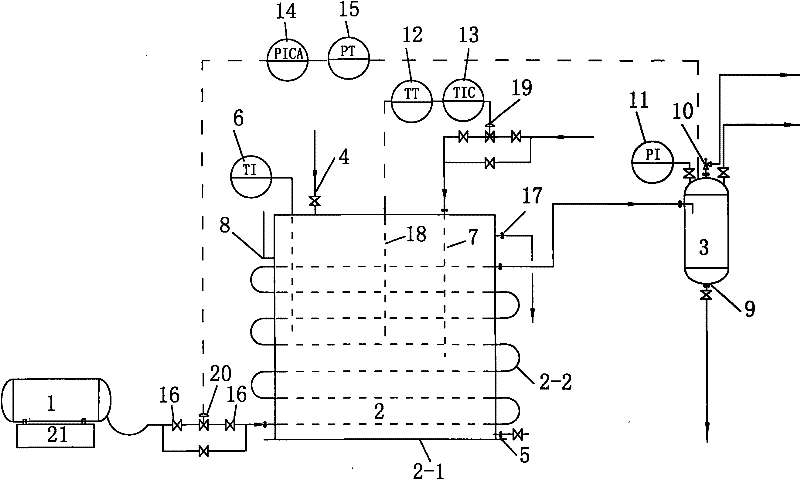

[0021] A liquid chlorine vaporization system for phosphorus trichloride production, the system is mainly composed of a liquid chlorine cylinder 1, a box-type exhaust pipe vaporizer 2, and a chlorine buffer tank 3; the liquid chlorine inlet of the liquid chlorine steel cylinder 1 and the box-type exhaust pipe vaporizer 2 Connection, the chlorine gas outlet of the box-type calandria vaporizer 2 is connected to the chlorine gas inlet of the chlorine gas buffer tank 3, the liquid chlorine cylinder 1 and the box-type calandria vaporizer 2, and the box-type calandria vaporizer 2 and the chlorine gas buffer tank 3 pass through The pipes are connected, and the box-type pipe-arranged vaporizer 2 is mainly composed of a box body 2-1 and a pipe-arrangement 2-2. The pipe-arrangement 2-2 is a horizontal serpentine pipe structure. The horizontal pipe section is located in the box body 2-1, and there is no weld seam in this section of the pipe row, and the horizontal section is made of whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com