Liquid chlorine gasification device and gasification method

A chemical device, chlorine technology, applied in the method of container discharge, fixed-capacity gas storage tank, gas/liquid distribution and storage, etc., can solve the problems of waste of resources, slow chlorine upward flushing speed, poor safety and reliability, etc. The gas has a strong upward impulse, the bubble rises quickly, and the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

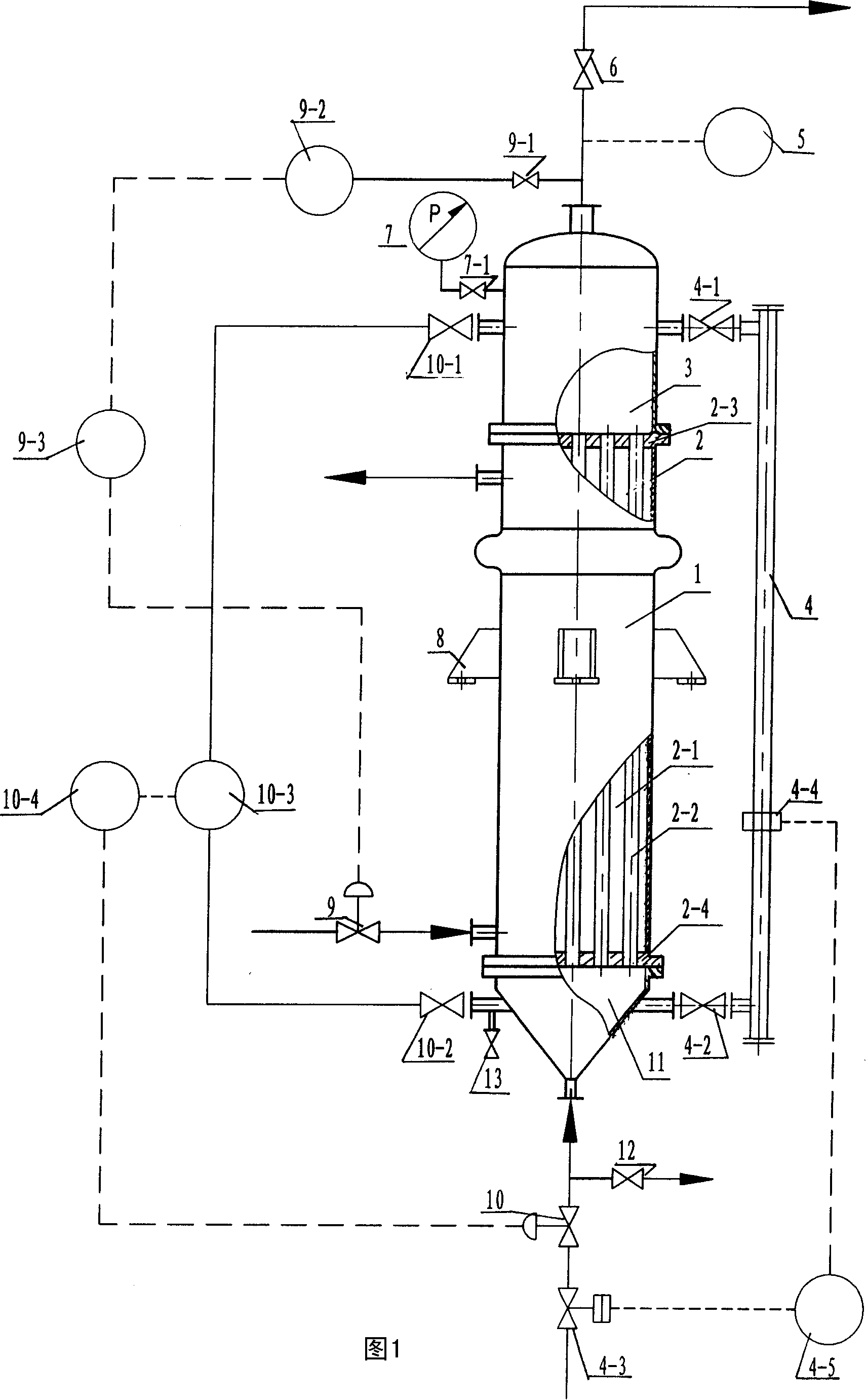

[0014] Take the device with a gasification capacity of 10t / h as an example: the cylindrical tower body 1 has an inner diameter of Φ900mm, a wall thickness of 14mm, a total height of 5800mm, a material of 16MnR, and a design pressure of 2.5MPa; the height of the hot water circulation chamber 2-2 is 3880mm, and the gasification tube 2-2 Diameter Φ32×4, height 4000mm, 239 pieces in total, heat exchange area 96m 2 , the thickness of the upper and lower partitions 2-3 and 2-4 are both 60mm, and 239 connecting holes of Φ32mm and the gasification pipe 2-2 are opened on each of them, and are sealed and welded with the corresponding gasification pipe; gas-liquid separation Cavity 3 is 1200mm high; liquid level gauge 4 is a magnetic flap liquid level gauge, and the inner diameters of pipes and valves 4-1 and 4-2 connected to it are both Φ50mm, rated pressure 4.0MPa, and liquid level signal collectors 4-4 The model is 1A / 220V (passive holding type), explosion-proof grade EExIb II CD5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com