Method for storing and gasifying liquefied chlorine gas and complete equipments thereof

A complete set of equipment, liquid chlorine technology, applied in container discharge methods, gas/liquid distribution and storage, fixed capacity gas storage tanks, etc., can solve the problems of chlorine gas pressure instability, unsafe gasification methods, etc., and achieve pressure stability , reduce the degree of accident hazards, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

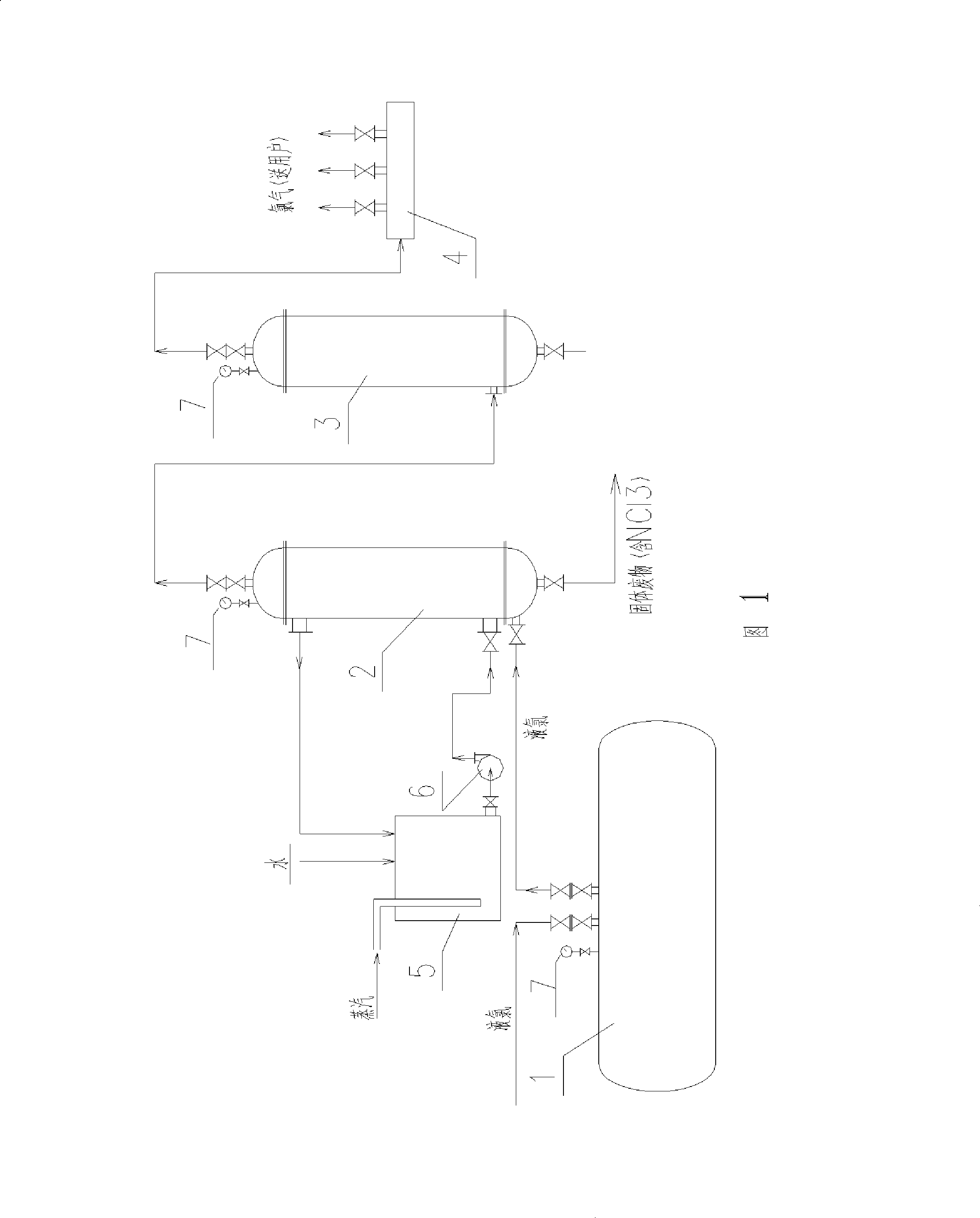

[0009] Embodiments of the present invention: as shown in Figure 1, the liquid chlorine storage tank 1 has a capacity of 40t to 80t, generally 60t. The number of liquid chlorine storage tanks is determined according to the amount of liquid chlorine required for production and the distance to the supply of liquid chlorine. The liquid chlorine storage tank is placed in the basement, one storage tank and one room, the rooms are reinforced concrete partition walls, and the basement roof is covered with insulation materials. The liquid chlorine transport tanker unloads the liquid chlorine into the liquid chlorine storage tank 1 in the basement. Depending on the pressure in the tank, the liquid chlorine is pressed into the evaporator 2, and the produced chlorine gas comes out from the top of the evaporator 2, enters the buffer tank 3 and the distributor 4 in turn, and is sent to the user after being decompressed by the pressure reducing valve. The evaporator 2 is a tubular structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com