Alkaline powder for treating leaked liquid chlorine and chlorine gas and preparation method of alkaline powder

A powder and alkaline technology, which is applied in the field of alkaline powder for disposal of leaked liquid chlorine and its gas and its preparation, can solve the problems of pollution transfer to water resources, complex manufacturing process, air pollution, etc., and achieve good settling performance and simple preparation method , fluffy residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Liquid chlorine and chlorine gas leakage disposal powder

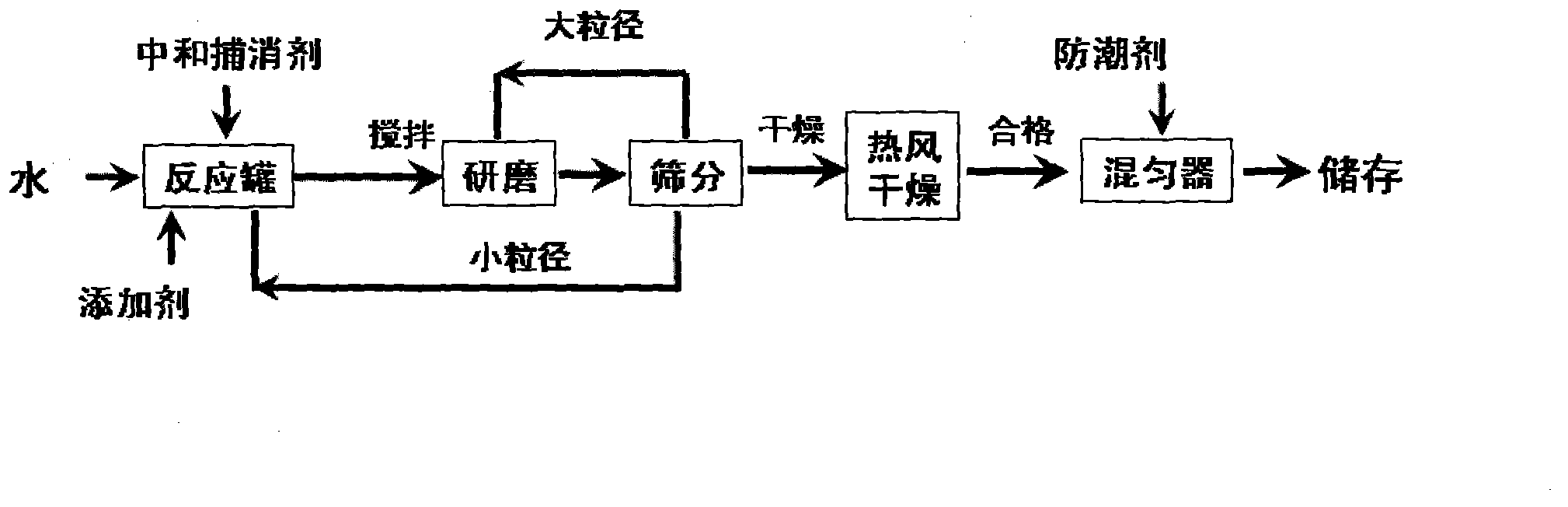

[0039] Prepare 100kg of alkaline powder for disposal of leaked liquid chlorine and chlorine gas, and its composition ratio is: 88.0kg (calcium hydroxide 44kg, sodium hydroxide 44kg), additive 6kg; moistureproof agent 6kg (silica gel). First, pour a certain proportion of additives and disinfectants into the reaction tank with a stirring device in turn, stir for 0.5h to 2h, add 5% to 50% of water, stir for 0.5h to 1h, and grind and sieve. Send the part that meets the particle size requirements to a hot air dryer for drying, and when the moisture content is less than 0.1% to 1%, send it to a mixer, add a moisture-proof agent for mixing, and grind and sieve again to obtain the particle size and specific surface area. , Bulk density requirements of qualified products; re-grind and sieve the particle size larger than 80 mesh, and send the particle size smaller than 150 mesh to the reaction tank for recycl...

Embodiment 2

[0042] Embodiment 2 Liquid chlorine and its chlorine gas leakage disposal powder

[0043] Prepare 100kg of alkaline powder for disposal of leaked liquid chlorine and chlorine gas, and its composition ratio is: 94.0kg of catching agent (75.2kg of carbide slag, 18.8kg of potassium hydroxide), 5kg of additive; 1.0kg of moisture-proof agent (silica gel). First, pour a certain proportion of additives and disinfectants into the reaction tank with a stirring device in turn, stir for 0.5h to 2h, add 5% to 50% of water, stir for 0.5h to 1h, and grind and sieve. Send the part that meets the particle size requirements to a hot air dryer for drying, and when the moisture content is less than 0.1% to 1%, send it to a mixer, add a moisture-proof agent for mixing, and grind and sieve again to obtain the particle size and specific surface area. , Bulk density requirements of qualified products; re-grind and sieve the particle size larger than 80 mesh, and send the particle size smaller than 1...

Embodiment 3

[0046] Embodiment 3 Liquid chlorine and its chlorine gas leakage disposal powder

[0047] Prepare 100kg of alkaline powder for disposal of leaked liquid chlorine and chlorine gas, and its composition ratio is: 96.0kg of catching agent (calcium hydroxide 32kg, sodium hydroxide 16kg, carbide slag 38.4kg, potassium hydroxide 9.6kg), additive 3.5kg; moisture-proof agent 0.5kg (silica gel). First, pour a certain proportion of additives and disinfectants into the reaction tank with a stirring device in turn, stir for 0.5h to 2h, add 5% to 50% of water, stir for 0.5h to 1h, and grind and sieve. Send the part that meets the particle size requirements to a hot air dryer for drying, and when the moisture content is less than 0.1% to 1%, send it to a mixer, add a moisture-proof agent for mixing, and grind and sieve again to obtain the particle size and specific surface area. , Bulk density requirements of qualified products; re-grind and sieve the particle size larger than 80 mesh, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com