Method and device for producing sodium hypochlorite

A production method, sodium hypochlorite technology, applied in the direction of hypochlorous acid, hypochlorite, etc., can solve the problems of high-efficiency automated sodium hypochlorite production process that has not been reported, and achieve the suppression of side reactions, avoiding overchlorination reactions, and realizing precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

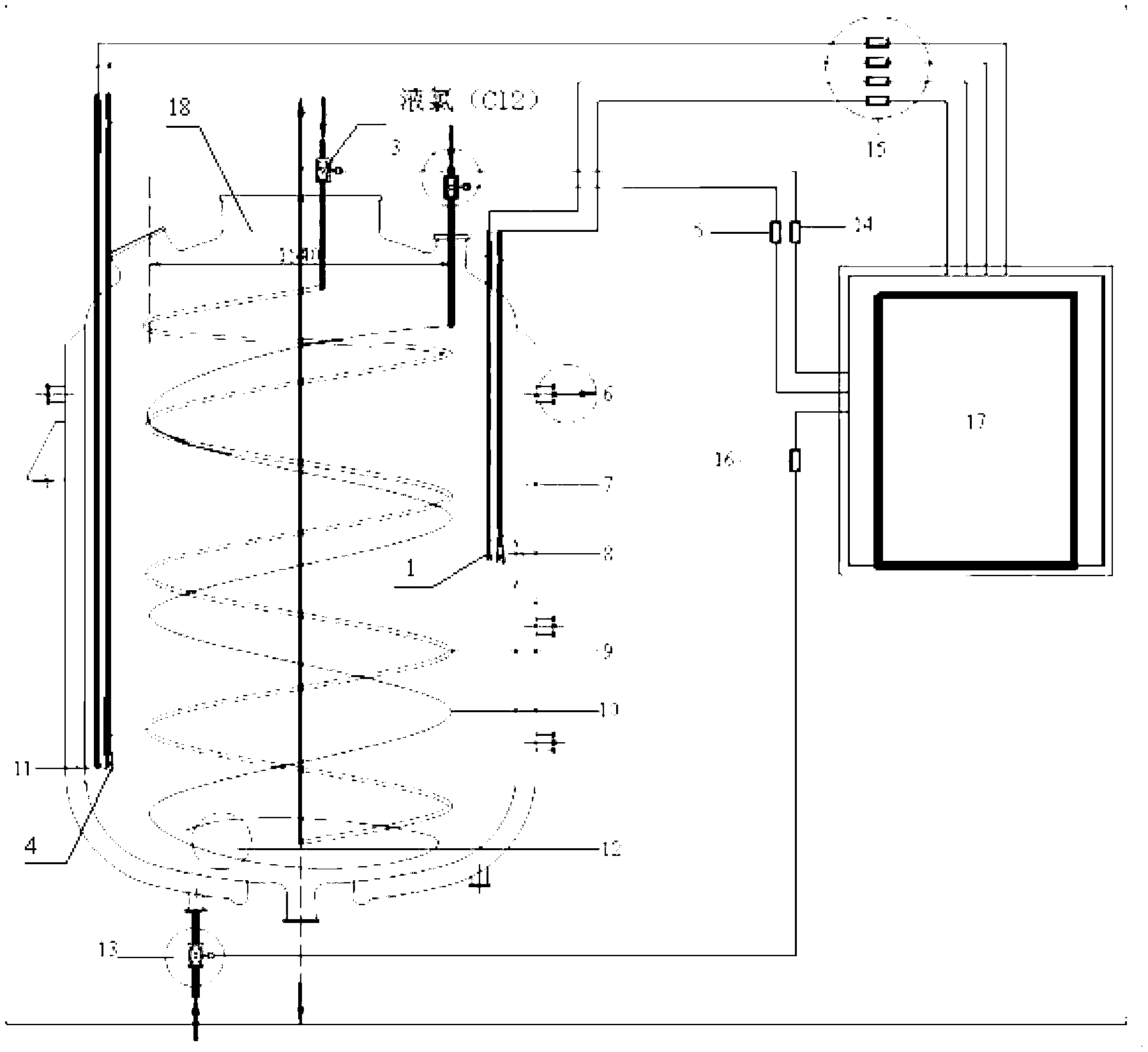

Method used

Image

Examples

Embodiment 1

[0073] In the following embodiments, the first time interval is set to 10 minutes, and the second time interval is set to 3 minutes, wherein the second time interval provides a basis for the control device to accurately determine changes in pH and temperature values.

[0074] The production method of the present invention includes two stages-a start-up section and a production control section.

[0075] (1) Startup section

[0076] Add 8000kg of 15% sodium hydroxide solution into the reactor. Before starting production, monitor the initial temperature of the sodium hydroxide solution through a temperature detection device, and determine whether to turn on the cooling device according to the initial temperature. The relatively larger temperature value T of the two initial temperature values detected by the high-level temperature detection device and the low-level temperature detection device of the present invention max Meet T max When >25°C, turn on the internal cooling dev...

Embodiment 2 Embodiment 10

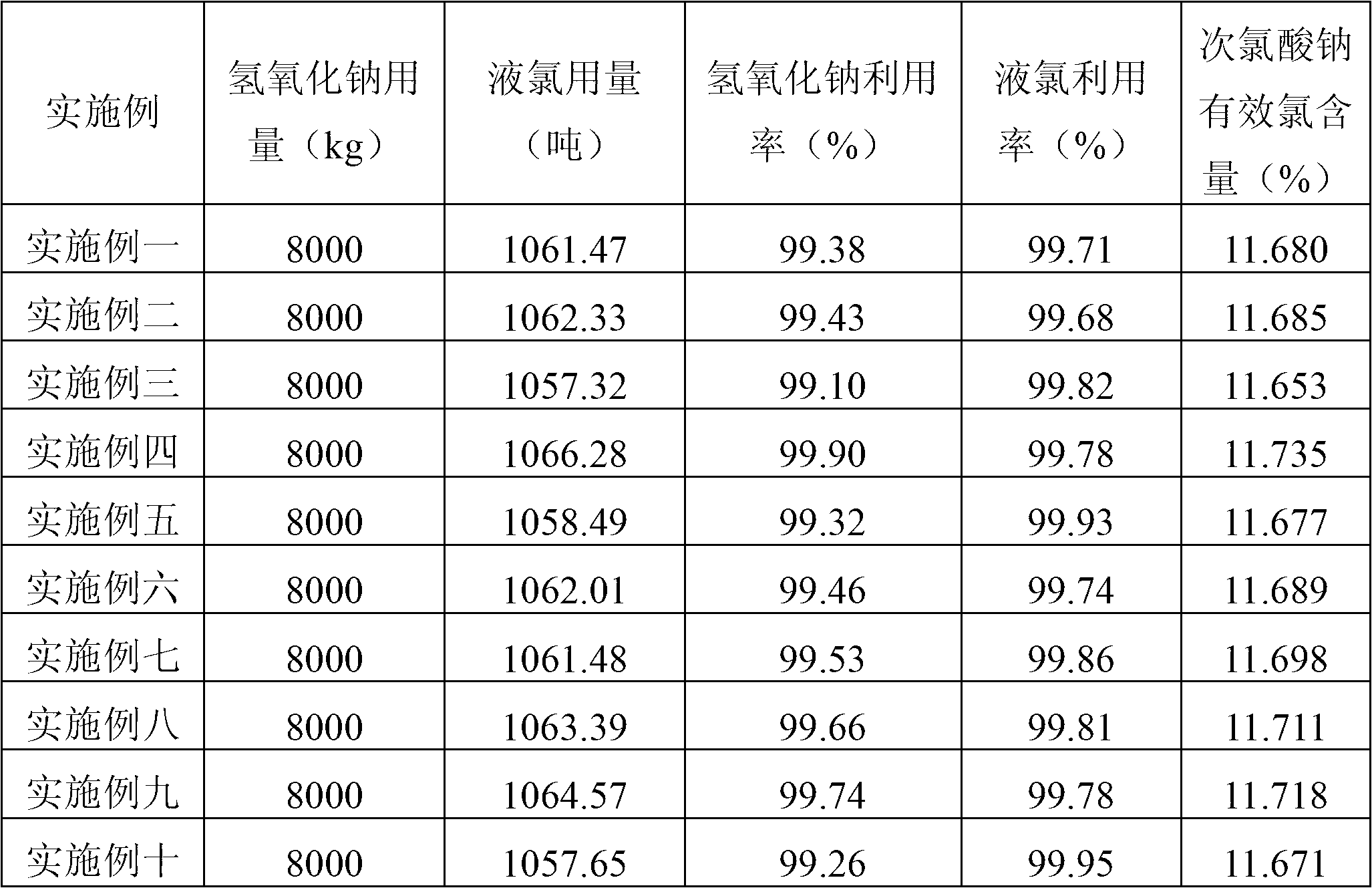

[0085] The following embodiment two ~ embodiment ten all adopt the same method as embodiment one, the sodium hydroxide consumption remains constant, and each step parameter in the implementation process is all consistent. The results of each embodiment are shown in Table 1.

[0086] Table 1

[0087]

[0088] The utilization rate of liquid chlorine in the present invention reaches 99.68%-99.95%, and the utilization rate of sodium hydroxide reaches 99.10-99.90%, which reduces the reject rate of the product, and the available chlorine content of the product sodium hypochlorite is more than or equal to 11.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com