Steel plate for normalizing type low-temperature pressure vessel at-70 DEG C

A technology for pressure vessels and steel plates, applied in the field of metallurgy, can solve problems such as increasing the difficulty of smelting, and achieve the effects of good plasticity and excellent low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

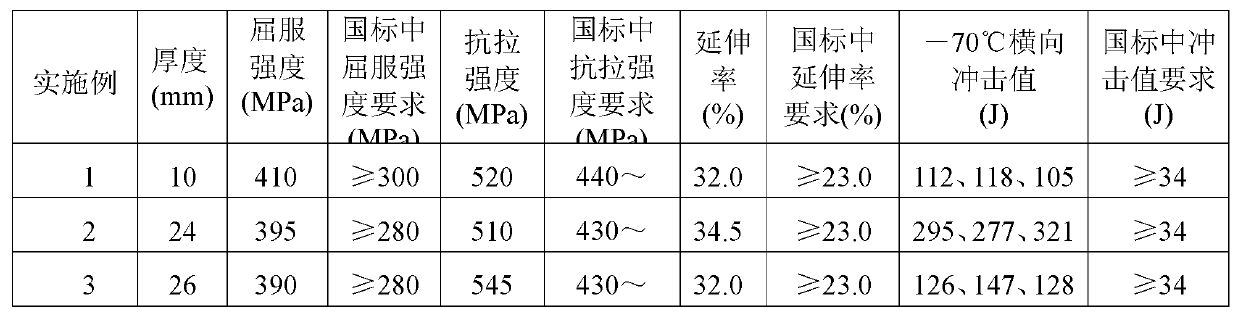

Embodiment 1

[0026] The raw molten iron undergoes deep desulfurization of molten iron, converter top and bottom blowing, ladle argon blowing, refining outside the LF furnace, RH vacuum treatment and continuous casting process to obtain a 250mm thick slab with the chemical composition weight percentage shown in Table 1. The heating temperature of the slab is 1230℃, the total time in the furnace is 322min, and the rolling temperature of the first stage is 1220℃. The relative reduction rate of single pass should be controlled at 25~40% for at least two passes. When the thickness of the rolled piece is 30mm, It is heated to 1040°C on the roller table, and then the second stage rolling is carried out. The final rolling temperature is not controlled, and the thickness of the finished steel plate is 10mm. After the rolling, the steel plate enters the hot straightening machine with air cooling, and the cooling bed cools after the hot straightening. After shot blasting, the steel plate is sent to th...

Embodiment 2

[0028] The embodiment is the same as in Example 1, where the heating temperature is 1235°C, the total furnace time is 319min, the opening temperature of the first stage rolling is 1223°C, the opening temperature of the second stage rolling is 916°C, and the intermediate billet is to be warmed. The thickness is 72mm, the final rolling temperature is 822°C, and the thickness of the finished steel plate is 24mm. After rolling, the steel plate enters the accelerated cooling (ACC) device, the final cooling temperature is 700℃, and the cooling bed is cooled after hot straightening. After shot blasting, the steel plate is sent to the normalizing furnace for treatment. The normalizing temperature is 870℃, the holding time is 10min+t×1.5min / mm, and t is the thickness of the steel plate. Finally, the steel plate can be obtained.

Embodiment 3

[0030] The implementation is the same as in Example 1, where the heating temperature is 1238°C, the total furnace time is 342min, the opening temperature of the first stage rolling is 1228°C, the opening temperature of the second stage rolling is 918°C, and the intermediate billet is to be warmed. The thickness is 73mm, the final rolling temperature is 832°C, and the thickness of the finished steel plate is 26mm. After rolling, the steel plate enters the accelerated cooling (ACC) device, the final cooling temperature is 695℃, and the cooling bed is cooled after hot straightening. After shot blasting, the steel plate is sent to the normalizing furnace for processing, the normalizing temperature is 870℃, the holding time is 10min+t×1.5min / mm, and t is the thickness of the steel plate. Finally, the steel plate can be obtained.

[0031] Table 1 Chemical composition of Examples 1 to 3 of the present invention (wt%)

[0032] Example

C

Si

Mn

P

S

Nb

Ni

Ti

Alt

1

0.10

0.29

1.48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com