Preparation method of chlorinated paraffin

A technology for chlorinated paraffin and paraffin, which is applied in the field of preparation of chlorinated paraffin, and can solve the problems of high toxicity to aquatic organisms, restricting the use of short-chain chlorinated paraffin, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

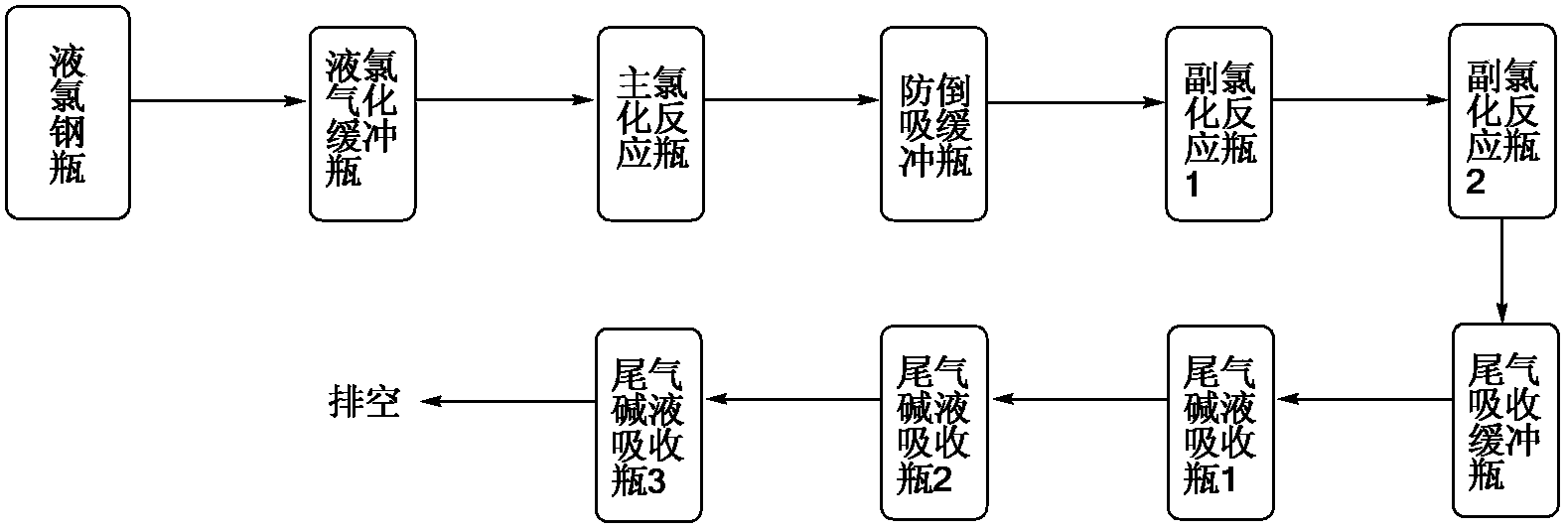

Method used

Image

Examples

Embodiment 1

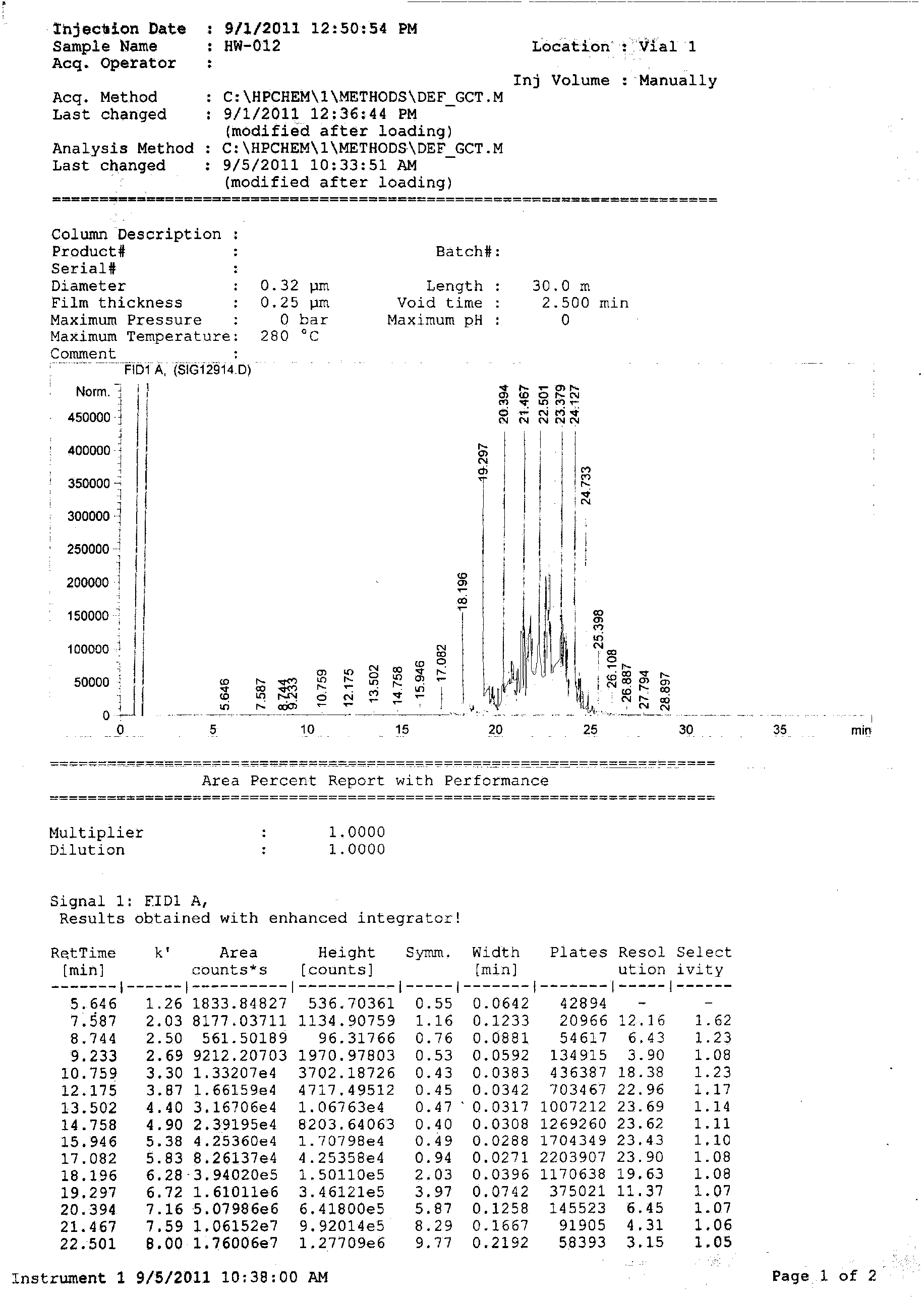

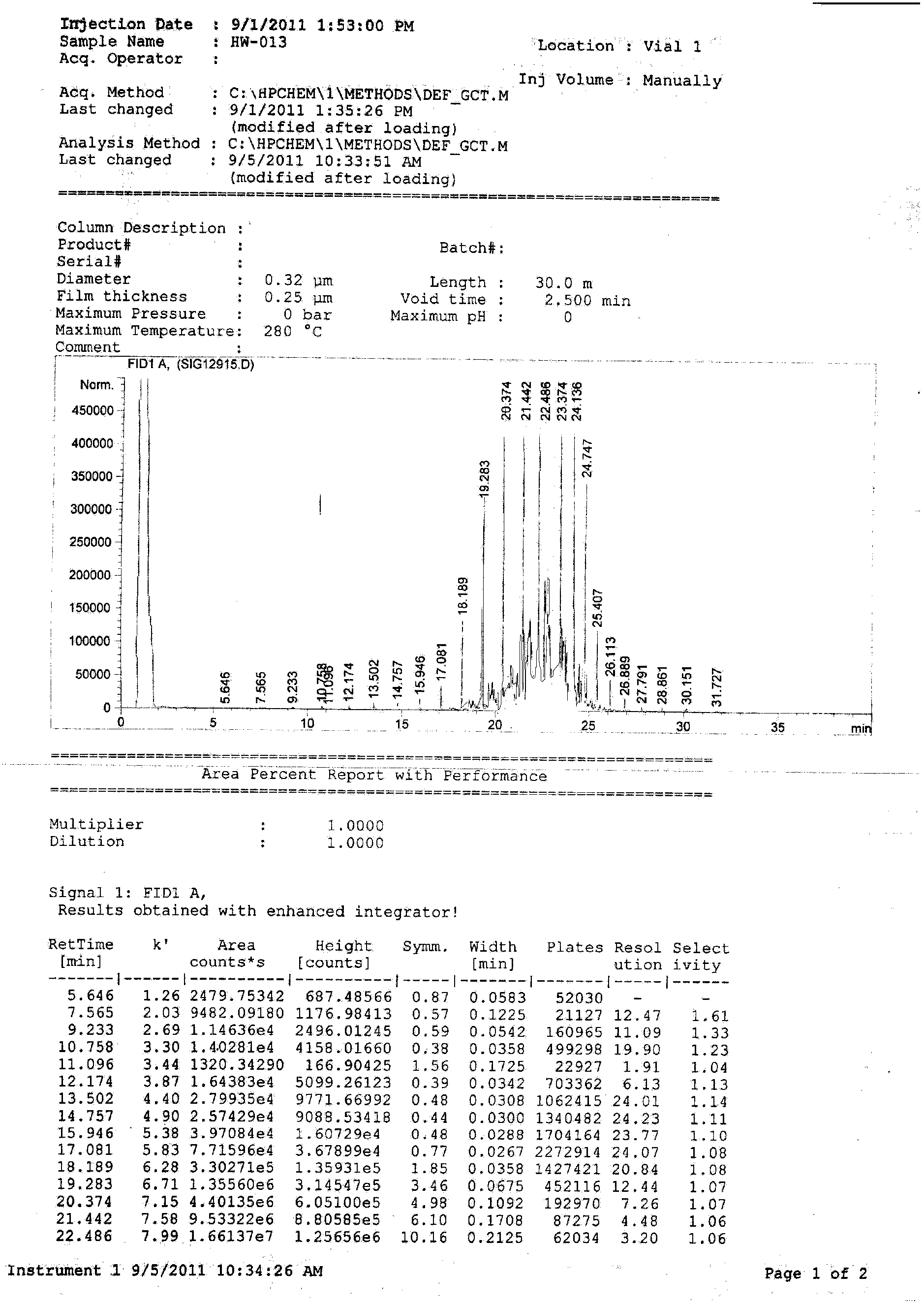

[0017] Example 1: Preparation of chlorinated paraffin-52 by thermal chlorination method

[0018] The solid paraffin was heated to 55°C and melted into liquid and then pumped into three 600ml tubular chlorination reaction flasks. Each chlorination reaction flask added 250 grams of paraffin wax. Connect the reaction device according to the reaction process. Place 3 chlorination reaction flasks in a 75°C water bath, and pass chlorine gas (70-80mL / min) for chlorination reaction. After the reaction is initiated within 15 minutes, the chlorine flow rate is adjusted to 160-200 mL / min for reaction. During the reaction process, take the reaction solution by weighing and measuring the density (density≥1.25g / mL) to judge the degree of chlorination. When the chlorination reaction proceeded for 47 hours, the chlorination degree reached 52%, and the introduction of chlorine gas was stopped. After the temperature was lowered to room temperature, nitrogen gas was introduced to blow out the re...

Embodiment 2

[0019] Example 2: Preparation of chlorinated paraffin-52 by thermal chlorination method

[0020] The reaction steps are the same as in Example 1, and the difference from Example 1 is that the reaction temperature is 60°C. The reaction time was 48 hours, the specific gravity of the reaction liquid sample did not reach 1.25g / mL, and the degree of chlorination did not reach the 52% standard. The chlorination reaction is slower at 60°C.

Embodiment 3

[0021] Example 3: Preparation of chlorinated paraffin-52 by thermal chlorination method

[0022] The reaction steps are the same as in Example 1, and the difference from Example 1 is that the reaction temperature is 85°C. After 47 hours of chlorination, the specific gravity of the reaction solution sample reached 1.25g / mL, and the degree of chlorination reached 52%. There is no significant difference between 85°C and 75°C reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com