Method for preparing rubber packing from modified oil shale semicoke

A technology of oil shale semi-coke and rubber filler, which is applied in the field of preparing rubber filler by using modified oil shale semi-coke, which can solve the problems of increasing carbon dioxide emissions, waste of resources, and low added value of building material products, and achieve the elimination of environmental pollution, The effect of low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

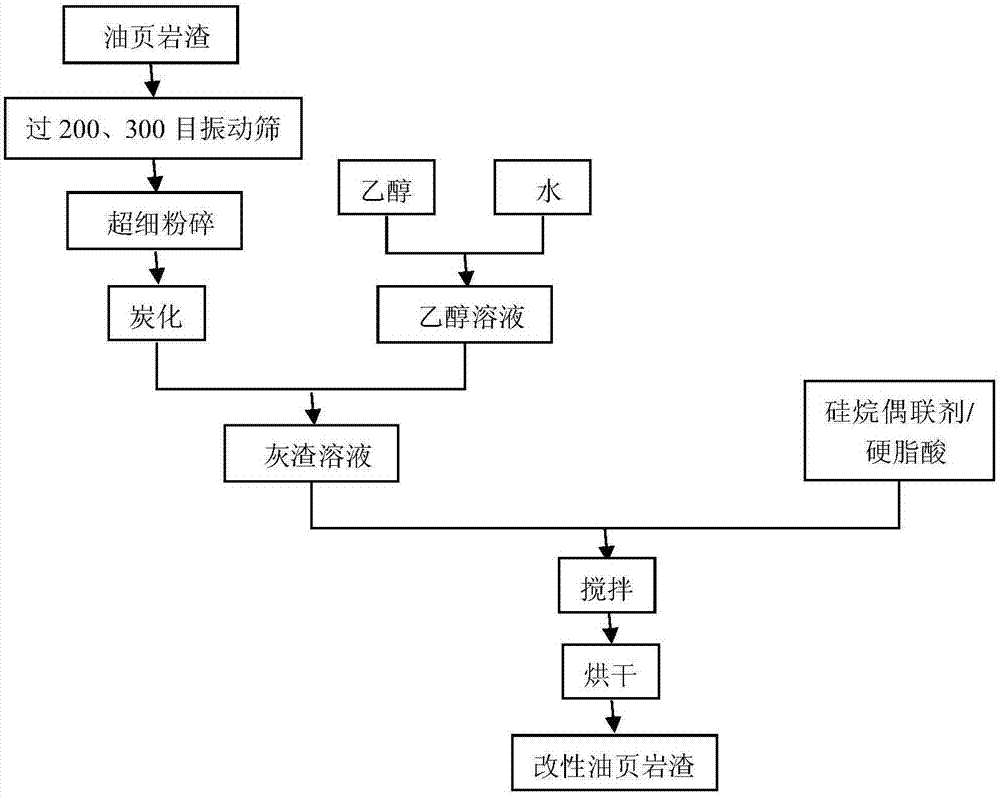

[0053] 1) Carrying out superfine pulverization of the oil shale semi-coke after dry distillation;

[0054] 2) Put it into a high-temperature furnace for roasting at a roasting temperature of 600°C, keep it warm for 2 hours in isolation from the air, and cool down with the furnace to make carbonized oil shale semi-coke;

[0055] 3) Modified oil shale semi-coke powder is obtained by modifying the carbonized oil shale semi-coke superfine powder with silane coupling agent kh-560, and the addition amount of the surface modifier is 2% of the powder mass %, modification temperature room temperature, modification time 30 minutes;

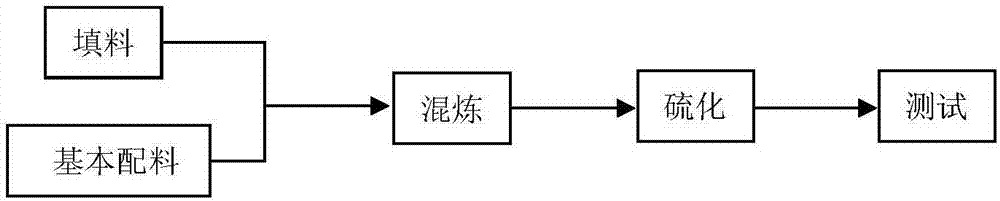

[0056] 4) Mix 5 parts of modified oil shale semi-coke, 100 parts of raw rubber, 60 parts of carbon black, 5 parts of zinc oxide, 1.5 parts of stearic acid, 3.5 parts of antioxidant, 45 parts of liquid paraffin, 1.5 parts of sulfur, accelerator 6 parts of DCP, 1.5 parts of accelerator TMTD, and 1.0 parts of accelerator MBT were placed in a mixer and mixed a...

Embodiment 2

[0060] 1) Superfinely pulverizing the oil shale semi-coke after dry distillation;

[0061] 2) Put it into a high-temperature furnace for roasting at a roasting temperature of 600°C, keep it warm for 2 hours in isolation from the air, and cool down with the furnace to make carbonized oil shale semi-coke;

[0062] 3) Modified oil shale semi-coke powder is obtained by modifying the carbonized oil shale semi-coke superfine powder with silane coupling agent kh-560, and the addition amount of the surface modifier is 2% of the powder mass %, modification temperature room temperature, modification time 30 minutes;

[0063] 4) Mix 10 parts of modified oil shale semi-coke, 100 parts of raw rubber, 55 parts of carbon black, 5 parts of zinc oxide, 1.5 parts of stearic acid, 3.5 parts of antioxidant, 45 parts of liquid paraffin, 1.5 parts of sulfur, accelerator 6 parts of DCP, 1.5 parts of accelerator TMTD, and 1.0 parts of accelerator MBT were placed in a mixer and mixed at 85°C for 15 m...

Embodiment 3

[0067] 1) Superfinely pulverizing the oil shale semi-coke after dry distillation;

[0068] 2) Put it into a high-temperature furnace for roasting at a roasting temperature of 600°C, keep it warm for 2 hours in isolation from the air, and cool down with the furnace to make carbonized oil shale semi-coke;

[0069] 3) Modified oil shale semi-coke powder is obtained by modifying the carbonized oil shale semi-coke superfine powder with silane coupling agent kh-560, and the addition amount of the surface modifier is 2% of the powder mass %, modification temperature room temperature, modification time 30 minutes;

[0070] 4) Mix 15 parts of modified oil shale semi-coke, 100 parts of raw rubber, 50 parts of carbon black, 5 parts of zinc oxide, 1.5 parts of stearic acid, 3.5 parts of antioxidant, 45 parts of liquid paraffin, 1.5 parts of sulfur, accelerator 6 parts of DCP, 1.5 parts of accelerator TMTD, and 1.0 parts of accelerator MBT were placed in a mixer and mixed at 85°C for 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com