Hot melt glue for aluminum-plastic composite panel and preparation method of hot melt glue

A technology of aluminum-plastic composite panels and hot-melt adhesives, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve the problems of low bonding strength of hot-melt adhesives, cracking of aluminum and plastic Poor aging performance and other problems, to achieve the effect of protecting the environment and human health, reducing the use of toxic and harmful solvents, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

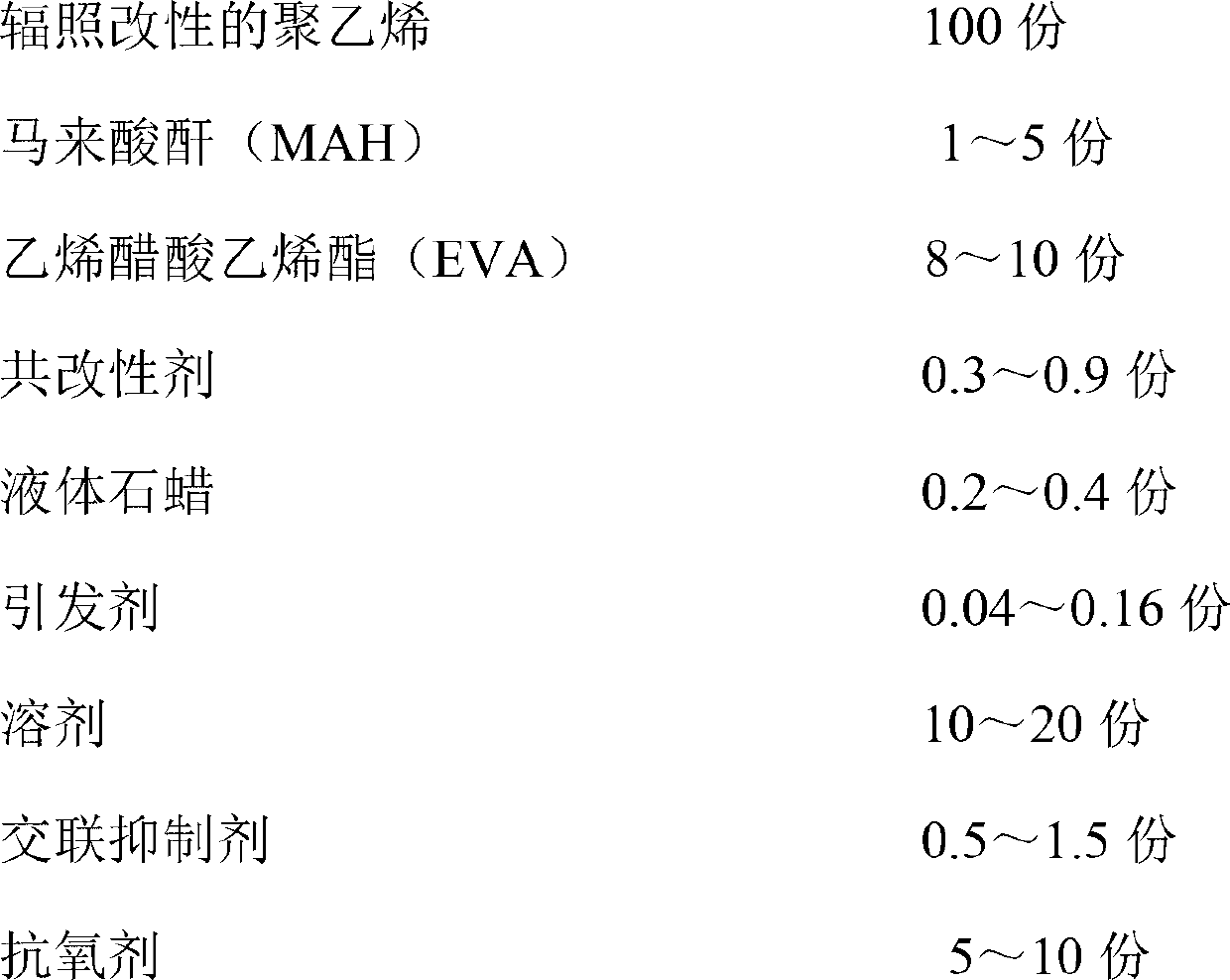

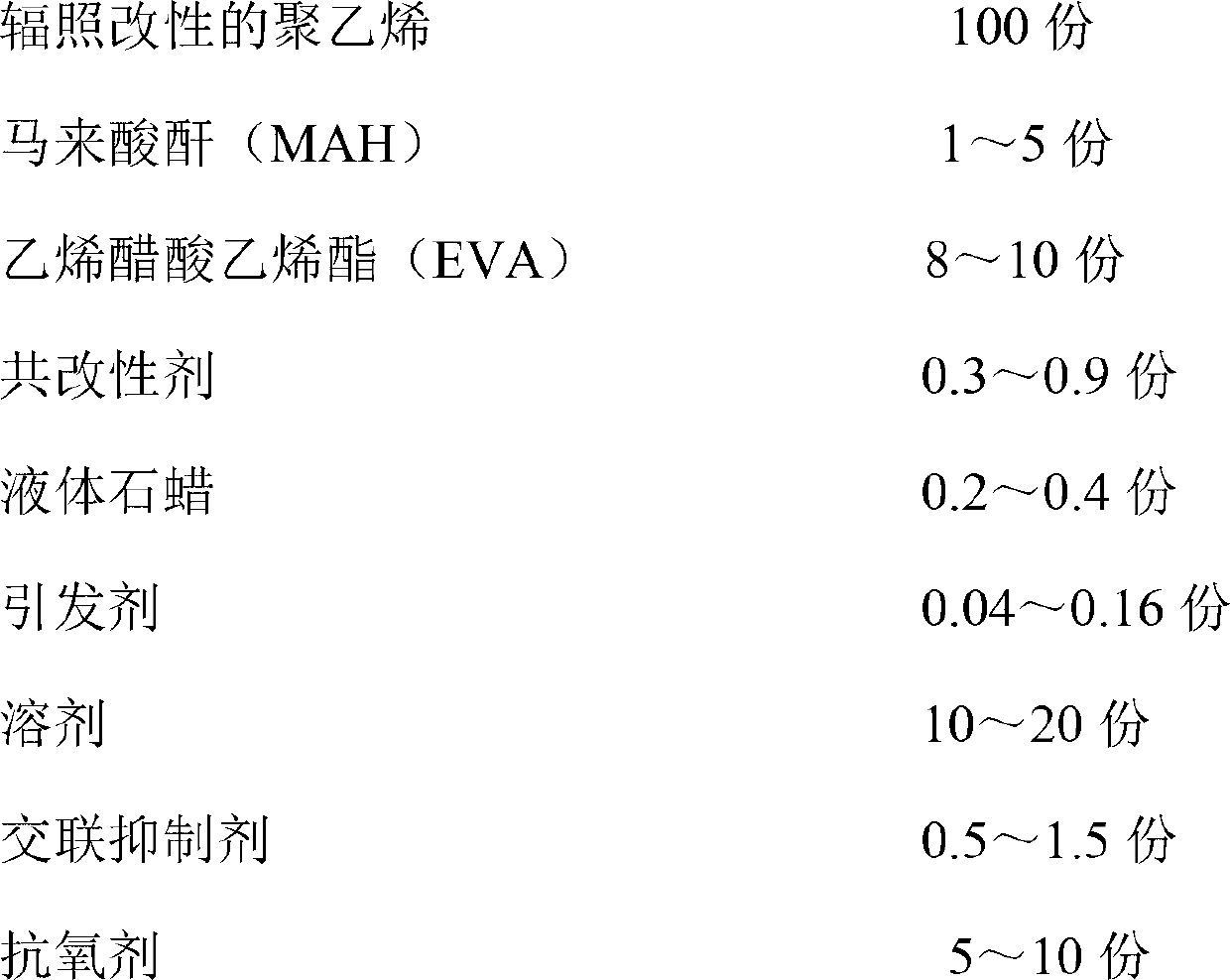

Method used

Image

Examples

Embodiment 1

[0034] (1) After mixing 50 parts of HDPE and 50 parts of LDPE evenly, irradiate for 6 minutes under a radiation source measured at 0.5 kGy for modification;

[0035] (2) Dissolve 0.04 parts of BPO, 0.12 parts of DCP and 5 parts of maleic anhydride in 20 parts of acetone, then mix with 0.4 parts of liquid paraffin, 0.6 parts of AA and 0.3 parts of MA;

[0036] (3) Weigh 10 parts of EVA, 10 parts of antioxidant 1010, 0.5 parts of CPL and 1.0 parts of DMF and mix well;

[0037] (4) Spray the solution in step ② on the surface of the polyethylene obtained in step ①, then continue to add the mixture in ③, fully stir and mix evenly in a high-speed mixer;

[0038] (5) Open the mouth in a fume hood to completely volatilize the solvent, and then use a twin-screw extruder to extrude and granulate to obtain the hot melt adhesive for aluminum-plastic composite panels of the present invention.

[0039] The shear strength is 6.87MPa, the peel strength is 5.53N / mm, the grafting rate is 14.5%...

Embodiment 2

[0041] Adopt the same method as embodiment 1, wherein:

[0042] (1) 70 parts of HDPE and 30 parts of LDPE were irradiated for 2 minutes under a radiation source measured at 1.5kGy for modification;

[0043] (2) Dissolve 0.01 part of BPO, 0.03 part of DCP and 1 part of maleic anhydride in 10 parts of chloroform, mix well with 0.2 part of liquid paraffin, 0.1 part of AA and 0.2 part of BAM;

[0044] (3) 8 parts of EVA, 5 parts of antioxidant 264, 0.25 parts of CPL and 0.25 parts of DMAC are fully mixed evenly;

[0045] (4) and (5) The same method as in Example 1.

[0046] The shear strength is 5.45MPa, the peel strength is 4.83N / mm, the grafting rate is 10.3%, and the softening temperature is 90°C.

Embodiment 3

[0048] Adopt the same method as embodiment 1, wherein:

[0049] (1) 80 parts of HDPE and 20 parts of LDPE are irradiated for 3 minutes under a 1.0kGy irradiation source for modification;

[0050] (2) Dissolve 0.02 parts of BPO, 0.06 parts of DCP and 3 parts of maleic anhydride in 15 parts of benzene, mix well with 0.3 parts of liquid paraffin, 0.3 parts of AA and 0.3 parts of 2-EHAM;

[0051] (3) 9 parts of EVA, 7 parts of antioxidant 1076, 0.40 parts of DMF and 0.40 parts of DMAC are fully mixed;

[0052] (4) and (5) The same method as in Example 1.

[0053] The shear strength is 4.63MPa, the peel strength is 4.43N / mm, the grafting rate is 12.7%, and the softening temperature is 92°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com