Low-dust unshaped refractory

A refractory material and refractory technology, applied in the field of low-dust amorphous refractory materials, can solve problems such as insecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Prepare the sample:

[0020] The first group: 5kg blank quartz sand MS1001BO0.8;

[0021] The second group: add 0.1% mineral oil E38 to 5kg of quartz sand, put it into the mixer and mix evenly;

[0022] The third group: add 1.0% mineral oil E38 to 5kg of quartz sand, put it into a mixer and mix evenly.

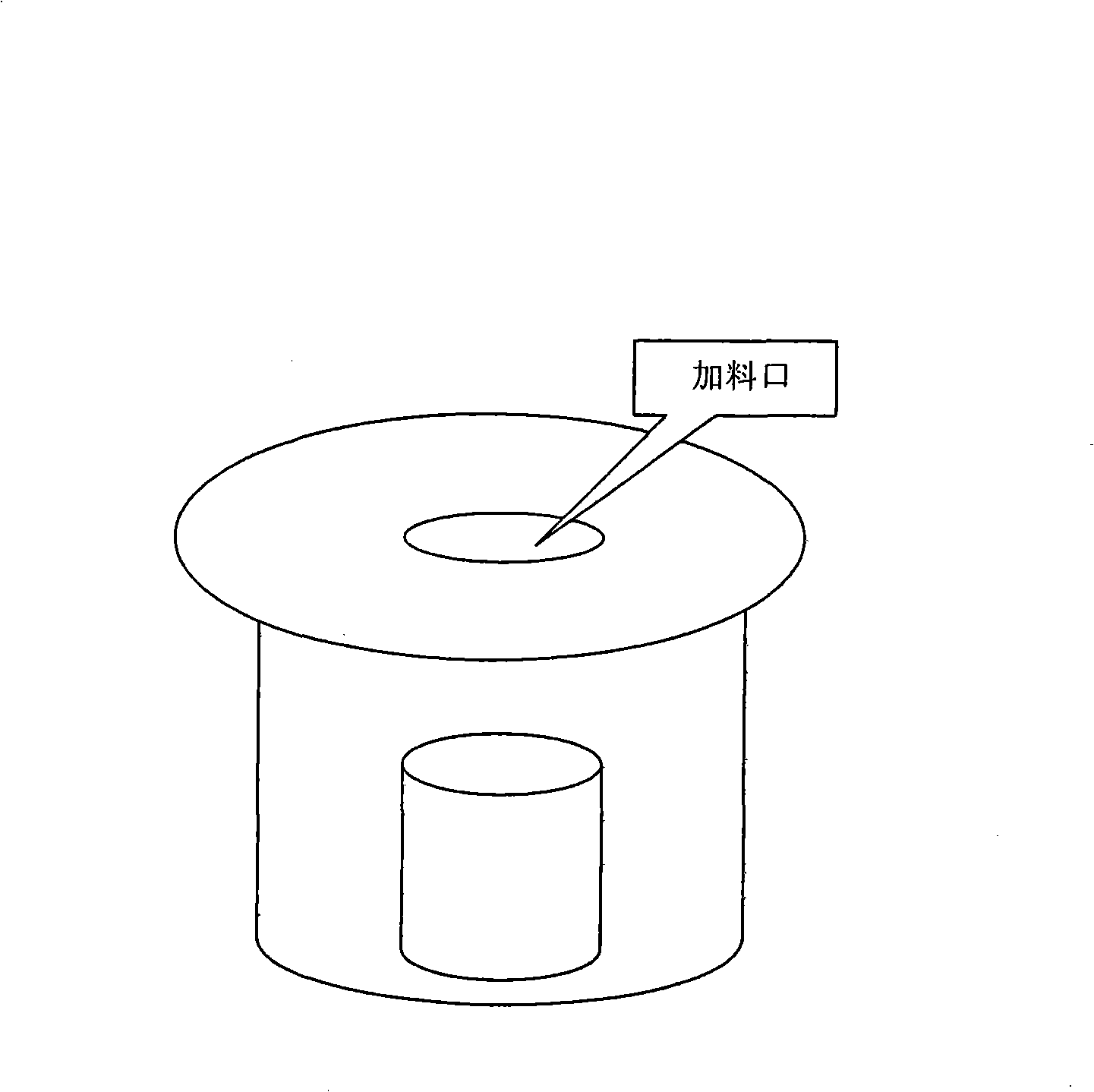

[0023] 2. Place the sample along the figure 1 The feeding port in the device shown is poured into the beaker, and each group of samples is repeated 10 times, and the dust scattered outside the small beaker is collected and weighed.

[0024] 3. Calculate the dust weight percentage that can be reduced according to the following formula:

[0025] Dust can be reduced by weight % = (weight of dust scattered by blank sample - weight of dust of sample containing mineral oil) / weight of dust scattered by blank sample

[0026] The concentration is directly proportional to the weight, and the weight calculation reflects the concentration.

[0027] Table 1

[0028] ...

Embodiment 2

[0031] The preparation and measurement steps of Example 1 were repeated except that vegetable oil was used instead of mineral oil. Similar to Example 1, the dust concentration can be reduced by at least 70%.

Embodiment 3

[0033] Use the sample prepared in embodiment 1 to carry out following test:

[0034] Table 2

[0035] Product name Dust concentration (mg / m 3 )

[0036] Low dust quartz sand MINRO-SIL LD 0.30

[0037] Ordinary quartz sand MINRO-SIL RAM 1001 3.18

[0038] table 3

[0039] Product name Dust concentration (mg / m 3 )

[0040] Low dust quartz sand MINRO-SIL LD 0.20

[0041] Ordinary quartz sand MINRO-SIL RAM 1001 1.58

[0042] The above results were obtained during the actual installation of low-dust quartz sand and ordinary quartz sand using standard air sample testing techniques. Sampling is carried out in two modes: manual collection and fixed monitor on the electric furnace deck. Through the above results, it can be proved that the respirable dust concentration reduced by low-dust quartz sand is 91% and 87%, respectively, both of which are above 80%.

[0043] Although the dust test results clearly prove that the dust concentration of low-dust quartz sand is very low, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com