Polyelectrolyte nanometer flame-retardant coating by adoption of layer-by-layer assembly and preparation method thereof

A layer-by-layer self-assembly, polyelectrolyte technology, applied in coatings, polyamide coatings, chitin polysaccharide coatings, etc., can solve the problem that the flame retardant efficiency needs to be further improved, and achieve a simple and easy preparation method, a wide range of sources, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to one aspect of the present invention, a kind of preparation method of layer-by-layer self-assembled polyelectrolyte nano flame retardant coating is provided, comprising the following steps:

[0027] Step 1 is a pretreatment step: soak the base material in an acidic solution, then wash it with water and dry it.

[0028] According to the present invention, the base material is fabric, wood, foam or plastic, preferably fabric such as polyester, foam material such as polyurethane. For immersion, the base material can be processed into a suitable shape such as a cuboid, and a suitable scale, such as centimeters, decimeters or even meters.

[0029] The matrix material is soaked in an acidic solution for pretreatment. This pretreatment helps to improve the adsorption of the surface of the matrix material, thereby facilitating the deposition of some compounds on the surface of the matrix material.

[0030] According to the present invention, soak in the acidic solu...

Embodiment 1

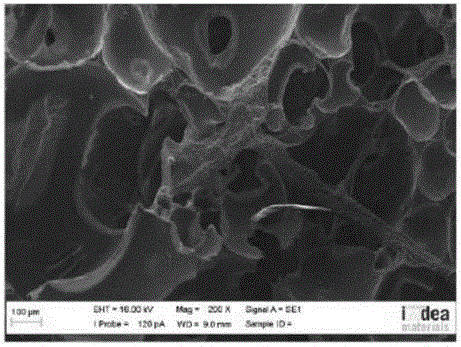

[0053] Cut the polyurethane foam to 10cm×10cm×3cm;

[0054] Weigh 0.5g of polyacrylic acid and add it to 99.5g of deionized water, stir until completely dissolved, and set aside;

[0055] Weigh 5g of chitosan and add it to 995g of deionized water, stir until completely dissolved, and set aside;

[0056] Weigh 20g of sodium alginate and add it to 980g of deionized water, stir until completely dissolved, set aside;

[0057] 1) Pretreatment: Take the cut polyurethane foam and immerse it in the above polyacrylic acid solution, soak it for 300 seconds, wash it with deionized water, and then dry it;

[0058] 2) Self-assembly: Put the above-mentioned pretreated polyurethane foam into the above-mentioned chitosan solution and soak for 60 seconds, then wash it with deionized water and dry it, then put it into the above-mentioned sodium alginate solution and soak it for 60 seconds, and use it Rinse with deionized water, then dry;

[0059] Repeat the above self-assembly process 5 time...

Embodiment 2

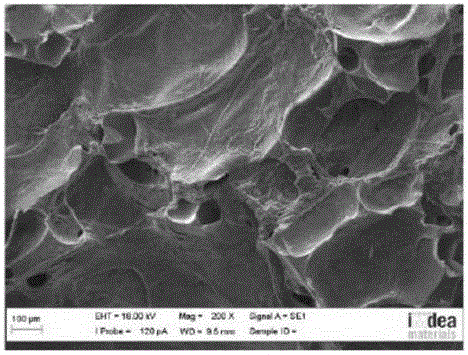

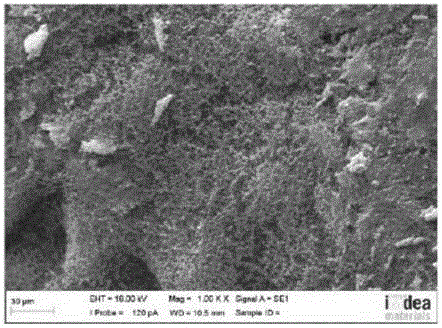

[0061] Cut the polyurethane foam to 10cm×10cm×3cm;

[0062] Weigh 0.5g of polyacrylic acid and add it to 99.5g of deionized water, stir until completely dissolved, and set aside;

[0063] Weigh 5g of chitosan and add it to 995g of deionized water, stir until completely dissolved, and set aside;

[0064] Weigh 20g of sodium alginate and add it to 980g of deionized water, stir until completely dissolved, set aside;

[0065] 1) Pretreatment: Take the cut polyurethane foam and immerse it in the above polyacrylic acid solution, soak it for 300 seconds, wash it with deionized water, and then dry it;

[0066] 2) Self-assembly: Put the above-mentioned pretreated polyurethane foam into the above-mentioned chitosan solution and soak for 60 seconds, then wash it with deionized water and dry it, then put it into the above-mentioned sodium alginate solution and soak it for 60 seconds, and use it Rinse with deionized water, then dry;

[0067] Repeat the above self-assembly process 10 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com