Preparation method of high imino methylated melamine resin

A technology of high imino methyl etherification of melamine and melamine, which is applied in the field of preparation of melamine resin, can solve problems such as industrial scale bottlenecks, achieve high promotion and application value, rapid curing reaction, and small baking weight loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

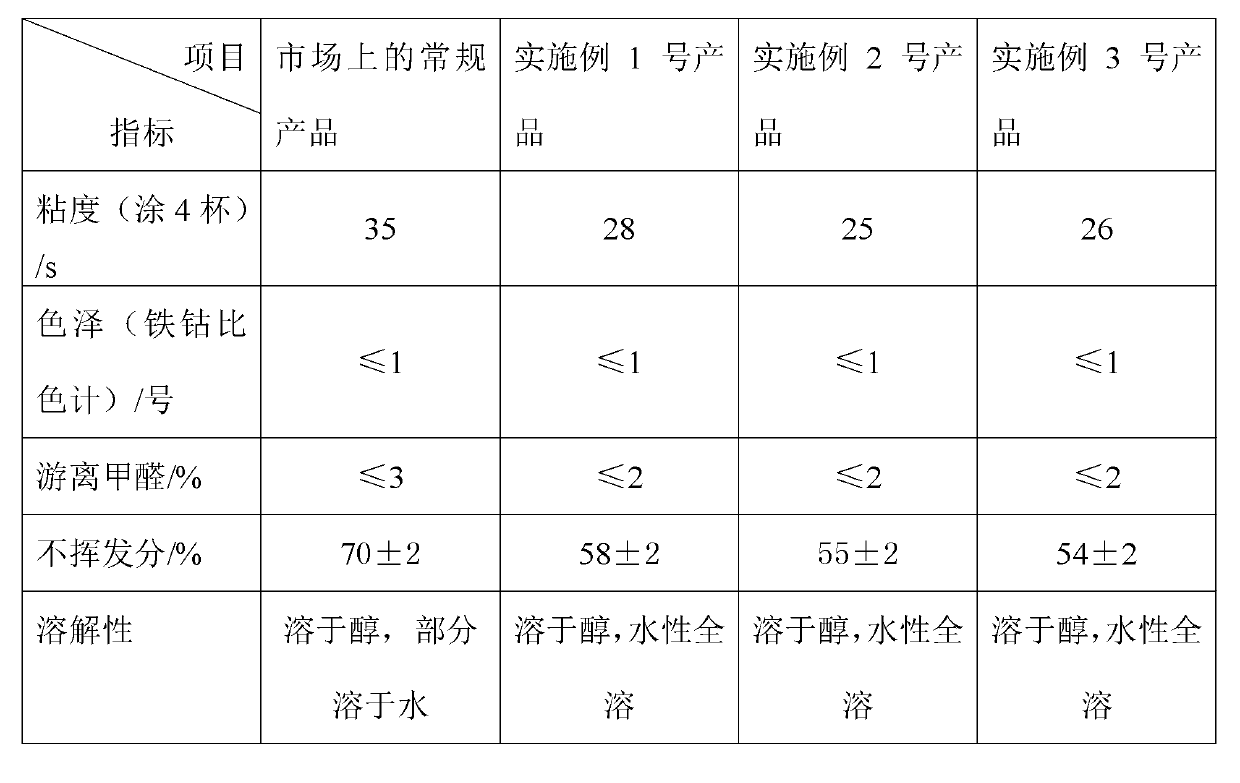

Examples

Embodiment 1

[0013] Embodiment 1: the preparation of imino methyl etherified melamine resin

[0014] (1) Mix melamine, solid formaldehyde, formaldehyde aqueous solution, and methanol in proportions by weight of melamine:solid formaldehyde:formaldehyde aqueous solution:methanol at 15:10:35:20, adjust the pH to 8.0 with NaOH solution, heat up to 60°C and keep it warm React for 90 minutes;

[0015] (2) After reacting for 90 minutes, add methanol. The ratio of the amount of methanol added to the weight of the mixture before adding is 1:1. Use hydrochloric acid to adjust the pH to 2.5. Keep the etherification reaction at 35°C for 60 minutes. Add NaOH solution to adjust the pH to 9.0, carry out negative pressure dealcoholization and dehydration.

[0016] (3) Add methanol to the mixture after negative pressure dealcoholization and dehydration, the ratio of the amount of methanol added to the weight of methanol added in step (2) is 1:2, add hydrochloric acid to adjust the pH to 2.5, and keep the ...

Embodiment 2

[0018] Embodiment 2: the preparation of imino methyl etherified melamine resin

[0019] (1) Mix melamine, solid formaldehyde, formaldehyde aqueous solution, and methanol in proportions by weight of melamine:solid formaldehyde:formaldehyde aqueous solution:methanol at 20:6:40:20, adjust the pH to 9.0 with NaOH solution, heat up to 80°C and keep warm React for 90 minutes;

[0020] (2) After reacting for 90 minutes, add methanol, the ratio of the amount of methanol added to the weight of the mixture before adding is 1: 2, adjust the pH to 4.5 with hydrochloric acid, keep warm at 50°C for etherification reaction for 60 minutes, add NaOH solution to adjust the pH to 9.0, carry out negative pressure dealcoholization and dehydration.

[0021] (3) Add methanol to the mixture after negative pressure dealcoholization and dehydration, the ratio of the amount of methanol added to the weight of methanol added in step (2) is 2: 1, add hydrochloric acid to adjust the pH to 4.5, and keep the...

Embodiment 3

[0023] Embodiment 3: the preparation of imino methyl etherified melamine resin

[0024] (1) Mix melamine, solid formaldehyde, formaldehyde aqueous solution, and methanol in proportions by weight of melamine:solid formaldehyde:formaldehyde aqueous solution:methanol at 10:10:45:20, adjust the pH to 8.5 with NaOH solution, heat up to 70°C and keep warm React for 90 minutes;

[0025] (2) After reacting for 90 minutes, add methanol, the ratio of the amount of methanol added to the weight of the mixture before adding is 3:1, adjust the pH to 3 with hydrochloric acid, keep warm at 40°C for 60 minutes, add NaOH solution to adjust the pH to 9.0, carry out negative pressure dealcoholization and dehydration.

[0026] (3) Add methanol to the mixture after negative pressure dealcoholization and dehydration, the ratio of the amount of methanol added to the weight of methanol added in step (2) is 1.5:1, add hydrochloric acid to adjust the pH to 3, and keep the ether at 40°C React for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com