Preparation of silane modified EVA hot-melt adhesive composition

A composition, hot-melt technology, applied in the direction of adhesive types, monocarboxylate copolymer adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

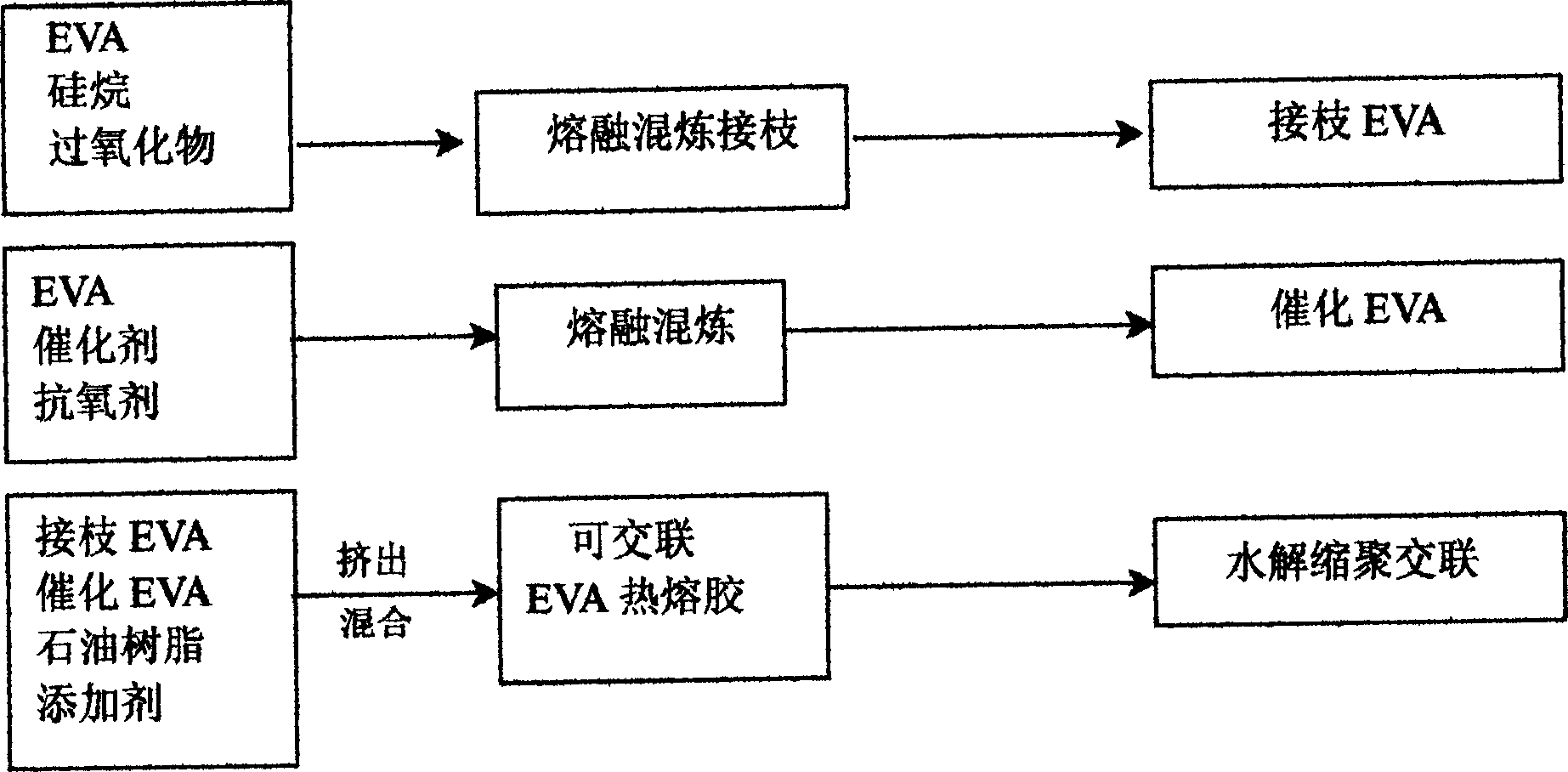

Method used

Image

Examples

Embodiment Construction

[0023] In certain embodiments of the invention, the bonded substrates are relatively thin and flat, in which case the resulting composite article is referred to as a laminate or laminated structure.

[0024] Implementation with 1

[0025] Install protective gas, thermometer, stirrer, and heating system on the reaction vessel. First add EVA resin, appropriate amount of initiator, silane graft, and antioxidant into the container, and raise the temperature to 110°C under gas protection. React at 110°C for 30 minutes, then lower the temperature to 90°C, add tackifying resin, paraffin and catalyst and react in nitrogen atmosphere for one hour, keeping the temperature at 100-105°C. Finally, the reaction product is poured into a container, granulated after cooling, and sealed for storage.

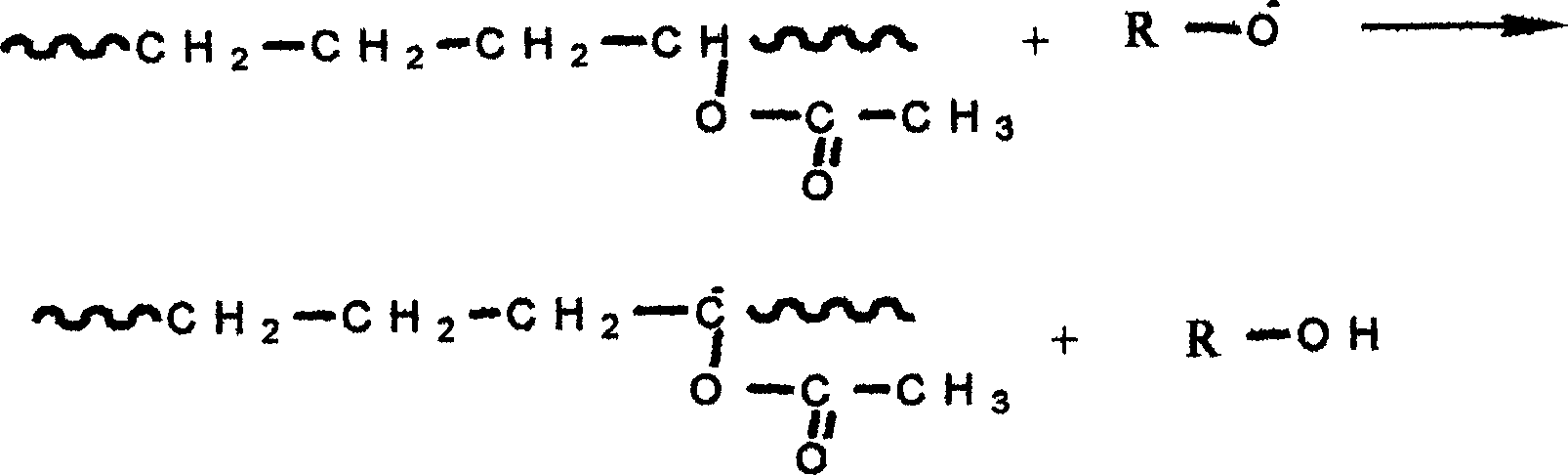

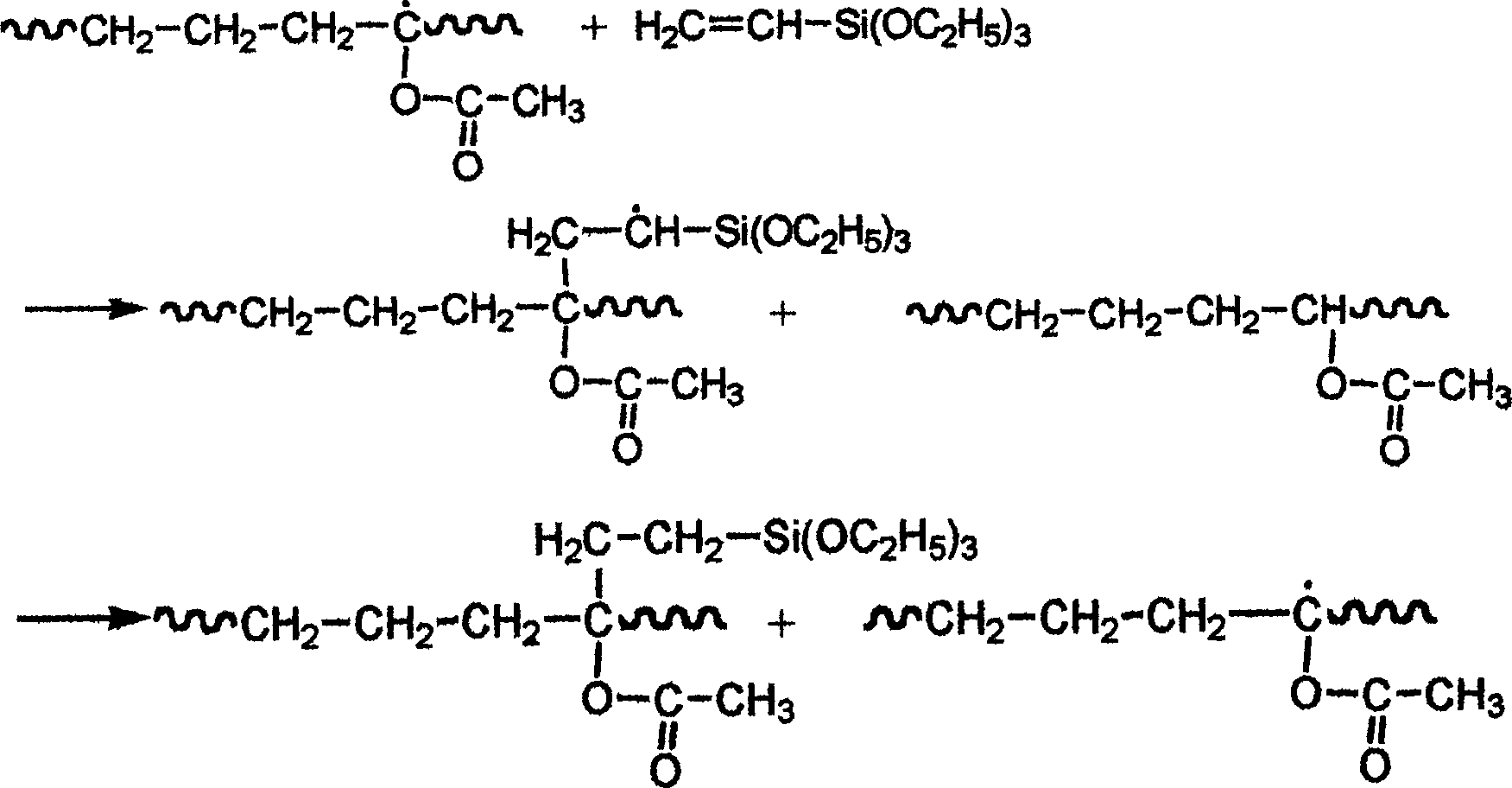

[0026] Reactive extrusion method or melt grafting method to prepare silane-modified EVA resin process chemical reaction formula;

[0027] ① Decompose peroxide into primary free radicals:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com