Solvent-free epoxy anti-permeability barrier coating and method for preparing same

A closed coating, anti-penetration technology, applied in epoxy resin coatings, coatings, buildings, etc., can solve the problems of waterproof coatings elasticity, toughness and adhesion to be improved, improve mechanical properties, promote curing reaction, The effect of high adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

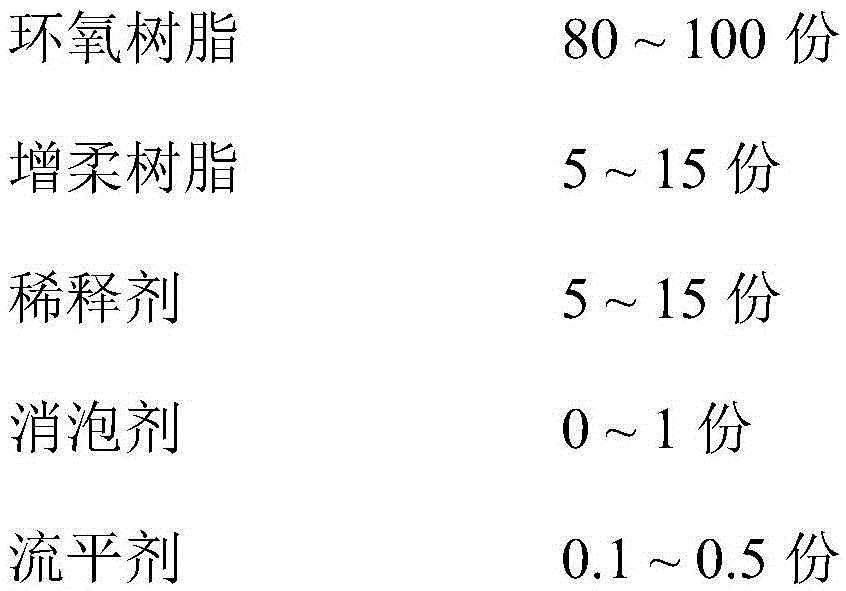

Method used

Image

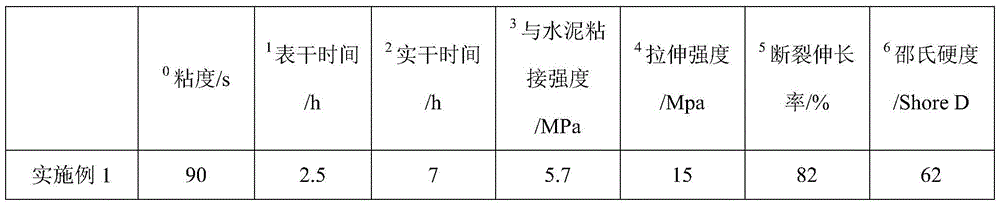

Examples

Embodiment 1

[0037] 1) Preparation of modified amine curing agent:

[0038] Put polyetheramine, N-aminoethylpiperazine, triethylenetetramine, and nonylphenol into the flask, pass nitrogen protection, keep at 40℃ and stir for 2h, then raise the temperature to 60℃, add nitrile rubber, Heat preservation and stirring for 3 hours, then cool to room temperature for later use; the ratio of polyetheramine, N-aminoethylpiperazine, triethylenetetramine, nonylphenol and nitrile rubber in parts by weight is 8.5:5.6:0.5:9: 4;

[0039] 2) Preparation of component A:

[0040] (1) The bisphenol A epoxy resin, double F epoxy resin and long-chain polyethylene glycol glycidyl ether liquid resin are preheated at 60°C for 6-8 hours;

[0041] (2) Under normal temperature conditions, 60 parts of bisphenol A epoxy resin, 30 parts of double F epoxy resin, 10 parts of long-chain polyethylene glycol glycidyl ether liquid resin, 10 parts of alkyl glycidyl ether, defoaming Add 0.2 part of agent and 0.1 part of polyether mod...

Embodiment 2

[0048] 1) Preparation of modified amine curing agent:

[0049] Put polyetheramine, N-aminoethylpiperazine, tetraethylenepentamine, and nonylphenol into the flask, protect by nitrogen, keep stirring at 40℃ for 2.5h, then raise the temperature to 60℃, add nitrile rubber , Heat preservation and stirring for 3h, and cool to room temperature for later use; wherein the ratio of polyetheramine, N-aminoethylpiperazine, tetraethylenepentamine, nonylphenol and nitrile rubber in parts by weight is 9:5:1:8 : 6;

[0050] 2) Preparation of component A:

[0051] (1) The phenolic epoxy resin, long-chain polypropylene glycol glycidyl ether liquid resin is preheated at 60°C for 7 hours in advance;

[0052] (2) Combine 85 parts of phenolic epoxy resin, 6 parts of long-chain polypropylene glycol glycidyl ether liquid resin, 10 parts of ethylene glycol diglycidyl ether, 0.2 parts of defoamer, and polyether modified polydimethyl ether at room temperature. Add 0.1 part of siloxane copolymer to the dispers...

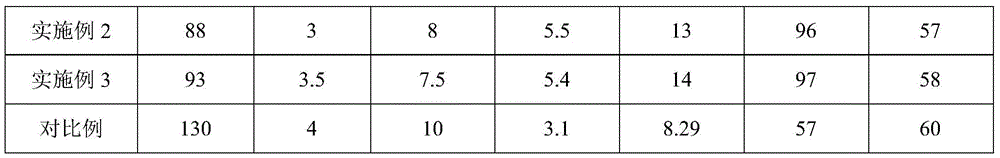

Embodiment 3

[0059] 1) Preparation of modified amine curing agent:

[0060] Add polyetheramine, N-aminoethylpiperazine, diethylenetriamine, and nonylphenol into the flask according to the proportions, pass nitrogen protection, keep at 40℃ and stir for 2~3h, then raise the temperature to 60℃, add Nitrile rubber, heat preservation and stirring for 3-5 hours, and cool to room temperature for later use; wherein the ratio of polyetheramine, N-aminoethylpiperazine, diethylenetriamine, nonylphenol and nitrile rubber in parts by weight is 9.6: 5.3: 1.5: 10: 6;

[0061] 2) Preparation of component A:

[0062] (1) The hydrogenated bisphenol A epoxy resin, bisphenol F epoxy resin and long-chain polybutylene glycol glycidyl ether liquid resin are preheated at 60°C for 6-8 hours in advance;

[0063] (2) At room temperature, first add 50 parts of hydrogenated bisphenol A epoxy resin, 40 parts of bisphenol F epoxy resin, 10 parts of long-chain polybutylene glycol glycidyl ether liquid resin, and butylene glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com