Leather care agent as well as preparation method and preparation device thereof

An oil emollient and leather technology, applied in the field of leather, can solve the problems of difficulty in adapting to low pollution, high environmental protection, reduced leather porosity and air permeability, and damage to leather hygiene performance, etc., and achieves improved smoothness and softness. Sex-enhancing, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

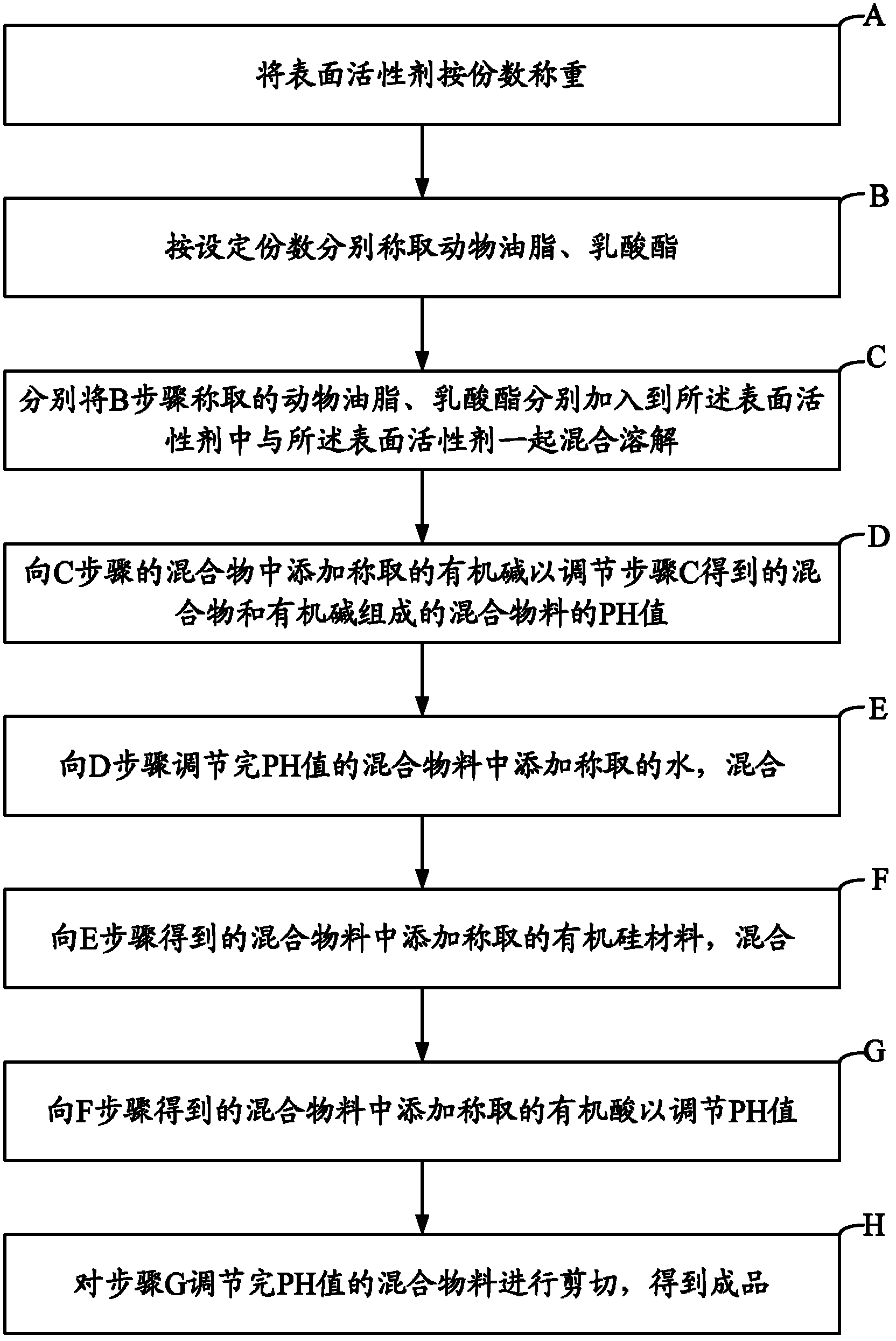

[0082] The present invention also provides a kind of preparation method of leather lubricant, such as figure 1 shown, including the following steps:

[0083] A. surfactant is weighed by parts;

[0084] B. Weigh animal fat and lactic acid ester respectively according to the set number of parts;

[0085] C. respectively adding the tallow and lactic acid ester weighed in the B step into the surfactant and mixing and dissolving with the surfactant;

[0086] D. in the mixture of C step, add the organic base that weighs to adjust the pH value of the mixture that step C obtains and the mixed material that organic base forms;

[0087] E. Add the water that weighs in the mixed material that D step has adjusted pH value, mix;

[0088] F. Add the organosilicon material weighed to the mixed material obtained in the E step, and mix;

[0089] G. add the organic acid that takes by weighing in the mixed material that F step obtains to adjust pH value;

[0090] H. Shearing the mixed mater...

specific Embodiment 1

[0126] Weigh 20 parts of Span-60 surfactant, 55 parts of isotridecyl alcohol (6EO) according to the proportion, put them in the reaction kettle, start stirring, raise the temperature to 50°C, add 90 parts of white oil, tallow 45 parts of oil and 40 parts of dodecyl were weighed and added to the reaction kettle in sequence. After all the materials were completely dissolved and uniform, 3 parts of triethanolamine were added to adjust the pH value of the material to 7.5, and the stirring was continued for 30 minutes, and then water 150 95 parts of the anionic hydroxy silicone oil emulsion was put into the reaction kettle, and the temperature was controlled at 50°C and stirred for 60 minutes, and the pH value of the product was adjusted to 7.0 with 2 parts of lactic acid, and the temperature was lowered to 35°C, with 15000 rpm high-speed shearing, start discharging.

specific Embodiment 2

[0127] Weigh 25 parts of Span-80, 45 parts of isotridecyl alcohol (9EO) and 10 parts of Pingjiao-910 according to the proportion and put them in the reaction kettle, start stirring, raise the temperature to 50°C, and put the naphthene 100 parts of oil, 50 parts of hoof oil, and 60 parts of lauryl lactate were weighed and added to the reaction kettle in turn. After all the materials were completely dissolved and uniform, 5 parts of hydroxyethylenediamine were added to adjust the pH value of the materials. 7.5, keep stirring for 30 minutes, then slowly put 140 parts of water into the reaction kettle, after stirring well, put 90 parts of non-ionic amino silicone oil emulsion into the reaction kettle, control the temperature at 50°C and stir for 60 minutes, then use glycolic acid 3 Adjust the pH value of the product to 7.0, stir for 30 minutes, then cool down to 35°C, and start discharging after high-speed shearing at 15,000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com