Waterborne polyurethane resin for nail polish and preparation method of waterborne polyurethane resin for nail polish

A water-based polyurethane and nail polish technology, applied in the field of water-based polyurethane, can solve the problems of reducing the protective effect of the coating film on the nails, the coating has poor grease resistance and temperature resistance, and is contrary to the development concept of green environmental protection, and achieves improved fastness and hydrolysis. Stability, good stability, the effect of improving the anti-flocculation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 environment-friendly type nail polish aqueous polyurethane resin

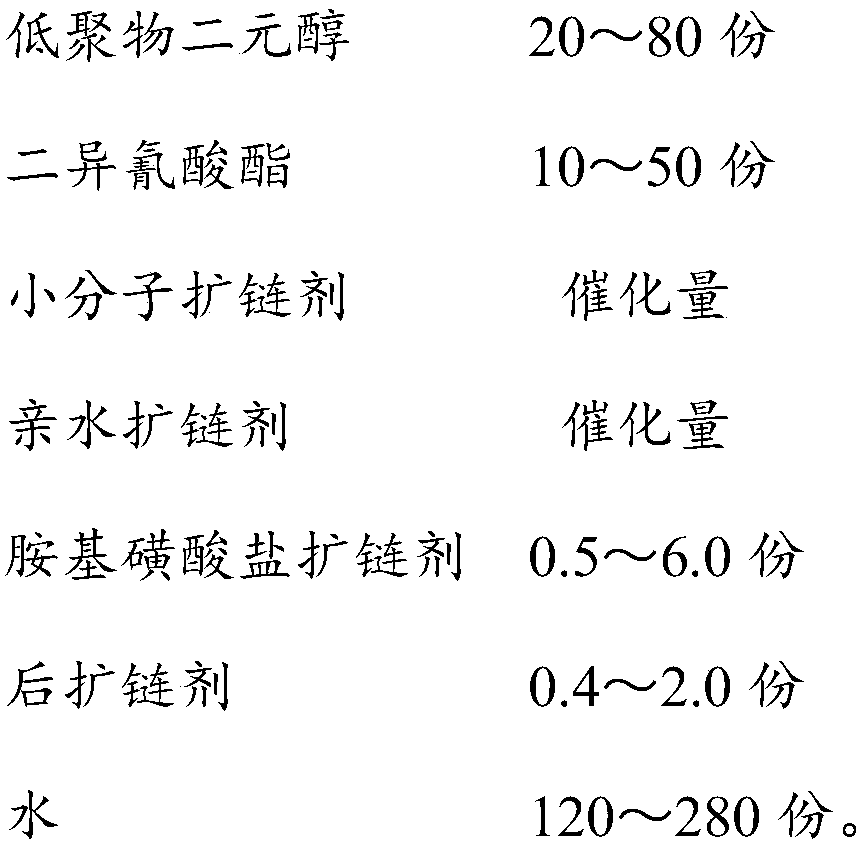

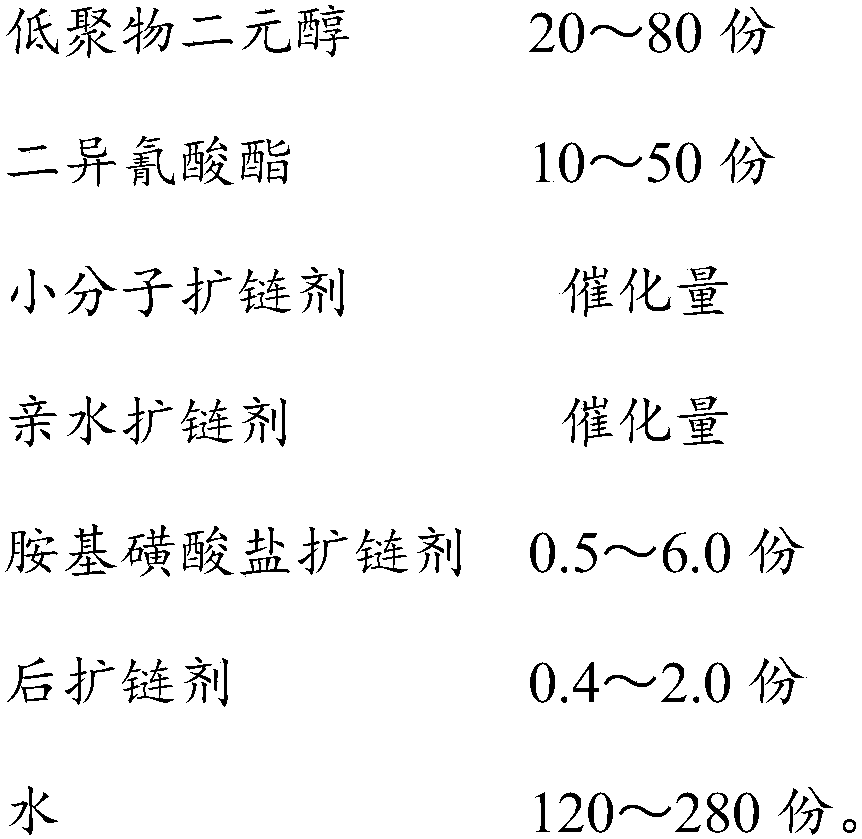

[0029] The environment-friendly nail polish water-based polyurethane resin of the present embodiment comprises the following raw materials prepared by weight:

[0030]

[0031]

[0032] The preparation method of above-mentioned environment-friendly solvent-free nail polish aqueous polyurethane resin comprises the following steps:

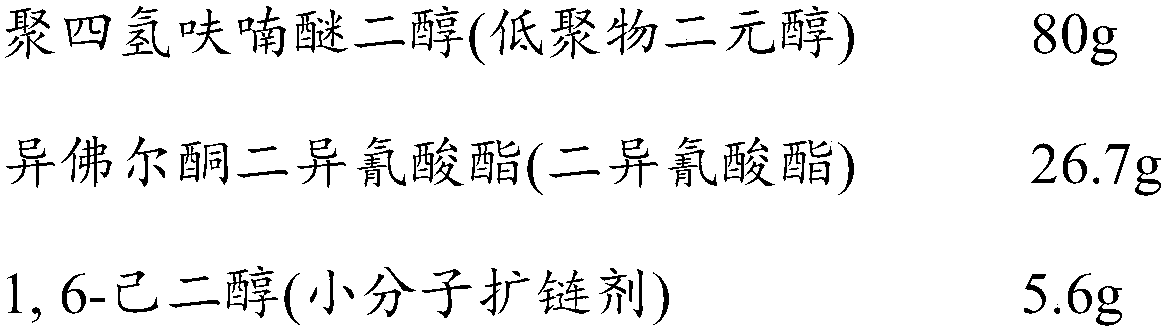

[0033] (1) Under the protection of dry nitrogen, add 80 grams of polytetrahydrofuran ether glycol and 26.7 grams of isophorone diisocyanate after vacuum dehydration at 120 ° C for 2 hours into the reactor, and control the temperature at 70-90 °C under mechanical stirring. ℃ for 2 hours;

[0034] (2) Reduce the temperature of the reaction system to 40-60°C, add 5.6 grams of 1,6-hexanediol and 3.5 grams of dimethylol propionic acid, and react at 70-85°C for 3 hours;

[0035] (3) Reduce the temperature of the reaction system to below 50°C, add 2.45 grams of t...

Embodiment 2

[0036] Embodiment 2 environment-friendly type nail polish aqueous polyurethane resin

[0037] The environment-friendly nail polish water-based polyurethane resin of the present embodiment comprises the following raw materials prepared by weight:

[0038]

[0039]

[0040] The preparation method of above-mentioned environment-friendly solvent-free nail polish aqueous polyurethane resin comprises the following steps:

[0041] (1) Under the protection of dry nitrogen, 40 grams of polytetrahydrofuran ether glycol, 40 grams of polypropylene glycol, and 44.4 grams of isophorone diisocyanate after vacuum dehydration at 120 ° C for 2 hours were added to the reactor and controlled under mechanical stirring. The temperature is 70 ~ 90 ℃ to react for 2 hours;

[0042] (2) Reduce the temperature of the reaction system to 40-60°C, add 4.0 grams of diethylene glycol, 5.0 grams of dimethylol butyric acid, and react at 70-85°C for 3 hours;

[0043] (3) Reduce the temperature of the re...

Embodiment 3

[0044] Embodiment 3 environment-friendly type nail polish aqueous polyurethane resin

[0045] The environment-friendly nail polish water-based polyurethane resin of the present embodiment comprises the following raw materials prepared by weight:

[0046]

[0047]

[0048] The preparation method of above-mentioned environment-friendly solvent-free nail polish aqueous polyurethane resin comprises the following steps:

[0049] (1) Under the protection of dry nitrogen, add 40 grams of polycaprolactone diol, 40 grams of polybutylene adipate diol, and 34.8 grams of toluene diisocyanate after vacuum dehydration at 120 ° C for 2 hours into the reactor , under mechanical stirring, control the temperature at 70-90°C for 2 hours;

[0050] (2) Reduce the temperature of the reaction system to 40-60°C, add 5.6 grams of diethylene glycol, 3.5 grams of bishydroxysulfonate, and react at 70-85°C for 3 hours;

[0051](3) Reduce the temperature of the reaction system to below 50°C, add 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com